CNC machining is a popular manufacturing process that has revolutionized the way parts and components are produced for various industries. One of the most common uses of CNC machining is for prototyping. In this article, we will explore why CNC machining is a good choice for prototyping and the benefits it offers.

CNC Machining for Prototyping

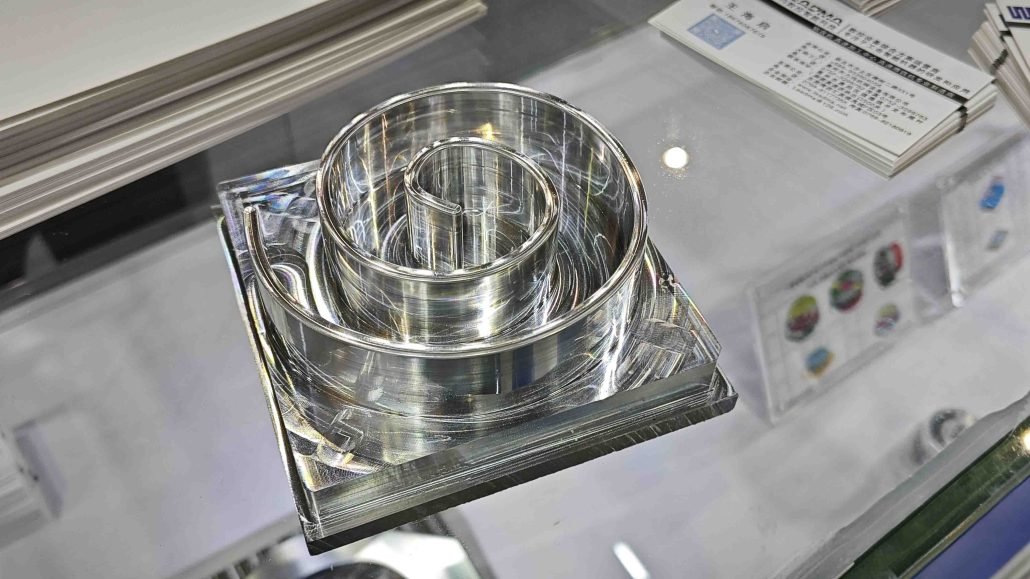

CNC (Computer Numerical Control) machining is a process that uses a variety of cutting tools to remove material from a block of material. The process is computer-controlled, which means that there is minimal human intervention required, thus reducing the risk of errors. With this process, complex shapes and parts can be created with high precision and accuracy. CNC machining is ideal for prototyping because it allows for the creation of parts quickly and at a low cost.

Benefits of CNC Machining for Prototyping

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed computer software to control the movement of tools and machinery. This technology has revolutionized the manufacturing industry, making it faster and more efficient to produce high-quality parts and prototypes. Here are some of the benefits of using CNC machining for prototyping:

Precision and Accuracy

CNC machining provides high accuracy and precision in the production of parts and prototypes. The use of computer software ensures that the machine follows the exact specifications of the design, resulting in parts that meet the required tolerances and dimensions.

Speed and Efficiency

CNC machines can produce parts and prototypes in a shorter time compared to traditional methods. The use of automated processes reduces the need for human intervention, leading to faster turnaround times and increased efficiency in the production process.

Flexibility and Versatility

CNC machining can produce a variety of parts and prototypes, from simple to complex geometries, with the same level of precision and accuracy. It can also work with a wide range of materials, including metals, plastics, and composites, making it a versatile technology for prototyping.

Cost-Effective

CNC machining can be a cost-effective option for prototyping, especially for small to medium production runs. The use of automation reduces labor costs and minimizes material waste, resulting in lower production costs.

Quality Control

CNC machining provides consistent quality control during the production process. The use of computer software ensures that every part produced meets the same specifications, reducing the risk of errors and defects.

In conclusion, CNC machining is a reliable and efficient technology for prototyping. It provides precision, speed, flexibility, cost-effectiveness, and quality control, making it an ideal option for a wide range of industries.

Conclusion

CNC machining is an excellent choice for prototyping due to its speed, precision, cost-effectiveness, and versatility. It allows for quick iterations and modifications, produces parts with tight tolerances, and can save money in the prototyping phase. If you are looking to prototype a part or component, consider using CNC machining for your manufacturing needs. online CNC machining is a reliable and efficient process that can help you bring your ideas to life.

FAQ

CNC machining can be used to create parts from a variety of materials, including metals, plastics, and composites.

CNC machining is a highly accurate process that can produce parts with tight tolerances. This is important for prototyping because it allows for the creation of parts that are as close to the final product as possible.

CNC machining is a cost-effective process that can save money in the prototyping phase. This is because it eliminates the need for expensive tooling and reduces the amount of material waste.

CNC machining is a fast process that allows for the production of parts in a short amount of time. This is ideal for prototyping because it allows for quick iterations and modifications.

The benefits of using CNC machining for prototyping include speed, precision, cost-effectiveness, and versatility. It allows for quick iterations and modifications, produces parts with tight tolerances, and can save money in the prototyping phase.