Rapid prototyping services are key to accelerating innovative products’ time to market. Yet many teams face long lead times, high costs, and repeated trial and error when seeking external support. The root cause lies in traditional suppliers only processing prototypes passively, with no early design involvement, allowing potential defects to emerge only during production—wasting valuable time and resources.

To address this, LS Manufacturing innovatively incorporates professional DFM analysis right upfront into the rapid prototyping process. We provide quotations transparently within hours, proactively optimize your designs, and prevent defects to get your prototypes “right first time” with drastically reduced costs and time, hence assuring successful product launch.

Full Reference Table for Rapid Prototyping Services

| Section | Core Content |

| Current Situation and Pain Points | Teams usually have to face long prototyping cycles, high costs, and multiple reworks, slowing down the time to market. |

| Core Problem to be Solved | Traditional suppliers only do passive processing of prototypes and never check the front-end design; problems remain until production. |

| Solution in This Article | DFM analysis will be included in the process at LS Manufacturing to optimize designs in advance for rapid quotes, getting it right first time. |

| Core Service Benefits | We offer a double service of “quotation + DFM.” We are proactive in the design process, reduce costs, and improve efficiency at the source to speed up product launch. |

| Customer Value Summary | We avoid later rework through early-stage engineering collaboration, and hence, shorten the development cycle to seize market opportunities. |

A common challenge in rapid prototyping is the lack of early supplier engineering involvement. LS Manufacturing integrates professional DFM analysis from the start, enabling fast, transparent quotes and proactive design optimization to prevent defects and control costs. This shifts the process from passive manufacturing to proactive collaboration, ensuring first-time success, shortening development cycles, reducing risks, and helping teams seize market opportunities.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

Not a neat showroom, but a real battlefield-this is our workplace where we clash with high-strength alloys, stringent tolerances, and complicated geometries every day. For consumer electronics, internal structural precision in iterative prototypes determines user experiences, while assembly reliability of motion joint prototypes decides the success of millions of tests in the robotics industry. Every delivery is practice for our commitment to “do it right the first time.”

In the last ten years alone, we have successfully provided tens of thousands of kinds of custom prototypes in the field of rapid prototyping. Each project gives us more profound insight into how to optimize the processing parameters for carbon fiber composites, reduce 3D printing post-processing time by up to 50% through optimization in design while maintaining functionality, and compress the delivery cycles to the extreme by end-to-end collaboration in response to urgent needs.

From material powder properties all the way to the final surface treatment specifications, each and every critical stage of the prototyping is religiously adhered to and embodies the best from the authoritative standards of National Association for Surface Finishing (NASF) and Metal Powder Industry Federation (MPIF). What you will read here forms the core insight that has been gained from countless successes and early lessons; all this helps your product make a smooth transition from blueprint into physical prototype.

How to Choose the Most Suitable Rapid Prototyping Service for Your Project?

In the search for rapid prototyping services, one should not be limited to selecting a partner based on quoted price only. A prudent assessment can facilitate your project in minimizing risks, costs, and considerably cutting time in further development. How then should you systematically screen suppliers to find one providing superior engineering value and not just simple manufacturing?

| Evaluation Dimensions | Key Considerations |

| Front-end engineering support | Can the supplier provide professional DFM analysis before manufacturing to optimize the design from the source? |

| Technical capability coverage | Does it possess comprehensive technological capabilities (such as CNC machining, 3D printing, vacuum casting, etc.) to meet diverse needs? |

| Quality System Certification | Does the supplier have any international certifications, such as ISO 9001, that ensure standardized processes for predictable results? |

| Communication and Response Efficiency | Does the team respond quickly, communicate transparently, and collaborate as efficiently as internal partners? |

When comparing rapid prototyping services, do not merely consider price. Instead, look into engineering depth, quality reliability, and collaboration efficiency. Real acceleration for your product’s success comes from a partner who truly understands your goals and can deliver with certainty. This explains how to choose a prototyping service that truly supports you.

What are the key processes and technologies of rapid prototyping?

