Rapid Prototyping Services

By offering minimal cost solutions, your services make it more accessible for startups and businesses with limited budgets to create high-quality prototypes. This can help foster innovation and entrepreneurship.

- All uploads are secure and confidential

3 day

Lead time

0.005 mm

Tolerances

1 pc

MOQ

40 +

Materials

High Quality Rapid Prototyping Machining

Rapid prototyping enables designers to validate their concepts and designs before committing to full-scale production. When choosing LS Manufacturing, customers have the method to choose the most suitable one for their project needs. Whether it’s 3D printing, CNC machining, or other technologies.

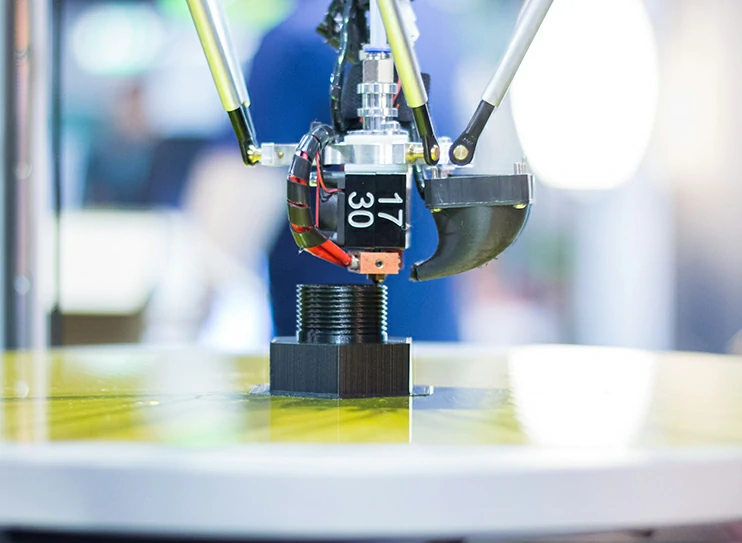

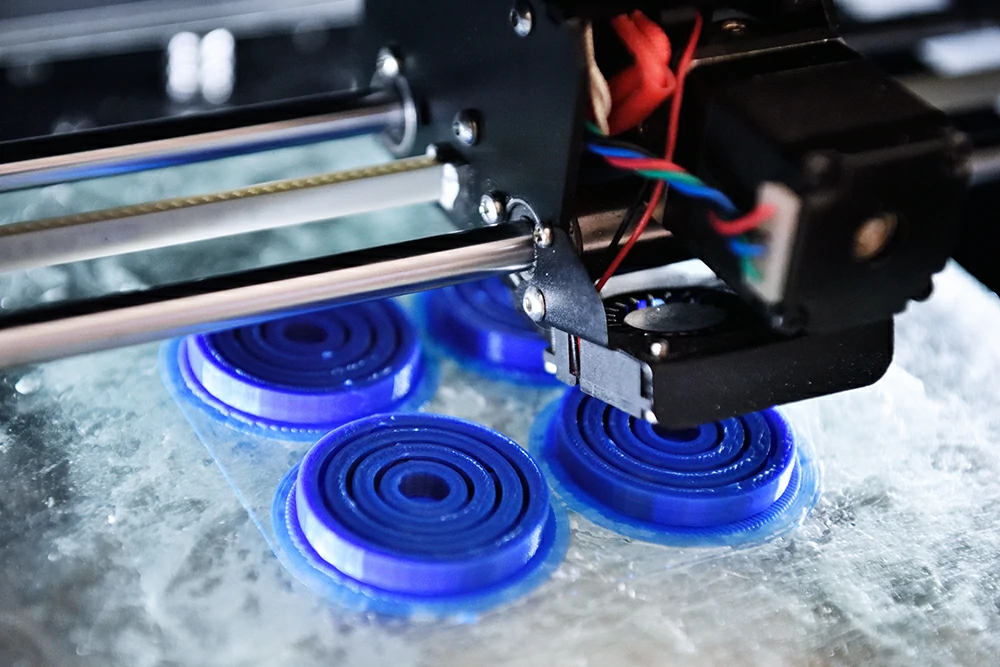

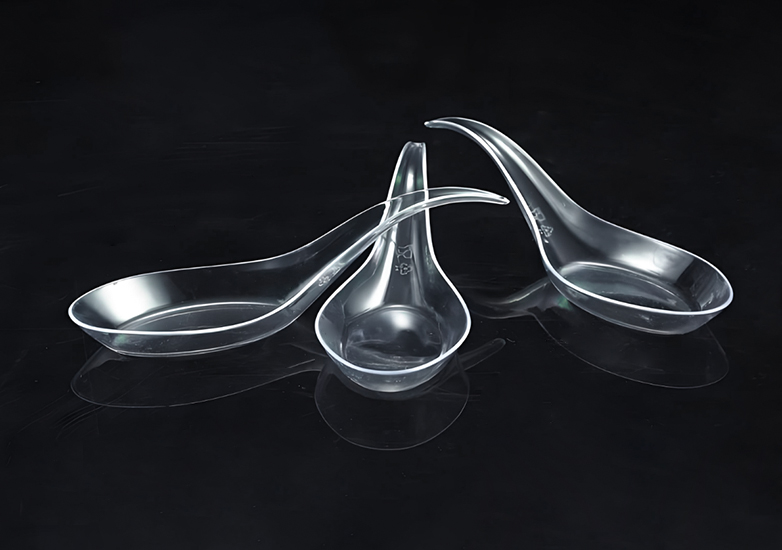

Rapid 3D Printing

Customers have the flexibility to customize their prototypes and receive them within hours or days. LS Manufacturing offers to allow customers to choose the most appropriate method based on the material characteristics, smoothness and cost requirements of their project.

