Plastic injection molding, the backbone of modern manufacturing, is widely utilized in every sector with its efficiency and flexibility. However, equally high total expenses are eroding profit margins and may become a challenging task for most managers.

Faced with cost pressures, many corporations are susceptible to the delusion of simply glancing at prices in selecting suppliers. But good cost control goes a lot further than that; it requires a thorough, integrated optimization of product design, process, and supply chain management. A small change in design or modification of a process parameter can have significant cost ripple effects.

As your business partner of choice, LS Manufacturing not only provides precise and reliable plastic injection molding services but also goes the extra mile to intervene from the concept product stage, employing its experience to provide clients with visionary cost-saving solutions throughout the manufacturing and design stages. To save you time, here’s a quick overview of the core conclusions.

Core Quick Reference Guide for Plastic Injection Molding Cost Optimization

| Optimization Dimensions | Critical Measures and Advantages |

| Design and Materials | Design for Manufacturability (DFM): Simplify the structure, reduce the number of parts, and reduce subsequent processing complexity and cost. Precise Material Selection and Substitution: With performance requirements fulfilled, consider replacing with more economical resins or vendors. |

| Process and Mold | Optimize the Injection Molding Cycle: Reduce cooling and holding time, improving output per unit of time directly. Invest in High-Cycle Molds: Adopt structures like hot runners to reduce scrap, improve production efficiency, and improve mold life. |

| Production and Supply Chain | Root Automation and Process Optimization: Reduce human interaction and energy consumption, and continually reduce operating cost. Seek Beyond Price Comparison, Increase Cooperation: Cooperate with suppliers providing early design intervention and end-to-end optimization to reduce total cost of ownership together. |

Reducing injection molding cost is not just about saving on price; it is a process optimization systematically throughout the entire process, such as design, materials, processes, production, and supply chain partnering.

Working together with a partner that provides collaborative design and end-process optimization is one of the key strategies to effectively manage total cost while realizing maximum value.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

We at LS Manufacturing have over two decades of intense experience and accumulated knowledge in the plastic injection molding field. We understand that every seemingly small design choice or process setting impacts the cost and marketability of the final product in some way.

The abilities of LS Manufacturing have been repeatedly put to the test on projects with hundreds of customers in diverse industries, such as automotive, medical, and consumer electronics. For example, through a structural optimization and material substitution solution of high criticality, we actually helped a home appliance customer reduce the total cost of a core component by 30% without affecting performance. This success proves the expertise of our engineering team in designing and manufacturing over 500 molds and their deep knowledge of thousands of material characteristics.

LS Manufacturing does not just provide injection molding services but strives to become an extended team for your product’s success. Cost minimization from concept through mass production is built into our fundamental engineering philosophy.

Why does the key to reducing injection molding costs begin at the product design stage?

The maxim “cost is designed in” holds particular significance in the context of plastic injection molding. Over 70% of the overall cost of a product is determined in design. Poor design has a direct impact on engaged mold geometries, extended production times, and excessive scrap rates, all of which are carried over to higher-cost plastic part prices.

Thus, reducing injection molding costs in actuality begins at the design stage, with the sole focus placed on the systematic application of design-for-manufacturing (DFM) injection molding concepts. LS Manufacturing engineers, by intervening early, optimize a number of dimensions at the cost estimation of plastic parts phase, with “design for cost reduction”:

- Simplified demolding and improved efficiency: By proper analysis and optimization of draft angles, it is possible to avoid complex mold structures (like reducing side core pulls), simplify the mold directly, and cut down on the injection molding cycle, and in turn, save injection molding costs in two ways.

- Uniform wall thickness and quality assurance: We design for uniform wall thickness distribution to virtually eliminate flaws such as sink marks and warpage. This conserves significantly in scrap rates, material and labor loss, and is the basis of stable manufacturing.

- Optimized structure and enhanced functionality: Through scientific design of the buckles and stiffening ribs, we achieve product strength and assembly function without contributing to wall thickness. This reduces unnecessary use of material while achieving weight savings and cost savings at the same time.

Through DFM analysis, we can successfully prevent issues during the drawing stage before production, which is ideal and mandatory in terms of cost saving.

How can we achieve significant cost savings through material selection and substitution?

Material costs alone typically account for 40% to 60% of a plastic part’s total cost and are the best predictor of the final cost of plastic injection molding. Scientific material selection is therefore one of the easiest ways to achieve significant cost savings. Clever material choice is not a question of which resin is cheapest; rather, it’s one of using several strategies to minimize total cost while ensuring product performance.

