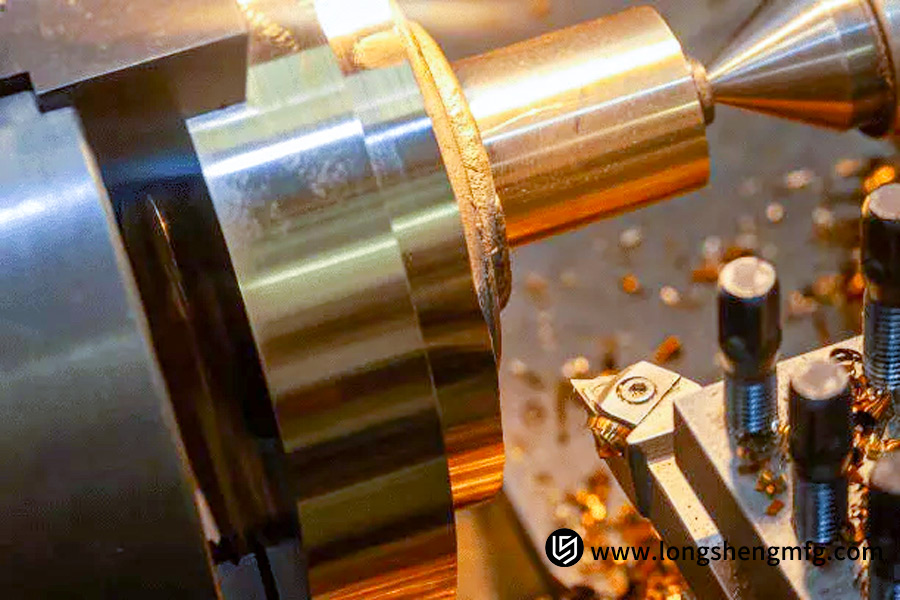

The oldest alloy ever employed by man, bronze is a signature, non-interchangeable metal in current precision manufacturing. Its improved physical properties—flawless wear resistance, low friction, and excellent corrosion resistance—make it a great material for bearing, gear, valve, and precision component manufacture. In CNC milling, the bronze’s self-lubricating and machinability are complementarily to each other to allow stable milling at high speed and low depth of cut, easily with micron-order accuracy of dimension and fine surface quality.

Faced with either the intense corrosive medium of sea water or core components of precision machinery that have to be run stably for a very long time, bronze components show unmatched stability. Throughout this manual, we shall explore the entire process of bronze CNC machining, from material properties to practical techniques and best practice, to allow you to see the enormous potential of this historic material to the fullest extent possible. To save time, there is an instant list of main conclusions.

Quick Reference: Choose Your Tap at a Glance

| Alloy Type | Key Characteristics | Processing Tips |

| Phosphorus Bronze | Excellent wear resistance, high strength, good fatigue resistance, and good elasticity. Easy to cut, but tough. | Use sharp tools, high cutting speeds, and low to medium feed rates to avoid hardening. |

| Tin Bronze | Excellent corrosion resistance (especially seawater resistance), wear resistance, and good castability. | Excellent machinability. Tools must be kept sharp and ample coolant must be used to achieve the best surface finish. |

| Aluminum Bronze | Highest strength, corrosion resistance, high temperature resistance, and excellent wear resistance. | High hardness can cause significant tool wear. Rigid machine tools and wear-resistant tools (such as tungsten carbide) must be used. Low speeds and slow feeds are recommended. |

| Lead Bronze | Highest self-lubrication, vibration resistance, and easy cutting. | Extremely easy to cut, allowing for high speeds and high feeds. However, due to its high lead content, dust collection and protection measures are important, and environmental protection requirements are high. |

| Silicon Bronze | Excellent corrosion resistance, high strength, and spark-free properties. | High toughness can easily produce long chips during cutting. Chipbreaker tools are required to control chips and prevent entanglement. |

The key to effective machining of bronze using CNC is proper selection of the alloy type for the desired performance (corrosion resistance, wear resistance, strength, or self-lubricating property) of the component and associated tool and process parameter modifications.

