In Dongguan, where the industry is extremely large in manufacturing, both appearance and toughness are valued, and powder coatings play an important role in achieving corrosion protection, beauty values, and added value. However, with many powder coating service companies present, few entrepreneurs can find a credible supplier in Dongguan that owns mature technology, good reaction, and stable quality.

For that purpose, we’ve worked tirelessly to compile a list of the “Top 10 Powder Coating Service Providers Near Me” in an attempt to help you with a good local Dongguan buying guide. This article not only looks at these quality producers but also reveals crucial and vital pointers to watch out for when picking a service provider to help you make an informed decision.

Among these outstanding companies, LS Precision Manufacturing is most superior in performance. We not only provide the best coats at LS but also the easy, one-stop solution, providing your product with a flawless surface, making us your buddy for life. To save you time, here’s a quick overview of the core conclusions.

Powder Coating Services Core Quick Reference

| Core Issues | Key points |

| How to choose a service provider? | Keep five things in mind: qualification and reputation of the company, technical team experience, high-tech manufacturing facilities, quality inspection mechanism, and satisfactory case histories. |

| Powder coating cost structure | Powder material, pretreatment, labor hours, and energy consumption are key cost drivers of powder coatings. Beware of low-cost traps and ask whether the quote includes potential costs such as pretreatment, color proofing, and rework. |

| Importance of Pretreatment | Pretreatment (e.g., phosphating and degreasing) forms the foundation of adhesion and coating durability and directly influences whether the coating blisters or delaminates and its overall lifetime. |

| Powder Type Selection | Choose the most appropriate powder type for the product application conditions (indoor/outdoor), substrate material (steel/aluminum, etc.), and performance needs (corrosion protection, wear protection, and appearance). |

| Advantages of Local Services | Quick response, easy communication, and on-site factory visits hugely eliminate logistics time and expense, allowing constant maintenance and quick resolution of surprise problems. |

| LS Precision Case Study | For example smart express lockers illustrate LS’s one-stop solution strength, from material analysis and powder choice to pretreatment and spray coating, to achieve long-term outdoor weatherability and appearance. |

| Get a Free Quotation | This is explained in detail. Typically, you will be asked to provide product drawings, materials, quantity, and requirements of performance in order to get an accurate quotation from the service provider. |

This article systematically answers fundamental questions about choosing powder coating services in Dongguan. Not only does it give practical tips to the choice of the right suppliers and a manual on cost pitfalls avoidance, but also offers the fundamental technical issues that affect the quality of the coating.

Through the successful experience of LS Precision Manufacturing, this article emphatically illustrates how an excellent local partner can protect the value of your products with professional technical ability and one-stop service. It’s an excellent reference for your decision-making when looking for a powder coating supplier near me.

Why Trust This Guide? Practical Experience From LS Experts

This guide draws on the experience of LS Precision Manufacturing’s over ten years of operation in the powder coating business in Dongguan. We are not just a service provider; we are professionals in solving various manufacturing problems. With highly advanced automated coating lines and an stringent quality control system, LS has successfully provided coating solutions to over one thousand clients in the electronics, smart home, outdoor light fixture, and medical devices sectors. We have a strong understanding of the general surface treatment requirements and issues of most industries.

LS Precision recommendations are not theoretical propositions but based on experience. To illustrate, one of the producers of smart locks had previously faced customer complaints about poor adhesion of coating. By performing a thorough analysis of the substrate characteristics and designing a custom pre-treatment process, we ended up increasing the rate of production for the product from 85% to 99.5%, with a significant increase in their brand image.

This hands-on experience in resolving some problems enables us to properly identify the strengths and weaknesses of service providers and cost-quality ratio, and hence, every recommendation obtained is precise.

How To Select A Service Provider? Five Key Factors

While searching for the “best powder coating service provider near me” in Dongguan, cost only or distance only will not do. An effective partnership is dependent on adequate assessment of the supplier’s core competencies. Five are here to consider when selecting powder coating services to help inform your decision:

1. Coating uniformity and adhesion:

Quality is basis. Uniform coating gives consistent corrosion resistance and appearance, and excellent adhesion prevents blistering and flaking. This directly relates to the manufacturer’s pre-treatment and spraying technology.

