CNC machining has revolutionized the manufacturing industry, and it’s now one of the most widely used manufacturing processes globally. It involves the use of computer-controlled machines to produce precise and precisio cnc machining parts. The accuracy of CNC machining is one of its most significant advantages, making it a popular choice for a variety of industries.

What is CNC Machining?

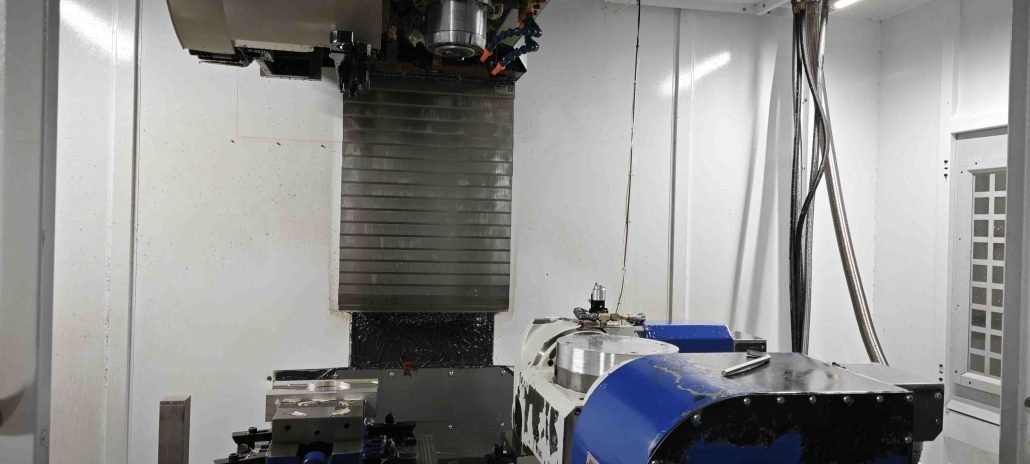

CNC machining, or computer numerical control machining, is a manufacturing process that involves the use of computer-controlled machines to produce parts from raw materials. The process involves programming the computer to control the movements of the machine, including the cutting tools, to create a precise and accurate part.

CNC machining has made it possible to produce complex parts that would otherwise be impossible to make using traditional manufacturing methods. With the ability to work with a wide range of materials, CNC machining has opened up new possibilities in various industries.

How Accurate is CNC Machining?

CNC machining is known for its high level of accuracy, with tolerances as low as 0.001 inches achievable. The accuracy of CNC machining depends on several factors, including the quality of the machine, the skill of the operator, and the complexity of the part being produced.

The quality of the machine is a critical factor in determining the accuracy of CNC machining. High-quality machines are designed to perform with precision, with features like high-speed spindles and linear guides to ensure accurate and consistent movements. These machines are also equipped with advanced software and controls that allow for precise measurements and adjustments.

The skill of the operator is another important factor in determining the accuracy of CNC machining. Experienced operators understand how to set up and program the machine to achieve the desired results, and they know how to make adjustments to ensure that the machine is operating at its highest level of accuracy.

Finally, the complexity of the part being produced can also impact the accuracy of CNC machining. Parts with intricate designs and tight tolerances require more precise movements and greater attention to detail, which can impact the accuracy of the machining process.

Applications of CNC Machining

CNC machining is used in a wide range of industries, including aerospace, automotive, medical, and electronics. It is commonly used to produce parts that require high levels of precision and accuracy, such as engine components, surgical instruments, and electronic components.

In the aerospace industry, CNC machining is used to produce parts that are crucial for the safe operation of aircraft. These parts include turbine blades, landing gear components, and structural elements.

In the automotive industry, CNC machining is used to produce engine components, transmission parts, and suspension components. The use of custom CNC machining in the automotive industry has led to significant improvements in the quality and reliability of vehicles.

In the medical industry, CNC machining is used to produce surgical instruments and implants. The ability to produce parts with high levels of accuracy and precision has led to significant advancements in the field of medicine.

In the electronics industry, CNC machining is used to produce components such as circuit boards and microchips. The high level of accuracy and precision required in the production of these components has made CNC machining an essential part of the electronics manufacturing process.

Conclusion

CNC machining is a highly accurate manufacturing process that offers many benefits to a variety of industries. With the right machine, operator, and part design, CNC machining can produce parts with tolerances as low as 0.001 inches, making it a popular choice for applications that require high levels of precision and accuracy. As technology advances, the accuracy and precision of CNC machining are expected to continue improving, opening up new possibilities for the manufacturing industry.