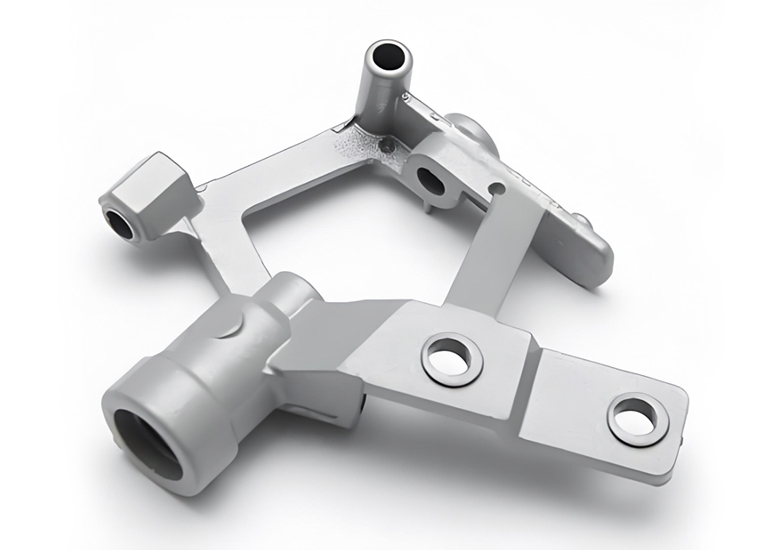

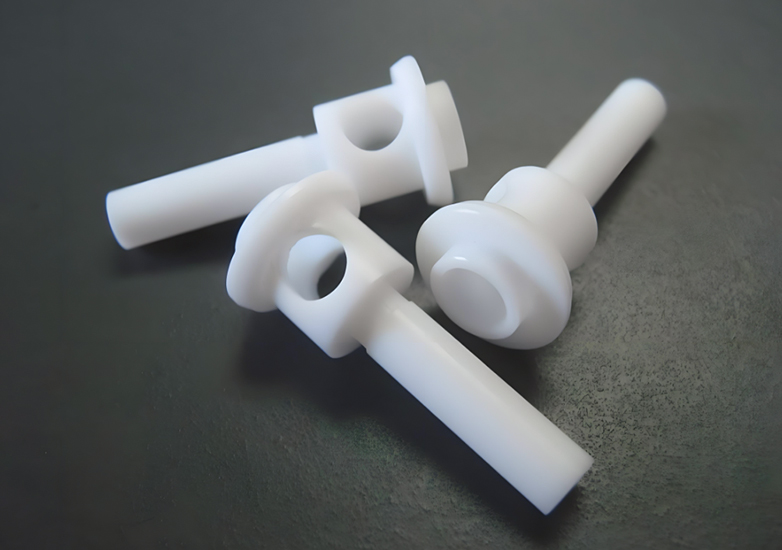

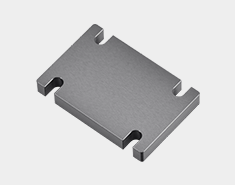

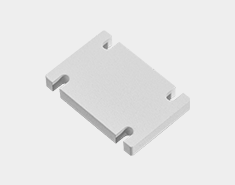

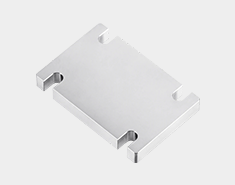

Rapid CNC Machining

The use of advanced 4-axis and 5-axis CNC machines for rotating and tilting workpieces enables multi angle machining, which helps with faster prototypes and shorter delivery times.

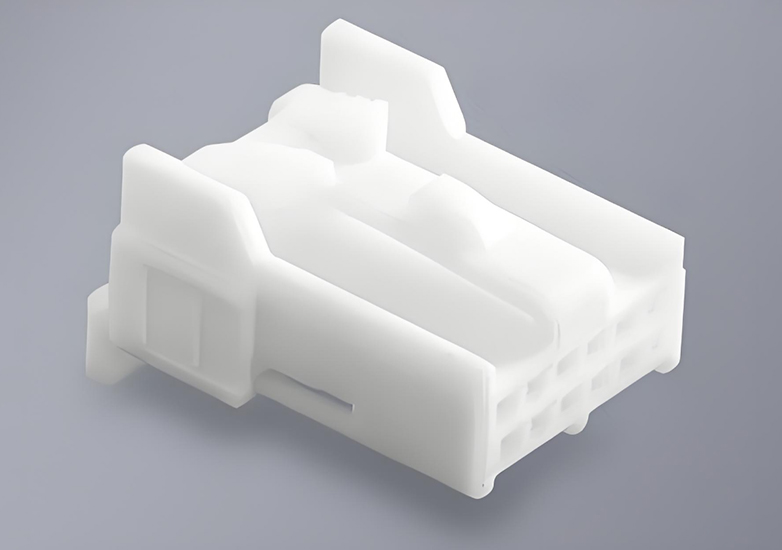

Rapid Injection Molding

