As a manufacturer, choosing the right material for your injection molding project can be a daunting task, especially if you’re new to the industry. With so many different types of plastics available, how do you know which one is the best fit for your product?

In this comprehensive guide, we’ll take a deep dive into the world of plastic injection molding and discuss the various types of plastic materials that are commonly used in this process. By the end of this article, you’ll have a better understanding of the pros and cons of each type of plastic and be able to make a more informed decision about which one to use for your project.

Before we dive into the specifics of each plastic type, let’s take a quick look at the basics of injection molding.

What is Injection Molding?

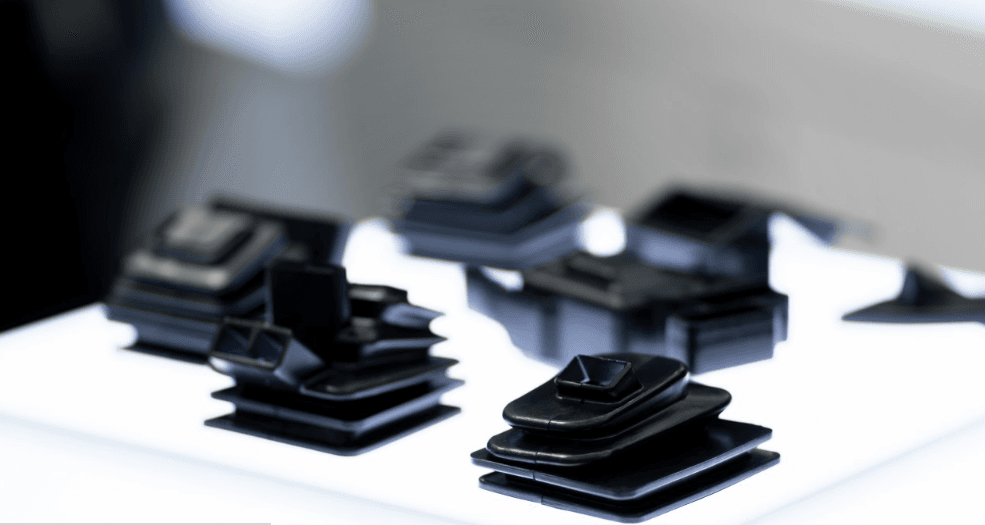

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity. Once the plastic cools and solidifies, the mold is opened, and the part is ejected. Injection molding is commonly used to produce high-volume plastic parts that are used in a wide range of industries, including automotive, medical, and consumer goods.

Types of Plastic for Injection Molding

There are a variety of plastic materials that can be used for injection molding, each with its own unique properties and characteristics. Here are some of the most common types of plastic materials used in injection molding:

Polypropylene (PP)

Polypropylene is one of the most commonly used plastics in injection molding. It is a versatile material that is both lightweight and durable, making it ideal for a wide range of applications.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a popular plastic material that is known for its strength, durability, and impact resistance. It is commonly used in the automotive and consumer goods industries.

Polycarbonate (PC)

Polycarbonate is a high-performance plastic that is known for its exceptional strength and impact resistance. It is commonly used in products that need to withstand harsh environments, such as electronic components and automotive parts.

Polyethylene (PE)

Polyethylene is a widely used plastic material that is known for its flexibility and durability. It is commonly used in products such as packaging materials and toys.

Polyethylene Terephthalate (PET)

PET is a strong, durable, and lightweight plastic material that is commonly used in the production of bottles and containers.

Nylon

Nylon is a highly versatile plastic material that is known for its strength and chemical resistance. It is commonly used in products such as gears, bearings, and other mechanical parts.

Material Properties and Applications

In this chapter, we will dive deeper into the properties of each type of plastic and its applications. We will discuss the mechanical properties, such as strength, stiffness, and toughness, as well as the thermal and chemical properties. We will also provide examples of products made using each type of plastic.

Material Properties: What Matters Most?

Choosing the right material based on the specific requirements of the product is crucial in the success of injection molding. The material used should possess certain properties that make it ideal for the intended application. Common material properties that are essential for the injection molding process include:

Melting Point: The melting point of the material is critical in the success of injection molding as it determines the temperature range at which the process can be performed.