At the start of a new product development, understanding rapid prototyping processes is essential. The right technology affects functional validation and project efficiency. An online quote rapid prototyping tool supports preliminary assessment and enables quick turn prototyping decisions. Though estimates are easy to get online, informed choices come from knowing core technical features. The table below compares key processes and their differences:

| Process Technology | Core Features and Advantages | Applicable Scenarios and Materials |

| CNC Machining | High precision, ±0.05mm excellent material property engineering plastics, metals excellent surface quality functional testing can be achieved. | High-precision, high-strength end-part prototypes & small-batch production; widest material selection |

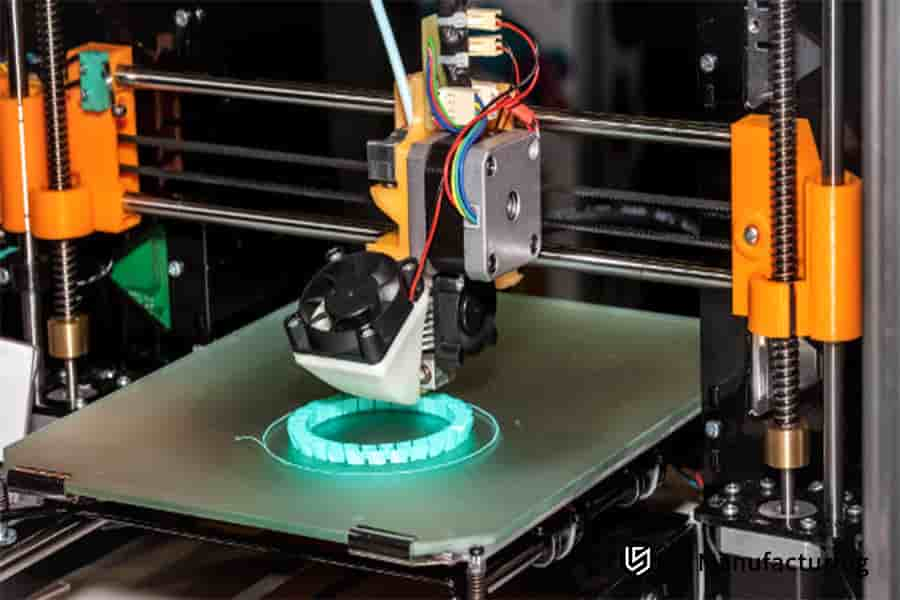

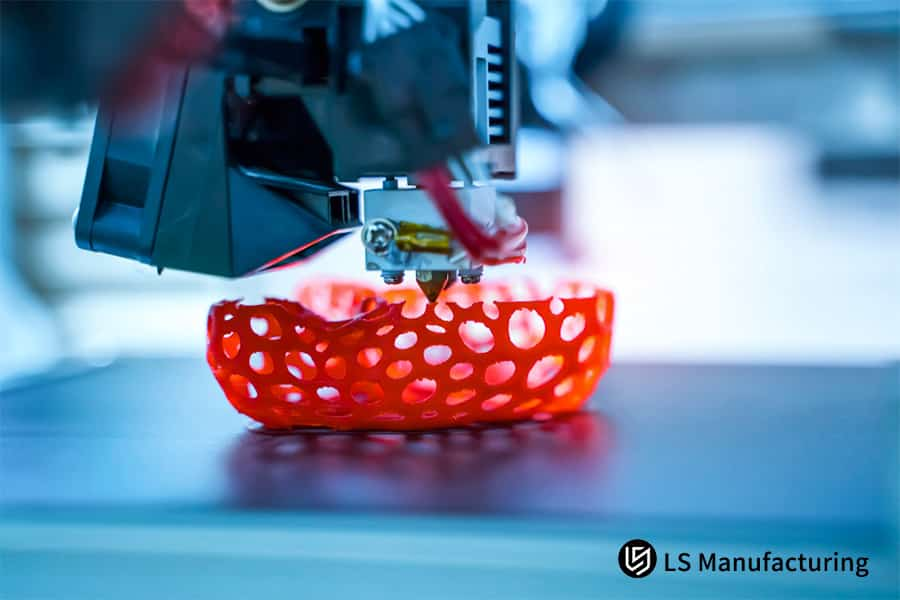

| 3D printing | It has a fast molding speed and can manufacture complex geometries (such as internal cavities and integrated structures), making it suitable for design verification. | Conceptual models and assembled test pieces are mostly made of resin (SLA), nylon powder (SLS), or PLA (FDM). |