LS Manufacturing, with its global connections to the world’s top material suppliers, offers the following proven optimization alternatives:

1. Performance Matching:

According to structural requirements and certification guidelines (i.e., UL and FDA), we will purchase commercially available or name-brand cost-effective items from our materials database to avoid unnecessary surcharges due to “over-performance.”

2. Structural Weight Reduction

We promote the utilization of engineered materials such as glass fiber reinforcement. They contribute strength and stiffness to allow thinner sections of walls in part designs, resulting in weight reduction in parts and further cost savings of plastic injection molding with less injection molding cycles.

3. Value-Driven Innovation

To meet industry pressures towards environmental protection, we can assist with reviewing the utilization of recycled or biodegradable materials. In addition to saving raw material purchase costs potentially, this optimizes the environmental value and company image of the product, generating unrecognized worth.

LS Manufacturing’s value lies not only in providing substitute solutions but also in carefully testing them with rigorous testing (e.g., mechanical and temperature endurance testing) in such a manner that each cost-saving material choice realizes a favorable balance between cost and performance.

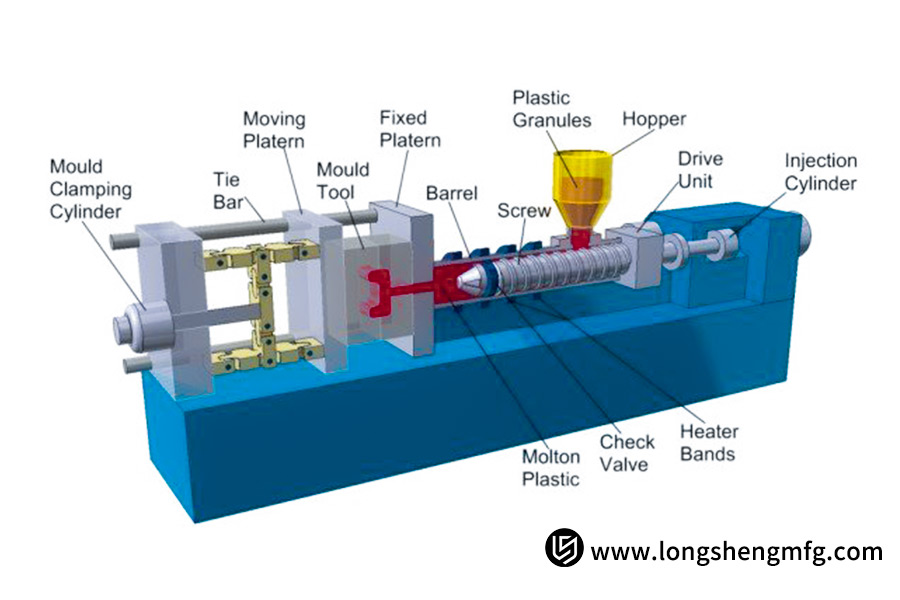

How does optimizing injection molding process parameters directly impact cost reduction?

If cost foundation is determined by material and design, then optimizing the injection molding process directly controls the “qualified product yield” and “efficiency threshold” of production and is the answer to the saving of injection molding cost in regular production. Unstable processes generate excess cycle time, wasted energy, and excessive scrap, all of which cut profits directly.

LS Manufacturing is dedicated to the scientific injection molding concept and, through systematic optimization of injection molding technology, maximizes the production process in an attempt to bring about deep plastic injection molding optimization strategies. Its direct influence primarily operates in the following two important dimensions:

| Optimization Dimension | Specific Impact and Implementation Methods |

| Compressing Cycle Time | Decrease in the injection rate, precise regulation of the holding pressure and time, and calculation of the minimum time for cooling needed can all be used to significantly compress the cycle time for a single part by molding. Saving one second per mold can mean enormous energy and labor savings at production volumes in the millions. |

| Improving Qualified Productivity | Utilizing DOE (Design of Experiments) methods to establish the optimum process window effectively removes defects such as flash, shrinkage, and short shots and reduces scrap rates. This automatically reduces material and labor waste and increases the production efficiency of quality parts. |

LS Manufacturing does not rely on the experience of skilled artisans, but on knowledge and advanced equipment to standardize and optimize process parameters. This highly controlled plastic injection molding optimization process directly guarantees stable and efficient production and reduces the injection molding cost from the manufacturing process itself.

