Titanium CNC Machining

Our titanium CNC machining services will provide you with a one-stop service, from product design to rapid prototyping, ensuring that your products meet your needs and requirements.

- Manufacturing on demand

- Tolerances down to +/- 0.005mm

- Delivery in as little as 3 days

- All uploads are secure and confidential

1 day

Lead time

1 pc

MOQ

0.005mm

Tolerances

20 +

Materials

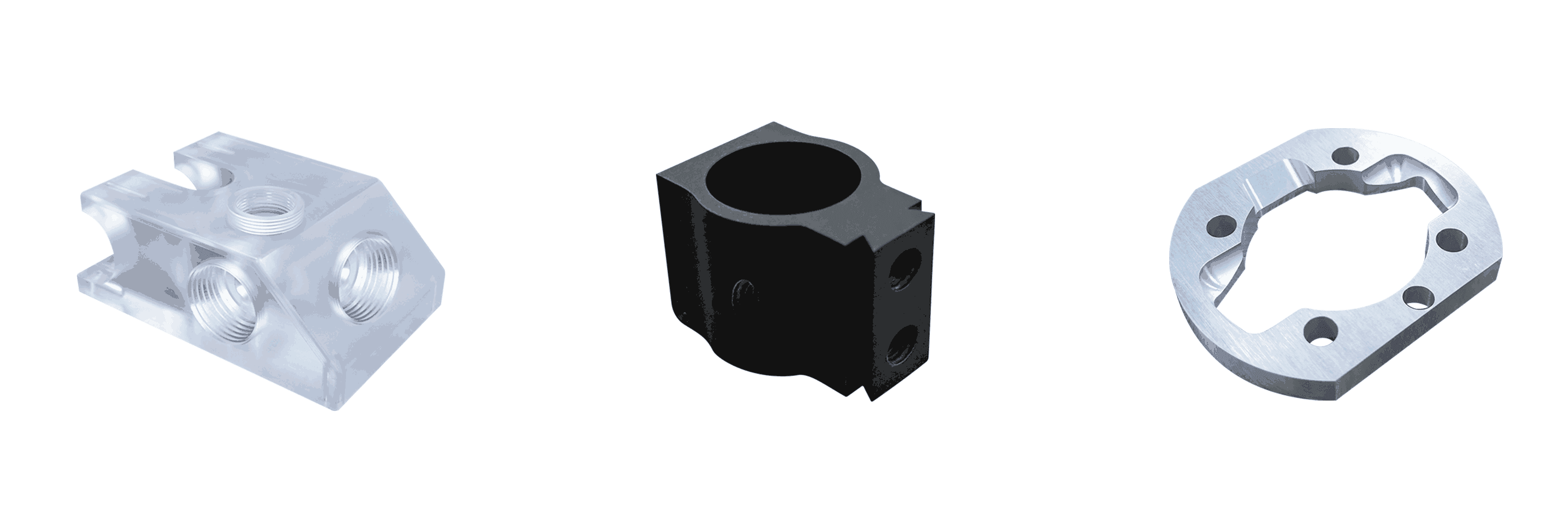

Custom Titanium CNC Parts

If you are looking for professional titanium CNC machining services, then you have come to the right place! Longsheng is a professional factory with many years of experience, committed to providing customers with high quality titanium CNC machining services. We can easily handle a wide range of CNC machining needs, from simple part machining to complex 3D shapes and curves

In our machining shop, we use high-tech machines and tools to perform a variety of CNC titanium machining services: titanium threads, holes, shafts, dimensions and surface treatments.

Our titanium parts Manufacturing Capabilities

If you need custom machined titanium parts with complex geometry, or an end-use product in the shortest possible time, Longsun Technology breaks through all of this and instantly realizes your idea. Our robust precision machining, milling and turning processes guarantee fast turnaround and quality of disposable prototype and production parts.

CNC Milling machining

Milling machijning is the process of cutting material surfaces using rotary cutting tools to produce fine contours, surface quality, and dimensional accuracy. In milling, we use advanced CAD/CAM software to help us create complex titanium parts designs and complete the machining process on high-speed milling machines. Our machining equipment has been fully automated, improving production efficiency and reducing manual errors.

