Vacuum Casting Services

- Instant Vacuum Casting Parts online quotes

- Tolerances down to ±0.02-0.5mm

- Get your custom parts at low prices

- Hot and cold chamber vacuum casting

- All uploads are secure and confidential

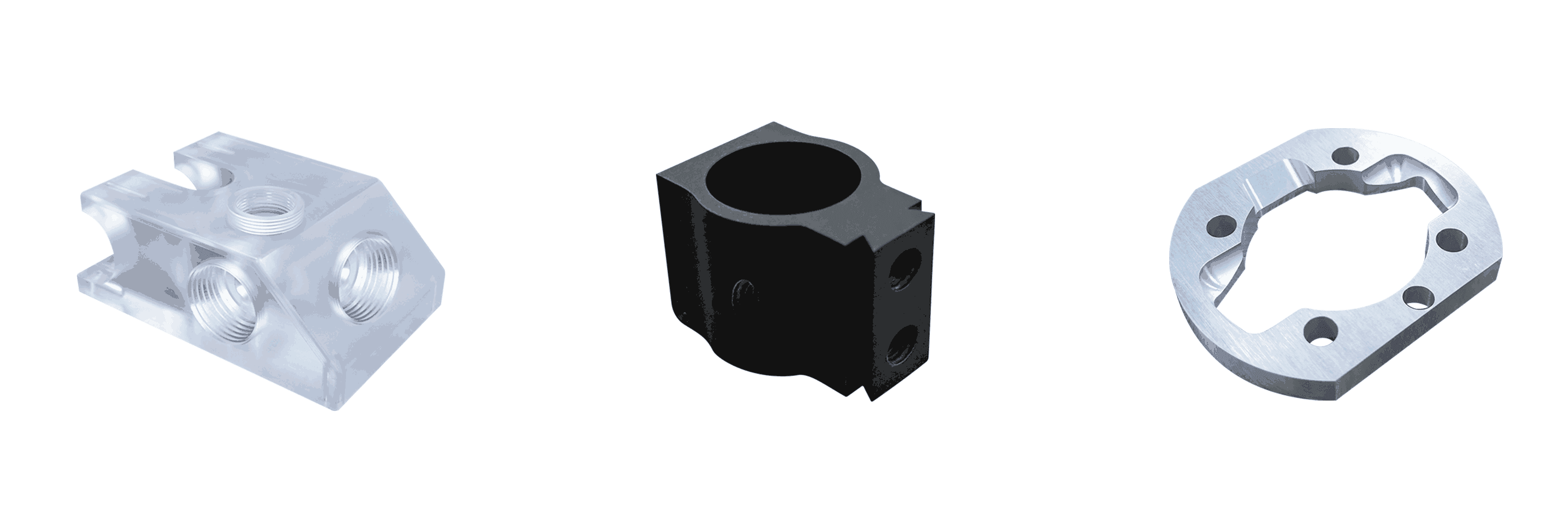

Custom Vacuum Casting Parts Service

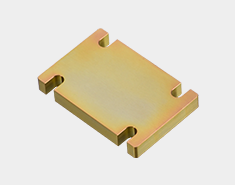

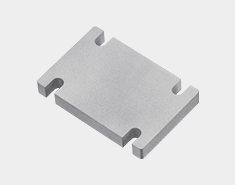

Pressure vacuum casting is an ideal method for making large quantities of metal parts with excellent surface finish and dimensional stability.We provide cast parts in aluminum, zinc and magnesium.

Why Choose Vacuum Casting Parts Machining?

When it comes to manufacturing high-quality metal parts, vacuum casting is one of the most popular and efficient methods. This process involves injecting molten metal into a mold at very high pressures, which allows for the creation of complex and precise parts with a smooth surface finish. vacuum casting parts machining is an efficient, durable, versatile, and cost-effective manufacturing method that is ideal for producing high-quality metal parts.

If you are in need of metal parts for your business or project, vacuum casting is definitely worth considering. LS Manufacturing adopts the latest vacuum-casting technology to provide high quality on-demand components. For aluminum and zinc materials, typical tolerances are usually in the ±0.05 mm to ±0.1 mm range, depending on the customer’s specifications.

Vacuum Casting Parts Machining Material

LS Manufacturing supports most of the industrial standard materials,The processing materials not listed above can consult customer service customization.

Metals

Plastics

We offer customization based on your specific material requirements. If you need a material not listed here, our team can source and process it to meet your exact needs.

