Metal injection molding is a cost-effective way of producing complex mechanical components in large quantities. The process involves mixing metal powders with a binder material, injecting the mixture into a mold, and then removing the binder from the resulting metal part. But how much does metal injection molding cost? In this article, we will explore the factors that influence metal injection molding costs and how you can optimize your metal injection molding process to achieve cost savings.

What is Metal Injection Molding?

Before we dive into the cost considerations, let’s first define what metal injection molding is. metal injection molding is a process that combines the benefits of plastic injection molding and powdered metallurgy. It involves melting metal powder and combining it with a binder material to form a feedstock.

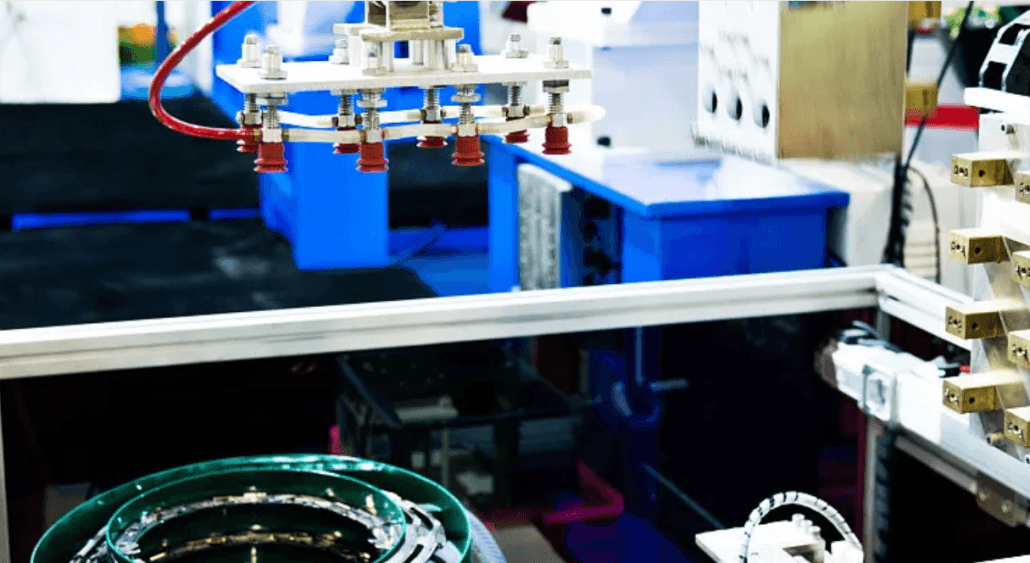

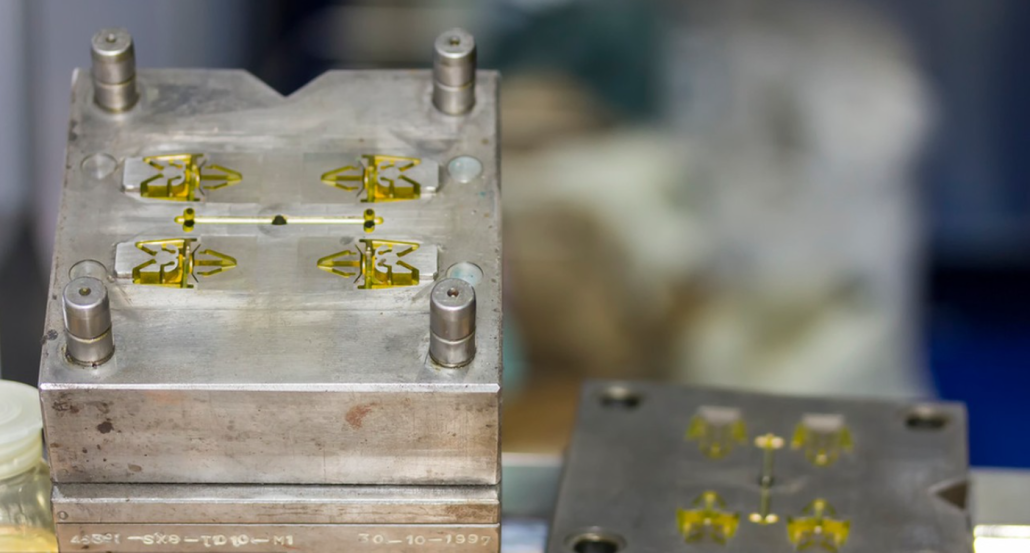

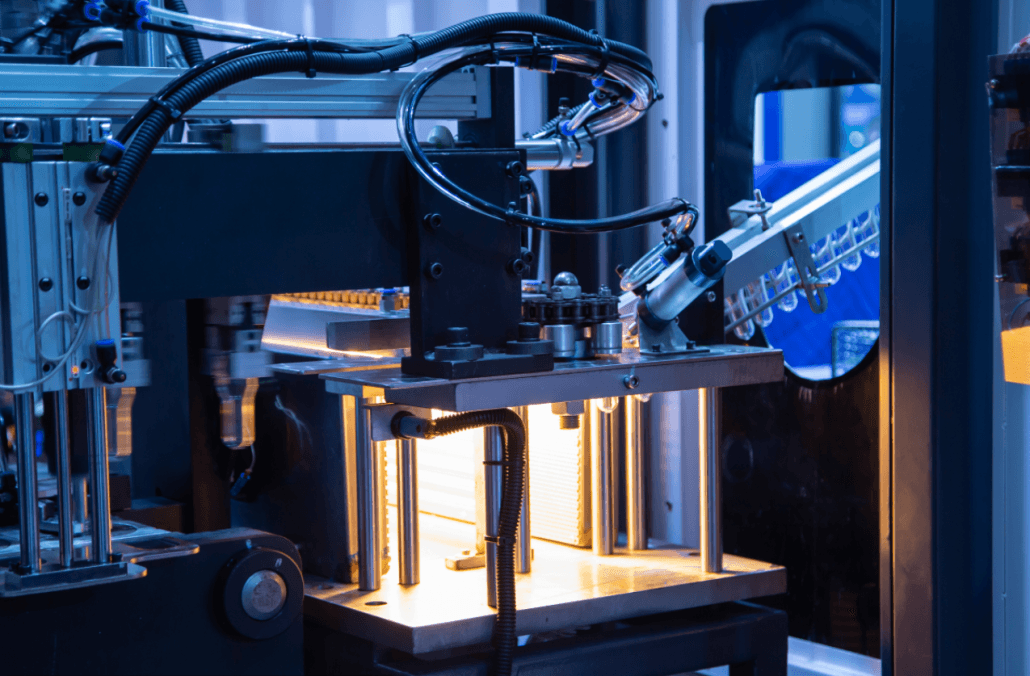

The feedstock is then injected into a mold cavity, where it solidifies and takes the shape of the mold. The part is then removed from the mold and goes through several processing steps, including debinding and sintering, to remove the binder and densify the metal.

Why Choose Metal Injection Molding

metal injection molding has several advantages over traditional manufacturing methods, including:

Ability to produce complex parts with tight tolerances

High accuracy and repeatability

Good surface finish and detail definition

Cost-effectiveness for medium to high-volume production

Ability to use a wide range of materials, including stainless steel, titanium, and tungsten

Factors that Affect Metal Injection Molding Costs

There are several factors that affect metal injection molding cost, including:

Material Selection:The type of material used in metal injection molding greatly influences the cost of production. Typically, metals like stainless steel, copper alloys, and titanium are costlier than other materials. The more exotic the material, the higher the cost.

Design Complexity: The complexity of the design of the part to be manufactured also has an impact on the cost of metal injection molding. Parts that have intricate shapes or multiple features require additional processing steps, which increases the cost.

Quantity: The number of parts you need to produce will have an impact on the cost. Large volume runs are generally more cost-effective than small ones, as the fixed costs associated with producing a mold are spread out over a larger production run.

Secondary Operations: Depending on the part’s design, secondary operations such as polishing, painting, or plating may be necessary. These additional steps will increase the overall cost of the project.

