When it comes to manufacturing plastic parts and products, injection molding is one of the most popular and efficient manufacturing methods available. However, one important factor that many companies tend to overlook is the cost factor associated with the process.Here, we will discuss the importance of considering injection molding costs and why it matters in your bottom line.

Injection molding cost influences pricing strategies

As a business owner, one of the biggest challenges you face is pricing your products to be competitive in the market. There are various factors that can impact your pricing strategies, and one of those factors is the cost of injection molding. Injection molding is a manufacturing process that involves the production of parts by injecting molten material into a mold. The cost of injection molding can be a significant factor in determining the final price of your product. In this article, we will discuss how the cost of injection molding influences pricing strategies.

Injection Molding Cost Breakdown:

Before we dive into how injection molding cost influences pricing strategies, it’s important to understand how injection molding costs are calculated. Injection molding cost depends on a few factors such as:

- Material cost per unit: The cost of the material used to manufacture the part.

- Tooling cost: The cost to manufacture the mold used to produce the part.

- Processing cost: The cost to run the injection molding machine, including labor, maintenance, and energy consumption.

How Injection Molding Cost Influences Pricing Strategies:

The cost of injection molding can impact the final price of your product in a few ways:

- Markup strategy: If your injection molding costs are high, you may need to set a higher markup on your product to maintain a healthy profit margin.

- Competitive pricing strategy: If your competitors are using injection molding processes that are less expensive than yours, you may need to adjust your pricing strategy accordingly to remain competitive in the market.

- Cost-saving strategy: If injection molding cost is a significant factor in your product pricing, you may need to explore ways to reduce your injection molding costs to maintain profitability.

How to Reduce Injection Molding Costs:

Reducing injection molding costs can help you maintain your profit margins and remain competitive in the market. Here are a few tips to help you reduce injection molding costs:

- Use a cost-effective material: Choose a material that is cost-effective and meets the necessary requirements for your product.

- Optimize tooling design: Work with your manufacturer to optimize your tooling design to reduce material waste and improve cycle time.

- Use efficient production processes: Utilize automation and process optimization to reduce labor and energy costs during production.

The cost of injection molding can have a significant impact on your pricing strategies. Understanding how injection molding costs are calculated and how they affect your pricing can help you make informed decisions about how to price your products. By exploring ways to reduce injection molding costs, you can maintain your profit margins and remain competitive in the market. Contact us today for more information about how our injection molding services can help you achieve your pricing objectives.

Injection molding cost affects production scale

When it comes to injection molding, cost is an important factor that affects production scale. Although the process is widely used for mass production, it can quickly become expensive if not optimized properly. The good news is that there are ways to reduce your injection molding cost and boost your production capacity. In this article, we’ll explore some of the key factors that impact injection molding cost and offer tips for optimizing your manufacturing process.

Understanding injection molding cost factors

Injection molding cost is influenced by a variety of factors, ranging from material and equipment costs to labor expenses and overhead. Let’s take a closer look at some of the most common factors that can drive up your injection molding cost:

Material costs

The cost of materials represents a significant portion of the total injection molding cost. The type of material used can greatly impact the price, with some materials being more expensive than others. High-performance polymers, for example, can be particularly costly.

Mold cost

The mold represents the largest upfront investment for injection molding, and the more complex the design, the more expensive the mold will be. Additionally, mold maintenance and repair can be costly over time.

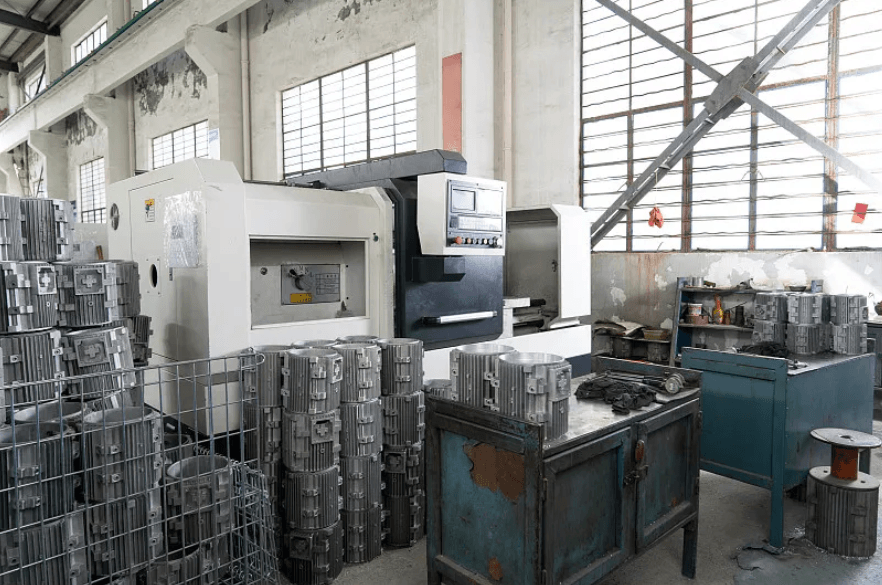

Equipment costs

Injection molding equipment can be expensive to purchase, operate, and maintain. The size and complexity of the machinery required can also impact the overall cost.

Labor costs

Injection molding requires skilled operators and technicians, whose salaries can add up quickly. Overtime costs and training expenses can also drive up labor expenses.

Overhead costs

Rent, utilities, insurance, and other overhead expenses can all contribute to the overall injection molding cost.

Optimizing your injection molding process

Now that we’ve identified some of the primary factors that influence injection molding cost, let’s explore some ways to optimize your manufacturing process and reduce your expenses.

Optimize the design

By minimizing complexity and avoiding unnecessary features, you can reduce the cost of the mold and the amount of material needed. Lean design principles can help streamline the production process and eliminate waste.