Although injection molding may require longer delivery times compared to other rapid prototyping methods such as 3D printing, it may be cost-effective when you require a large number of identical parts.

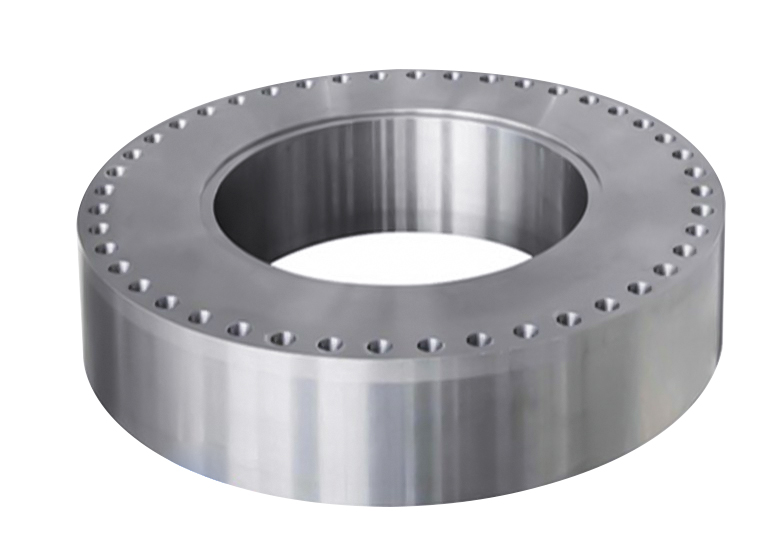

Rapid Sheet Metal Fabrication

Sheet metal fabrication can create prototypes that are very similar to the final metal components, providing realistic representations for evaluation and feedback. Especially when customers need multiple iterations or plan to shift to small-scale production.

