In 3D printing, the material selection has a direct impact on the functional performance, durability, and user experience of the final product. Without the right 3D printing materials, not only will prints fail and performance be subpar, but also cost and time will be wasted.

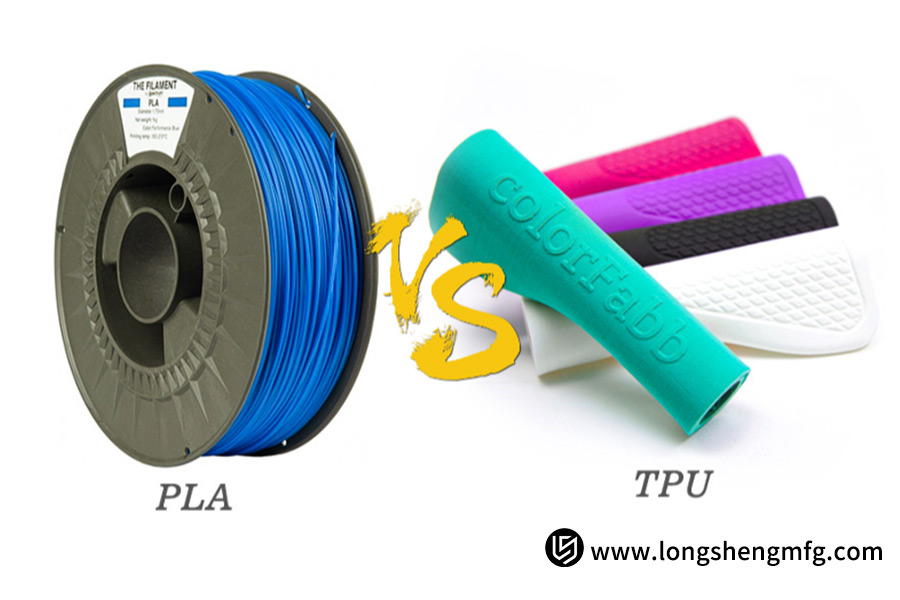

Of all the materials 3D printing technologies can print with, TPU and PLA are among the most widely used due to their exceptional properties: TPU is flexible and abrasion-resistant, suitable for elastic structures; PLA is easy to print with and stable in shape, suitable for prototypes and demo models.

Using the right materials can be a crucial difference to your project. LS Precision is not only your reliable printing service business partner, but also an expert material application consultant, helping you find your requirements with ease and get the maximum benefit from your prints.For your ease, below is the synthesis of the main findings.

Quick Reference: Choose Your Tap At A Glance

| Properties | PLA | TPU |

| Core Characteristics | Rigid, very hard, easy to print | Flexible, abrasion and impact resistance |

| Print Speed | Fast enough | Slow printing needed |

| Building Precision | Very high, great details | Average, will string easily |

| Strength & Robustness | Brittle, fractures on stress | Highly elastic, wear- and tear-resistant |

| Heat Resistance | Low, 50-60°C | Medium, 80°C |

| Appearance | Smooth, fine, can be transparent | Usually matte or frosted finish |

| Typical Applications | Concept models, show pieces, toys, home decor | Functional components: anti-slip mats, shock absorbers, hoses, phone covers, insoles |

| Advantages | Cheap, non-odorous, high print success rate, easy to use | Very high wear-resistance, drop-resistance, impact-resistance |

| Disadvantages | Brittle, not heat-resistant, not impact-resistant, and easily degraded | High printing requirements, slow speed, and dust-prone surface |

- Print with PLA: For exposure prototyping, static modeling, or high precision and low printing requirement, use PLA. It is the best 3D print material for a beginner.

- Print with TPU: For flexible use, wear protection, or impact protection, TPU is required. It’s designed for long, flexure, compressible parts.

Your project selection is up to you. PLA precision and surface finish or TPU durability and elasticity? LS Precision provides excellent print service and expert 3D printer material consultation.

Why Trust This Guide? Practical Experience from LS Experts

LS Precision years of additive manufacturing experience are the basis on which to experience in additive manufacturing provided by this guide. Not only do they run tens of dozens of commercially qualified 3D printers and buy thousands of designs, but they also have an in-house materials engineering staff. They test, validate, and build a humongous database of 3D printing filament performance daily, i.e., every and each recommendation is data-driven on humongous scientific data and gigantic process knowledge, not guesswork.

LS Precision’s actual experience is that theory is nine times out of ten irrelevant in printed reality. As just one illustration, LS Precision had a bona fide customer for smart wearables who simply kept snapping snap fasteners off PLA-printed proof samples. With revelation of the repeated disassembling need of the customer, our engineers found it adventurous enough to recommend the material change from TPU and print setting optimization and ultimately double or triple the strength and stiffness of the product.