Viscosity: The viscosity of the material determines how easily it flows through the injection molding machine.

Tensile Strength: This property determines the amount of force the material can withstand before it breaks or deforms.

Flexural Strength: This property measures the ability of the material to resist bending.

Impact Strength: This property determines how well the material can withstand sudden impacts.

Chemical Resistance: The material should be resistant to chemicals to ensure that it does not react with any chemicals used in the production process.

Applications: Where Can We Use Injection Molding?

Injection molding can be applied to various industries, including automotive, aerospace, healthcare, electronics, and sports equipment. Here are some examples of products that are commonly manufactured using injection molding:

Automotive Industry: Bumpers, dashboard panels, interior trims, door panels, and many more.

Aerospace Industry: Panels, knobs, switches, and electronic components.

Healthcare Industry: Medical device components, surgical instruments, and diagnostic products.

Electronics Industry: Enclosures, connectors, switches, and covers.

Sports Equipment: Helmets, paddles, balls, and protective gear.

Injection molding is an incredibly versatile and cost-effective manufacturing process, making it the perfect choice for businesses looking to mass-produce plastic components. One of the major advantages of injection molding is the ability to produce intricate and complex parts with a high degree of accuracy, consistency, and repeatability.

In addition, injection molding enables manufacturers to use a wide range of materials to produce products that are durable, lightweight, and of high-quality. This is especially valuable in industries such as healthcare and aerospace, where products need to meet strict regulations and standards.

Choosing the Right Type of Plastic

Now that you have a better understanding of the different types of plastic materials that are commonly used in injection molding, how do you go about choosing the right one for your project?

In this chapter, will focus on how to choose the right type of plastic for your injection molding project. We will discuss the factors to consider, such as the application, part design, production volume, cost, and environmental impact. We will also provide some tips on how to optimize your injection molding process for each type of plastic.

Factors to Consider

Application

The first and most important factor to consider is the application of your plastic part. Will it be exposed to harsh chemicals or high temperatures? Will it be used in a medical or food-grade environment? Understanding the application of your part will help identify the plastic material that best suits your needs.

Part Design

The design of your part will also play a crucial role in determining the right type of plastic. Some plastics are more flexible, while others are more rigid. Some are suitable for small intricate parts, while others are better suited for large and simple designs.

Production Volume

Another factor to consider is the volume of production. If you’re planning on producing a large quantity of parts, you’ll want to choose a plastic that can be easily and efficiently molded in high volumes.

Cost

Cost is always a consideration in manufacturing projects. Some types of plastics are higher in cost than others. You’ll want to weigh the benefits of each type of plastic against its cost to determine which is the most cost-effective solution for your project.

Environmental Impact

Lastly, you’ll need to consider the environmental impact of your plastic choice. If you’re aiming for a more sustainable solution, you’ll want to choose a plastic material that is easily recyclable or biodegradable.

Tips for Optimizing Your Injection Molding Process

Once you’ve chosen the right type of plastic for your project, it’s important to optimize your injection molding process to ensure the best possible results. Here are some tips to consider:

Ensure your mold design is optimized for the type of plastic you’re using.

Use the right injection molding machine and settings for the chosen plastic type.

Control the temperature and pressure during the molding process to ensure consistent results.

Use the right mold release agent to prevent sticking and prolong the life of your mold.

Choosing the right type of plastic for your injection molding project involves considering several factors, including application, part design, production volume, cost, and environmental impact. Once you’ve narrowed down your choices, it’s important to properly optimize your injection molding process for the chosen plastic type to ensure the best possible results. With these tips and guidelines in mind, you’ll be well on your way to choosing the right plastic for your project and producing high-quality plastic parts.

Conclusion

Choosing the right type of plastic for your injection molding project is crucial to the success of your product. By understanding the different types of plastics that are available and their respective strengths and weaknesses, you can make an informed decision about which material is best suited to your needs.

If you’re in the market for injection molding services, it’s important to work with a trusted provider who has experience working with a wide range of plastic materials. At [Longsheng Technology], we have the expertise and knowledge to guide you through every step of the process, from material selection to final production. Contact us today to learn more.