Choose the right materials

Selecting cost-effective materials that still meet your performance requirements can help lower your material costs. Consider using recycled or reprocessed materials to further reduce your expenses.

Control machine settings

Properly calibrating the injection molding equipment can help reduce material waste and increase efficiency. Monitoring machine settings and performing regular maintenance can also help prevent breakdowns and costly repairs.

Streamline logistics

Reducing lead times and minimizing inventory can help lower overhead costs while boosting production capacity. Just-in-time manufacturing can help ensure a steady supply of materials and reduce the need for costly warehousing.

By optimizing your injection molding process, you can reduce your costs and increase your production scale. Partnering with an experienced injection molding provider can also help you achieve your production goals while staying within your budget. Contact us today to learn more about our injection molding services and how we can help you maximize your manufacturing efficiency.

Considering Cost-Cutting Measures

In addition to considering the cost factor, it is also important to assess potential cost-cutting measures. Redesigning a product, for example, can reduce the complexity of the mold and, in turn, lower the cost of production. Adjusting the design can also reduce the mold material usage required for the injection molding process.

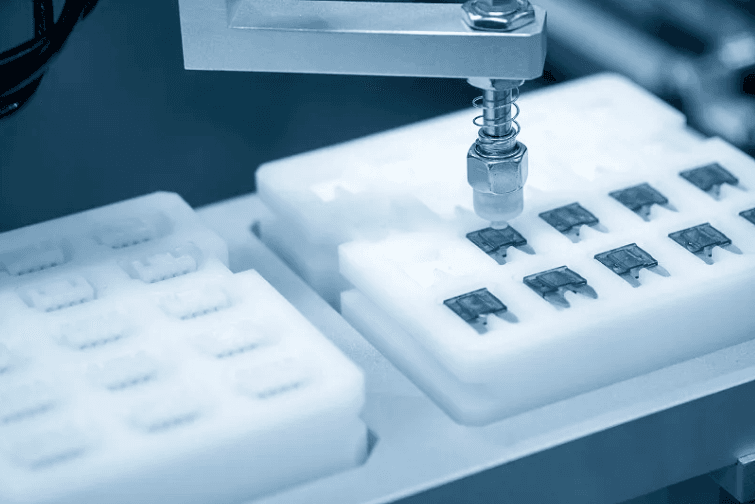

Injection molding is a manufacturing technique that involves injecting molten material into a mold to create a specific shape. This process can be used for a wide variety of materials, including plastics, metals, and even rubber. The benefits of injection molding include:

Greater efficiency

Injection molding allows for high-volume production with repeatable, consistent results. This means you can produce a large number of parts quickly and with little variation between each piece.

Lower labor costs

Because injection molding is an automated process, it requires fewer workers to operate than traditional manufacturing methods.

Reduced waste

Because injection molds are designed to create specific shapes, there is little material waste in the production process. This means you can reduce your material costs while also minimizing your environmental impact.

High-quality parts

Injection molding produces parts with a high degree of accuracy and quality. This means you can create complex parts with tight tolerances that meet or exceed industry standards.

By adopting injection molding as a manufacturing method, you can see significant cost savings in the long run. However, there are additional steps you can take to optimize your process and achieve even greater efficiency.

One such step is to work with an experienced injection molding partner who can help you refine your process and identify areas for improvement. By partnering with a team that specializes in injection molding, you can benefit from their expertise in material selection, tooling design, and process optimization.

At the end of the day, cost-cutting measures can help businesses remain competitive in an ever-changing marketplace. By adopting injection molding as a method for creating high-quality parts, you can not only save money but also improve the overall quality of your products. So why not consider injection molding for your next project?

Choosing the Right Supplier

Are you in the market for an injection molding supplier? Choosing the right one is crucial for the success of your project. With so many options out there, it can be overwhelming to make the right decision. However, fear not – Longsheng is here to provide you with the best injection molding services available!

As an industry leader with over 20 years of experience in the field, Longsheng has built a reputation for delivering high-quality injection molding services. Our team of experts is dedicated to working with you closely to understand your unique requirements and provide customized solutions that exceed your expectations.

Choosing Longsheng means you can expect the following benefits:

Quality Materials

We believe in using only the best materials to produce high-quality products. Our team of experts selects each material carefully, ensuring that every product meets the highest standards possible.

Experienced Technicians

Our team of experienced technicians are dedicated to ensuring that your project is completed on time and with the highest quality possible. They go above and beyond to exceed your expectations and deliver products that are second to none.

Advanced Technology

We invest in the latest in injection molding technology to ensure that your product is produced accurately and efficiently. Our state-of-the-art equipment guarantees that every product meets the specifications outlined in your design.

Competitive Pricing

We understand that budget is an important consideration for any project. That’s why we offer competitive pricing for our injection molding services, without sacrificing quality.

Choosing the right injection molding supplier can be challenging, but with Longsheng, you can rest easy knowing that you’ve made the right decision. Contact us today to learn more about our services and how we can help you bring your project to life!

FAQ

The cost of injection molding can vary based on a number of factors, including the volume of parts you need and the complexity of the mold design. At Longsheng, we offer affordable injection molding solutions without sacrificing quality. Contact us today for a custom quote based on your specific needs.

Several factors that influence the cost of injection molding include the complexity of the mold design, the size and shape of the part, the material used, and the production volume. The more complex the mold design, the higher the cost. Similarly, larger parts require more material and a bigger mold, which also increases the cost.

The best way to ensure that you are getting the best value for your money is to work with a reputable manufacturer who can offer you a competitive price without compromising on quality. Conducting regular quality checks during production can also help eliminate errors and reduce waste, ultimately saving you money in the long run.