This is what LS Precision is worth: We don’t sell as a supplier, but as a partner that uses our knowledge with 3D printer material to assist you in coming out of the woods.

Why Is PLA The Most Popular Entry-Level Material?

Of all the groups of all-around sets of 3D printing materials, the most popular and final starter material is PLA (polylactic acid). It’s first on our list because it has the optimal set of features.

1. Advantages of PLA:

PLA is a bio-plastic derived from renewable resources (such as corn or sugarcane) and is biodegradable, the key environmental advantage. Its greatest asset is its exceptional print-friendliness: prints at low temperatures, warps less, contracts very little, and has dimensional stability. It almost eliminates the need for a hot bed to print well, significantly lowering the barrier to entry.

Moreover, it produces nice, thin print layers and rich color, creating very beautiful models. The print is practically smell-free, thus it is ideal for use in domestic or workplace environments.

2. PLA Disadvantages:

PLA material also possesses major drawbacks, though. It is brittle and not tough, readily shattering when struck or bent. It also possesses low heat resistance, normally softening and warping above 60°C, which disqualifies it for high-temperature usage. In addition, it degrades gradually in the outdoor environment, which, although eco-friendly, also equates to low long-term durability.

Due to this, the optimum uses of PLA are primarily for concept models for construction, display pieces, artworks and crafts, educational models, and other non-load bearing, non-functional elements. PLA best serves the user’s basic need for “rapid realization of ideas.”

PLA 3D printing filament with its unmatched convenience and excellent printing quality is the perfect and most reliable starting point to the world of 3D printing for new users.

How Does TPU Impart Flexibility And Impact Resistance To Your Products?

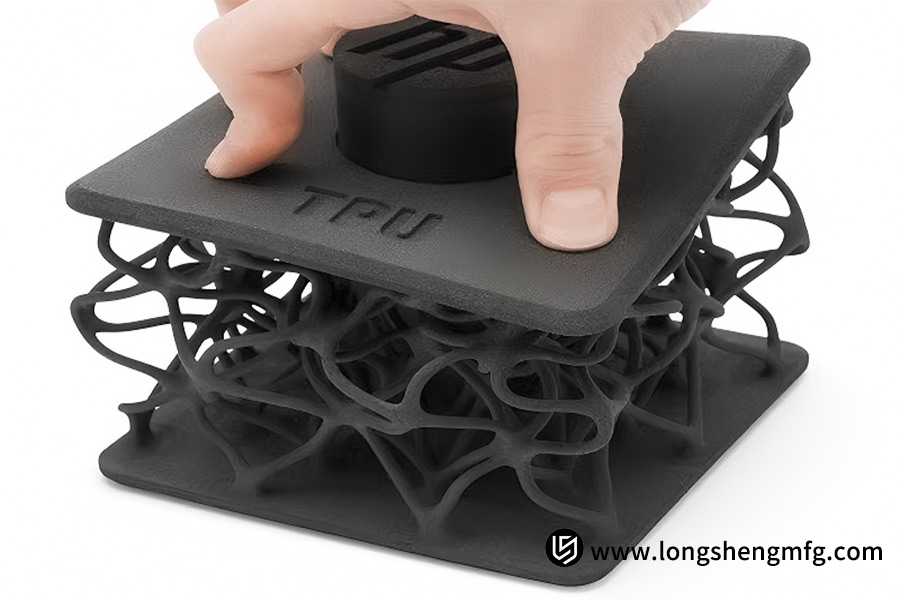

As the search continues for functional 3D printing, TPU (thermoplastic polyurethane), as a high-performance soft 3D printing material, is emerging as a secret recipe for creating flexible and resistant products.

1. Core Properties of TPU:

TPU is actually an elastomer between rubber and plastic. This unique molecular structure directly imparts its irreplaceable physical characteristics.

TPU’s inherent advantages are its excellent elasticity, wear resistance, and tear resistance. Unlike other hard materials, TPU 3D printing filament will quickly return to its original shape after extreme bending, compression, or stretching, and absorbs and dissipates impact energy, effectively protecting the product’s internal structure. Furthermore, its oil and wear resistance enables even more severe use and resists the wear and tear of long-term use.

2. TPU Printing Performance:

Printing this flexible 3D printing material is harder, of course. Its flexibility makes it curve when it’s fed through, jamming. This seems to require a short-range extruder on a 3D printer and reduced print speeds in order to be reliable. While it is a harder process, it’s worth it: it prints flexible functional parts that are impossible otherwise with conventional rigid plastics.