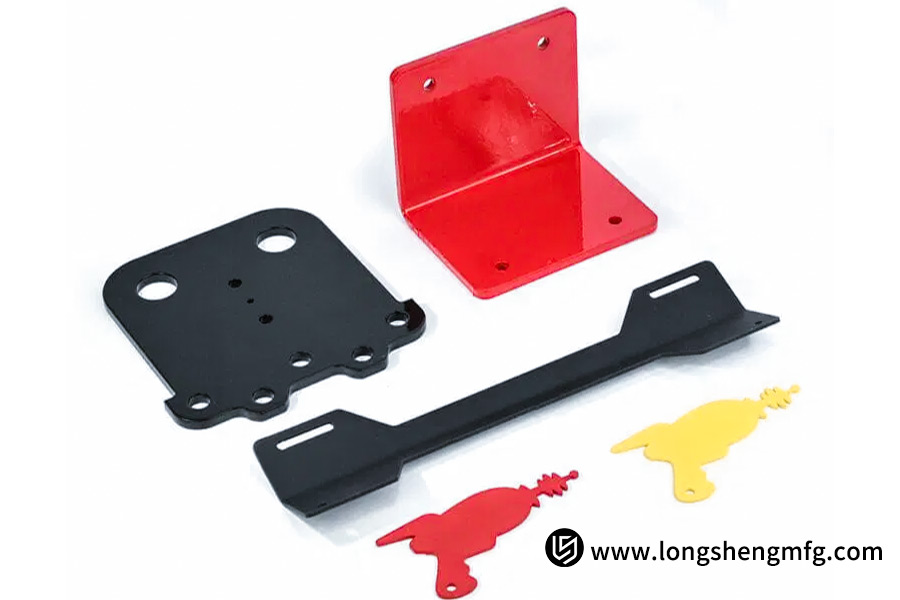

2. A wide range of colors and textures:

A quality service provider should offer a wide range of standard color palettes and various types of textures (matte, crinkle, sandblasted, etc.) as well as the ability to properly customize color palettes to meet your product’s unique design needs.

3. Productivity and delivery speed:

Aligning with your project’s production speed is important. Look at the supplier’s automated machinery, production line capabilities, and flexibility in scheduling to ensure they can work through your orders effectively and provide on-time delivery.

4. Environmental protection and compliance:

A professional powder coating service company ought to be an environmental-certified firm, and their processes and waste disposal also need to comply with national and local regulations. It’s not only a demonstration of corporate social responsibility but also in order to prevent interruptions of your supply chain due to environmental issues.

5. Cost transparency:

A clear quote must identify the material, pre-treatment, and processing fees, free of surprise fees. Reputable service providers will be happy to itemize cost sources and provide the most cost-effective alternatives.

At LS Precision Manufacturing, for example, we have set industry standards in all five of these categories. Not only do we possess completely automated production lines and aggressive adhesion testing to ensure superior coating uniformity, but we also possess significant color development capability and flexible production capability.

All processes are compliant with the environment and we provide clear and transparent pricing—these are some of the reasons why LS Precision is the first choice of many companies.

What Is The Cost Structure Of Powder Coatings? How Can Hidden Fees Be Avoided?

In planning a budget for a project, the initial step towards making a smart decision is the understanding of the cost scenario of powder coatings. A majority of first-time customers are perplexed with price fluctuations. Actually, the overall expense heavily rests on the following key factors. Understanding the mentioned factors keeps you away from quotation pitfalls and helps you get the best value for money.

| Influencing Factors | Specific Explanation |

| Workpiece size and complexity | More sizeable or complex workpieces (e.g., those with multiple edges or holes) are harder to spray and use more powder, and are the chief determinants of powder coating cost. |

| Powder quality and type | The cost variation between general epoxy powders and very weather-resistant outdoor polyester powders is large. Special functional powders (e.g., antimicrobial, conductive) are more expensive but can fulfill special needs. |

| Pretreatment Process Requirements | The cost of general cleaning is different from that of workpieces undergoing advanced processes such as phosphating and vitrification. More intensive pretreatment ensures long-lasting adhesion of the coating and has a proportionally larger cost. |

| Order Volume and Timeline | High-order quantities tend to spread fixed costs and offer better unit prices. Rush orders, however, may have more expedited fees. |

To avoid the industry trap of “bidding low and increasing prices mid-project,” one should choose a provider that promises transparent costs. We at LS Precision Manufacturing believe strongly in integrity being the foundation for our collaborations. All quotations that we provide include a thorough itemized list of all the aforementioned items with clear costs, with no surprise charges.

LS Precision professionals will go out of their way to communicate clearly about sources of cost and recommend the most cost-efficient solution according to your budget and product requirements so that your investment is precise, clear, and effective.

Why Is Pretreatment Critical To The Lifespan Of Powder Coatings?