Why Trust This Guide? Practical Experience From LS Experts

Bronze turning has been a specialty at LS Precision for over fifteen years of CNC turning experience. LS Precision has become thoroughly familiar with the unique characteristics of each bronze alloy. From selecting the optimal toolpath and material to optimizing cutting parameters, we have compiled hundreds of projects in a database.

All of the advice presented in this guide is derived from our real experience of our day-and-night running fleet of high-end CNC machines and our whole-hearted commitment to “zero defect” quality. All these suggestions are not academic recommendations.

The practical experience of LS Precision has been stringently tested and proven by high-tech products in numerous areas. From extremely intricate aerospace-required bronze bushings for self-lubrication and high pressure resistance to precision valve bodies of medical equipment requiring absolute sterility and corrosion proofing, or even greater wear-resistant gears for high-load automated manufacturing lines, we have furnished custom solutions in quantities.

These demanding applications across a variety of industries have progressively enhanced LS Precision machining art and optimized every best practice and process you’ll view in this cost guide.

Why Is Bronze An Ideal Material For CNC Machining?

In accurate manufacturing, the selection of the material directly reflects on the performance and lifespan of the part. Out of other metals, bronze with all its wonderful qualities always holds a position in the top class of CNC-machined bronze components and hence is a reliable source for designers.

1. Mechanical properties:

Its greatest advantage is its extremely good machinability. Bronze is very ductile and fairly hard. This ensures that the tool cuts well into the material and uniformly loads the material when CNC machining, making high accuracy and complicated geometry more easily obtained and avoiding the tool from being destroyed and extending its lifespan.

2. Wear resistance:

The excellent wear resistance of Bronze is also a basic advantage. Parts sustain very little wear and tear with extended duration of running and friction, largely due to its low coefficient of friction, and is an excellent material to utilize in dynamic contact components such as bearings, bushings, and gears.

3. Corrosion resistance and self-lubrication:

Bronze also possesses greater corrosion resistance, resisting attack by steam, water, chemicals, and atmospheric corrosion, with long-term stability and dependability in extreme environments. Most bronze alloys, such as lead bronze, are also self-lubricating, giving ease of operation and reducing the risk of failure where lubrication is impossible or limited.

It is this balance between machinability, wear resistance, corrosion resistance, and self-lubrication that makes bronze the superior material for CNC machining of precision bronze parts and therefore the superior material solution for demanding, long-life applications.

What Are The Main Types Of Bronze Materials? How To Choose?

With all the kinds of bronze alloys available, selecting the right material for your project matters to ensure product performance. Some of the most popular CNC machining types of bronze include phosphor bronze, aluminum bronze, tin bronze, and silicon bronze. Each has different properties and is suitable for certain purposes.

Phosphor bronze

Phosphor bronze (e.g., C54400) is characterized by good wear resistance, high strength, and fair fatigue resistance and is a satisfactory material for production of bearings with high loads, springs, and connectors in electronics.

Aluminum bronze

Aluminum bronze (e.g., C95400) possesses high strength and good corrosion and wear resistance and is a suitable material for heavy gears, nuts, and components that are to perform in aggressive corrosive environments.

Tin bronze

Tin bronze (e.g., C90500) offers high castability and corrosion resistance in seawater and is popular for valves, pump cases, and other parts requiring top-notch corrosion resistance.

Silicon bronze

Silicon bronze (e.g., C65500) has mechanical properties very close to those of mild steel but with the added advantages of very good corrosion and non-sparking properties, making it a favorite chemical equipment and explosion-proof tool material.

When selecting material, follow these guidelines:

- For optimal wear resistance, phosphor bronze or aluminum bronze should be used.

- In very corrosive applications, use aluminum bronze and tin bronze.

- For structural elements where strength and load are critical, aluminum bronze should be preferred.

Equating the functional requirements of the part (pressure, speed, and environmental media) with the inherent qualities of the material will be the most astute decision.

Key Techniques and Best Practices for CNC Machining Bronze

Having mastered bronze CNC machining perfectly and achieving outstanding results entails extremely rigorous control over numerous crucial parameters. Choosing an effective process not only significantly improves the efficiency of machining and surface quality, but also effectively controls the cost of production.

