In precision manufacturing, material selection has a direct impact on product life, performance, and cost. Stainless steel is commonly used because it is highly corrosion resistant and strong. Being the two most utilized austenitic stainless steels, 304 and 316 are typically the focus of technical choice. So, then which is better, 304 or 316?

There is no straightforward answer to this question—the catch is in the application environment. 304 stainless steel, with its excellent corrosion resistance, formability, and affordability, is ideal for most conventional environments. 316 stainless steel, with additional molybdenum, however, significantly increases its chloride corrosion resistance and is ideal for harsh environments like chemical and marine applications. This article will address compositional differences, performance attributes, and corresponding applications of the two, help you make more economical material selections and provide design and manufacturing optimization of precision fabrication products.

304 vs. 316 Stainless Steel Selection Quick Reference

| Comparison Dimensions | 304 Stainless Steel (Austenitic) | 316 Stainless Steel (Austenitic) |

| Alternative Names/Grades | 18/8 Stainless Steel (18% chromium, 8% nickel) | Marine Grade Stainless Steel |

| Core Chemical Composition Differences | Cr (Chromium): ~18% Ni (Nickel): ~8% C (Carbon): ≤0.08% | Cr (Chromium): ~16% Ni (Nickel): ~10% Mo (Molybdenum): 2-3% |

| Corrosion Resistance | Excellent resistance to atmospheric, freshwater, and mild chemical corrosion. | Much superior to 304. Excellent resistance to chloride and acid corrosion, especially pitting and crevice corrosion. |

| Mechanical Properties | Moderate strength and hardness, good toughness, and a high work-hardening rate. | Slightly higher in strength and hardness than 304 (due to the molybdenum element), it also offers excellent toughness. |

| Machinability | Excellent. One of the easiest stainless steels on the market, it offers balanced performance in turning, milling, drilling, and tapping. | Good. Due to the molybdenum content, it exhibits increased toughness, which may lead to tool sticking and slightly greater tool wear than 304, requiring appropriate adjustment of machining parameters. |

| Cost | Low. The most common and economical stainless steel choice. | Higher (typically 20%-40% more expensive than 304). This is due to the higher price due to alloying elements (particularly nickel and molybdenum). |

| Typical Applications | • Household appliances, kitchenware, and tableware • Architectural decoration and hardware • Food processing equipment (non-severely corrosive environments) • General industrial containers, pipes, and racks | • Shipbuilding and offshore equipment • Chemical and pharmaceutical equipment (reactors and pipes) • Medical implants and surgical instruments • Building exteriors in coastal areas • Food processing in high-chloride environments |

Key Tips:

- Don’t Pay for “Excessive Performance”: If your product is only going into clean, dry indoor air environments or general consumer usage, 304 stainless steel is a perfectly adequate and cost-effective option.

- Invest in “Reliability”: If your product will be exposed to chemicals, saltwater, perspiration, or. deployed in mission-critical applications such as medical, marine, and energy, the additional cost of 316 stainless steel is a worthwhile investment in terms of long-term product life and reliability.

- Consult an Expert: As a professional precision manufacturing service firm, LS strongly suggests sharing the final working environment with our engineers. LS can make authoritative material recommendations by considering your specific working conditions (temperature, concentration, stress, etc.) so that your product is foolproof.

Why rely on this guide? LS experts’ real-world experience

The conclusions you observe aren’t based solely on textbooks or the world wide web; they’re the lessons LS Precision Manufacturing has acquired through hundreds of actual projects. We believe that these rules because they’re based on our hands-on production experience.

For starters, our understanding comes from direct machining experience. Our operators and CNC programmers have a very intimate understanding of the personalities of these two materials. They remember firsthand that cutting 316, as tougher, necessitates tweaking cutting parameters to avoid tool adhesion, which has a direct effect on production efficiency and cost. This hands-on knowledge is priceless and can only be acquired through high levels of practical exposure.

Second, it’s informed by our close study of component failures. We witnessed firsthand how a critical component which had mistakenly utilized 304 stainless steel in a chloride-bearing environment prematurely failed due to pitting corrosion. We’ve also been able to help a customer switch to 304 in a lower-stress environment and reap enormous cost savings. These positive and negative examples provide us with a complete understanding of where to concentrate and where to optimize.

