Plastic injection molding has become an integral part of many industries, from healthcare to electronics. If you are considering using plastic injection molding for your product, one of the most important aspects to consider is the cost. In this article, we will guide you on how to estimate the cost of plastic injection molding, providing a personalized and professional approach to help you make informed decisions.

Understanding the factors affecting cost

Before estimating the cost of plastic injection molding, it is important to understand the factors that influence it. Some of these factors are:

Size and Complexity of the Part/Product

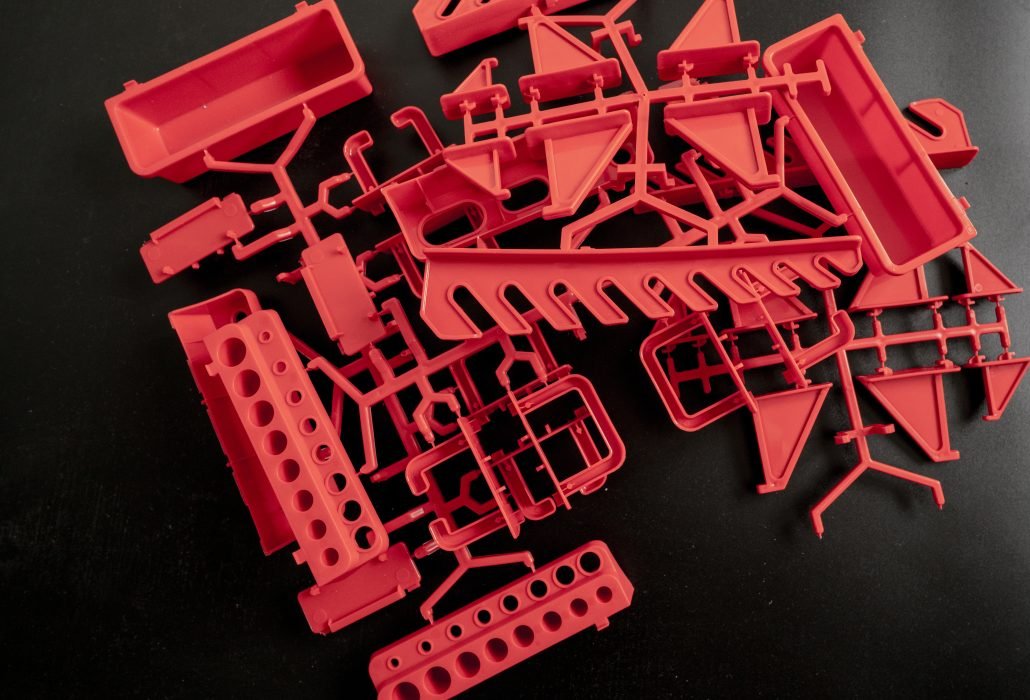

The size and complexity of the part or product being produced can greatly affect the cost of plastic injection molding. Larger and more complex parts/products require more material, more extensive mold design, longer run times, and more labor, all of which increase the production cost.

The Type of Plastic Used

Different types of plastics have different properties and will require different processing conditions and equipment. Some plastics may be more expensive than others, so the type of plastic used can affect the overall cost of production.

Mold Design

The design of the mold used in plastic injection molding is critical in determining the final cost. A well-designed mold will be more efficient, require fewer materials, and produce high-quality parts/products.

Tooling/Equipment

The cost of the tooling and equipment required for plastic injection molding can also affect the total cost of production. High-quality equipment may be more expensive, but it will produce higher quality parts and products.

Quantity

The higher the quantity of parts or products to be produced, the lower the unit cost will be. This is because the cost of setting up the mold and equipment is spread out over a larger number of parts/products.

How to Estimate the Cost of Plastic Injection Molding

Once you have a basic understanding of the factors that influence the cost of plastic injection molding, you can begin to estimate the cost based on your specific requirements. One of the most accurate ways to estimate the cost is to request a quote from a professional injection molding company.

Provide detailed information about your project, such as the part dimensions, material selection, quantity, and any design specifications. The molding company will use this information to provide you with a detailed quote, which includes the tooling cost, unit cost, and any additional costs such as shipping.

It is important to note that the initial tooling cost is a significant portion of the overall cost of plastic injection molding. This is because the mold must be designed and created before production can begin. However, the tooling cost can be reduced by choosing a simpler mold design and using more cost-effective materials.

Another way to estimate the cost plastic injection molding is to use online calculators. These calculators use a range of factors, such as part volume, material selection, and mold complexity, to estimate the cost per unit.

Cost Calculation Method For Injection Molding

As an injection molder, identifying the most accurate and efficient cost calculation method is critical to your business’s success. While many molding companies use traditional methods such as spreadsheets, there are more advanced and modern approaches that are worth considering.

Traditional Cost Calculation Methods

The traditional cost calculation methods are spreadsheets, which are straightforward and easy to use. However, spreadsheets have several limitations, such as the inability to provide accurate data, make adjustments, and create detailed reports.

These limitations can lead to pricing inaccuracies, preventing you from maximizing profits and reducing inefficiencies.

Modern Cost Calculation Methods

Modern cost calculation methods use advanced software that provides accurate data and reports while reducing the margin of error. The software also offers real-time information, allowing you to adjust production costs, pricing, and quantities as needed.

Examples of modern cost calculation software systems include MoldEZ, Costimator, and The Estimator, among others.

Advantages of Using Modern Cost Calculation Methods

Using modern cost calculation methods provides several advantages, including:

Increased Accuracy – The software’s advanced algorithms provide accurate data, reducing the margin of error when calculating production costs.

Real-time Data – Modern cost calculation software provides real-time information, allowing you to adjust costs, quantities, and pricing as needed.

Customizable Reports – The software provides customizable reports, enabling you to track and analyze your business’s performance, pricing, and profitability.

Time-Saving – Modern cost calculation software saves time by automating the process and reducing the need for manual entries, which can be time-consuming and prone to errors.

Cost Reduction – Modern cost calculation methods help identify inefficiencies and reduce production costs, increasing your profitability.

Tips for Minimizing the Cost of Plastic Injection Molding

Optimize Mold Design

As mentioned earlier, a well-designed mold can help reduce the cost of production. Consider simplifying the design of the part or product which can help reduce complexity and materials usage, leading to lower costs.

Choose the Right Plastic

Selecting the right plastic that offers the right balance between quality and cost will help reduce the overall production cost. By selecting the correct plastic, you can avoid unnecessary expenses that arise when working with the wrong material.

Reduce Tooling Costs

Consolidating multiple parts/products into one mold can help reduce the cost of tooling, especially when a hot runner system is utilized. The hot runner system removes the need for a cold runner which lowers material usage.

Optimize Production Runs

Longer runs reduces the marginal cost of production, and can significantly lower the unit price of the part/product. By increasing production order quantities, you can gain greater economies of scale.

Why choose plastic injection molding

Although plastic injection molding can initially seem expensive, it offers many benefits over other manufacturing methods. Injection molding can produce high-quality, consistent parts at a low cost per unit, making it ideal for large-scale productions. Additionally, injection molding allows for more complex designs and tight tolerances, giving you more control over the final product.

Conclusion

Estimating the cost of plastic injection molding is an essential part of any plastic manufacturing project. By understanding the factors that influence cost and working with a professional injection molding company, you can make informed decisions about your project and ensure that you get the best value for your money. If you are considering using plastic injection molding for your next project, contact a reputable molding company for a detailed quote today.