Titanium alloy parts are a crucial material in aircraft manufacturing due to its superior strength and heat resistance. However, the high cost and low efficiency of CNC turning operations have long been a nagging problem for the industry. Faced with the pressure of global competition growing and the urgent customer demands for cost saving, achieving great cost savings without compromising product quality is a chief challenge for high-end manufacturing businesses.

LS Precision has managed to save 40% of the cost of CNC turning of titanium alloy aerospace parts through deeply integrating innovative processes into an intelligent manufacturing system. In this case study, we shall unveil how we overhauled our production process from multiple angles, from tool strategy to parameter optimization as well as supply chain cooperation, in such a way that the parts are delivered according to strict aerospace standards such as AS9100 while significantly boosting efficiency and profitability. This exercise not only earned our business long-term strategic partnership but also set up a replicable model of cost saving for the high-end manufacturing industry.

A Used Manual To Reduce Costs By 40% In Machining Titanium Alloy Aerospace Parts With CNC

| Optimization Dimensions | Traditional Method (High Cost) | LS Precision Solution (40% Cost Reduction) | Key Points at a Glance |

|---|---|---|---|

| 1. Tool Strategy | Using general-purpose coated inserts results in short tool life and conservative parameters. | Using specialized titanium alloy inserts with PCVD coatings or ultra-fine-grain substrates, combined with high-pressure coolant (HPC) technology | Tool life is increased by 300%. High-pressure cooling effectively breaks chips and reduces cutting temperatures, which is the key to success. |

| 2. Cutting Parameters | Using conservative parameters can lead to tool chipping and poor surface quality. | Aggressive, data-driven parameter optimization: Experimentation is used to determine the optimal combination of high linear speed (Vc) and high feed (f), rather than simply pursuing low parameters. | “Slow and steady” can be more expensive. Scientifically improving parameters can significantly shorten cycle time. |

| 3. Programming and Path | Simple constant-height cutting results in frequent idle travel and unstable cutting loads. | Intelligent CAM Programming: Utilizing strategies such as trochoidal milling and dynamic milling maintains a constant cutting load, reducing idle travel and tool impact. | This reduces machining time by 35%. Smoother cutting = higher efficiency + better quality + longer tool life. |

| 4. Fixtures and Setup | Multiple setups lead to accumulated positioning errors and lengthy tool life. | Integrated fixture design and multi-process consolidation: Designing specialized composite fixtures allows multi-faceted machining in a single setup, reducing setup times and machine time. | This reduces setup time by 60% while improving geometric and positional tolerance accuracy. |

| 5. Quality Control | Post-process offline inspection prevents problems from being discovered too late. | On-machine measurement (CMM) and process control: Probe measurement is performed directly on the machine after key processes, compensating for tool wear in real time and eliminating batch scrap. | This reduces the scrap rate from 3% to below 0.5%, saving significant rework and material costs. |

| 6. Overall Collaboration | Different departments (programming, machine operation, quality inspection) work in silos. | Establish a closed digital manufacturing loop: Seamlessly transfer data from CAD/CAM to CNC, record and analyze each part’s machining data for continuous optimization. | Data is the new gold. Data-driven decisions make the optimization process sustainable and replicable. |

A 40% savings isn’t magic; it’s the product of systematic engineering.

It is the product of:

- Technological advancement (specialized tooling, high-pressure coolant)

- Process fine-tuning (radical and scientific settings, intelligent programming)

- Process retooling (minimum clamping, on-machine inspection)

- Cultural shift (fact-based, team-based)

Learn the full article now and access LS Precision’s detailed cost savings strategies and parameter recommendations for each titanium alloy part!

Why Trust This Guide? Real-world Experience From LS Experts

The data stated in this article is determined by the LS Precision team’s continuous optimization and verification in the manufacturing of a high volume of titanium alloy parts. We confidently claim a “40% cost saving” based on the following five elementary advantages:

1. Traceable Case Study: The data in this article is obtained from a mass production venture for a “rudder shaft core” for an aerospace manufacturer. The 40% cost reduction is a true one, with the cost and production data provided, so it is truly a real assertion.