LS Manufacturing Rapid Prototyping Tolerances

Rapid CNC Machining

Rapid CNC machining is particularly suitable for rapid prototyping of plastic and metal parts. We can manufacture all the prototypes you need through CNC machining technology and complete your rapid prototype in 3 days.

| Type | Tolerance |

|---|---|

| Linear dimension | +/- 0.025 mm (+/- 0.001 inch) |

| Hole diameters | +/- 0.025 mm (+/- 0.001 inch) |

| Shaft diameters | +/- 0.025 mm (+/- 0.001 inch) |

| Part size limit | 950 * 550 * 480 mm(37.0 * 21.5 * 18.5 inch) |

Rapid 3D Printing

LS Manufacturing’s most advanced SLA, SLS, FDM and other 3D printing technology. With efficient production capacity and simplified processes, we can guarantee you custom parts in as little as 1 day.

| Capabilities | Tolerance |

|---|---|

| Min. wall thickness | +/- 1.0 mm |

| Layer height | 50 – 300 μm |

| Max. build size | 600 * 600 * 600 mm |

| Tolerance | +/- 0.05 mm |

| Capabilities | Tolerance |

|---|---|

| Mold cavity tolerances | +/- 0.05 mm |

| Standard lead time | 10 business days or less |

| Part to part repeatability | +/- 0.01 mm |

| Production grade | 1-100,000 cycles |

Rapid Injection Molding

Our rapid injection molding is ideal for the production of small batches of molds and large quantities of plastic parts to create products that make your brand unique.

Rapid Sheet Metal Fabrication

LS Manufacturing’s rapid sheet metal fabrication services enable the efficient production of metal parts. The combination of advanced equipment and in-house production ensures fast delivery and strict quality standards.

| Type | Tolerance |

|---|---|

| Bend edge straightness | +/- 0.2 mm |

| Edge to edge, single side | +/- 0.01 mm |

| Bend angle | +/- 1° |

| Hole to hole, single side | +/- 0.1 mm |

Put your parts into production today

- All information and uploads are secure and confidential.

Material Selection For Rapid Prototyping

We offer a wide range of materials for rapid prototyping to meet the diverse needs of various industries. Our selection includes metals, plastics, and composites to ensure that your parts are manufactured with the best-suited material for your application. Below are some of the materials we commonly work with:

Metals

Plastics

We offer customization based on your specific material requirements. If you need a material not listed here, our team can source and process it to meet your exact needs.

These are just a few examples of the materials we work with. If you have a specific material requirement, please contact us to discuss your needs.

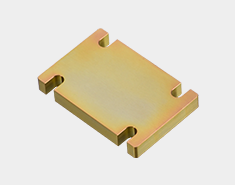

Surface Finishing for Rapid Prototyping

Our surface finishing allows you to customize the appearance and texture of your milling parts. Various textures, colors, and finishes are available to match the aesthetic requirements of your product or brand.

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Anodizing

Anodizing

|

Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Chromate

Chromate

|

Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

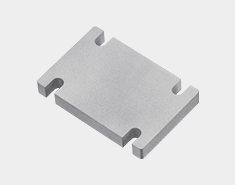

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

Why Choose Us For Rapid Prototyping Services

LS Manufacturing provides customers around the world with excellent quality, fast turnover, and cost-effective rapid prototyping services.

No MOQ

We are flexible for one-off prototypes and low-volume parts. No matter the size of your order, we can handle it.

Manufacturing Capabilities

We provide and support a wide range of manufacturing capabilities in CNC machining, injection molding.

Consistent High Quality

We use high-quality materials and maintain a high level of process stability to ensure component delivery capability.

