Vapor Polishing Services

Steam polishing gives your plastic parts a smoother, optically clearer surface and high transparency.

- All uploads are secure and confidential

Vapor Polishing Specifications

| Project | Info |

|---|---|

| Applicable materials | Polycarbonate (PC), Acrylic, ABS, Nylon |

| Colors | Clear |

| Texture | Smooth and glossy |

| Thickness | 10μm to 80μm |

| Surface finish | Ra < 0.2 |

| Pressure range | 0.5 - 2.0 bar |

| Temperature range | 40-60°C |

| Surface bubble | No bubbles, no blemishes |

| Process time | 30 minutes |

| Applications | Remove small scratches, enhance transparency, and reduce surface friction |

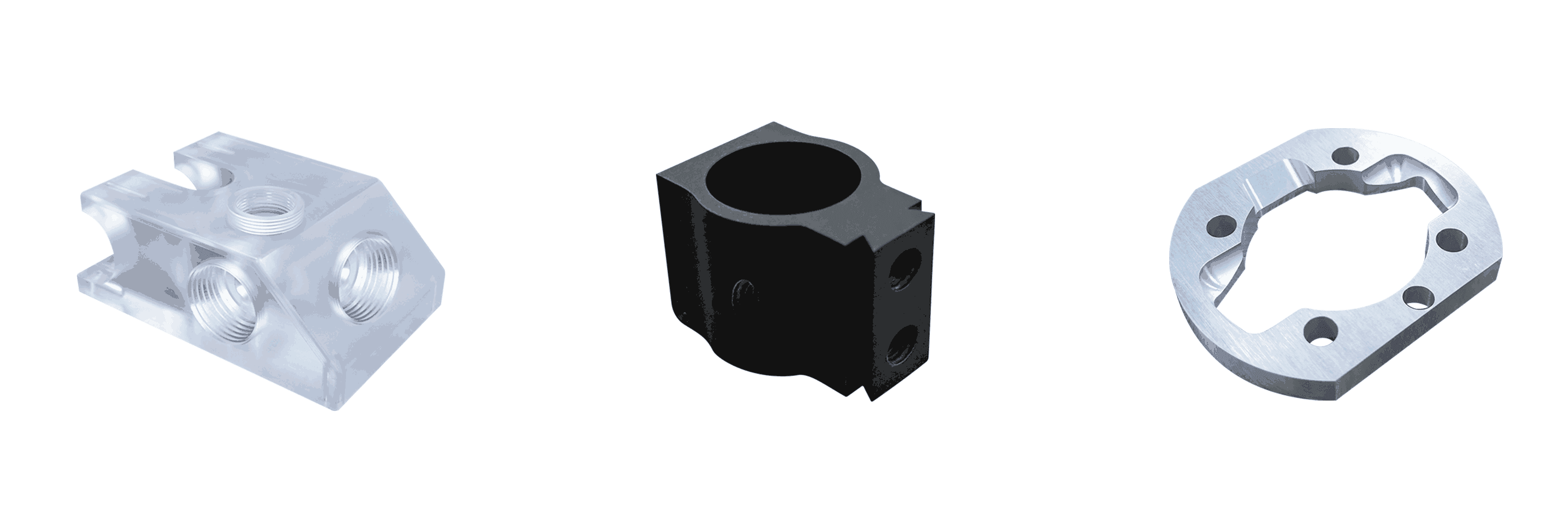

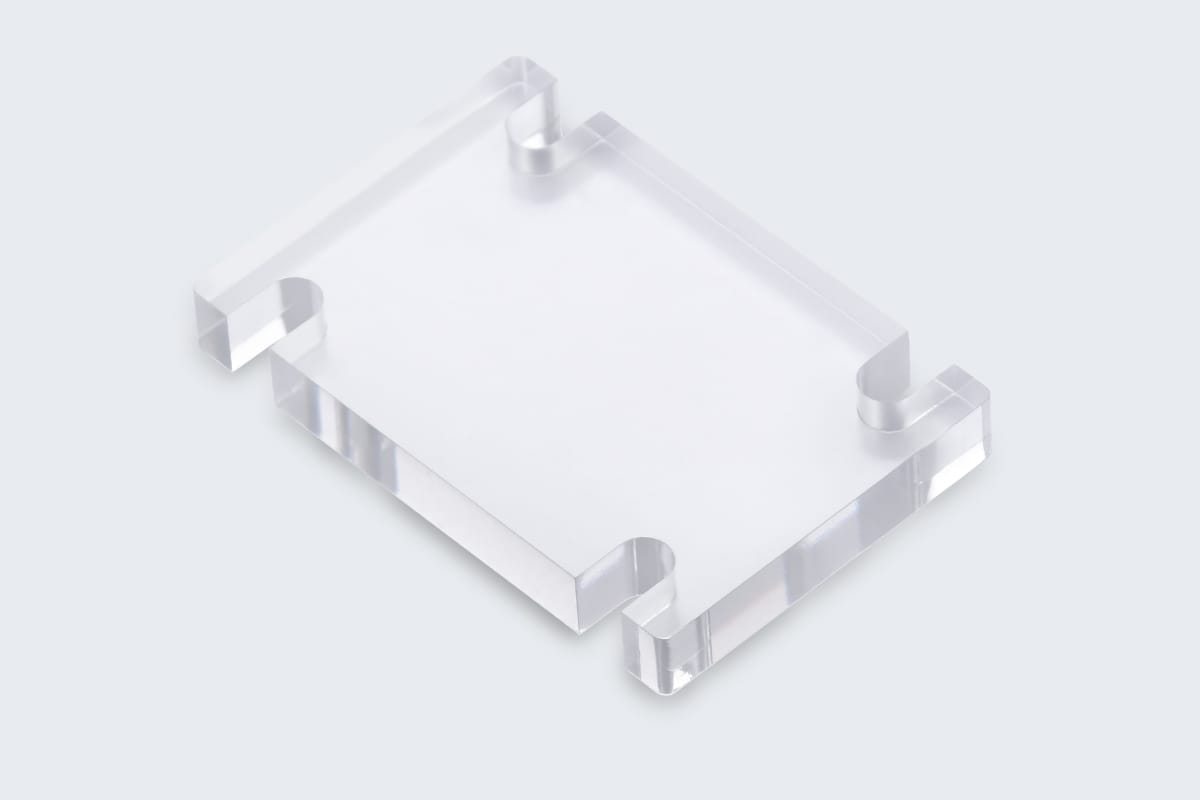

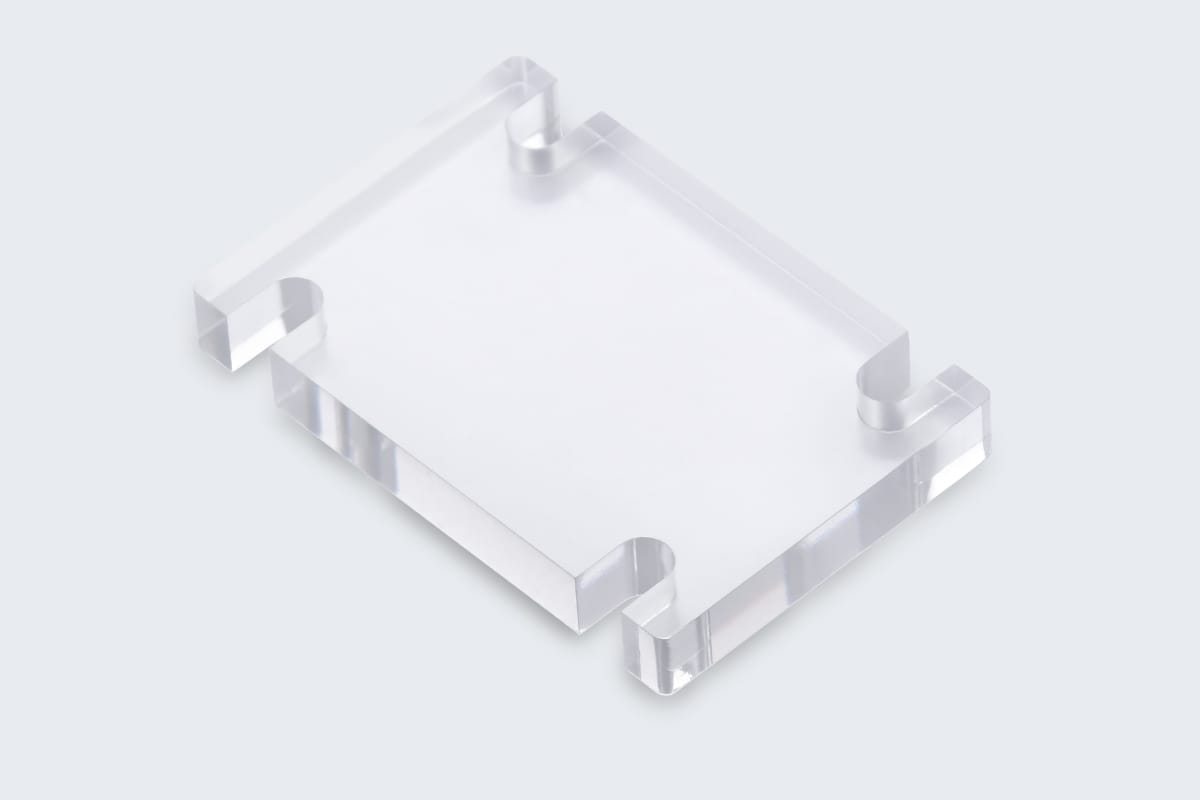

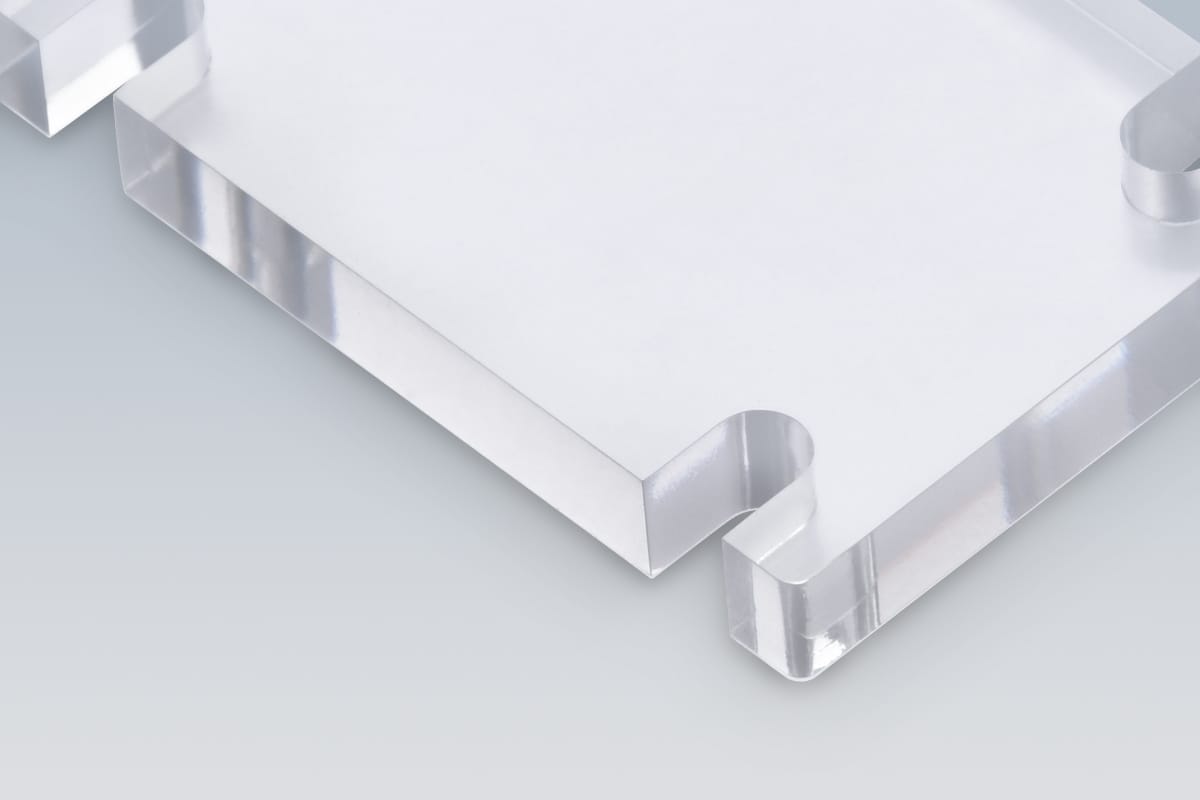

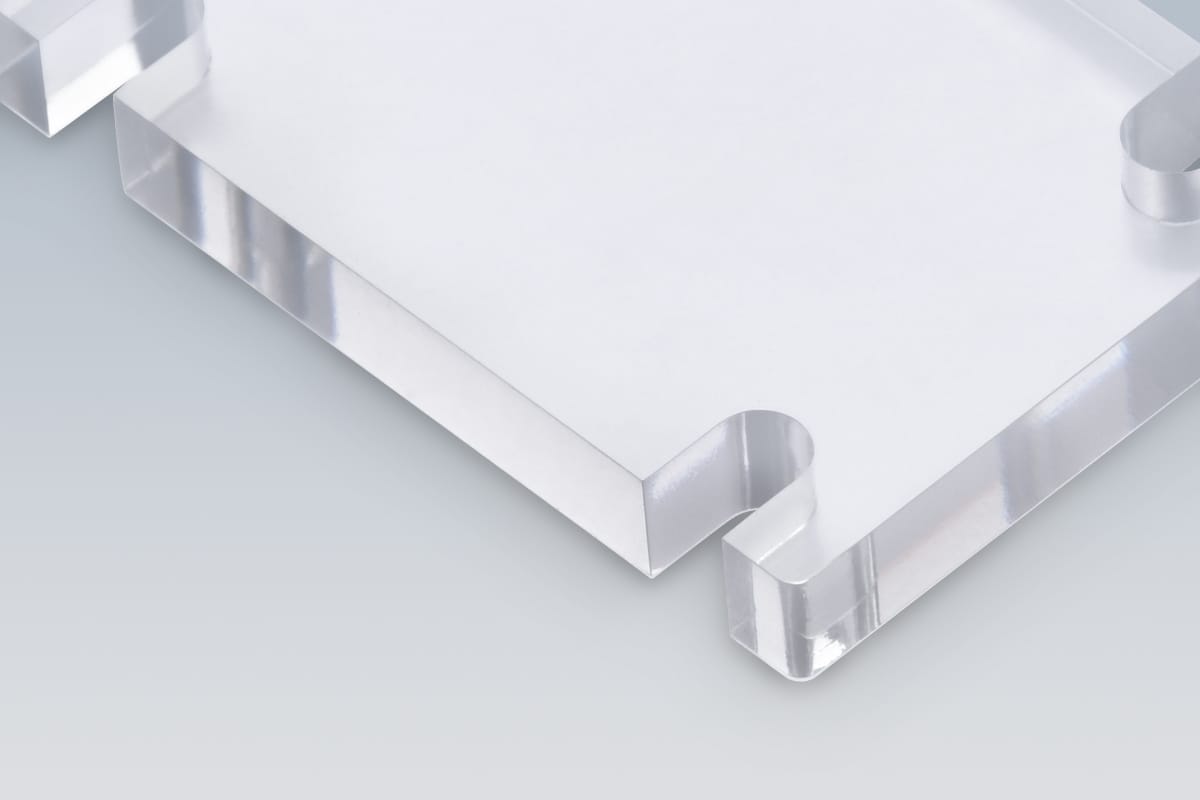

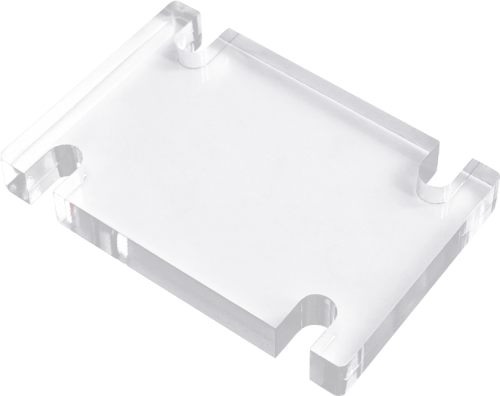

Example Of A Vapor Polishing Parts

About Vapor Polishing

Vapor polishing is a surface finishing technique used primarily with thermoplastic materials, such as acrylics (PMMA), to achieve a smooth and glossy finish on their surfaces. It is a chemical process that involves exposing the plastic part to vaporized solvent or a specific chemical mixture, allowing the surface to become slightly molten. As the plastic re-solidifies, it forms a smooth and clear surface.

Vapor polishing is often used in applications where a highly polished and transparent surface is desired, such as in the production of optical components, displays, signage, and various acrylic-based products. It is an effective way to improve the visual appeal of plastic parts and can be particularly useful for removing the “frosty” appearance that may occur during machining or laser cutting of acrylics.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.