Tooling and Equipment:The cost of tooling and equipment for metal injection molding can vary depending on the complexity of the part design. The molds used in metal injection moldingare made from tool steel and require precision machining, which can be costly. However, the molds can be used for high-volume production, leading to lower costs in the long run.

Volume Requirements:The volume of parts needed for your project will affect the cost of metal injection molding. metal injection molding is generally more cost-effective for medium to high-volume production. However, it can also be used for small volume runs, as the tooling costs can be amortized over multiple parts.

Quality Requirements:The required quality level of your parts will affect the cost of metal injection molding. Parts with tight tolerances and surface finish requirements may require additional processing steps, such as polishing, which can add to the cost.

Ways to Lower Metal Injection Molding Costs

Several ways to help lower metal injection molding costs without sacrificing quality include:

Optimizing design for manufacturability: An experienced metal injection molding manufacturer can help you optimize the design of your parts to eliminate unnecessary complexity and minimize the number of secondary operations needed. This greatly reduces production costs.

Choosing the Right Material: Choosing the right material for your parts can be tricky. The more exotic the material, the higher the cost. However, choosing the wrong material can compromise the quality of the final product.

Increase Volume: The more parts you need, the lower the cost per piece. High volume production runs offer the best value per part.

Minimize Secondary Operations: Keep your production run simple by avoiding additional secondary operations. This will reduce the overall production costs.

Final Thoughts

Overall, the cost of metal injection molding can vary depending on the materials used, part complexity, volume, and secondary operations. To achieve a cost-effective and quality product, it is best to partner with an experienced metal injection molding manufacturer who can help optimize the design and production process.

In conclusion, while the cost of metal injection molding production can seem daunting, there are several strategies you can implement to help lower the costs while still maintaining quality. Always remember, the more you know about the process and how to optimize it, the better positioned you will be to achieve cost-effective solutions for your projects.