From anti-slip pads and shock absorbers to flexible hinges and wearable device brackets, the applications for TPU are far-reaching. It allows designers to expand the limits of fixed geometries and create innovative products that merge comfort, resilience, and expert performance.

Choosing TPU 3D printing filament means choosing to add a pinch of ruggedness to your designs. While it requires some special printing modes, it opens up the door to the production of high-performance flexible parts and serves as an important material in realizing product functional innovation.

Head-to-Head: TPU vs. PLA, A Comprehensive Comparison Of Key Characteristics

When choosing 3D printing filaments, TPU vs. PLA is most frequently a topic of discussion. Both of these filaments have inherently different properties and are used in completely different applications. The chief parameter comparison below will allow you to make an informed initial choice in a timely manner according to your requirements.

| Property Dimensions | PLA (Polylactic Acid) | TPU (Thermoplastic Polyurethane) |

| Strength/Rigidity | High rigidity and high hardness | Low rigidity and high elasticity |

| Flexibility | Brittle, almost inelastic | Excellent, can bend and stretch significantly |

| Durability | Fair, prone to breakage and degradation | Excellent, resistant to abrasion, tearing, and fatigue |

| Temperature Resistance | Low, ~60°C | Medium, ~80°C |

| Printing Difficulty | Very easy, suitable for beginners | Difficult, requires experience and equipment |

| Print Speed | Fast | Must print at slow speeds |

| Cost | Low | Moderate |

| Typical Applications | Display models, toys, prototypes | Functional parts, anti-slip mats, hoses, protective covers |

This detailed PLA-TPU comparison clearly reveals the following on an objective basis:

- If you need to print static models, proof-of-concepts, or display parts that require high surface finish, PLA is a cost-effective solution.

- But if your model needs to withstand impact, bending, or abrasion, and you need functionality, durability, and toughness, TPU is a go-to solution.

The professionals at LS Precision await to provide advice and make your material choice an ideal match for the goals of your project.

Should I Choose TPU Or PLA For My Project?

When it comes to choosing 3D printing materials, many users hesitate between TPU and PLA. The answer depends entirely on the end use and functional requirements of your project. Choosing the right 3D printing material isn’t about finding a “one-size-fits-all” material, but rather matching the most appropriate properties for a specific application.

1. Choosing PLA:

You can find this out quite easily by asking yourself just one basic question: Does my item need to be “hard” or “soft”? If the answer is “hard,” PLA is likely a good choice. It works best for items that must have shape stability and visual detail, such as rigid product casings, concept models, artwork, toys, and most non-load-bearing structural components.

2. Choosing TPU:

Otherwise, when the response is “soft” or requires flexibility, then TPU is the ideal solution. Apply TPU when your design needs to resist deformation, absorb shocks, or generate friction. Typical applications include in shock absorbers, seals, soft grips, wearable device accessories, anti-slip pads, and any functional parts that require flex or compression.

When selecting materials for 3D printing, remember: no single “best” material, but the “best” material for your project needs. PLA prevails at static display with ease of handling and precision, and TPU allows for functional innovation with resilience and flexibility.

If you are unsure, LS Precision’s material experts are happy to provide a professional selection analysis for your project, so your thoughts are easily translated from design to finished product.

How Does LS Precision Enhance Part Performance And Value Through Professional Post-Processing?

3D printing finishing is only the starting point of part manufacturing at LS Precision Manufacturing. Optimal value comes through professional 3D printing post-processing. We are aware that an object printed directly from the build platform will always bear layer marks, support remnants, or a bumpy finish, far from the condition of being usable directly. Therefore, we offer comprehensive and detailed post-processing services such that all parts we send to our clients are high-quality, ready-to-use parts.

1. PLA Part Post-Processing:

For PLA parts, LS Precision Manufacturing hand-sands carefully, putty fills, and polishes to completely eliminate exposed layer lines and achieve a smooth, injection-molded finish. We then complete expert spray painting, dip-dyeing, or screen printing to attain precise color matching and incredible visual effects so that display models are on par with commercial-grade appearance requirements.

2. TPU Part Post-Processing:

For functional, elastic TPU components, our 3D post-processing is particularly designed to the removal of support structures with precision without compromising the delicate surface to avoid any scarring or damage. Necessary surface treatment and cleaning are also done to provide uncompromising functionality and appearance.

LS Precision is not just an “inked part”; it’s an extremely highly processed, ready-to-assemble finished part that goes through high levels of quality control for appearance and performance as well. This indicates that LS Precision Manufacturing gets the significance of the details and has a deep understanding of customer value.

