Have you ever wondered how plastic products are produced in large quantities with high precision and accuracy? Well, the answer is injection molding. It is one of the most common manufacturing processes used in the production of plastic products, including toys, automobile parts, medical equipment, and electronic products. In this article, we will provide a comprehensive definition of injection molding, its advantages, and applications.

What is Injection Molding?

Injection molding is a manufacturing process that involves melting raw plastic material and injecting it into a mold. The mold will then cool and solidify the plastic, resulting in the desired shape. The process is repeated multiple times to produce multiple identical pieces. Injection molding can produce practically any shape, size, and texture at scale.

What You Need to Know Before Using Injection Molding

Before you decide to use injection molding, it’s crucial to consider several factors. One of these is the cost of production. It’s important to get an accurate cost estimate from an injection molding company before starting production. Additionally, it’s crucial to consider design and tooling costs. You must design the product to fit the molding process and take into account any additional tooling or parts required.

It’s also important to consider production lead times. Injection molding takes time to set up, and the production process can take weeks to complete. It’s crucial to factor this into your production timelines and schedules.

Another important consideration is compatibility with materials. Some materials don’t work well with injection molding and may require other manufacturing processes. Finally, it’s essential to choose the right injection molding company. Look for a company with experience in your industry, quality control processes, and good customer service.

How Does Injection Molding Work?

The process of injection molding consists of several steps. First, the plastic pellets are melted and fed into the injection molding machine. The melted plastic is then injected into a mold, where it takes the shape of the mold cavity. Once the plastic has solidified, the mold is opened, and the finished part is ejected.

The injection molding machine consists of several main components, including the hopper, heater, plunger, and mold. The hopper is where the plastic pellets are stored before they are melted. The heater heats the plastic to the required temperature. The plunger is used to inject the melted plastic into the mold, and the mold creates the final product.

Advantages of Injection Molding

There are many advantages to using injection molding as a manufacturing process. Here are a few of the most notable:

High Efficiency: Injection molding has a high production rate, allowing for the creation of large volumes of identical products in a relatively short amount of time.

Accuracy: Injection molding allows for the creation of highly accurate and precise products, making it an ideal choice for industries that require tight tolerances.

Versatility: Injection molding can be used to create a wide variety of products, from small, intricate parts to large, complex objects.

Disadvantages of Injection Molding

While injection molding has many advantages, there are also some disadvantages to consider. Here are a few of the most notable:

High Initial Investment: Injection molding requires a significant investment in equipment and tooling, making it a pricey upfront cost.

Limited Flexibility: Once the mold is created, it cannot be easily modified, making it difficult to make changes to the product design.

Material Limitations: Injection molding is most commonly used with plastic materials and may not be suitable for other materials.

Applications of Injection Molding

Injection molding is used in a wide range of industries, including automotive, electronics, consumer goods, and medical devices. Here are some examples:

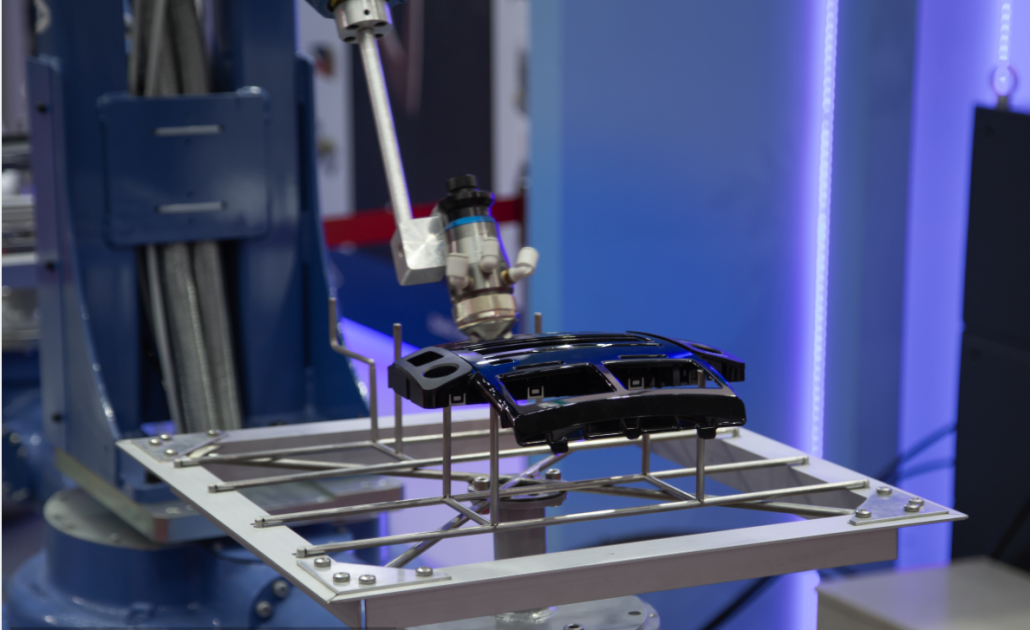

Automotive Industry

Injection molding is widely used in the production of automotive parts such as dashboards, door panels, and bumpers. The process enables the production of high-quality parts with consistent dimensions and a perfect finish.

Medical Industry

Injection molding is extensively used in the manufacture of medical equipment such as syringes, catheters, and medical implants. The process offers high precision and accuracy for the production of medical parts that must meet strict safety and quality standards.

Consumer Electronics

Injection molding plays a crucial role in the production of electronic products such as mobile phones, laptops, and cameras. The Injection molding process ensures the production of high-quality parts with complex shapes and features required in these products.

Household Goods

Injection molding is used to produce household goods such as toys, kitchen utensils, and containers.

Conclusion

Injection molding is a widely used manufacturing process that has revolutionized the way products are made. While there are both advantages and disadvantages to this method, the benefits often outweigh the drawbacks.

If you are in the manufacturing industry, injection molding may be the ideal choice for your business. By understanding the definition, process, advantages, disadvantages, and applications injection molding, you can make an informed decision on whether or not it is the right choice for your specific needs.