1. Tool selection:

Tool selection is the success factor. Sharp but positive tungsten carbide (carbide) tools are recommended because they have excellent wear resistance capable of withstanding abrasive wear caused by some of the elements in bronze, such as aluminum. K-type carbide can be suitable for use with most bronze alloys. The sharpness of the tool is an important consideration; dull tools can easily create work hardening of the material and make the subsequent cutting difficult.

2. Cutting parameters:

Cutting parameter optimization is important in optimizing efficiency and quality. Even though bronze is a simple material to cut, parameter setting must be correct. High cutting speeds with moderate or low feed rates are generally recommended. High speeds provide good chip formation and reduce cutting forces, and proper feed rates prevent built-up edge and result in very good surface finish. Cutting depth must be optimized based on the end-part requirements.

3. Coolant use:

Coolant application is also necessary. LS Precison highly suggest a water-soluble emulsion coolant be used for wet machining. Proper cooling not only efficiently removes cutting heat, which avoids workpiece deformation and tool performance deterioration, but also instantly cleans away chips, keeping them from scratching the machined surface. This is important in the determination of dimensional accuracy and in obtaining a mirror-like finish.

The secret to CNC machining bronze is using sharp carbide tools and focusing on targeted bronze alloys, combined with a combination of high speeds and moderate feeds, and applying copious consistent coolant.

Common Problems and Solutions in Bronze Part Machining

Although bronze is usually an easy-material-to-machine, some common problems can be encountered during CNC machining in case process parameters are not properly set. Identification of such problems and implementing right countermeasures are crucial for preserving production efficiency as well as part quality.

Problem 1: Premature Tool Wear

This is common when machining high-strength grades such as aluminum bronze. The hard phase in these materials acts like abrasives, gradually wearing away the tool edge. The solution is to favor wear-resistant tungsten carbide (hard alloy) tools and ensure effective and proper coolant injection at the cutting location to effectively reduce cutting temperatures.

Problem 2: Low Surface Finish

Chatter, scratches, or excessive roughness on the part surface, this is usually caused by dull tools, excessively high feed rates, or vibration. Correction includes frequent usage of sharp, new tools or tool resharpening, feed rate decrease and increasing speeds as required, and inspection and stiffening the workpiece and tool clamping rigidity to eliminate sources of vibration.

Problem 3: Material Work Hardening

A dull tool or a too-narrow depth of cut (DOP) may cause the tool to “squeeze” onto the work surface rather than cut, causing hardening of the surface and making subsequent machining difficult. The solution is to employ sharp tools and depth of cut that can cut through under the hardened surface of the material.

Prevention of these problems requires an integrated strategy: the right tooling choice, best cutting conditions, and correct continuous effective cooling.

What are the post-processing processes for bronze CNC-machined parts?

After shearing off the bronze parts from the CNC machine, the correct post-process can further enhance their mechanical properties, dimensional tolerances, and service life and greatly improve their finish. These processes are the perfect complement to precision machining.

1. Deburring and polishing:

Common post-processing methods include deburring and polishing. Vibratory polish, magnetic polish, or hand finishing will remove microscopic burrs from cutting and create smooth edges. For items with particular aesthetic requirements, mechanical polishing or electro-polishing can be used to create a metallic or even mirror finish.

2. Sandblasting:

Sandblasting is another common treatment. Striking the surface with fine abrasive particles to treat the surface makes the surface matte and uniform. It not only enhances texture but also toughens the surface and camouflages machining marks.

3. Surface treatment:

For specialized functions required for parts, surface treatments at higher levels are required. For example, chemical passivation is applicable for parts which operate in harsh environments to form a dense protective film on the surface that enhances corrosion resistance significantly. Electroplating with nickel or chromium can also be employed as needed to enhance surface hardness, abrasion resistance, and appearance.

Choosing the proper combination of post-treatments based on the desired application of the part (wear resistance, corrosion protection, appearance, or sealing) is a critical step in guaranteeing it will meet end-use requirements.

LS Case Study: How to Process High-Precision Bronze Valve Cores for a Shipbuilding Client?