| Vacuum molding | Small-batch replication is highly efficient and relatively low-cost, and can simulate various finished materials (such as silicone and soft rubber). | This applies to small-lot productions of exterior parts, the making of prototypes, and silicone pieces ranging from tens to hundreds, which are suitable for trial production and promotional products. |

| Sheet metal processing | Specifically designed for sheet metal forming, it can quickly manufacture chassis, shells, brackets, etc. The technology is mature and the cost is controllable. | Prototype and mass production of sheet metal structural components such as electronic device housings, cabinets, and metal brackets. |

In practice, many projects blend multiple technologies. We recommend deciding based on the prototype’s main purpose—appearance, structure, or functional testing—along with material, budget, and quantity needs. Professional service providers now offer online quote rapid prototyping tools and expert consultation, enabling efficient selection of technical solutions that support quick turn prototyping. This combination of analysis and guidance ensures prototyping is both economical and effective.

Why is professional DFM analysis such an important first step in successful prototyping?

One of the essential yet often overlooked steps in rapid prototyping is conducting a manufacturability review of the design before production—often called a DFM analysis service. This value-added analysis, typically included as part of a free prototype quote, protects your project from the start. Professional DFM analysis involves systematically reviewing and optimizing key design dimensions to achieve the best balance between manufacturing efficiency and cost.

Optimizing structural and process adaptability

The given analysis is targeted to see whether the design’s draft angle is such that it enables demolding, whether the thickness of the wall is even so that there will not be deformation or shrinkage, and if enough fillets have been added in areas which may cause stress concentration. For instance, a design structure of a deep cavity without any draft angle leads to the damage of the part or inability to demold it in the case of injection molding or vacuum molding. A change in such a design at this stage of prototyping costs almost nothing.

Rationalising Tolerances and Assembly Relationships

Overly tight tolerances increase the cost and time to process such parts exponentially, while too loose tolerances will lead to assembly failure. According to the real functional needs of the prototype, such as static exhibition, motion, or airtightness requirements, DFM analysis proposes the most economic and reasonable tolerance bands and checks assembly sequence and interference between many parts so that the design ensures assemblability.

Optimize material selections and post-processing solutions

It could also provide suggestions on cost-effective material recommendations based on functional requirements the prototype will be subjected to, such as strength, temperature resistance, and transparency among others. Besides that, planning for efficient post-processing paths will be suggested, including spraying, screen printing, and anodizing services, among other processes, so that performance deficiencies or cost overrun due to wrong material and process choice can be avoided.

Eventually, professional DFM analysis is not an added cost but rather a high-return investment. Just by investing a little in the very beginning, it avoids wasting much time and money later on. Finding a service provider who proactively provides in-depth DFM analysis in the free prototype quote stage means you are choosing not only manufacturing capability but also a forward-thinking engineering partner.

What are some of the key factors to evaluate when requesting an online rapid prototyping quotation?

Reliability in an online rapid prototyping quote can be greatly improved in systematic preparation in order to control cost, reduce potential hidden risks, and avoid unnecessary wasting of time and money later on. For a valuable quotation, the following core information shall be clearly provided during the request for quotation:

- The clear and complete design documents: Providing high-quality and error-free 3D models is the very basis of this, and general formats such as STEP and IGS are recommended. The document should include accurate material settings and key dimension annotations, which are the main basis for the service provider to accurately assess the manufacturing difficulty and time.

- Clear process, material, and post-processing requirements: Clearly state the type of process to be used such as CNC machining or SLA 3D printing, specific material grades, and performance requirements, together with any surface finishing, painting, screen printing, electroplating, etc, assembly, and other post-processing requirements. Vague requirements are one of the biggest contributors to extra costs.

- Understanding the Components of a Professional Quote: A trustworthy free quotation in prototype manufacturing should not be just one total price. Check if it clearly shows the material cost, programming/processing cost, post-processing cost, tax, and shipping in detail. This will help you analyze the cost structure to judge how transparent the supplier is.

