In precision CNC machining factory to better serve customers, we must be familiar with many kinds of CNC machining technology, in order to leave a professional image in front of customers, if there is a strange customer, mention a lot of CNC machining technology, you have never heard of, how can you communicate with customers? For example, the material of Bitech iron, the minimum hardness of HRB85, the surface treatment of environmental color zinc, 96 hours of salt test, the customer threw in an inquiry like this, do you understand? If you want to get this order for a precision CNC machining plant, you have to be more professional than the customer.

In this article, Longsheng technology will take you to deeply understand the secret of precision CNC machining technology, from the technical principle to the application range of comprehensive analysis, so that you have a deeper understanding of precision CNC machining.

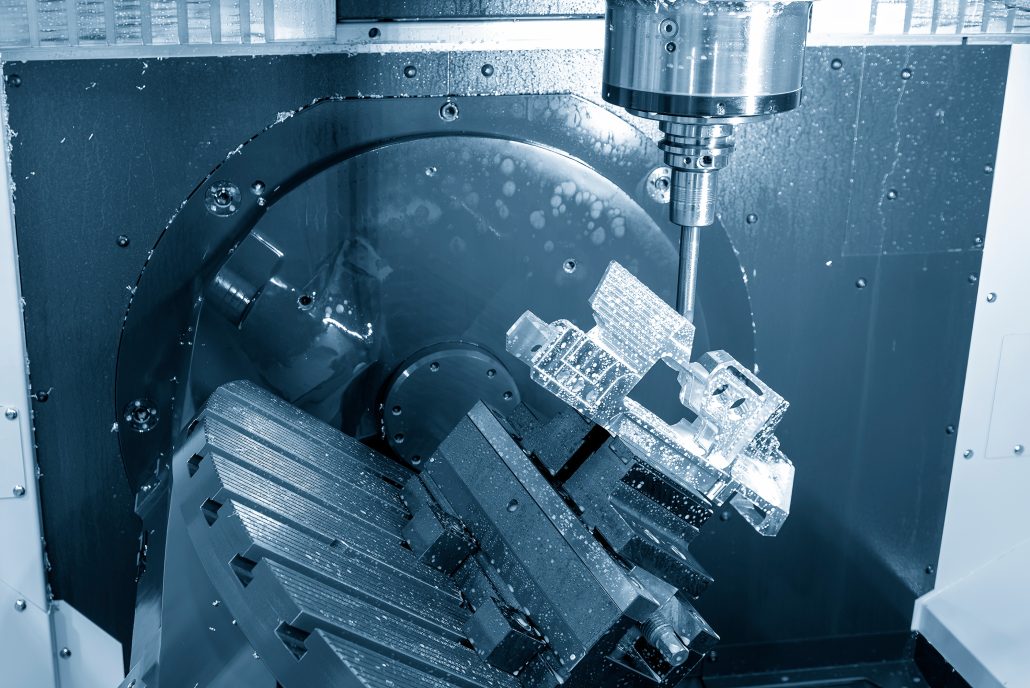

Principle and characteristic of precision CNC machining

CNC machining is a kind of CNC machining technology based on computer control, its machining precision is high, high efficiency, has a strong flexibility and adaptability. CNC machining mainly relies on computer programs, the 3D model of the processing object into G code instructions, through the control of each part of the control system to achieve mechanical movement, so as to complete the machining object cutting, punching and other process operations. The basic principle of CNC machining is to control the action of the machine tool through the computer program, and in this way to control the relative movement of the workpiece in each dimension. Compared with traditional machining, CNC machining has the following significant characteristics:

With high precision and high efficiency. Because CNC machining using computer program control, can accurately control the position of the tool and cutting depth, so as to achieve high precision machining of the workpiece.

Remote monitoring and control: Because CNC machining needs the support of computer processing, so you can use remote monitoring and control, man-machine cooperation and automatic information collection.

Automated production without human involvement. CNC machining process is generally controlled by numerical control system operation, through the numerical controller to control the whole machine tool processing process, reduce manual intervention, improve production efficiency.

Flexibility and repeatability. CNC machining can carry out repeated processing, and will not affect the processing accuracy and efficiency because of the difference of people, fatigue and so on.

Ability to process on complex shape parts and products. Due to the support of computer programs, CNC machining can process a variety of complex shapes of parts and products, such as engraving, trapezoidal shape and so on, reducing the traditional processing technology is difficult to complete the work.

At the same time, CNC machining also has some limitations and shortcomings. Due to the limitations of equipment and technology, CNC machining needs to consume a lot of energy, materials and human input, the cost is relatively high. In addition, CNC machining requires a higher level of technology and professional knowledge, the technical requirements of the operator is higher, not easy to get started. Therefore, CNC machining is generally suitable for mass manufacturing and high precision processing fields.