1.Client challenge:

A prominent marine equipment manufacturer was faced with a daunting task: a bronze valve core, the heart of its propulsion system, needed to achieve amazingly high sealing and strength for extended periods in high pressure and high salinity seawater.

Traditional cast-and-machine operations struggled to achieve both precision and uniform microscopic density of the delicate internal flow passages at the same time, leading to extremely high chances of corrosion and leakage.

2. LS Precision’s innovative solution:

Faced with such a situation, LS Precision’s in-house customized CNC machining service provided a novel solution. We utilized high-tin bronze CNC material, whose superb seawater corrosion resistance was the main element of success.

In machining, our engineers employed multi-axis high-precision CNC machine tools to complete the high-precision milling and turning of the valve core body and sealing cone in one step, with micron-level consistency on the key geometry and positional tolerances.

To achieve the absolute best in sealing, we optimized cutting tools and tool paths in order to obtain a near-mirror surface finish. We also incorporated an online measurement system within the personalized CNC machining process, providing 100% true-time measurement of critical dimensions for each part, and leaks stayed out of the manufacturing process.

3. The ultimate value of the result:

The valve core assembly we supplied not only performed to the customer’s higher-than-required levels of performance, but its superb durability stretched maintenance intervals by a significant margin. This success tale demonstrates LS Precision’s technical ability to provide highly reliable custom CNC machining solutions for highly demanding applications, enhancing the market competitiveness and reputation of the customer’s end-product.

How does online CNC machining simplify the bronze part manufacturing process?

For engineers and customers, traditional outsourcing of bronze component manufacturing often involves tedious questions, lengthy communications, and unpredictable lead times. Now, professional online CNC machining services completely redefine the experience, giving customers uncompromising convenience and efficiency through digitization and automation.

1. Rapid quoting and process confirmation:

The core of the company’s competitive edge is its quick quoting and process verification. Clients simply post a 3D model and engineering prints of a bronze piece on the web, and the intelligent system instantly performs a Design for Manufacturability (DFM) analysis and provides a clean, detailed quote within minutes.

Powered by a strong algorithm, it determines material cost, processing time, and process routing automatically, eliminating time-consuming back-and-forth email approvals and significantly accelerating project start-up.

2. Progress monitoring:

Furthermore, the online CNC machining service platform provides unprecedented visibility of the manufacturing process. Once an order is placed, customers are no longer necessary to keep calling or emailing to inquire about progress. You can track order status in real time from a personal online account, just like tracking a courier delivery.

From material sourcing and CNC machining to post-processing and quality inspection, all critical milestones are visible at any time. This open management approach efficiently manages customer expectations and reduces uncertainty.

The online CNC machining service significantly streamlines the path from design intent to actual parts by integrating quoting, process collaboration, and manufacturing control into a high-speed digital system.

Not only does online CNC machining service reduce lead times, but, through intelligence and transparency, provides a more hassle-free and trustworthy new manufacturing solution to procure bronze parts.

What Are The Main Factors Influencing Bronze CNC Machining Prices?

It is important to estimate and know the CNC machining cost of bronze parts for planning and costing of the project. The cost ultimately is not determined by one, but it’s a product of many determinants like material, design complexity, and process requirement. Proper knowledge of these determinants allows for proper cost optimization.

The following is a brief analysis of the most significant influencing factors and the intensity of their influence:

| Influencing Factor | Effect on CNC Machining Price | Cost Optimization Suggestions |

| Material Type and Cost | Base prices, which are a high percent. Different bronze alloys (phosphor bronze versus aluminum bronze) cost very differently, and raw material blank size directly influences material use. | When ensuring performance, select the lowest-cost alloy grade; reduce blank size to avoid material waste. |

| Machining Time | Core cost. The more structurally complex the part, the more features (e.g., deep holes, small threads), and tool changes, the longer the machine tool operates, creating more cost. | Simplify the design to remove overly complex features; relax appropriately fillet and non-fit tolerances wherever possible in non-critical areas. |

