How to Reduce Flow Mark in Injection Molding

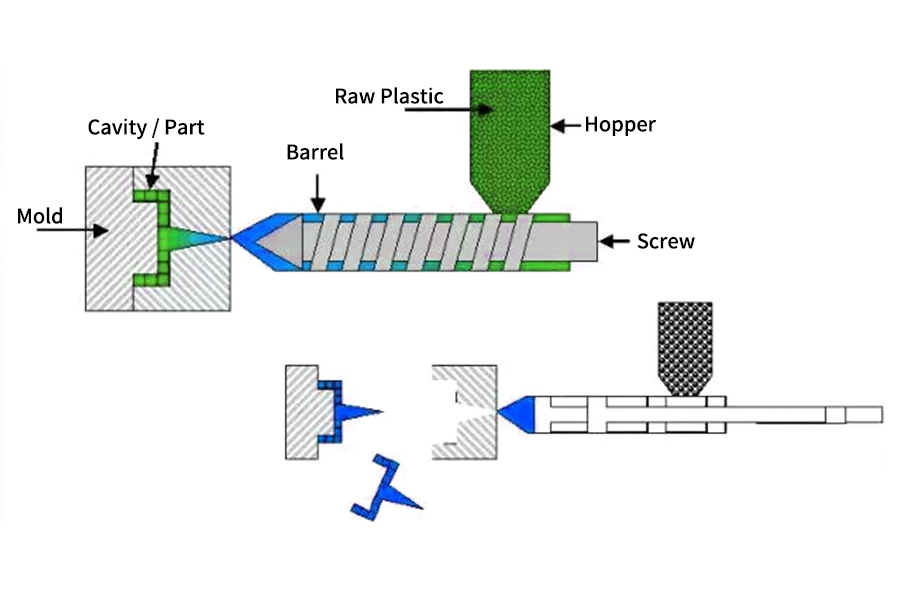

As a leading provider of custom injection molding services, Longsheng understands the challenges that many manufacturers face when it comes to minimizing flow marks in their molded products. Flow marks are unsightly lines or streaks that appear on a plastic surface, caused by uneven flow of plastic material during the injection molding process. These marks not only compromise the aesthetic quality of the finished product, but can also weaken its structural integrity.

How to Reduce Flow Mark in Injection Molding Read More »