Through expert post-processing of 3D printing, LS Precision not only delivers maximum performance and value of parts, but also gets your project ready to be operated at the best condition, saving you precious time and energy.

LS Success Story: How Does TPU Material Solve The Wearing Comfort Challenge Of Smart Wearable Devices?

As wearables move increasingly along the journey of functional realization, material selection is the very real make-or-break factor for user experience success or failure. Taking advantage of its material strength, LS Precision Manufacturing was poised to exploit TPU 3D printing filaments to address a critical issue for one of its clients.

1. Client’s Challenge:

A new med-device company designed a long-term wearable health monitor. At the prototype stage, the wristband was produced using standard PLA material. The PLA material generated two main issues:

- It was hard and unpleasant to wear with minimal flexibility;

- It cracked easily at the hinge due to normal use. This impacted not just the user experience but also the continuity and reliability of the monitoring data.

2. LS Precision’s Innovative Solution:

Faced with this problem, LS Precision Manufacturing engineers proposed a turnkey, professional solution:

- Material Science Application: We proposed and used 94A hardness medical-grade TPU 3D printing material. The hardness of the material was selected deliberately to provide sufficient support to securely position the precision sensor while possessing excellent flexibility to accommodate the wrist curvature well.

- Innovation in Printing Process: Considering the characteristics of TPU, we tuned printing temperature, velocity, and retraction parameters to their optimum levels, significantly enhancing interlayer adhesion and the structural integrity and uniformity of printed parts and thus completely eliminating delamination or fracture.

- Value-Added Post-Processing: We hand mechanically polished and micro-coated all of the inner surfaces of the wristband which will be in skin contact, eliminating all wrinkles and creating a smooth, skin-friendly surface, significantly enhancing long-term wear comfort.

3. Value Created and Achievements:

LS Precision Manufacturing printed and delivered 500 samples of high-performance wristbands in one run to the customer. Upon field trials, the new wristband fully satisfied the design performance in terms of comfort, longevity, and ease of use with a highly satisfactory rate of customer satisfaction. This collaboration not only satisfied a pressing need but also fully demonstrated the huge potential of TPU 3D printing filaments in producing flexible functional components.

Due to the outstanding performance, the customer has made LS their favorite long-term supplier of product development and small-batch production.

FAQs

1. Which is more durable, TPU or PLA?

“Durability” is dependent on conditions: PLA is very rigid and pressure-resistant, but brittle, impact-sensitive, and breakable. TPU is more flexible, wear-resistant, tear-resistant, and resistant to repeated bending, with generally superior durability under dynamic conditions (e.g., shock absorbers, wearable technology). Thus, if fatigue and bending are necessary, TPU would be a superior option.

2. Can my standard consumer-grade 3D printer print TPU?

The majority of consumer-grade 3D printers use a Bowden extrusion system, which has difficulty delivering flexible TPU material steadily and is prone to clog and failure on print jobs. Successful printing can only be achieved with a near-extruder, metal hot end, and temperature-controlled. Unless your hardware has been optimized for flexible filaments, we recommend leaving your printer in the capable hands of a service provider with industrial printer and process expertise, such as LS, to maintain cost-effectiveness and quality.

3. Besides TPU and PLA printing, what other materials does LS offer?

LS Precision offers a whole-process, multi-material answer, such as engineering plastics and high-performance resins. For example, high-strength nylon (PA-CF) can be used on structural parts; high-temperature resistant ABS can be machined and surface-finished; photosensitive resins meet requirements for high precision and transparent appearance; and ubiquitous functional materials such as PETG and PC are also offered, fully answering a range of applications from prototyping to manufacturing of end products.

4. How can I obtain a 3D printing quote and design optimization advice from LS?

Simply upload a 3D file (in STL/STEP format) on the LS website’s “Instant Quote” page and the system will automatically offer a preliminary quote. Our engineers will also provide a free design for manufacturing (DFM) analysis, including structural optimization, support planning, and material selection. We will also provide a final quote and delivery timeline to help you in the successful completion of your project.

Conclusion

TPU and PLA, each with its own traits—previously more elastic and wear-resistant, the latter more convenient to handle and accurate—are meant for completely different areas of application. Selecting the material is not so much a science as an art which requires deep experience.

LS Precision does not just boast cutting-edge industrial-standard 3D printing technology, but also engineers well seasoned in their field. We provide one-stop-shop service, from experienced material selection, manufacturing design (DFM), to accurate post-processing, ensuring the success of your project from concept to completion.

If you’re not yet convinced about material selection for your project, or even have a clear idea in mind, please go ahead and upload 3D designs. LS Precision’s professionals will give you tailored material selection guidance and a free, on-the-spot quote. Contact LS Precision!

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.