What does “Swiss-type lathe” mean in CNC machining? This is a question that mulls over the minds of those who are in the manufacturing industry. The Swiss-type lathe has gained a lot of popularity in recent years, thanks to advancements in technology that make it more efficient.

At Longsheng, we are one of the leading suppliers of CNC turning parts. In this article, we’ll explain what a Swiss-type lathe means in CNC machining. We’ll delve into its features, advantages, and disadvantages, and we’ll also examine how it differs from other types of lathes.

What is a Swiss-type lathe?

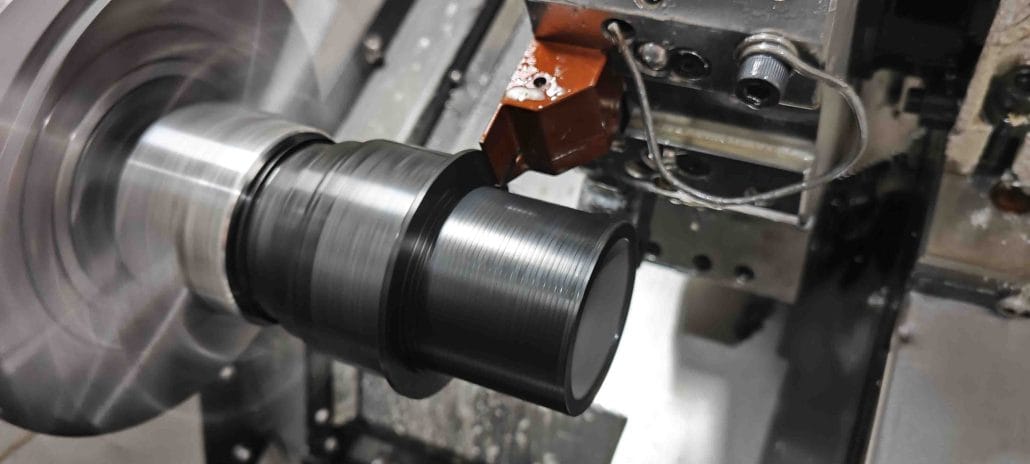

A Swiss-type lathe is a type of lathe used in CNC machining for the production of small parts. It’s also commonly referred to as a sliding headstock lathe or a Swiss screw machine. The machine is designed to hold small parts in a fixed position while using computer-controlled movement to cut the material to the desired shape.

The Swiss-type lathe is named after the Swiss watchmaking industry, which began using these types of lathes in the mid-1800s. Today, the Swiss-type lathe is used in a wide range of industries, including medical, automotive, telecommunications, and aerospace.

Features of a Swiss-type lathe

The Swiss-type lathe is designed in such a way that it reduces the amount of vibration and chatter that occurs while cutting small parts. The machine uses a guide bushing to support the material being machined, which helps to keep it stable and centered while the cutting tool moves along the length of the part.

Another feature of the Swiss-type lathe is the use of a sliding headstock. This allows the material to be loaded into the machine and held in place by the guide bushing, while the cutting tool moves along the length of the material. The sliding headstock also allows for faster and more precise machining, as it reduces the amount of deflection that occurs when cutting small parts.

Advantages of a Swiss-type lathe

One of the biggest advantages of the Swiss-type lathe is its ability to machine small parts with high precision and accuracy. The use of the guide bushing and sliding headstock allows for minimal deflection and vibration during machining, which leads to higher quality products.

Another advantage of the Swiss-type lathe is its ability to handle long, slender parts with ease. The guide bushing holds the material in a fixed position, which allows for more precise machining of longer parts. This makes the Swiss-type lathe an ideal machine for producing parts for the medical and aerospace industries.

Disadvantages of a Swiss-type lathe

One of the main disadvantages of the Swiss-type lathe is its cost. These machines are more expensive than other types of lathes, and they require skilled operators to run them correctly.

Another disadvantage of the Swiss-type lathe is that it’s not suitable for machining larger parts. The machine is designed specifically for small parts, and attempting to machine larger parts can lead to problems with stability and accuracy.

How does a Swiss-type lathe differ from other types of lathes?

The main difference between a Swiss-type lathe and other types of lathes is the use of a guide bushing and sliding headstock. Traditional lathes use a stationary tool to cut the material, while a Swiss-type lathe uses a sliding headstock to hold the material and guide bushing to support it.

Another key difference is that the Swiss-type lathe is designed specifically for small parts, while other types of lathes can handle a wider range of parts. This makes the Swiss-type lathe ideal for high-precision machining of small parts, while other lathes are better suited for larger parts.

Why Choose Longsheng for Swiss-Type Lathe CNC Machining?

Longsheng is equipped with state-of-the-art Swiss-type lathe machines that can accurately and efficiently produce small, complex parts. Our highly trained technicians and engineers use the latest technology and software to ensure tight tolerances, high accuracy, and consistent quality control. We specialize in producing CNC turning parts for the watchmaking, medical device, and other precise manufacturing industries. Our commitment to customer satisfaction means that we offer competitive pricing and fast turnaround times, making us the ideal choice for Swiss-type lathe CNC machining.

Conclusion

In conclusion, a Swiss-type lathe is a type of lathe used in online CNC machining for the production of small parts. The machine is designed to hold small parts in a fixed position while using computer-controlled movement to cut the material to the desired shape. The Swiss-type lathe is named after the Swiss watchmaking industry, which began using these types of lathes in the mid-1800s.

At Longsheng, we provide CNC turning parts machining services using the latest technology and top-of-the-line equipment. Contact us today to learn more about our services and how we can help you with your CNC machining needs.