In accurate production, acrylic (PMMA) and polycarbonate (PC) are the most commonly thought-of materials for transparent components. Even though they may appear identical, each has distinct features directly linking to product functionality, life, and cost.

PMMA (acrylic) has very good optical clarity, high surface hardness, and fair weather resistance, but poor toughness. PC (polycarbonate), on the other hand, is renowned for its extremely high impact strength and fair toughness, but it is more easily scratched and yellows when exposed to UV radiation for a long time.

We understand that the choice of right material is the success key of a project. In this respect, we here directly contrast PMMA and PC on the basic parameters of strength, hardness, weather resistance, and cost to help you make the most accurate and efficient choice for medical, electronic, or automobile parts.

Reference Table Of The Difference Between PMMA And PC

| Feature Dimension | PMMA (Acrylic/Plexiglas) | PC (Polycarbonate) | Winner |

|---|---|---|---|

| Transparency | Very high (up to 92%, better than glass) | High (88%-90%) | PMMA |

| Surface hardness | High (more scratch-resistant) | Relatively low (easily scratched) | PMMA |

| Toughness/Impact Resistance | Poor (hard but brittle, easily broken) | Very high (“unbreakable glass,” highly impact-resistant) | PC |

| Heat resistance | Low (continuous use, approximately 80°C) | High (continuous use, approximately 120°C) | PC |

| Weather resistance | Excellent (UV-resistant, low yellowing) | Good (but may slightly yellow with long-term exposure) | PMMA |

| Processability | Easy to cut, engrave, and polish | Easy to injection mold and extrude, but stress cracking must be avoided during processing | This depends on the process |

| Cost | Relatively low | Relatively high | PMMA |

| Typical applications | Advertising light boxes, display racks, landscape sheds, bathrooms | Safety glasses, explosion-proof covers, car lampshades, electronic transparent parts | – |

PMMA (acrylic) and PC (polycarbonate) are the two most common clear plastics, but they are quite different in their properties and applications. The choice is simply a matter of application priority.

For the choice of PMMA (acrylic):

- When high clarity, good surface scratch resistance, good weatherability (non-yellowing), and lower cost are prime considerations.

- Characteristic applications: Static displays (e.g., light boxes for advertising and display stands), landscape lighting ceilings that require high light transmittance, and bathroom equipment that requires high gloss and aesthetics.

When to use PC (polycarbonate):

- When extremely high impact strength and high heat resistance are of paramount importance.

- Typical applications: Any application that requires safety protection (e.g., safety glasses, blast shields, and bank windows), and components exposed to potential impact (e.g., automotive headlight covers and electronic product housings).

In short: PMMA is the choice for “aesthetics and weatherability,” and PC is the choice for “toughness and safety.”

Why Trust This Guide? Practical Experience From LS Experts

There is no shortage of material comparison data online, but what is typically missing is what that data means in terms of actual manufacturing in the real world. Every conclusion in this guide is derived from thousands of real-world projects at LS Precision Manufacturing, making it a decision-making system validated by CNC machining centers, injection molding lines, and product testing.

Four Reasons to Trust:

- Lessons Learned: We say “PC must be rigorously dried” because we’ve personally witnessed entire batches of parts being scrapped due to silver streaks and bubbles from negligence. We say “PMMA is brittle” because we’ve precisely measured its critical fracture point through hundreds of machining tests.

- A Balance Beyond Theory: Not only material characteristics, but also processability are also considered by us. PC is better in impact strength, yet tool wear when machining is 20%-30% higher compared to PMMA. PMMA is easily polishable to a mirror finish, yet PC bonding entails a more rigorous process. Our recommendations are the optimal compromise, considering performance, cost, and process.

- Responsible for Results: Because we’re your manufacturer, we stake our reputation on our recommendations. Incorrect use of PC for outdoor use, resulting in yellowing, or incorrect use of PMMA for load-bearing components, resulting in cracking, can directly result in the failure or success of both parties’ projects. Our recommendations, therefore, are extremely practical and conservative.

- Verified by hundreds of industry case studies: From ultra-high-transmittance PMMA for optical instruments to impact-resistant PC with toughened coatings for electronic housings to weathering tests of automobile headlamps, our database covers every major industry. We understand which materials and processes really perform under the most demanding conditions.