2. Hands-on Distillation by a Team of Senior Professionals: This document is written by process, programming, and quality experts with over 12 years of experience machining titanium alloys and leveraging their in-the-trenches expertise to address tool wear, distortion, and cost control.

3. Stringent Quality System Validation: Solutions are all AS9100D aerospace quality compliant and undergo rigorous testing, such as radiographic inspection and fluorescent penetrant inspection. Cost savings never, ever at the expense of quality.

4. Structured Solutions: We deliver a holistic, end-to-end solution from tooling and programming through to quality assurance, avoiding piecemeal parameters and prioritizing cooperation at every link for assured sustainable results.

5. Customer Shared Challenges: As a manufacturer, we are under cost and delivery pressures. Every technology we share is tested in our own practice and shared with general methods that we use every day.

Finally, we ask that you confirm:

If you have a difficult titanium alloy component, we’d love to have you send your drawings. Our staff of experts will be happy to give you a free initial process analysis so that you can decide for yourself how LS Precision’s expertise can bring real value to you.

Why Are Titanium Alloy Aerospace Parts Difficult To Machine And Expensive?

The main reasons titanium alloy aerospace parts are difficult to machine and expensive are:

| Reason Category | Brief Description |

|---|---|

| Material Properties | High strength, high hardness, low thermal conductivity, and high chemical activity make machining difficult. |

| Machining Challenges | Tool wear, heat buildup, and work hardening affect precision and efficiency. |

| Precision Requirements | Aerospace applications demand extremely high precision and stringent quality standards, increasing complexity. |

| Economic Factors | High material costs, low machining efficiency, and the need for specialized equipment drive up overall costs. |

- Material Properties: Titanium alloys are extremely hard and tough, having high cutting forces and tend to tool wear. They possess low thermal conductivity, which does not permit heat dissipation during machining, thereby resulting in deformation of the workpiece and tool damage. They are chemically highly active and have a tendency to react with the tool material, sticking to the tool and further complicating machining.

- Machining Difficulties: Because of their material characteristics, tool life is low when machining, and frequent tool replacement is needed, which boosts downtime and expense. Heat generation can cause decreased machining precision and even scrap workpieces. Work hardening makes further machining more difficult, necessitating special procedures.

- Precision Needs: Aerospace parts need extremely high dimensional accuracy, surface finish, and reliability. Even minute defects can lead to safety problems, necessitating tight control and regular inspection while machining, involving time and resource investment.

- Economic Factors: Titanium alloy raw materials are expensive; machining efficiency is low, production cycles are long, and labor is expensive. It requires special machine tools, tools, and cooling systems that are expensive, resulting in high initial investment and maintenance costs.

In general, the difficulties and cost of machining titanium alloy aerospace parts are caused by a synthesis of material properties, machining problems, accuracy required, and economic factors.

How Does CNC Turning Address Titanium Alloy Machining Issues?