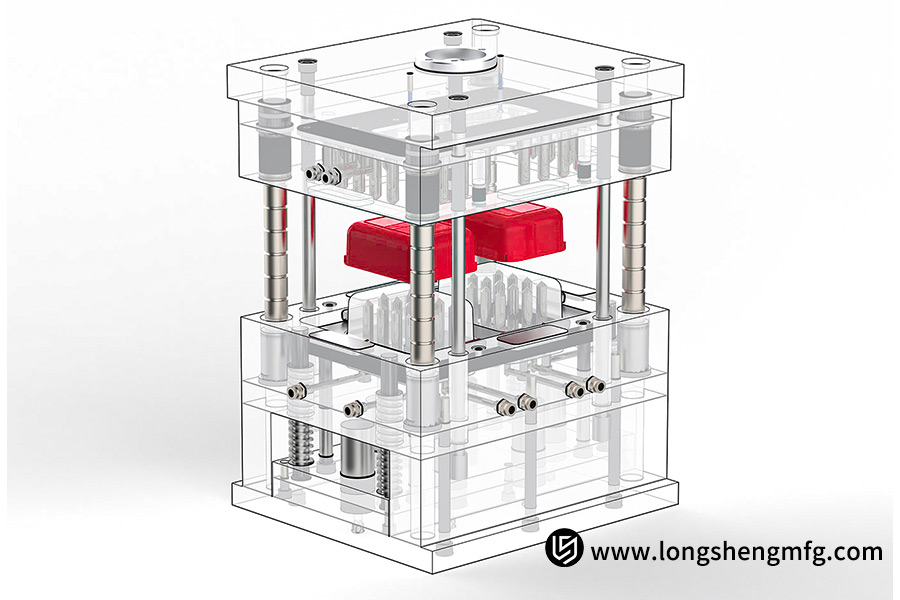

What are some often-overlooked cost reduction opportunities in mold design and manufacturing?

When costing the plastic injection mold, the majority of companies will, by default, include the initial cost price of the mold quote, and not completely calculate the full impact the mold, as a long-term enterprise. The natural value of a good design mold is the ongoing cost savings and efficiency that it gains throughout the entire production process. That is precisely the way the design, management, and performance (DFM) injection molding concept is finely incorporated in the mold.

In mold production and design, LS Manufacturing adopts the following often neglected cost-cutting variables that can reap massive dividends in the long term:

1. Intelligent Runner System Selection:

While hot runner systems require higher initial capital investments, they are able to effectively reduce scrap, slow down molding cycles, and improve the quality of cavity filling. We closely examine production volume and material properties in an effort to choose the most suitable solution for our customers, avoiding unnecessary waste of cold runner-regrind and regulating plastic injection molding expenses from the very beginning.

2. Ultimate Cooling Efficiency Optimization:

Mold cooling time typically consumes more than half of the injection molding cycle. In engineering conformal cooling channels by simulation analysis to supply even and effective cooling, significantly shortening production cycles, increasing production capacity, and reducing unit production costs directly.

3. Invest in Mold Life and Reliability:

The selection of high-quality steel for large parts and employing suitable surface finishing (such as chrome plating and nitriding) can significantly enhance the wear and corrosion resistance of the mold. Although the investment in the initial period raises mold cost somewhat, it repays extensively in the form of minimized maintenance downtime and risk of premature mold failure, with the added benefit of long-term stable, low-cost production to customers.

By incorporating Design for Manufacturing (DFM) injection molding principles into the mold design phase, we are not designing to make the cheapest mold, but a production tool with the lowest life cycle cost and highest long-term value to our customers.

How can automation and lean production sustainably reduce injection molding costs?

In order to overcome the injection molding cost control bottleneck, we must shift our vision from one-shot manufacturing to the overall production system optimization. Automation and lean production are precisely such an optimization strategy for plastic injection molding that can reduce injection molding costs in a sustainable way.

They attempt to remove waste in a systemic manner, stabilize quality, and improve overall efficiency, thereby creating long-term competitiveness against rising labor costs and unstable quality. LS Manufacturing applies this method to create sustainable value for customers in the following manners:

1. Full-Process Automation Reduces Labor and Increases Efficiency:

LS Manufacturing team extensively utilizes robotic arms to automatically insert and remove components and uses robots for secondary processing (i.e., nozzle cutting and labeling). Apart from reducing direct reliance on labor and the associated cost, it maintains a uniform rate of production, removes variable quality due to human contact, and reduces injection molding costs both in efficiency and yield.

2. Lean Processes Eliminate the Seven Wastes:

LS Manufacturing uses lean production tools on a regular basis, utilizing value stream analysis to identify and eliminate the seven most important wastes in production: waiting, handling, over-processing, and defective items. As an example, by optimizing the layout of equipment and material flow, non-value-added time is reduced, which optimizes the value of every minute and every unit of material.