CNC turning machining

Turning machining is a cutting process that places a rotating tool on a workpiece and then rotates the workpiece to form the desired shape on the workpiece. In turning machining, our automated control system can accurately control the reduction process, ensuring the accuracy and surface quality of titanium parts. Our lathe can process a wide range of diameters, ranging from 1mm to 500mm, while also featuring high speed and precision.

Custom Titanium parts

We offer a full range of titanium CNC machining services to manufacture custom CNC parts for Grade 1, 2 and 5 titanium. Titanium parts have corrosion resistance, excellent durability, high melting point and a wide range of uses. We are able to process a wide range of products, from simple “post-machined” workpiece jigs to complex organic geometry with tight tolerances. When manufacturing titanium CNC parts, you can choose from up to 10 different post-treatment/surface finishing options, including sandblasting, powder coating, smooth finishing and polishing to meet your needs.

Why Choose Us for Titanium CNC Machining Service

We provide capabilities from design to rapid prototyping production services to meet the requirements of your project. As a leader in the industry, our titanium parts manufacturing capability is a benchmark to lead the trend. We cooperate with global customers to help them achieve Profit maximization

Design Phase

Use the latest CAD software and tools to assist customers in jointly evaluating the manufacturability of parts and conducting design. Our professional engineers have adopted appropriate models and compliant specifications to provide the most efficient manufacturing solution

material selection

We have a variety of titanium alloys that can be selected according to customer needs. Whether you need it as medical equipment or high-performance aviation parts, we can provide high-quality and reliable titanium alloys.

production process

Our standardized manufacturing processes enable faster and more repeatable production. From CNC machine tools to prototype manufacturing, we have a complete production process that allows us to ensure the timely delivery of high quality titanium parts to customers in all sectors around the world.

Titanium material properties

LS supplies most of the industry standard titanium alloy materials. If you do not find the materials you want in the list, please contact us

| Property | Description |

|---|---|

| Density | 4.5 grams per cubic centimeter |

| Melting Point | 1668 degrees Celsius |

| Thermal Conductivity | 21.9 thermal watts per meter-Kelvin |

| Electrical Conductivity | Low electrical resistance, good conductor |

| Magnetism | Non-magnetic, not affected by magnetic fields |

| Elastic Modulus | 116 GPa |

| Hardness | Depends on alloy composition and heat treatment, typically in the range of 150-300 on the Vickers hardness scale |

| Tensile Strength | Depends on alloy composition and heat treatment, typically in the range of 550-1000 MPa |

| Latent Heat of Fusion | 425 J/g |

| Coefficient of Thermal Expansion | 8.6 x 10^-6 per degree Celsius |

Acid Etching:Removes oxide layers and contaminants, improves surface purity.

Electrochemical Polishing:Improves surface smoothness and appearance.

Mechanical Polishing:Provides high surface smoothness and quality.

Sandblasting:Increases surface roughness, improves adhesion, masks scratches and defects.

Hard Anodizing:Enhances surface hardness and wear resistance, increases corrosion resistance.

Dyeing:Adds color options and decorative effects, improves appearance.

Carbide Coating:Increases surface hardness and wear resistance.

Coating:Enhances corrosion resistance, wear resistance, high-temperature resistance, and decorative effects.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

FAQ on Titanium Parts Manufacturing

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required titanium CNC machining services support by reading FAQ.

What is titanium material?

Titanium is a chemical element. It’s a metal. Its chemical symbol is Ti and its atomic number is 22. The advantage of titanium compared to other metals is that it has very good strength and corrosion resistance as well as low weight.

What is your minimum order quantity?

We do not have a minimum order quantity. Whether you need a single titanium parts or thousands of titanium parts, we are happy to work with you.

How long does the titanium CNC machining process take?

This depends on the size and complexity of the CNC titanium parts to be produced, as well as the batch size of processing. Generally speaking, producing a high-precision CNC titanium part may take several hours or even days.

What is the difference between titanium CNC machining and other machining methods?

Compared with other processing methods, the advantages of titanium CNC machining are obvious. Due to factors such as titanium hardness and corrosion resistance, this gives it a certain advantage in terms of processing costs. CNC machining technology can realize complex parts of various shapes, allowing titanium parts to create better performance.

What is your pricing structure?

Our pricing is based on the complexity and quantity of the parts being manufactured. We will provide you with a detailed quote when you submit your order.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.