| Tolerance Needs | Significant impact. Tight tolerances (e.g., ±0.01mm) require more precise machine tools, lower cutting speeds, and multiple measurements, significantly increasing labor and inspection costs. | Apply tight tolerances only to those mating surfaces that are absolutely essential, and reserve loose tolerances in the non-mating areas. |

| Surface finish | Extremely high surface finishes (e.g., Ra0.4) require additional machining and polishing, which adds equipment and time expense. | Call for an economic surface finish based on functional requirements, not too extreme a quest for a mirror finish. |

| Order quantity | Influences unit cost. High-volume production has the potential to significantly reduce unit price by keeping tool path optimization to a minimum and spreading startup costs (programming and setup). | Batch in production and group orders wherever feasible and allocate unit cost. |

| Post-processing processes | They are additional costs. Surface treatments such as electroplating, passivation, and sandblasting come with additional charges based on treated surface area and process complexity. | Determine the functional requirement of post-processing and select the most economically benign approach. |

The final CNC machining cost is a trade-off between manufacturing economics and technical requirements. The optimal cost control strategy begins in the design phase.

FAQs

1.What is the difference between bronze and brass in CNC machining?

Bronze (such as phosphor bronze and aluminum bronze) has better wear resistance, corrosion resistance, and heavy load-carrying capacity, and therefore is more appropriate for manufacturing heavy-duty mechanical parts such as bearings and gears that require long-term stability. Brass (such as C36000) is soft and relatively cheap to cut, and it is well suited to machining both decorative parts and valves and general structural components.

2. What special considerations are required when machining bronze?

Bronze machining requires attention to thermal management and tool selection. Cutting temperature must first be controlled carefully so that material softening (especially with tin bronze) is avoided. Continuous cooling by applying a water-soluble coolant is the recommended method. The second aspect is to use sharp tungsten carbide tools and appropriate feed rates in order to minimize tool wear and surface quality degradation due to work hardening.

3. What is the minimum machining tolerance that can be achieved?

LS Precision uses five-axis CNC machining along with strict process control to achieve high tolerance levels of ±0.01mm for bronze parts. However, achievable tolerance is influenced by part geometry (e.g., thin-walled features tend to warp), material properties (e.g., alloy shrinkage), and downstream processing requirements.

4. How to Get an Accurate Processing Quote?

With the LS Precison online CNC machining platform, all you do is upload 3D models (STEP/IGES format). The software will automatically analyze material usage, machining time, and process complexity (e.g., deep holes, threads) and generate an accurate quote within minutes.

Conclusion

Bronze, with its special corrosion and wear resistance and self-lubricating characteristics, remains a strategic material for manufacturing high-reliability, long-life precision parts. It is essential to select a trustworthy machining service provider in order to transform this material’s potential into world-class products.

Now receive professional help to your creativity! We extend a warm welcome to the LS Precision Manufacturing online platform and send your design files or drawings. Our engineers will provide you with a free in-depth design for manufacturability (DFM) check and a highly competitive immediate quote, so you can start your next winning project in the best way possible.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Thank you, I have just been looking for info about this topic for ages and yours is the best I’ve discovered till now. But, what about the conclusion? Are you sure about the source?

Really nice style and design and fantastic subject matter, very little else we want : D.

Wow, thank you so much for such high praise! “I don’t want anything else” is truly the best compliment a designer could receive. Thank you very much!

Thank you very much for your recognition! You raise two excellent questions. Regarding the conclusion, [please briefly add the conclusion or specify where in the article it appears]. Regarding sources, my information is primarily based on [briefly indicate the source, such as industry reports, academic research, recognized practical cases, etc.] to ensure accuracy. If you would like to delve deeper into a specific point, I would be happy to provide more information!

What’s Happening i’m new to this, I stumbled upon this I’ve discovered It positively helpful and it has helped me out loads. I am hoping to give a contribution & assist different users like its helped me. Good job.

Fantastic site. Plenty of helpful information here. I’m sending it to several pals ans also sharing in delicious. And obviously, thanks for your sweat!

Some genuinely wonderful information, Gladiola I detected this. “Life is divided into the horrible and the miserable.” by Woody Allen.

You have brought up a very fantastic points, regards for the post.