3. Data-Driven Continuous Improvement:

By involving automation systems within the Manufacturing Execution System (MES), true-time, correct production data is provided. This enables LS Manufacturing to closely watch Overall Equipment Effectiveness (OEE) and change it, spot bottlenecks in relation to the data, and make adjustments, which creates a positive feedback cycle of continuous cost savings.

LS Manufacturing’s production methods demonstrate that this plastic injection molding optimization strategy is only effective as a one-time investment insofar as it is actually a continuously self-optimizing system of production translating stable low cost and high quality into inherent strengths customers can rely upon over the long term.

Is choosing the right injection molding supplier a cost-reduction strategy in itself?

The days of just looking at injection molding supplier selection as a “place-and-make” operation are behind us. Actually, selecting a good partner is an important and very lucrative approach to lowering injection molding costs. The value gained from a better quality supplier goes significantly beyond the cost per unit of the part itself. With through professional services, they intelligently minimize your overall cost of ownership.

A better plastic injection molding service partner should generate added value above and beyond your expectations in the following crucial areas:

1. Added-value technology, reducing costs at the source:

A genuine partner will actively offer DFM (Design for Manufacturing) analysis, inserting itself into the stage of product design. Through the optimization of the structure, materials, and mold solutions, it can essentially prevent expensive later manufacturing issues and changes.

2. Process optimization, guaranteeing efficiency:

Leveraging their state-of-the-art process engineering know-how, they offer a reliable and effective production process. With scientific injection molding and strict quality control, they maximize yields, minimize cycle times, and directly decrease unit production costs.

3. Supply Chain Integration, Ease of Operation

Suppliers offering one-stop shops, from mold making and injection molding to post-assembly, can significantly ease your management tasks, reduce the friction of coordination among multiple parties, and allow you to focus on your core business. This in itself is a cost saving behind the scenes.

Thus, strategic injection molding supplier choices must be based on a complete review of their technological competence, optimization policies, and level of service.

One such strategic partner is LS Manufacturing, and we are committed to turning each partnership into a chance for enhancing our customers’ competitiveness and achieving long-term cost savings.

How did LS Manufacturing reduce total costs for its clients by 30% through collaborative design?

One of the world’s best-known home appliance companies, suffering from a 15% defect rate and high expense of producing its housing components, brought in LS Manufacturing. The following is a case study of how LS Manufacturing, through collaborative design solutions, was able to lower overall costs for the client by 30%.

1. Customer Dilemma:

- The core housing component of a home appliance company had long-standing issues. The original design had significant uneven wall thickness and excessive internal buckles. It directly led to lengthy injection molding cycles, serious cooling deformation, and a product defect rate of up to 15%.

- Besides, the complex mold structure led to heavy maintenance jobs, high overall manufacturing costs, and significant impacts on product profitability and market competitiveness.

2. LS Manufacturing Solution:

Faced with this complex situation, our design team was heavily engaged from the start of the project, conducting a systematic Design, Measurement, and Function (DFM) injection molding analysis:

- First, we redesigned the wall thickness profile of the product to ensure even transition and automatically reduce the risk of warpage.

- Second, we optimized the size and layout of the reinforcement ribs to achieve maximum material distribution with structural integrity.

- Technically, we innovatively substituted the previous complex internal buckle structure with an ultrasonic welding assembly solution, which greatly reduced the complexity of the mold structure.

For further optimization of this product design, we also set up an economical hot runner mold system and optimized a balanced and efficient cooling system, which laid a solid foundation for follow-up production. This overall plastic injection molding optimization strategy provided the technical support for achieving considerable injection molding cost reduction.

3. Results and Value:

With our systematic optimization tool, the key metrics of the project were completely optimized: the production cycle time reduced by 22%, the rate of product defects decreased dramatically from 15% to less than 2%, and mold maintenance cycles were raised by an unbelievable 300%.

Although the initial capital was slightly greater due to the use of better mold solutions such as hot runners, the overall manufacturing cost of this part was significantly reduced by 30%.

The customer not only obtained stable and long-term economic profits, but more importantly, enjoyed a more stable and efficient supply chain, with valuable experience for the next product research and development.

How to accurately estimate plastic part costs to avoid budget overruns?

Most projects experience cost overruns during the middle of a project due to excessively rough initial plastic part cost estimates that focus only on unit prices of materials and disregard most costs hidden costs. A good plastic part cost estimate must be a science-based, holistic financial model that completely takes into account all the costs from development all the way to production. A proper plastic part cost estimate must be holistic in containing the following necessary factors:

1. Material and Production Costs:

It is the foundation, comprising material cost (including the value of nozzle recovery), injection molding machine time (properly quantified in terms of cycle time), and subsequent secondary processing (e.g., painting and assembly). An accurate plastic injection molding cost estimate should be derived using optimized process parameters.