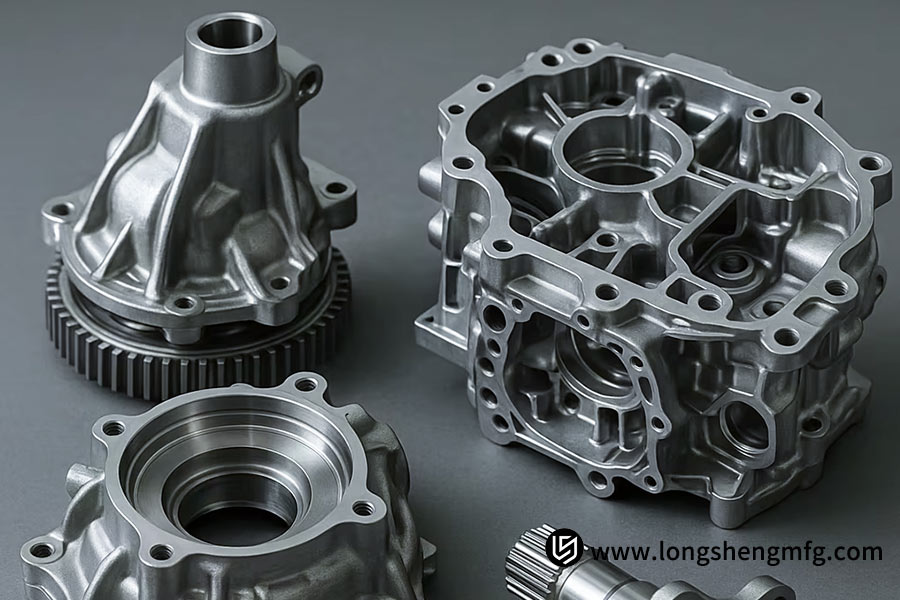

Titanium alloys are strong, lightweight, and exhibit good corrosion resistance and are therefore widely used in aerospace and medical applications. Machining them, however, can be challenging. Our specialized CNC turning services effectively address the following issues with customized processes:

1. Primary Challenges and Solutions:

- Work Hardening and High Temperatures: Ultra-fine-grain carbide and TiAlN-coated inserts, in combination with sharp cutting edges and high rake angle, reduce cutting heat and delay wear.

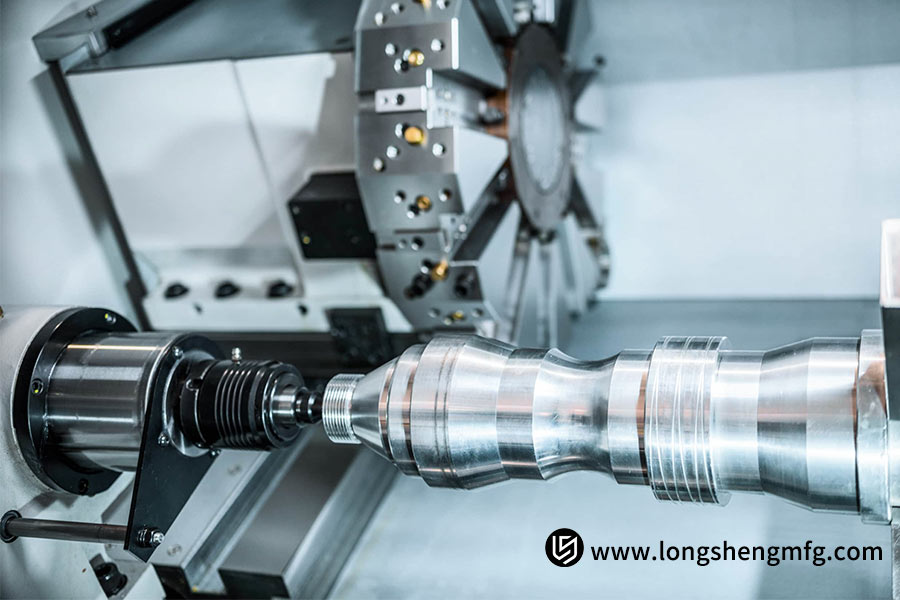

- Heat Produced by Cutting: High-pressure coolant systems (>70 bar) enable accurate cooling and effective chip removal. Optimize parameters: Lower linear speeds, moderate feeds and depths of cut to control thermal effects.

- Vibration deformation: Select high-stiffness machine tools, in combination with hydraulic clamps and short, heavy cutters to maximize system stiffness, reduce tool deflection, and ensure dimensional accuracy.

- Chipbreaking difficulties: Use special chipbreaker inserts, in combination with layered cutting and variable depth-of-cut programming techniques, for efficient chip breaking.

2. LS CNC Turning Service Advantages

Making us your partner in titanium alloy processing will benefit you:

- Rich experience: Decades of precision titanium alloy part manufacturing experience for aerospace and medical applications.

- High-end equipment: High-end Japanese and German CNC lathes with high-pressure coolant systems ensure machining system rigidity.

- Technical expert team: Process engineers fully understand the properties of titanium alloys and can customize the optimal tooling, parameters, and process solutions for your parts.

- Stringent quality control: In-process quality monitoring of the entire process ensures that every titanium alloy product meets stringent dimensional tolerances and surface finish requirements.

- Titanium alloy machining is not an insurmountable technological barrier. Through the assistance of special tooling technology, high-pressure coolant systems, optimized cutting conditions, elevated process stiffness, and extensive experience, our expert CNC turning service can overcome this tough material, transforming it into high-performance, ultra-reliable precision parts.