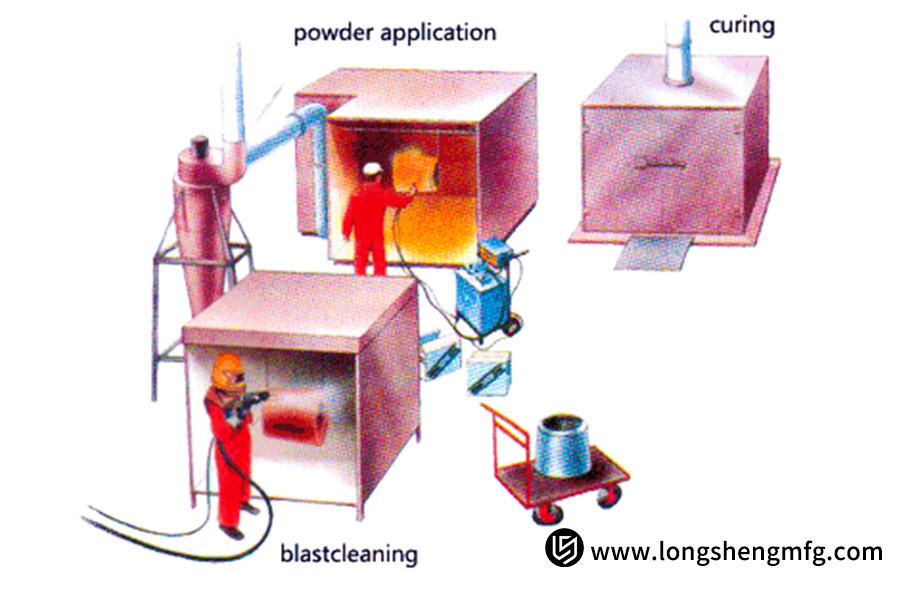

Of the whole metal powder coating process, it is the spraying stage that typically receives the most attention, but the key to a coating’s longevity lies right here in this otherwise seemingly insignificant pretreatment stage. A good coating must be formed over an absolutely clean and optimized substrate; otherwise, even best-of-the-best powder will be unable to perform properly. Pretreatment is crucial in the following three ways:

1. Thoroughly remove contaminants:

Metal workpieces tend to trap oil, grease, dust, and rust during handling and transportation. Pretreatment through processes like degreasing and de-rusting provides an “absolutely clean” background for subsequent spraying, enabling an even, imperfection-free coating.

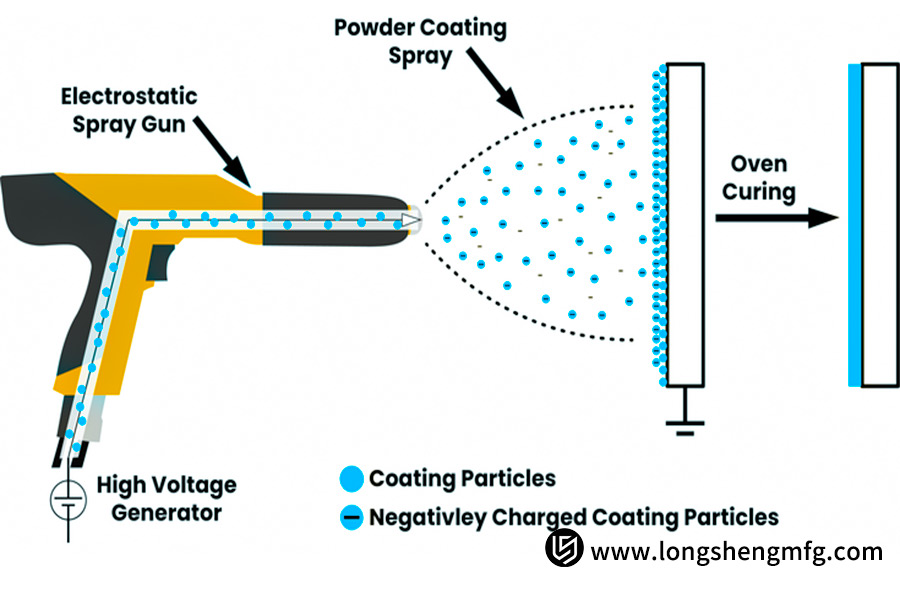

2. Create strong adhesion:

A clean metal surface is smooth. Chemical conversion treatments such as phosphating or vitrification create a compact, microcrystalline, even protective coating on the substrate. Such a coating greatly increases the surface area, providing an excellent “grip” for the powder coating and virtually preventing blistering or flaking due to inadequate adhesion.