Depending on this guide is to gain from expert direction that has been proven in production, considers several factors, and provides accountability for results. We look forward to applying this experience to your next project.

What Is PMMA (Acrylic)? What Are Its Basic Properties?

PMMA, which is polymethyl methacrylate from a chemical perspective, is a widely used synthetic polymer. It’s more commonly referred to as acrylic or organic glass.

Its basic properties are as follows:

- Ultra-high transparency: The most significant advantage of PMMA is this. It has light transmittance of over 92%, higher than regular glass (about 80-90%) and even better than some optical glasses. It is called “plastic crystal” and possesses extremely good optical clarity.

- Excellent weatherability: PMMA boasts better weather resistance. It can withstand outdoor exposure over long durations, combating the sun and rain without yellowing, fogging, or gloss loss, and its physical properties do not significantly degrade.

- Good surface hardness but poor toughness: PMMA has one of the best surface hardness among plastics, making it less scratchable than other plastics. However, its toughness is poor, and its brittleness causes it to be more prone to cracking and breaking on impact, rather than bending or deforming. This is one of the key differences between it and tough plastics like PC (polycarbonate).

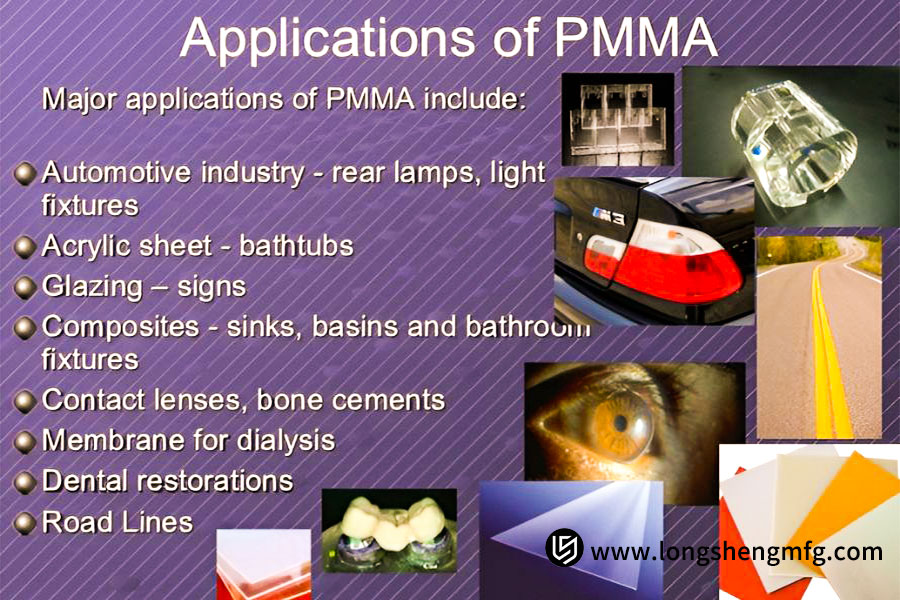

In brief, PMMA (acrylic) plastic is one that has excellent transparency and high weatherability, high surface hardness but comparatively low impact resistance. This has made it find wide usage in architectural lighting, advertising light boxes, automotive taillights, optical devices, bathroom fittings, and display racks of all types.

What is PC (polycarbonate)? What are its outstanding benefits?

PC, which is chemically polycarbonate, is a very good engineering thermoplastic. It is best described as “unbreakable glass,” a description that sums up its fundamental properties very well.

Advantages of PC:

- Extremely high impact strength (ultra-high toughness): This is the biggest and intrinsic advantage of PC. Its impact strength is among the highest for general-purpose plastics, 250 times that of ordinary glass and over 30 times that of acrylic (PMMA). It’s therefore highly resistant to impact and dropping. When subjected to powerful external force, it bends rather than shatters, so it’s widely used in safety-related applications.

- Good heat resistance: PC has the ability to withstand heat up to a temperature of about 120°C and even more (about 135°C) for short-term application. This allows it to maintain its shape and properties even at relatively high temperatures, far better than other clear plastics, i.e., PMMA (about 80°C). It is well suited for products that undergo high-temperature sterilization or come in contact with heat sources.