In a word, valid no-trap online quote rapid prototyping depends on your clear requirements and the professional cost breakdown of the service provider. Take this inquiry process as the first cooperation: provide detailed and standardized information proactively, and carefully check every detail in the quotation. This approach, especially when backed by a free prototype quote, not only secures an accurate budget but also effectively evaluates the supplier’s professionalism, laying a solid foundation for smooth future collaboration.

The IoT Enclosure Challenge: How LS Manufacturing solves the Cost and Process dilemma

This is a common challenge in smart hardware development: a design may look perfect on paper, yet face manufacturing issues like “impossible to produce, cost overruns, or long lead times.” Take IoT enclosures, for example—they require structural strength, heat dissipation, and electromagnetic shielding. Let me share a real case of how we turned seemingly “impossible” manufacturing hurdles, through engineering collaboration, into a successful product launch.

Client Challenge

In the development of an advanced IoT device casing made from aluminum alloy, an IoT startup created several deep cavities and thin-walled structures that supported wiring and heat dissipation. Seeking rapid prototyping services, they encountered a number of barriers-most suppliers said their design was too complex for integrated CNC machining-and even when suppliers did accept the project, quotes were far over their budget, with lead times as high as four weeks, severely impeding product development.

LS Manufacturing Solution

Upon receipt of the client drawings, we promptly conducted a professional review. Within two hours, we not only provided an LS Manufacturing prototype quote based on the initial design but also delivered a detailed DFM analysis report alongside it, at no additional cost. The key recommendations from the report are as follows:

- Several deep-cavity integrated structures that are very complicated and inaccessible to tools are ingeniously optimized to the precision-assembled modular design, which greatly reduces the difficulty and cost of processing while maintaining strength and aesthetics.

- Based on functional requirements, recommending an aluminum alloy grade with comparable performance but easier processing and higher cost-effectiveness. We also committed to delivery within 10 business days after adopting the optimized solution.

Results and Value

The customer fully adopted the solution of DFM optimization. Eventually, it reduced the manufacturing cost of the prototype by 40% compared to the initial estimate and delivered the first batch of fully functional and dimensionally accurate aluminum alloy shell prototypes 8 days in advance. We used such high-quality prototypes for key investor presentations and initial functional testing while satisfying design feasibility to pave the way for further mold development and mass production in catching the valuable market window.

This case shows that professional rapid prototyping is more than just “making to order.” Beginning with a detailed LS Manufacturing prototype quote and proactive engineering involvement, we can help you overcome design bottlenecks. Through DFM analysis and extensive experience, we work with you to find the optimal solution—balancing cost, manufacturability, and timeline without sacrificing core function, accelerating your product’s journey from concept to reality.

Looking for solutions for complex designs and prototyping? Upload your drawings now for a free DFM analysis and quote!

What is the average cost structure and timeline for rapid prototyping?

The cost and timeline of rapid prototyping are fundamental to budget and schedule planning in new product development. Many clients are confused by the wide variation in free prototype quotes from different suppliers during initial inquiries. This is often due to complex cost structures and diverse process options. Transparent cost analysis helps you understand cost drivers and make informed decisions. A typical rapid prototype cost mainly includes the following components, while the timeline is directly linked to the chosen process:

Core Cost Structure

It comprises mainly of three parts: materials, equipment time, and labor or post-processing. Material prices will depend on the type of plastics, resins, or metals one may choose to use, while equipment time is another critical constituent-particularly for complicated or precision parts that include programming and machining/printing time. Last but not least, labor costs are reflected in process planning, post-processing that includes sanding, painting, assembling, etc., and quality control. Hence, a professional free prototype quote will clearly break down the details.

Typical Timeline and Price Range

Timelines vary significantly by process. For instance, 3D printing (SLA) typically takes 1–3 business days, while CNC machining, known for its high precision, generally requires 3–7 days due to programming and setup. Vacuum molding, suitable for small-batch replication, usually takes 5–10 business days. Costs also range widely—from a few hundred RMB for simple 3D-printed parts to several thousand or more for complex CNC metal parts with stringent material requirements.

In rapid prototyping services, understanding cost and timeline is essential for a smooth project. A detailed quote reflects a supplier’s transparency and professionalism. At LS Manufacturing, we provide transparent, free prototype quotations and go further: through expert DFM analysis and process optimization, we help you achieve the best value—meeting your quality and timeline needs without wasting time or money.