3. Create a long-lasting corrosion barrier:

This conversion coating itself possesses better corrosion resistance, effectively prohibiting water and oxygen from directly contacting the metal substrate. It complements the outer powder coat with a two-protection mechanism that’s “1+1>2,” significantly enhancing the final product’s salt spray and corrosion resistance.

High-quality pretreatment is impossible for any type of hand cleaning in a small facility. LS Precision has invested money in a complete automatic pretreatment production line. With precise bath control, constant temperature control, and spray pressure, we ensure every product receives a completely uniform, standardized treatment.

Such careful attention to necessary craftsmanship is the fundamental reason why LS Precision’s metal powder coatings provide an exceedingly long life.

Which Powder Is Suitable For Your Product?

Choosing the right type of metal powder coating for your product is an important step toward delivering its ultimate performance and value. Different types of powders are very different in their sustainability, appearance, and durability. Below is a side-by-side analysis of the characteristics of three popular powders to help you make your initial selection.

1. Epoxy Powder: Excellent Protection and Adhesion

- Advantages: Superior chemical resistance, hardness, and adhesion for optimum indoor uses.

- Limitations: Less good UV resistance and chalking prone (gloss loss and color discoloration) for extended outdoor exposure.

- Applications: For mostly indoor uses, i.e., computer cabinets, indoor metal furniture, and electronic product casings.

2. Epoxy-Polyester Hybrid Powder: Excellent Balance

- Advantages: Better UV resistance than epoxy powder while retaining superior mechanical properties and leveling, providing a cost-effective option.

- Limitations: Still behind pure polyester powder in long-term outdoor weathering resistance.

- Applications: Farm equipment and exercise equipment where outside weather resistance is less crucial, or indoor products requiring a top-quality surface finish.

3. Pure Polyester Powder: Superior Outdoor Weather Resistance

- Advantages: Excellent UV and weathering resistance, with long-term protection against sunlight and rain, and resists chalking or gloss loss.

- Limitations: Somewhat lower chemical resistance than epoxy powder.

- Applications:Exterior architectural aluminum profiles, guardrails, automotive components, outdoor appliances, and any other product subjected directly to the elements.

When faced with these choices, the safest option is to consult a professional.

LS Precision’s team of engineers will conduct a comprehensive analysis based on your product’s end use (indoor/outdoor), substrate material, and specific performance requirements to recommend the most cost-effective metal powder coating solution, ensuring the best return on your investment.

Why Is Local Service Important? What Are The Advantages Of Choosing A Nearby Location?

When you choose a powder coating service, the supplier’s location is often an undervalued but highly significant factor. For Dongguan factory and the nearby areas, choosing a local, or preferably locally available, service provider as your “powder coating near me” supplier has so much to gain that you may hardly realize.

1. Efficient Communication and Smooth Collaboration:

Less physical distance equates to smaller communication distances. Face-to-face interaction reduces miscommunication errors by a large margin. From primary proofing and colour checking, through monitoring of progress through production, proximity services deliver prompt and accurate communication, leading to better-running projects.

2. Prompt Response and Timely Support:

Unforeseen circumstances always arise in production schedules. If you have a fast urgent order or there is some issue in the production line, a local vendor can respond immediately, even dispatching engineers to resolve the issue on the spot. This rapid, on-call response can’t be beaten by remote suppliers and effectively safeguards your production schedule.

3. Convenient Logistics, Reduced Costs and Risks:

Short-distance transport not only reduces logistics costs significantly but, above all, reduces the risk of damaging workpieces, e.g., bumps and scratches, during long, bumpy trips significantly. This not only ensures pristine product condition at shipment time, but also saves rework time and money.

As a veteran powder coating service provider in Dongguan, LS Precision knows inside and out the speed and requirements of the domestic market.

Leaping over our convenient location, LS Precision can provide proximate customers with unparalleled responsiveness and customized service, becoming truly a reliable and efficient extension of your supply chain.

LS Case Study: How To Solve The Challenges Of Outdoor Durability And Aesthetics For Smart Parcel Lockers?

In the highly competitive smart device industry, the long-term stability of a product’s look directly affects the reputation of the brand. We used to have a smart device company whose parcel lockers outside the building were experiencing serious challenges.

1. Customer Dilemma:

Approximately a year following their outdoor deployment, the parcel lockers of the brand began to show noticeable chalking and surface coating fading. Not only did these appear old, but they also caused product quality issues, bringing in a steady increase in complaints. This issue was caused by an initial underestimation of how weatherable the powder coating must be and exposed loopholes within the previous supplier’s material selection and process control.