CNC machining of the main equipment

The main equipment required for CNC machining includes CNC machine tools, control systems, tools and accessories. CNC machine tool is the basic equipment of CNC machining, it can realize the workpiece for cutting, drilling, milling, turning and other processing operations, with high precision, high efficiency, high automation and other advantages, can greatly improve the production efficiency. The control system is an important part of CNC machining, which transforms the mathematical model into the machine tool control instruction through the computer program, and controls the mechanical movement of each part in the machining process. Tools and accessories are essential tools for CNC machining operation. Different processing processes require different kinds of tools and accessories, which can achieve different processing effects.

CNC machining of the main technology

CNC machining technology is the use of computer data control machine tools for processing operations, widely used in the production of various parts, such as automobile parts, aircraft parts, watch movement, etc.

The main technology of CNC machining includes the following aspects:

CNC milling machine

CNC milling machine is a kind of machine that uses rotary cutter to create three-dimensional shape parts. CNC milling machine is mainly used for machining precision cnc parts online, molds and similar parts. CNC milling machine can precisely control the position and speed of the tool, one time can complete a variety of different machining.

CNC lathe

A CNC lathe is a machine tool with a rotating tool. CNC lathes are mainly used for machining cylindrical, conical and prismatic parts. It is often used for surface precision machining of rotating parts, high-speed drilling, boring and other operations.

CNC spark machine

CNC spark machine is a machine tool that generates heat by burning the electric spark on the metal material and uses the plasma for processing. CNC spark machine is mainly used in machining mold, high precision parts, small metal grinding and other industrial fields.

CNC wire cutting machine

CNC wire cutting machine is a kind of machine tool that uses metal wire to cut metal by discharge phenomenon when it passes through water or oil and other conductive liquid at high speed. CNC wire cutting machine can process various shapes of the workpiece, especially suitable for processing thin sheet, small bridge parts, slender parts, etc.

5 axis machining

Five-axis machining is a new CNC machining method, the traditional three-axis machining in the two direction control increased to five, with more efficient attitude, higher machining accuracy, and more freedom of design. 5 axis machining is often used in aerospace, medical, shipbuilding and other industries, which requires the machining of parts with high technical difficulty.

CNC machining technology advantages:

- High machining accuracy, the accuracy can reach micron level;

- High degree of automation, which can greatly reduce manual intervention;

- High working efficiency, suitable for large quantity processing and complex parts processing;

CNC machining technology shortcomings:

- High investment in equipment and the need for more funds and facilities;

- High maintenance requirements for equipment, and equipment debugging and operating personnel should have high technical ability;

- High material requirements, high temperature resistant, non-deformable metal materials and high strength bridge and base.

Precision CNC machining application range

In practical applications, CNC machining has been widely used in a variety of different fields and industries, such as machinery, electronics, automotive, aviation, medical, stage art and so on. The following Longsheng technology will take some specific cases to introduce the application and effect of CNC machining in various fields.

Machinery manufacturing and casting:

CNC machining is widely used in the field of machine manufacturing and casting, and can be used to manufacture a variety of different parts, tools and equipment. For example, CNC machine tools can be digitally cut and processed to transform various materials (such as steel, aluminum alloy, plastic, etc.) into parts and components. At the same time, precision CNC machining can also be used for casting and molding, through the digital control of different parts of the casting machine, to ensure accuracy and consistency.

Electronics and Communications:

CNC machining in the field of electronics and communication applications have been very mature. CNC machining can be used to manufacture various electronic components, printed circuit boards (PCB), mobile phone cases, electronic cases, etc. Through CNC machining, these electronic parts can achieve high precision machining and mass production at the same time.

Medical equipment:

With the development of science and technology and the improvement of people’s health awareness, the demand for medical equipment is increasing, and the application of CNC machining in the field of medical equipment has become very extensive. For example, CNC machining can be used to manufacture medical surgical instruments, prostheses, artificial organs and so on. High efficiency, high precision, not easy to break or damage, CNC machining has become an indispensable part of the manufacturing of medical devices.

Stage art:

CNC machining is also widely used in the field of stage art. For example, CNC machining can be used to manufacture a variety of exquisite stage equipment, lamps and stage props, through the high precision and consistency of CNC machining, can make these artworks in the performance of the best effect.

CNC machining technology is more and more widely used in modern industry, its precision and efficiency will affect product quality and production cost. With the continuous development of technology, CNC machining will bring more new opportunities and results in the field of production. By understanding this technique and applying it to your work, you can do your work better and improve your productivity and quality. If you want to deeply understand the precision CNC machining process, learn the corresponding technical details, then please join us

This article from Longsheng technology, original is not easy, reprint please contact authorization.