- Good transparency and mechanical strength: PC possesses high light transmittance (nearly 90%) inherently. Even though its optical transparency is slightly lower than that of PMMA, it is still good enough to meet the requirements of most applications. It also possesses high rigidity and good load-bearing capability, making it “hard and tough” a valuable characteristic.

Disadvantages of PC:

- Scratch-prone: It possesses a relatively low surface hardness of only around 3M Mohs, thus it is easily scratched by sharp items. Its abrasion resistance is worse than that of PMMA and glass. Therefore, a hardening coating for better scratch resistance is required by most PC products.

- Possibly Inadequate Chemical Resistance: PC is susceptible to certain chemicals, such as strong bases, aromatic hydrocarbons, and esters, which can cause stress cracking or dissolution.

- Poor long-term weathering resistance (unmodified): Prolonged exposure to ultraviolet (UV) light can lead to yellowing and brittleness. UV stabilizers are generally required for outdoor exposure.

Briefly, PC (polycarbonate) is an engineering plastic that has the most important advantages of being very impact-resistant and very heat-resistant, along with being quite transparent and rigid. Due to its “indestructible” quality, it has widespread uses in bulletproof glass, safety glasses, safety helmets, automobile headlights, medical equipment, electronic and electrical housings (e.g., mobile phones and notebooks), and baby bottles (widely used in the past, but now replaced to some degree by other materials).

What Is The Difference Between PC (Polycarbonate) And PMMA (Acrylic)?

In the category of engineering plastics, PC (polycarbonate) and PMMA (polymethyl methacrylate, also referred to as acrylic or plexiglass) are two very popular and easily comparable clear plastics. They appear similar but have very different inherent properties. The use of the wrong one can lead to project failure, excessive costs, or product defects.

1. Transparency

- PMMA: It is one of the clearest of all clear plastics, with light transmittance of up to 92%, even greater than that of regular glass. It is crystal clear with virtually no color cast and is frequently utilized where high optical performance is required, e.g., optical lenses, art display, and high-end window display.

- PC: Its light transmittance is also high at about 88-89%, but a very faint bluish or yellowish tint can be detected on close inspection. Its transparency is good enough for most applications but falls a bit short of the “ultra-transparency” of premium PMMA.

2. Hardness & Scratch Resistance

- PMMA: It boasts a harder and more scratch-resistant surface. Day-to-day friction and cleaning (such as wiping with a cloth) will not readily scratch its surface, a significant advantage.

- PC:PC’s biggest weakness is that it is soft, and its surface is very easy to scratch. Even scratching it forcefully with a fingernail will leave a mark. Therefore, a scratch-resistant hardened coating is applied to most PC products (such as eyeglass lenses and phone cases) to compensate for this weakness.

3. Toughness & Impact Resistance

This is the most basic and most common difference between the two.

- PMMA: Very brittle! While it is approximately 10 times more impact-resistant than glass, it will crack and shatter like glass under sufficient force, a classic brittle fracture.

- PC: Extremely tough! It is 10-20 times more impact-resistant compared to PMMA and is a familiar “unbreakable plastic.” It does not break so much as bend and deform, with high energy absorption power. Striking it with a hammer might whiten or dent it but is difficult to penetrate. Therefore, it’s used in blast shields, safety glasses, helmet visors, etc.

4. Heat Resistance

- PMMA: Heat deflection temperature is around 80-90°C. That is, it will soften and deform when subjected to continuous high temperatures (e.g., left next to a hot water bottle or in a car exposed to the summer sun).

- PC: Its heat deflection temperature is 120-130°C, making it more resistant to temporary heat. It has improved resistance to high temperatures and can be used in applications such as car lampshades, kettle bodies, and microwave ovens.

5. Weather Resistance (UV Resistance)

- PMMA: It has excellent resistance to UV and does not chalk or yellow even on long exposure outdoors. It also maintains good mechanical properties. This makes it an apt material for outdoor signs and advertisement boxes.

- PC: It is very sensitive to UV radiation. Without the use of UV protection treatment, it will degrade quite noticeably and become brittle after prolonged exposure to sunlight, with a sudden loss of strength and clarity. Outdoor PC must therefore be treated with UV stabilizers or a UV-resistant coating.

6. Price

- PMMA: With abundant raw material sources and a comparatively mature process, it is low in cost and a very cost-effective transparent material.

