How to Avoid Sink Marks in Injection Molding

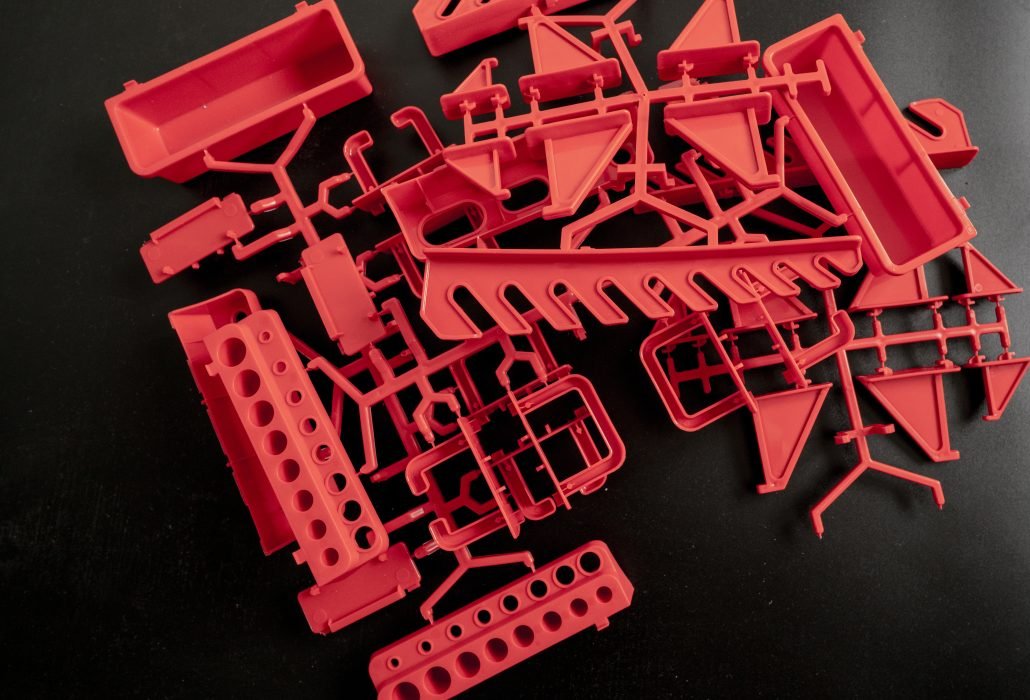

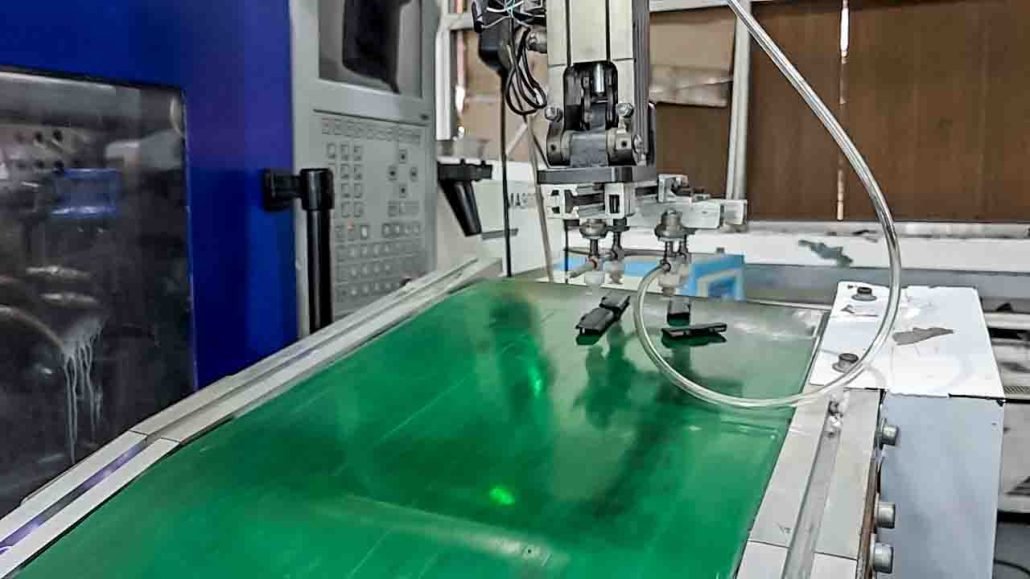

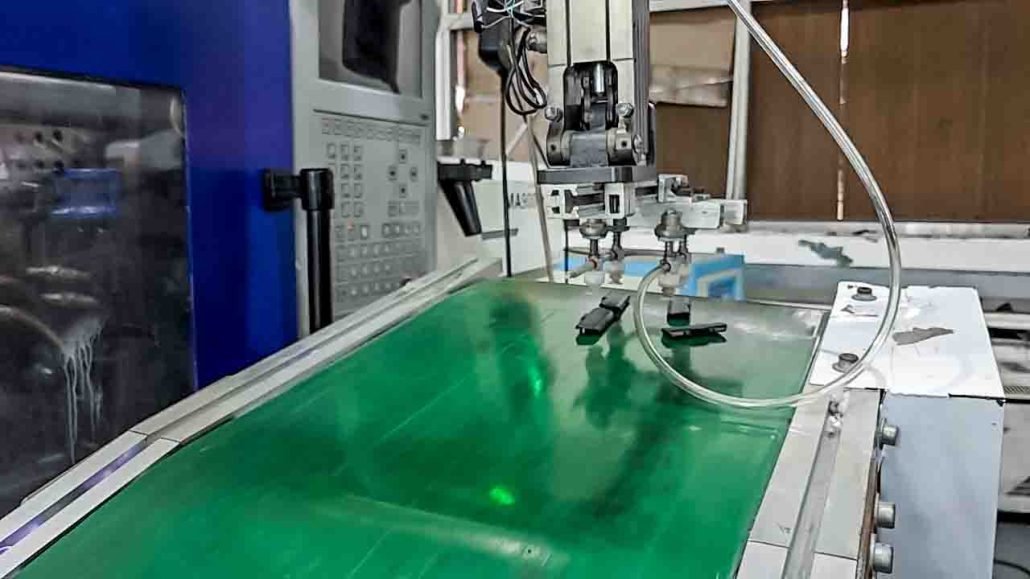

Injection molding is an incredibly versatile process that can produce everything from small plastic parts to large automotive components. However, one of the most common issues faced by injection molders is sink marks. Sink marks are depressions or dimples that form on the surface of a molded part, detracting from its appearance and potentially affecting its functionality.

How to Avoid Sink Marks in Injection Molding Read More »