To what extent is it possible to protect the intellectual property rights of a prototype design?

When sharing core design documents with external partners, protecting your intellectual property and trade secrets is a primary consideration. To address this concern, we translate our security commitment into a comprehensive, enforceable system that integrates legal, technical, and process safeguards. This enables you to collaborate with peace of mind from the moment you receive a LS Manufacturing prototype quote for our rapid prototyping services. Our confidentiality mechanisms cover every stage from initial contact to final delivery, including specifically:

- Legal Barrier: Before the submission of your design documents, the system automatically takes both parties through an online signing of a legally binding Non-Disclosure Agreement, which explicitly lays out information coverage, use restrictions, and responsibility for confidentiality-the backbone of any good legal protection.

- Technical Protection: We provide a dedicated secure channel for file transfer where all uploaded data, including 3D drawings and technical specifications, will be encrypted from end to end. Consequently, it is not accessed or intercepted by unauthorized persons during transmission over networks or when stored in the server.

- Personnel Management: All of our staff sign strict personal confidentiality agreements on the first day they join our team for a client project. In practice, we adopt management by “project segregation,” meaning restricting access to project information to only the necessary number of employees, and record logs for traceability of responsibility in accessing data.

- Physical and Process Security: From document receipt and production processing to finished product delivery, independent production and logistics records are generated for key projects. Upon completion, we securely archive or completely destroy relevant digital files, under your direction, hence ensuring information control over its entire life cycle.

With LS Manufacturing, you are guaranteed an accurate and transparent LS Manufacturing prototype quote for our rapid prototyping services, backed by top-tier manufacturing and a partner-level commitment to the security of your information. We build a robust four-level “firewall” defense—through legal contracts, IT systems, internal controls, and physical processes—that safeguards your innovations from concept to reality, allowing you to focus fully on product development.

How specifically does it work in co-operating with LS Manufacturing?

LS Manufacturing partners with you to provide a smooth, effective journey from concept to reality. We believe a smooth process is half the battle won. To ensure an easy, transparent, and controllable rapid prototyping experience, we have standardized collaboration into five seamless steps. This allows you to stay on top of progress and avoid uncertainty, whether you’re a first-timer or a long-term partner. From design submission to final product receipt, the entire process is clearly outlined in the following steps:

- Online Submission and Requirements Communication: Just upload your 3D drawings on our secure platform in a format like STEP/IGS and describe your project requirements, including materials, processes, quantities, surface finishes, and expected delivery time. The following provides the basis for an accurate online rapid prototyping quote.

- Professional Review, Quotation, and DFM Analysis: Our engineering team will review your documents ASAP. Within a few hours, you will get a detailed and transparent LS Manufacturing prototyping quote. More importantly, we will also provide you with a free DFM analysis report, including professional suggestions for design optimization, cost reduction, and cycle shortening. Then we will confirm together on the best solution.

- Solution Confirmation and Online Payment: Confirm the final solution and quotation, then complete the order through our secure online payment channel. Once the payment is made successfully, the project will be scheduled for production immediately, and a dedicated project manager will be assigned as your single point of contact.

- Intelligent Production and Rigorous Quality Inspection: Your project will flow into our digital production system. From programming to machining/printing, and then to post-processing, everything is done according to standardized procedures. Every prototype must pass the stern quality checks before shipment to ensure the models meet specifications.

- Packaging, Shipping, and Logistics Tracking: Products that have passed quality inspection will be properly packaged to avoid any damage during transportation. After that, the logistics information will be updated on your customer portal, through which you can track in real time the status of your package until it is safely delivered to you.

The core value of partnering with LS Manufacturing is our professional, proactive engineering support and complete information transparency. Rather than passively taking orders, we proactively add value—starting with a free DFM analysis included in your online quote rapid prototyping request. This process ensures you stay informed and in control at every stage, making complex prototyping as simple and reliable as online shopping, and transforming your ideas into high-quality products efficiently.

Besides prototyping, do you give support to the transition from small-batch pilot production to mass production?