Rapid Turnaround

Our capabilities enable us to complete your rapid prototyping project within 3 days.

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

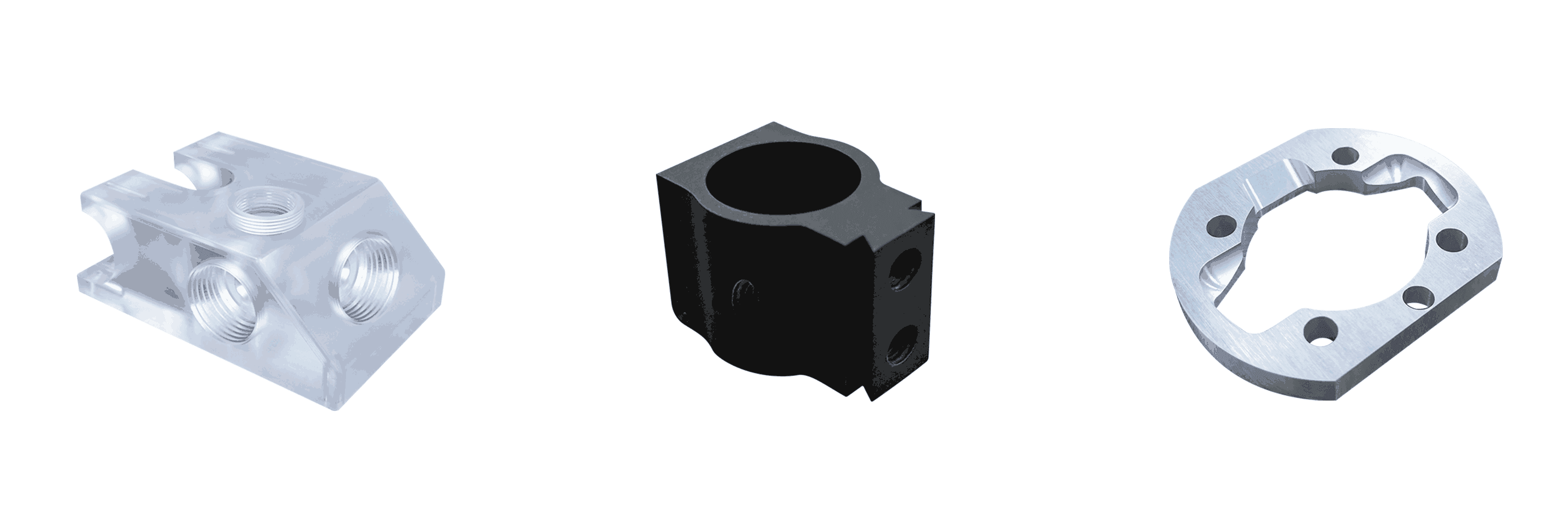

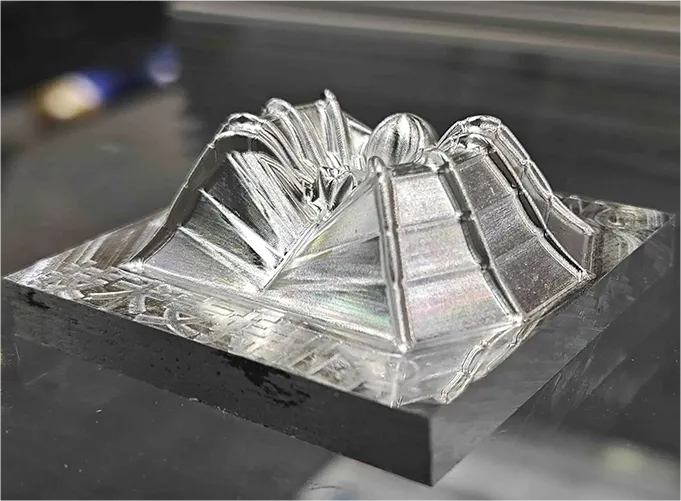

Gallery Of CNC Turning Parts

Check out our custom turning parts for valued customers, from rapid prototyping, to low-volume production, to mass production orders.