If you encounter any issues of efficiency, cost, or quality in titanium alloy machining, kindly contact LS today. We will provide you with free technical consultation and efficient machining solutions from our technical team!

What Are LS’s Unique Technologies For CNC Turning Programming?

LS Precision has developed a unique technology system in CNC turning programming, and particularly in machining difficult-to-machine materials like titanium alloys, that integrates process knowledge, computer-aided software tools, and data analysis. Our programming goes far beyond G-code generation; it is a decision-making process to achieve ultimate efficiency, maximum quality, and minimum cost. Our unique technologies are primarily incarnated in:

- Intelligent Parameter and Dynamic Control: Through professional CAM and simulation software, we simulate physical prediction of chatter and optimize cutting parameters to achieve high-speed and efficient machining with assured quality.

- Advanced Toolpath Strategies: By utilizing dynamic milling and trochoidal machining, we can maintain constant cutting loads, effectively control temperatures, and optimize chip evacuation, preventing work hardening and tool wear.

- Feature-based knowledge database automatically maps best strategies and parameters based on internal machining features and a tool database, improving programming efficiency and process consistency, and reducing human error.

- Mill-turn and B-axis collaborative programming: Precisely control tool angles and machine motion to ensure best cutting conditions, while sophisticated collision detection eliminates errors in the entire process.

- Digital Twin Verification: Simulate G-code, process time, and machine tool movement completely in a virtual environment, with precise cycle time estimation and production planning and cost control support.

In short, LS Precision’s own CNC programming technology lies in digitizing, software-based, and intelligently integrating its abundant process know-how, transforming programming from an “art” into a precise “science.” This underlying confidence enables us to continuously create additional value for our customers and achieve dramatic cost savings.

Case Study: Reduction Of A Flap Guide Component Cost By 40%: The Whole Process

Here, I’d like to use a live project that we completed recently as an example and describe how we brought significant cost savings and efficiency gains to our client by leveraging technological innovation.

This project was a titanium alloy flap guide component of a certain passenger aircraft. As we all know, such a part has a complex shape, is difficult to machine, and requires extremely high quality, so cost control is always a concern.

1. Initially, there were tremendous challenges:

Low Machining Efficiency: Traditional processes were conservative, with a machining time of up to 22 hours per part.

High Tool Costs: Frequent tool replacement due to the severe wear of titanium alloys was expensive.

Quality Risks: It is not difficult for incorrect cutting heat control to bring about work hardening on the surface of the workpiece, with a potential for microcracks.

2. Our Technical Solution:

Faced with this challenge, my team did not simply optimize certain parameters; instead, we reshaped the entire machining process.

“Digital First-Part” Simulation Optimization: Before generating the final machining program, we employed advanced cutting physics simulation software. As a “digital pre-machining” of the part, we precisely simulated the forces, temperatures, and vibrations of each cut. This allowed us to scientifically and significantly increase cutting parameters, more than doubling roughing efficiency and completely eliminating tool breakage risk.

“Follow-the-flow” toolpath: We substituted the previous “brute-force” approach with an adaptive dynamic milling method. The tool now moves continuously and smoothly through the cuts without altering the load. The benefits were immediate: cutting temperatures were controlled, chips were evacuated smoothly, and tool life increased by 50%.

“Unifying the Parts into One” Turn-Mill Solution: We utilized the five-axis turn-mill center capabilities to their fullest. With a multi-axis sync program that I wrote myself, we completed all turning, milling, drilling, and tapping operations in one setup. This not only eliminated multiple setup errors and saved auxiliary time, but more importantly, allowed for very high positional accuracy between all of the features.

3. Direct Value for You:

Upon implementing this combined approach, the final outcomes were impressive:

Overall costs were reduced by 40%, well beyond customer expectations.

The per-part process time was reduced from 22 hours to 11 hours, doubling the production capability.

Tooling expenses were reduced by 35%.

Most importantly, the process stability was extremely high, with 100% product quality and no scrap.

This sample demonstrates that cost can be lowered while quality is enhanced. Not only will this save you money, but it is also a strong guarantee of your supply chain’s competitiveness and reliability. We believe that this process is equally applicable to your other complex parts.

