CNC (Computer Numerical Control) programming is a vital aspect of modern-day manufacturing. It involves the use of computers to control machine tools, which can produce highly accurate and complex parts. In this article, we will focus on how to write CNC programs for turning operations.

Understanding Turning Operations

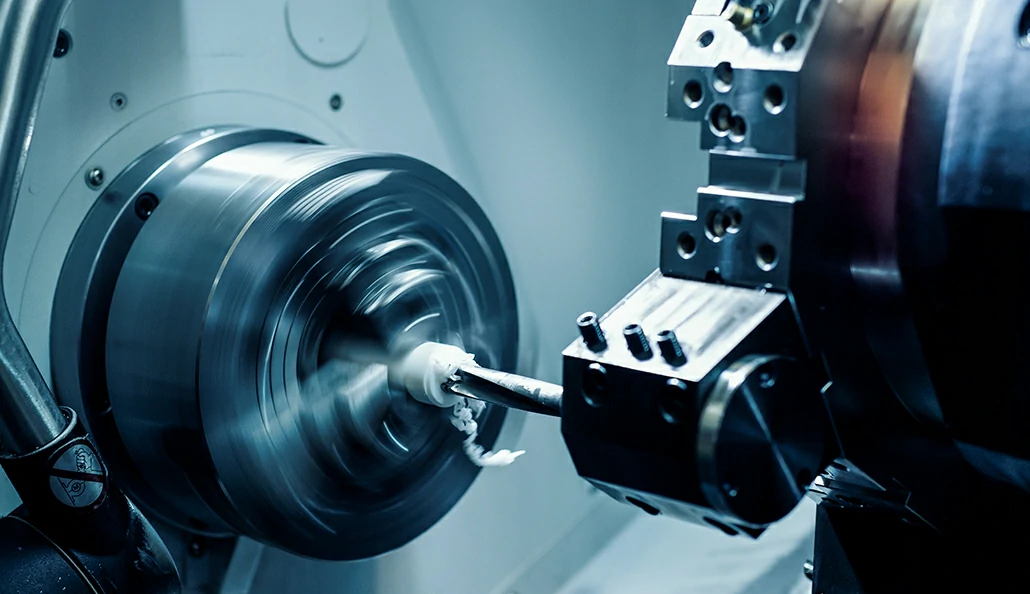

Turning is a machining process that involves rotating a workpiece while a cutting tool removes material from it. The cutting tool is typically positioned perpendicular to the workpiece axis, and the tool’s movement is controlled by the CNC program. Turning can be used to produce cylindrical, conical, and spherical parts, among others.

Steps to Write CNC Program for Turning

- Determine the Workpiece Geometry – Before writing a CNC program for turning, you need to know the dimensions and geometry of the workpiece. This includes the diameter, length, and any features or contours that need to be machined. You should also consider the material that the workpiece is made of, as this will affect the cutting tools that you use and the feed rates that you set.

- Identify the Cutting Tools – You also need to identify the cutting tools that will be used for the turning operation. The tool selection will depend on the material being machined, the desired surface finish, and the required cutting speed and feed rate. You should also ensure that the cutting tools are properly sharpened and in good condition before beginning the machining process.

- Plan the Toolpath – Once you have the workpiece geometry and cutting tools identified, you need to plan the toolpath. This involves determining the path that the cutting tool will follow to remove material from the workpiece. The toolpath should be optimized for efficiency and accuracy. You can use specialized software to help you plan the toolpath, or you can do it manually.

- Write the CNC Program – With the workpiece geometry, cutting tools, and toolpath determined, you can now write the CNC program. The program will consist of a series of instructions that tell the machine tool how to move the cutting tool to produce the desired part. The instructions should include information such as spindle speed, feed rate, and tool position.

- Test the Program – Before running the CNC program on the actual workpiece, it is important to test it on a simulation or a scrap piece of material. This will help identify any errors or issues that need to be corrected before machining the final part. You should also ensure that the machine tool is properly calibrated and that all safety precautions are in place before beginning the CNC machining process.

What is the format of CNC turning program?

The CNC turning program is a set of instructions that are used to control the movement of the machine tool and the cutting tool to produce the desired part. It is a series of code written in a specific format that the machine tool can understand. The format of the CNC turning program typically includes information such as spindle speed, feed rate, and tool position, among other parameters.

In addition to these factors, the program also includes data about the tool used for the operation, such as its size, shape, and material. The program must also take into consideration the workpiece’s dimensions and geometry, as well as any features or contours that need to be machined. The material being machined also plays a crucial role in determining the parameters of the program, as it affects the cutting tools and feed rates that need to be used.

Writing a CNC turning program requires attention to detail and careful planning. The program must be optimized for efficiency and accuracy, and it must be tested before being run on the actual workpiece. This testing process helps identify any errors or issues that need to be corrected before machining the final part. Additionally, the machine tool must be properly calibrated, and all safety precautions must be in place before beginning the machining process.

Overall, the CNC turning program is a crucial aspect of modern-day manufacturing, as it allows for the production of highly accurate and complex parts. By following the steps outlined in the previous section and mastering the skill of CNC programming, you can produce high-quality turned parts and improve your programming abilities.

Conclusion

Writing a CNC program for turning operations requires careful planning and attention to detail. By following the steps outlined in this article, you can produce accurate and high-quality turned parts. Remember to always test the program before machining the final part to ensure optimal results. Additionally, it’s important to keep in mind that CNC programming is a skill that takes time and practice to master. Don’t be afraid to experiment and try new techniques to improve your programming abilities!