- PC: With more expensive raw materials and a more complex synthesis process, its price is considerably higher than that of PMMA.

Which Is More Expensive, PMMA Or PC? Why?

In plastic items, PMMA (polymethyl methacrylate, or acrylic) and PC (polycarbonate) are two well-liked high-performance items. Their cost differences matter significantly to numerous users. Overall, PC is more expensive than PMMA, largely due to raw material costs, performance disparities, and processing methods.

1. High Raw Material Costs

PC’s petroleum-based raw materials are more expensive than PMMA’s chemical raw materials. Furthermore, PC’s polymerization procedure is more complex and energy-intensive, directly adding to its fundamental cost.

2. Performance Benefits Justify a Premium

PC has superior mechanical strength, impact strength, and heat resistance (with the capability of being used for prolonged periods at temperatures up to 120°C) compared to PMMA. The advantage in performance is best manifested in drop-resistant and high-temperature-resistant applications such as electronic device casings and automotive parts.

3. Processing Difficulty and Cost

PC injection molding and molding must be at higher temperatures and more stringent process control (i.e., moisture-proof), so there is a higher rate of loss in processing. PMMA, on the other hand, is easy to process, easy to precision cut and shape, and has lower overall production costs.

Although PC is more expensive than PMMA, material selection should be based on actual demand: PMMA for high-transparency, low-load applications (e.g., ad light boxes), and PC for high-strength, high-weather resistance applications. Overall cost should be based on material characteristics, processability, and product lifespan.

The above analysis will allow you to more scientifically select the suitable material, cost and performance requirement balancing.

Case Study: Why Did LS Choose PC Over PMMA For Its Explosion-proof Observation Windows?

In the manufacture of safety equipment, the choice of material directly affects the level of protection and operational safety of the product. The LS Precision Manufacturing team was recently faced with the question of whether to utilize PMMA or PC when customizing a transparent explosion-proof observation window for a safety equipment manufacturer. Ultimately, PC, which boasts better impact resistance and flame retardancy, was the only choice and completed rigorous safety testing with ease.

1. Critical Requirements: Explosion Proofing and Safety

This explosion-proof observation window needed to maintain structural integrity under high pressure or explosive situations to prevent cracking and secondary damage. The team’s preliminary evaluation revealed the following:

- PMMA: While highly clear and cost-effective, it is not durable and has a tendency to experience brittle fracture upon impact, with potential flying debris and injury, which is non-compliant with explosion-proof standards.

- PC: With impact strength over 10 times that of PMMA, it can withstand high-energy impacts with bending or deformation only, rather than breaking. It also has a flame retardant rating (UL94 V-0), which can effectively suppress fire spread.

2. Testing and Verification Results

The LS team conducted comparative tests of the two materials:

- Drop ball impact test: PC sheet had no crack at 5J impact energy, while PMMA cracked under the same test;

- Environmental weatherability: PC had greater stability than PMMA in a -40°C to 120°C temperature range, versus embrittlement due to temperature fluctuation;

- Flame retardancy test: PC self-extinguished when removed from flame, while PMMA continued to burn.

3. Precision Machining Maximizes Performance

PC processing requires more rigorous process requirements (such as anti-hygroscopic treatment and high-temperature injection molding). Through strict temperature control and mold design, the LS team realized the final product as stress-free with transparency of over 90%, completely meeting the optical and structural requirements of the observation window.

Safety Value Far Exceeds Material Cost: Though PC is more expensive than PMMA, its explosion-proof safety and resistance significantly reduce the risk of failure and maintenance cost of the end product. This case verifies that performance-based material selection is the most cost-saving strategy in the protection and safety industry.

LS Precision Manufacturing empowers product safety through technology, helping customers create high-quality protection equipment!

How Do I Choose PMMA Or PC For My Application?

Based on the above comparison, make your choice according to your project’s critical needs:

Choose PMMA (acrylic) when you need:

- Ultimate optical clarity: Applications such as microscope slides, optical lenses, and high-end cosmetic display bottles.

- Scratch-resistant surface: Applications such as instrument panels, touch screen surfaces (maybe with a PC layer underneath), and signs.

- Outdoor long-term application: Applications such as light boxes for outdoor signage, skylights (domes) for buildings, and windows for transportation.