2. LS Precision’s Solution:

When they received the customer’s order, LS’ design team conducted in-depth research of the specific environment of the product. We set ultra-weather-resistant pure polyester powder with excellent UV resistance as the requirement. In the meantime, we do know that material is only the pillar; process is the warranty:

- Enhanced Pretreatment: Strictly carry out standardized phosphating pretreatment process to ensure maximum level of coating adhesion.

- Precise Temperature Control Curing: With a fully automatic curing oven, curing temperature and curing time of the workpiece are kept in the optimum range, allowing for complete cross-linking of the coating and maximum performance.

- Uniform Film Thickness Control: Computerized spraying ensures uniform coating thickness, forming a constant, dense protective coat.

3. Results:

Since the introduction of the latest consignment of smart express lockers that had been equipped with the LS coating solution, they have survived the test of two years of weathering and weathering, and the surface coating still looks healthy and unblemished. Not only did it solve totally the customer’s long-standing quality problem, but also restored and upgraded their brand image. As a result, they have chosen LS Precision Manufacturing to be their long-term official powder coating service supplier.

Is your product also facing severe environmental conditions? Contact LS Precision today for professional coating services and free samples!

How To Easily Get A Free Powder Coating Quote?

After you have an idea of the price of powder coating, a clear, concise, and free powder coating quote is the most crucial first step towards getting your project underway. LS Precision ensures the ease of the question process so that you may obtain a professional, open budget quote immediately without any inconvenience. Kindly have the following easy information prepared, and our professional team will be in a position to effectively direct you:

- Provide product information: Supply drawings, photos, or actual product samples. Clearly mark the substrate material (e.g., cold-rolled steel, aluminium alloy), approximate dimensions, and surface area.

- Describe the requirements details: Tell us of your expected order quantity, desired powder type (e.g., epoxy, polyester), color/texture requirement, and intended end-use environment of the product (indoor/outdoor).

- Submission and Communication: Let us have your information through convenient media such as our website and phone. Our customer service engineer will contact you within an hour to nail down details and offer a free powder coating rough estimate quotation and process recommendations.

The entire process is free of charge, but provides you with a clear picture of project costs and key control points.

LS Precision offers you more than an estimate; you will also receive professional pre-project technical guidance. Contact us today for a hassle- and timely-free service experience and the initiation of your powder coating project!

FAQs

1. What is LS Precision’s minimum order quantity (MOQ)?

LS Precision knows the customer’s requirements at different stages of their process and therefore does not have a hard minimum order quantity. We are flexible and can accommodate orders from product development proofing to tiny pilot runs. Our goal is to assist your innovation and market response in whole, and we will provide the same rigorous service, even for one part.

2. Can you match specific color standards (such as Pantone color charts)?

Yes. LS Precision has a sophisticated color matching laboratory and advanced computer color matching systems, enabling accurate color matching with the overwhelming majority of international color standards, including RAL and Pantone. Simply provide us with a color number or physical sample, and we will blend up an extremely consistent color for you, maintaining your product’s brand consistency and rigid color management specifications.

3. How long does the entire powder coating process take?

Standard turnaround is 3-5 business days from receipt to shipping. The actual timeframe will differ based on the order’s complexity, quantity of parts, and special processes involved. LS Precision values efficiency and knows time is crucial. If you have a hurry-up requirement, we provide dependable expedited service to completely fit into your production timeline and deliver on time.

4. Besides metal, can other materials be powder coated?

Powder coating is specifically suited for conductive metals such as steel and aluminum. However, with the application of special pretreatment and low-temperature curing, certain non-metallic materials such as MDF (medium-density fiberboard) can also be powder coated successfully. We greet your specific material sample, and our engineers will assess feasibility and provide professional suggestions.

Conclusion

Choosing powder coating services for your product is not just about price shopping; it’s choosing a partner for the long term, one that can guarantee product quality and grow market value. A locally based supplier that is technically skilled, responsive, and has a deep understanding of your market will be an essential and stable factor in your supply chain.

LS Precision Manufacturing with thorough process knowledge, stringent quality control, customer-centric philosophy of services, and convenient accessibility in Dongguan totally meets all the vital requirements of superior powder coating services. We are not just a supplier; we are a member that will help your product succeed.

Take the first step towards greatness now! Submit your part details now and have a free, accurate quote in 60 seconds! Contact LS Precision and allow the expert team to bring the most valuable solution to your project.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.