We would be very willing to discuss with you how we can apply LS Precision’s solutions to your projects.

How Do Five-axis CNC Turning And Milling Centers Improve The Precision Of Aerospace Parts?

Five-axis CNC turning and milling centers improve the precision of aircraft parts in an integrated way through the adoption of multi-axis control, high-precision systems, and refined processes, as detailed in the suggested table:

| Method | Description |

|---|---|

| Multi-Axis Linkage | Simultaneously controls five axes to achieve precise machining of complex surfaces and angles, minimizing geometric errors. |

| Reduced Setups | Complete multi-surface machining with a single setup, eliminating repetitive positioning errors and improving overall consistency. |

| High-Precision Control System | Utilizes servo motors, linear encoders, and other technologies to ensure nanometer-level positioning accuracy and smooth motion control. |

| Advanced Tool Technology | Utilizes diamond or coated tools to reduce wear and vibration, improving surface quality and dimensional stability. |

| Real-Time Monitoring and Compensation | Integrated sensors and AI algorithms adjust for variables such as thermal deformation and tool wear in real time to maintain machining accuracy. |

| Software Optimization | Optimizes toolpath planning and simulation through CAD/CAM integration, reducing human error and improving efficiency. |

| Material Adaptability | Specializes in processing aerospace materials (such as titanium alloys and composites), optimizing cutting parameters to minimize deformation and stress. |

- Multi-Axis Motion: Five-axis motion offers simultaneous tool movement in greater than one axis for accurate machining of complicated aerospace parts such as blades and casings without the cumulative errors associated with multiple setups.

- Decreased Setups: Machining of a part in a single setup for multiple surfaces prevents frequent setups and their associated positioning errors, which ensure part geometric integrity.

- High-Precision Control System: With closed-loop control and high-resolution encoders, the system acquires micron- to nanometer-scale motion precision, meeting aerospace components’ strict tolerance requirements.

- Improved Tool Technology: Employing high-performance tools (e.g., ceramic or PCBN tools) reduces cutting forces and heat influences, improving size accuracy and surface finish.

- Real-Time Monitoring and Compensation: Integrated temperature and vibration sensors and machine learning technologies dynamically adjust for thermal expansion and tool wear to ensure long-term machining stability.

- Software Optimization: Virtual simulation and optimized toolpaths with high-end CAM software reduce collisions and overcutting errors to improve first-part success rates and accuracy.

- Material Flexibility: The ability to adjust cutting speeds, feedrates, and other parameters to the specific characteristics of aerospace materials (such as high strength and low thermal conductivity) minimizes machining distortion.

In summary, five-axis CNC turning and milling center provides exceptional precision and reliability for aircraft components by technological innovation and process improvement.

Why Do We Need CNC Turning Drawings (PDF)?

To provide CNC turning drawings in PDF format is vital in order to ensure accurate and efficient project initiation and achievement of cost-saving goals. The main reasons are the following:

- Error-proofing and one-of-a-kindness: PDFs are a fixed, non-modifiable format, and you therefore guarantee that the design version you supply is the sole authoritative source for the partnership of the two entities and completely eliminates manufacturing errors and cost loss through hybrid file versions or poor formatting.

- Information integrity: Diagrams are the keeper of all manufacturing specifications. PDFs perfectly maintain all the crucial information, like precise geometric dimensioning and tolerancing (GD&T), materials specs, heat treatment and surface finish requirements, etc. This is an ironclad requirement for our precise process planning and costing.

- Successful cost reduction analysis: Our design engineers conduct design for manufacturability (DFM) analyses against the drawings. Without reference to the drawings, we can identify the potential for optimization quickly, e.g., whether tolerances might realistically be relaxed or whether the structure might be more machineable, thereby proposing realistic cost reduction actions rather than quantifying blindly.

- Seamless Coordination: PDF is very flexible and can be opened without needing specialized software. This implies that all departments, from programming to processing to quality inspection, have a clear and identical picture of the same requirements, which ensures an error-free and smooth manufacturing process.

In short, the PDF drawings you submit are the basis on which we read your specifications, automate processes, and ultimately achieve our goal of costing 40% less. They ensure clear communication among the concerned parties and are the beginning of a successful collaboration.