- Cost savings: In applications where impact resistance is less critical, PMMA is a cheaper option.

Choose PC (polycarbonate)when you need:

- Ultimate impact resistance and safety: Applications such as blast shields, safety glasses, labor masks, baby bottles, and phone covers.

- Need toughness and flexibility: Applications such as protective flexible covers, leaflets, and electronics housings.

- High-temperature resistance: Applications such as medical devices, hot water bottles, LED lampshades, and automotive headlight covers.

- Injection Molding of Complex Parts: PC has good fluidity and is extremely well suited for the manufacture of complex, thin-walled parts.

Precautions and Special Treatments

- PC Surface Hardness: If your application requires both impact strength and scratch resistance (e.g., eyeglass lenses), a hard coating can be applied to the PC surface to successfully increase its surface hardness.

- PMMA Toughness: If your application needs PMMA’s high clarity but is sensitive to cracking, look for impact-modified PMMA or try thickening it to enhance its flexural strength.

- PC Weatherability: For PC products that will be used outdoors, make sure to select sheets with a co-extruded UV protective layer or sheets with a high-efficiency UV inhibitor. Otherwise, they will prematurely age, yellow, and degrade in performance.

FAQs

1. Which is more scratch-resistant, PMMA or PC?

PMMA is significantly harder on the surface compared to PC, with a Rockwell hardness of M80-M90. It is less prone to scratching and it is easier to maintain it with a glossy finish. PC, while renowned for its high impact strength, features a softer surface, with a Mohs hardness of only about 3B, which scratches easily. Therefore, in applications that require high scratch resistance, such as in instrument panels, PMMA is typically the preference, or PC can be hardened through a coating for the same application.

2. Can PMMA and PC be differentiated visually?

It is difficult by visual inspection alone, but physical testing will aid. PC is extremely tough and will bend through large angles without shattering. PMMA is brittle and hard and will tend to whiten or even shatter under bending. Further, a tap with a metal object will give a nice, crisp sound on PMMA, and a quite dull sound on PC. Solvent testing (PC has higher alcohol resistance) is also a normal industry practice for the distinction between the two materials.

3. What are their respective temperature ranges of resistance?

PMMA also possesses a low heat deflection temperature of 80-95°C. It should be used at continuous temperatures below 80°C to avoid deformation from overheating. PC has significantly better heat resistance of 125-135°C. It is capable of withstanding short-term temperature over 120°C, and glass fiber-reinforced grades give additional enhancement. Special considerations depend on the material’s grade and load conditions.

4. Does LS offer custom processing for both PMMA and PC?

Yes, LS Precision Manufacturing offers customized processing for a variety of profiles, including PMMA and PC sheets and rods. We also possess various precision CNC and laser cutting and polishing equipment. We can provide professional material selection advice based on your application (e.g., optical lenses, covers, and parts) and complete the entire production process, including cutting and engraving, and surface hardening.

Conclusion

Both PMMA and PC offer excellent transparent materials. There’s no such thing as “better”; one is simply “more suitable.” Your choice should be based on a scientific balance of your product’s specific application, mechanical requirements, aesthetic standards, and budgetary constraints.

If you’re still hesitant about selecting materials for your project, please contact the technical team at LS Precision Manufacturing today. With years of material knowledge and processing experience, we’ll provide you with the most professional material selection advice and cost-effective precision processing solutions to help you achieve product success.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Hi my loved one I wish to say that this post is amazing nice written and include approximately all vital infos Id like to peer more posts like this

Attractive section of content I just stumbled upon your blog and in accession capital to assert that I get actually enjoyed account your blog posts Anyway I will be subscribing to your augment and even I achievement you access consistently fast

Your writing is like a breath of fresh air in the often stale world of online content. Your unique perspective and engaging style set you apart from the crowd. Thank you for sharing your talents with us.

Some truly interesting details you have written.Assisted me a lot, just what I was looking for : D.

Loving the information on this internet site, you have done outstanding job on the articles.

Thank you for your appreciation and kind words! I will continue to work hard.

Attractive section of content. I simply stumbled upon your web site and in accession capital to claim that I acquire in fact enjoyed account your weblog posts. Anyway I’ll be subscribing to your augment or even I fulfillment you get entry to persistently rapidly.