As a seasoned injection molding professional, you have probably heard the question asked several times: “Why is injection molding so expensive?” As a leading provider of injection molding services, we understand the frustration that many people face when they realize just how much it costs to produce their plastic parts. However, we have compiled this in-depth look at the costs of injection molding in order to shed some light on this highly complex and misunderstood process.

What is Injection Molding?

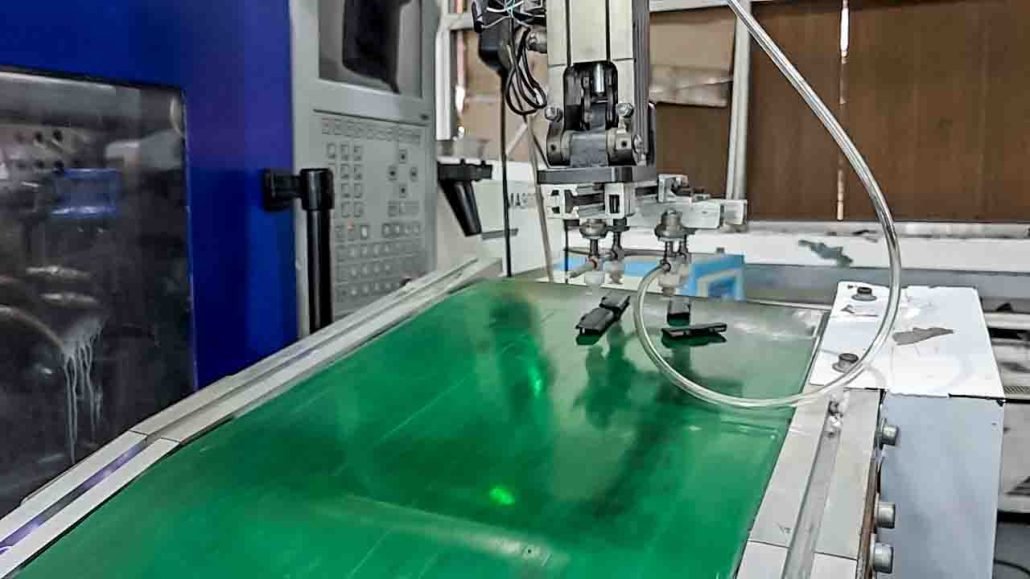

Injection molding is a manufacturing process used for producing parts from thermoplastics and other composite materials. It involves melting the plastic in a heated barrel and injecting it into a mold cavity. The plastic then solidifies, and the final product is removed from the mold. The process can be automated, making it ideal for mass production as well as for producing complex parts with high precision.

The Costs of Injection Molding

To fully understand why injection molding is so expensive, we first need to break down the different costs that come with the process. These include:

Material Costs

The raw materials used in injection molding, such as resins and additives, can be expensive, particularly if special colorants or additives are required.

Equipment Costs

Injection molding machines are highly sophisticated and require skilled operators to run them. This level of technology and expertise comes at a cost, which is reflected in the high price point of these machines.

Tooling Costs

One of the biggest expenses in injection molding is the cost of making the molds. These can be extremely complex and require expert design and fabrication, which can lead to high costs.

Labor Costs

As previously mentioned, injection molding requires skilled labor to operate the equipment. Additionally, the process often requires post-processing, further driving up labor costs.

Overhead Costs

Finally, injection molding companies must factor in overhead costs such as rent, utilities, and insurance, further driving up the cost of production.

High Initial Investment

The process of injection molding requires a significant initial investment. The cost of equipment, molds, and raw materials can quickly add up, making it a significant financial burden. Even small-scale manufacturers find it challenging to enter this market due to the high initial investment cost.

Complex Design of Molds

The design of molds used in injection molding must be complex to make it feasible for mass production. The design must be made to meet exact specifications and tolerances. The design is not just about creating the mold but also about its maintenance, repairs, and replacements. This complexity adds to the cost of injection molding.

In order to keep costs down, injection molding companies must strike a delicate balance between all of these different cost factors

Breaking Down the Costs

Although it can be difficult to put a precise figure on how much injection molding truly costs, we have compiled some general estimates to help you understand just how much you can expect to pay for your plastic parts.

Material costs typically make up around 30% of the total cost of injection molding, with equipment costs accounting for another 25%. The cost of tooling can vary widely depending on the complexity of the molds, but can be as much as 60% of the total cost. Labor and overhead costs make up the remaining 15%.

Reducing the Costs of Injection Molding

Although injection molding is expensive, there are ways to reduce the costs associated with the process. One of the most effective ways to do this is by working closely with your injection molding company to identify areas where costs can be reduced. This may include redesigning the part to make it easier to produce, or sourcing less expensive raw materials.

Another effective way to reduce the cost of injection molding is by investing in multi-cavity molds, which can produce multiple parts in one cycle, reducing the amount of time required for production.

How Does Injection Molding Affect Selling Price?

Injection molding has a significant impact on the selling price of the final product. The expensive nature of the injection molding process leads to high manufacturing costs, which ultimately affects the selling price. To cover the high costs of production, manufacturers set higher selling prices, leading to an expensive final product.

Injection molding is an essential manufacturing process used to create plastic parts that are efficient, of high quality, and high precision. However, its usefulness comes at a cost. The intricate design of molds, high labor costs, energy and raw material costs, and the high initial investments all contribute to the expensive nature of injection molding. Although this process adds to the cost of production of the final product, it remains the preferred method due to its precision and efficiency. In summary, injection molding is expensive but worth the investment.

The Benefits of Injection Molding

While injection molding can be expensive, it also offers several benefits that make it a worthwhile investment for many businesses, including:

High-Quality Parts – Injection molding produces high-quality parts that are consistent in size, shape, and texture. This ensures that the parts meet the required specifications and are suitable for use in various applications.

Design Flexibility – Injection molding allows for a wide range of design possibilities, including intricate shapes and details. The process can also create parts with multiple material properties, such as soft-touch surfaces or hard, durable shells.

Cost Savings in the Long Run – While injection molding can be expensive initially, it can lead to cost savings in the long run. The process is highly efficient, with a low scrap rate, minimal waste, and fast production times. This makes it a cost-effective option for high-volume production runs.

Environmentally Friendly – Injection molding is a sustainable manufacturing process that produces minimal waste and reduces the carbon footprint of businesses. The process also uses recyclable materials, reducing the impact on the environment.

Conclusion

Injection molding is a complex process that requires a high degree of expertise and sophisticated equipment. However, by understanding the different costs associated with the process and working closely with your injection molding company, it is possible to reduce the costs of production and get the results you need. If you have any further questions about the cost of injection molding or would like to discuss your specific needs, don’t hesitate to get in touch with our team of experts today.