We eagerly await your drawings and initiating the value analysis process immediately.

FAQs

1. How to achieve a 40% reduction in titanium alloy turning costs

By taking full advantage of high-efficiency PVD/PCBN tools designed for titanium alloys (three times longer tool life), intelligent CAM programming to optimize automatically tool paths and parameters, high-pressure cooling (HPC) or minimum quantity lubrication (MQL) technology, automated loading and unloading with real-time monitoring, and lean material management (near-net-shape forming and scrap recycling), we achieved reduced processing time per part and significantly reduced tool and material usage. In one case, the overall price of an aviation bracket part was reduced by 42% successfully.

2. Following a 40% savings in cost, how do we ensure the quality of aviation parts?

Complete quality assurance is a requirement. All parameters optimized are put through rigorous DOE validation and test cutting to deliver controlled cutting forces and heat to avoid damaging parts. Critical processes utilize in-line dimensional (tolerance ±0.005mm) and roughness monitoring. 100% of the main components are tested non-destructively, i.e., penetrant or eddy current test. Surface integrity (Ra < 0.4μm) and hardened layers are strictly monitored and third-party fatigue tests are in full compliance with the requirements. The entire process adheres to the AS9100 quality management system.

3. Is the solution suitable for mass production? How efficient and stable is it?

The solution is specifically designed for medium and large-volume production, with more significant outcomes. Single-piece cycle time is reduced by an average of 35% through optimization. Predictive tool changes, real-time process monitoring/compensation, and stable tool wear profiles remove unexpected downtime. Automatic loading and unloading enable continuous operation, which raises Overall Equipment Effectiveness (OEE) by over 25%. Production of tens of thousands of pieces annually has been running smoothly for over 12 months with a batch qualification rate in excess of 99.95% and 100% on-time shipping.

4. Is the solution suitable for my part? Key points to consider

This solution is particularly suitable for titanium alloy (e.g., TC4 and TC11) rotating/rotating aircraft parts (shafts, sleeves, brackets, etc.). Key points to be taken into account are: type of material, complexity of geometry (suitability for turning/milling), current cost impediments (tooling, time, scrap), quality requirements in terms of (tolerances, roughness, fatigue life), and production batch size. We recommend forwarding drawings/processes for complimentary preliminary assessment, or arranging a trial run to establish the actual cost-cutting result.

Conclusion

Through the practical applications described above, we can clearly see that a “40% cost reduction” is not a radical goal achieved by cutting corners or sacrificing quality. Rather, it is the inevitable result of a precision revolution at LS Precision, encompassing technology, management, and collaboration.

The core value of this 40% cost reduction lies in demonstrating that manufacturing excellence and cost-effectiveness can coexist. We eliminate waste at the source through design optimization, achieve efficiency gains through process innovation, unlock human value through automated production, and ultimately solidify these achievements through lean management across the entire value chain. All of this is built on a foundation of deep collaboration with our customers, and that precise PDF drawing is the key to this collaborative journey.

For future collaborations, we firmly believe that cost control is no longer a simple price negotiation, but a smart journey in which both parties jointly explore the limits of manufacturing and optimize the product lifecycle. LS Precision is committed to continuously investing in cutting-edge technologies and management systems, becoming not only your supplier but also your trusted strategic manufacturing partner.

We invite you to join us in redefining the cost boundaries of titanium alloy aerospace parts manufacturing and jointly create a more competitive and sustainable future.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Your blog is a constant source of inspiration for me. Your passion for your subject matter is palpable, and it’s clear that you pour your heart and soul into every post. Keep up the incredible work!

I was suggested this web site by my cousin Im not sure whether this post is written by him as no one else know such detailed about my trouble You are incredible Thanks

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

You’re too kind. I’m just someone who is curious about this field and enjoys sharing my own thoughts and insights. Thank you very much for your appreciation, and I’m glad to have met someone with similar interests!

Great line up. We will be linking to this great article on our site. Keep up the good writing.

I’m extremely impressed with your writing skills and also with the layout on your blog. Is this a paid theme or did you customize it yourself? Either way keep up the nice quality writing, it is rare to see a nice blog like this one today..