Our rapid prototyping services extend beyond initial development, and we are committed to providing a seamless, one-stop solution from prototyping to production. We ensure the product journey is smooth, maintaining design integrity and quality throughout with the following key services:

- Design validation and process lock-in: Our professional DFM analysis service can optimize the prototype and provide early process validation for mass production in a rapid prototyping process. In processing prototypes, accumulated processing parameters, material properties, and assembly experience directly contribute to later pilot production and reduce the risk of process change afterwards.

- Flexible small-batch pilot production bridge: Upon successful prototype validation, we provide different pilot production solutions, such as vacuum molding, small-batch CNC machining, or rapid injection molding. For example, via vacuum molding, one can get 50-500 parts with an appearance and performance close to the final product at a much lower price than after mold making. These parts are applicable for market testing, crowdfunding, or the initial sales, perfectly bridging development and mass production.

- Design Optimization for Mass Production: Throughout the phase of pilot production, your product will have its manufacturability, assembly efficiency, and cost structure further optimized from the perspective of mass production by our engineering group to ensure that your design is not only “workable” but also “easy to mass-produce efficiently and economically.”

- Supply Chain and Resource Collaboration: As your long-term manufacturing partner, we use the deep understanding of your product that we gathered from past collaborations to help you determine the path of mass production for your product or suggest qualified molds and mass production resources so that continuity in knowledge transfer can be guaranteed without fluctuating quality caused by changing suppliers.

LS Manufacturing is your strategic partner, supporting you through all product life cycle stages. From rapid prototyping and DFM analysis, we focus on your product’s ultimate success. We ensure you “make it successful” with seamless, one-stop services that reduce risk and time to market, making innovation smoother and more effective.

FAQs

1. Are your free quotes and DFM analyses really free?

Absolutely free. Quotes and DFM analyses comprise our standard services, done in support of the optimization of designs and avoidance of cost overruns by early engineering intervention. There are no fees to pay and there is no subsequent collaboration pressure thereafter.

2. How long does it take from submitting documents to receiving a quote?

We guarantee efficiency in response: for standard formats of 3D files, such as STEP and IGES, a clear quotation and preliminary DFM summary can normally be provided within 4 business hours from the date of submission, which ensures rapid progress on the project.

3. Will design changes based on your DFM recommendations change the functionality of the prototype?

Rest assured, all our recommendations regarding DFM are based on ensuring the core functionality of the product. We optimize the manufacturability of only those processes and structures which will enhance quality and shorten cycle time without affecting original functionality and performance of the design.

4. Do you support material certification and provide quality inspection reports?

We fully support comprehensive quality verification, including material certificates upon request, with each prototype receiving a basic inspection. When required, the full-size inspection report (FAIR) will also be provided to guarantee complete conformance to specifications.

5. What is MOQ? Is it possible to make only one prototype?

Full support for R&D: We focus on prototyping and small-to-medium batch production, with no restriction on the minimum order quantity, order acceptance for single pieces, and help you finish the job of design verification and functional testing at a lower cost.

6. I’m not happy with the quotation I received; may I cancel my order?

Please note that all quotes and solutions provided are for reference only until you confirm and settle the payment. You can cancel any time or request modifications for free. We will optimize the solution as per your feedback; no restrictions or fees apply.

7. How do you handle very urgent expedited orders?

We have an expedited production channel. In urgent situations, resources may be allocated for priority processing. In general, the lead time can be shortened by over 50% compared to the standard. Please communicate with customer service for specific expedited arrangement and feasibility confirmation.

8. How do new customers place their first orders?

The process for a new customer is very simple: log in to the “Online Inquiry” page on our official website, attach your 3D files, and describe your needs. One of our professional engineers will contact you without any delay to help you through every step regarding your first order.

Conclusion

Choosing the rapid prototyping service partner means choosing a strategic ally who can accelerate your product innovation and mitigate your R&D risks. Equipped with comprehensive technical capabilities and in-depth DFM engineering support, with a customer-centric service model, LS Manufacturing is committed to making every prototype an efficient and reliable value-creation process.

Your ideas deserve the most professional realization. Stop hesitating any longer because of uncertain quotes or design risks that may catch you off guard. Click the “Get a Free Quote and DFM Analysis” button now, upload your 3D files, and enjoy professional, transparent, efficient rapid prototyping services from LS Manufacturing! Let our professional team safeguard the success of your product.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.