2. Mold Investment Amortization:

Molds are not a fixed expense; their cost has to be reasonably allocated to the anticipated total volume of production. The greater the volume of production, the less expensive the mold per piece, which it is essential to influence the long-run cost structure.

3. Management and Risk Costs:

An effective quote also includes sound project management, sound quality control margins, and a provision percentage for some scrap loss. This allows the supplier with sufficient funds to provide a stable service and avoids surprise expense down the line due to delivery or quality issues.

LS Manufacturing is committed to completely open cost analysis. We are happy to enter a project early and, using our vast database and knowledge base, provide an initial free estimate of cost of plastic part.

Besides price, what other costs influence your injection molding TCO?

In selecting an injection molding supplier, unit price alone is merely seeing the tip of the iceberg. True cost—the total cost of ownership (TCO)—also involves a great deal of underestimated “hidden costs.” A low bid may well be hiding high costs in terms of quality, delivery, and communication.

The key value of high-quality plastic injection molding services is precisely in systematically cutting these hidden costs:

- Quality costs: Inconsistent quality not only causes scrap but also lost production line time, post-sale fix-it jobs, and even brand damage. All these costs overwhelm any unit price savings.

- Delivery costs: Unreliable or tardy delivery disrupts your manufacturing schedule, causes you to increase buffer inventory, and even forfeit market opportunities. On-time and steady delivery is cost-reducing by its very nature.

- Communication and management costs: Having a supplier who is lacks effective communication skills and must be constantly verified can cost your project a lot of management time and effort. Smooth collaboration significantly reduces internal management costs, allowing you to focus more on core business.

Thus, smart selection of injection molding supplier decisions need to peer beyond comparisons of unit prices.

LS Manufacturing is committed to actually reducing these invisible costs through higher quality systems, reliable supply chain management, and optimal collaborative processes, providing you with a real low total cost of ownership (TCO).

FAQs

1. Does reducing injection molding costs mean sacrificing product quality?

Not at all. Genuine cost reduction is eliminating wastage and inefficiencies in the process of manufacturing by scientific methods such as Design for Manufacturability (DFM) and scientific process improvement. This means reducing material redundancy, reducing cycle time, and controlling scrap rate. These are all founded on uncompromisingly securing or even improving product performance, consistency, and long-term reliability. Cost reduction’s secret lies in providing the greatest value per dollar spent, not compromising quality.

2. Is cost reduction achievable under small-batch production?

Yes. For small-batch production, LS Manufacturing adopts a differentiated strategy: reducing mold structure complexity (e.g., using pre-hardened steel and minimizing slides), selecting cost-effective standard materials, and simplifying production changeover operations to minimize downtime. These actions significantly reduce mold investment and unit production costs so that small-batch jobs become economically viable without benefiting solely from economies of scale.

3. What does your free plastic part cost estimate include?

LS Manufacturing’s free estimate, based on your provided 3D drawings, provides an open cost breakdown structure with material usage and cost, approximate break-down of the mold investment allocation, per-part injection molding process charges, and possible post-processing fees. The estimate is designed to enable you to easily view the critical cost factors up front in the project, prevent potential later budget risk, and create a solid foundation for decision-making.

4. What core capabilities should you consider when selecting an injection molding supplier?

Aside from basic manufacturing capability, engineering support capability and willingness to work with you to solve issues by your supplier are also critical. An active partner who performs design-for-manufacturing (DFM) analysis, process parameter optimization, and ongoing technical consultation can control cost and ensure quality from the beginning, ultimately optimizing your overall cost of ownership (TCO).

Conclusion

Cost savings in plastic injection molding isn’t price negotiation; it’s a process that involves product design, material optimization, process optimization, mold building, and collaborative supply chain. Instead of taking prices from multiple suppliers, it is better to work with a single end-to-end supplier who provides end-to-end technical assistance along with cost control solutions.

LS Manufacturing, with excellent technical capability and customer-driven philosophy of service, has successfully helped numerous businesses achieve value and cost improvement of considerable extent.

Your following injection molding project deserves higher cost performance. Contact us and upload your 3D drawings via email and receive a complimentary “Injection Molding Project Cost Optimization Assessment Report” prepared by our experienced experts. Let us leverage our knowledge in safeguarding your product value and profit margins!

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.