These are just a few examples of the materials we work with. If you have a specific material requirement, please contact us to discuss your needs.

Vacuum Casting Parts Machining Surface Treatment Option

Surface treatment is the last step of precision vacuum casting parts processing. It can be used to remove surface defects of castings, enhance mechanical or chemical properties, and improve the appearance of products. Users can choose different surface treatment processes according to different needs

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Anodizing

Anodizing

|

Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Chromate

Chromate

|

Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

Why Choose Our Vacuum Casting

By choosing our precision vacuum casting manufacturer, you will receive high-quality, customized parts, fast delivery, and competitive prices. We will cooperate with you to provide excellentsheet metal solutions for your project.

Quick quotation

Just upload your design file and configure the materials, finishing options, and requirements. Our engineers analyze your part geometry and provide real-time and competitive pricing as well as comprehensive DFM feedback.

Assured High Quality

We are a sheet metal fabrication factory certified by ISO 9001:2015 and can provide sheet metal component materials and full size inspection reports according to your requirements.

Reliable Delivery

From prototype design to efficient production, we deliver high-quality sheet metal parts within our standard delivery time of 3 days.

Readily available capacity

We have over 70 machines, and your sheet metal fabrication services can provide immediate and available production capacity.

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

Our Vacuum Casting for Various Applications

LS Manufacturing’s sheet metal fabrication services provide critical support for enterprises in various industries, whether it is metal automotive components or electronic equipment components.

Order LS Manufacturing Die Casting Parts Advantage

What Is CNC Machining?

CNC machining is an automated manufacturing process in which computer numerical control (CNC) systems are used to control tools and machines to cut, shape, and process various materials to make parts, components, and products.

What Is CNC Machining Process?

CNC machining involves the use of computer programs to control machines for the precise manufacturing of complex components. To start, a designer uses computer-aided design (CAD) software to create a geometric model of the component. Then, a process engineer translates this model into CNC code, which comprises detailed instructions for cutting, movement, and machining. This program uses G-codes and M-codes to describe the tool's path, speed, cutting depth, and more. The CNC machine tool follows these instructions, moving the tool to cut and shape the raw material, such as metal or plastic, into the desired component. The high-precision movements of the machine tool and tool ensure that the final component meets the design requirements, with the necessary dimensions, surface quality, and geometric shape.

Which Is Better CNC Or 3D Printing?

CNC machining is widely used in industries such as aerospace, automotive, medical, and industrial equipment due to its ability to effectively produce precision parts using production grade materials. Typical applications of CNC machining include: - Aerospace components - Prototypes for product development - Medical implants and instruments - Circuit board prototypes - Automotive engine parts - Wind turbines

What Are The Applications Of CNC Machining?

CNC machining is preferred when you need strong, precise parts from a variety of materials, whereas 3D printing is ideal for quickly producing complex and customized designs. Your choice depends on material, part complexity, precision, and production quantity.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

Frequently Asked Questions About Metal Parts Manufacturing

What types of parts can be created using CNC machining?

CNC machining can be used to create a wide variety of cnc parts, from simple components to complex assemblies. cnc parts can be made in a range of sizes, shapes, and configurations, and can be customized to meet specific requirements.

Do you accept small batch orders?

Yes, we accept small batch orders. We have flexible production capabilities that can meet the personalized needs of customers, whether it is for small or large orders.Learn more about our small batch production capabilities here.

Do you have design support capabilities?

Yes, we have a professional design team and CAD/CAM software that can provide design support and advice, including manufacturability evaluation, process recommendations, and optimization of cnc parts. We work closely with customers to ensure that the design of the cnc parts meets the machining requirements.

What is your delivery time?

Yes, we have rich experience in machining complex parts, including Multiaxis machining, micro machining and surface machining.

What is your precision CNC machining ability?

We have advanced CNC machine tools and a technical team that can achieve high-precision, complex shapes and fine details machining, meeting customer precision requirements.

Can you provide samples or prototype production?

Yes, we can provide samples or prototype production services according to customer requirements. We can process according to design drawings or samples to verify and confirm the quality and applicability of the cnc parts.Learn more about our rapid prototyping capabilities here

Do you have experience in handling complex part machining?

The delivery time varies depending on the complexity, quantity, and machining technology of the cnc parts. We will provide accurate delivery times based on customer order requirements and strive to deliver on time.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.