Types of rapid prototype

Rapid prototyping is a tool widely used in various industries, providing a variety of technology and material choices to meet different needs. This process also includes various types of prototypes.

Concept model

This prototype is used to validate the feasibility and feasibility of product concepts. They are usually not the final product version, but can be used to test basic concepts and technologies.

Functional Prototype

Functional prototypes are used to test the performance, working principle, and operability of a product. They can simulate the basic functions of a product, helping development teams identify potential problems and improve design.

Display Prototype

A display prototype is a type of prototype that focuses on appearance and appearance, usually produced by engineers or designers to make it as close to the appearance of the final product as possible.

Pre-Production Prototype

Pre production prototypes are usually the final prototypes made before the product is put into actual production. These prototypes are used to validate batch manufacturing processes and ensure that the manufacturing of the final product can proceed as planned.

Rapid prototyping completed within 3 days

No longer waiting, no longer delaying, compared to traditional production methods, our rapid prototyping service is more cost-effective, taking only 3 days to quickly turn your ideas from concept to reality. Our engineering team and technical equipment ensure that your prototype meets the highest standards in appearance and performance.

Our Rapid Prototyping for Various Industrial Applications

Crossing numerous industries, LS Manufacturing uses highly advanced technology, from prototype production to on-demand manufacturing, and then to large-scale production, to ensure the excellent quality and reliable performance of parts, ensuring the success of your project.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

FAQ

What rapid prototyping technologies do you offer besides CNC machining?

We offer various rapid prototyping methods including 3D printing (SLA, SLS, FDM), vacuum casting, and CNC machining to suit different project requirements and materials.

How fast can I expect to receive a prototype after submitting my design?

Typical turnaround times range from 3 to 10 business days depending on the complexity, technology chosen, and material availability. Expedited options are available upon request.

Can I make design changes after the prototype has started production?

Minor design adjustments may be possible early in the production process, but significant changes might require restarting the prototyping. We recommend finalizing designs before production begins.

What is the accuracy level of your rapid prototyping parts?

Accuracy varies by technology: CNC machining can achieve ±0.01mm, SLA printing around ±0.1mm, and SLS typically ±0.2mm. Please specify your tolerance needs when requesting a quote.

Do you provide finishing services for prototypes?

Yes, we offer finishing options such as sanding, painting, anodizing, and plating to enhance the appearance and functionality of prototypes.

Can you prototype parts with complex internal geometries?

Yes, especially with 3D printing technologies like SLS and SLA, we can create complex internal structures that traditional machining cannot achieve.

What file formats should I provide for rapid prototyping?

We accept common 3D CAD files including STEP, IGES, STL, and native formats such as SolidWorks and CATIA to ensure smooth production.

Do you offer prototypes in production-grade materials?

We can provide prototypes in various materials, including some production-grade metals and plastics, to closely simulate the final product’s performance.

How do you handle intellectual property (IP) and confidentiality for prototypes?

We strictly protect customer IP by signing NDAs and using secure data handling processes throughout the prototyping stages.

Can you assist with design optimization to improve prototype performance?

Yes, our engineers can review your designs and suggest modifications for better manufacturability, cost reduction, and enhanced product performance.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.

Rapid Prototyping Services: Get a Free Quote & DFM Analysis | LS Manufacturing

Reducing Rapid Prototyping Costs with 3D Printing: Methods, Materials, and Tips

CNC Prototype Machining: Definition, Types, Methods, Applications, Online Quotes

What is Metal rapid prototyping? A Comprehensive Guide 2025 | LS Manufacturing

What is Rapid Injection Molding: Key Applications, Benefits, and When to Use It

LS Manufacturing: 40% Faster Product Development with Rapid Prototyping

Brass vs. Stainless Steel vs. Aluminum Alloy: The Ultimate Comparison For Rapid Prototyping

How Can Rapid Prototyping Help You Save Up To 50% Of Product Development Costs?

Put your parts into production today

- All information and uploads are secure and confidential.