Furthermore, we have a better understanding of cost. To us, cost is not the cost of purchasing the material; it’s the total cost, encompassing machining efficiency, tool life, and even product reliability throughout its lifespan. We are dedicated to providing you with the least-cost solution, not necessarily the most expensive material.

Finally, our perspective is pan-industry. From the strict requirements of 316 for medical devices to material selection under multiple operating conditions in food equipment, our work spans a wide range of industries. This allows us to put your needs in perspective and provide recommendations that have been proven in use.

Faith in this guide is placing your confidence in a manufacturer partner with in-depth material expertise. We are committed to utilizing such hands-on experience to ensure the quality of your products.

What is 304 stainless steel? What are its properties and typical applications?

304 stainless steel is the world’s most common and generally applied stainless steel material, commonly called “all-purpose stainless steel.” LS Precision Manufacturing will provide you with a concise idea of the composition, characteristics, and main applications of 304 stainless steel (such as household products, cooking utensils, and architectural ornament), which will make you familiar with this important material in depth.

1. Composition of 304 Stainless Steel

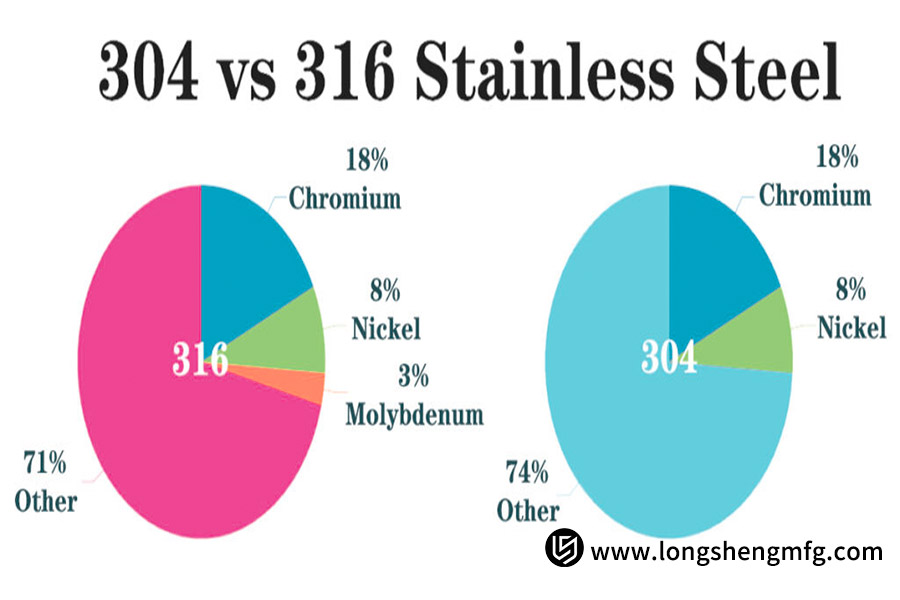

304 stainless steel is an austenitic stainless steel with the following primary ingredients:

Chromium (Cr): Approximately 18% offers corrosion and oxidation resistance.

Nickel (Ni): Approximately 8% enhances ductility and acid and alkali resistance.

Carbon (C): Less than 0.08% offers weldability and resistance to intergranular corrosion.

Other elements such as manganese (Mn) and silicon (Si) function as ancillary elements.

Because of the chromium-nickel content ratio of approximately 18:8, 304 stainless steel is also called 18/8 stainless steel.

2. Characteristics of 304 Stainless Steel

Great Resistance to Corrosion:It is resistant to corrosion from most inorganic and organic acids and alkalis at room temperature, thus can be utilized in humid and mildly corrosive environments (kitchen and outdoors).

Great Resistance to Heat:It can withstand cyclic high temperatures of up to 800°C and steady-state high temperatures of up to 925°C, and therefore perfect for applications in kitchenware and machinery manufacturing.

Easy Processability and Welding:It is highly ductile, easy to stamp, draw, and weld, and therefore perfect to make complex parts.

Hygienic and Eco-Friendly:It has a smooth, fouling-resistant surface, is odorless and non-toxic, food-grade compliant (e.g., GB4806.9-2016), and 100% recyclable.

Aesthetically Appealing and Low Maintenance:It can be polished or brushed to a metallic finish, is easy to clean, and resists long-term degradation.

3. Major Applications

Home and Kitchenware

- Kitchenware: pots, knives, sinks, and tableware (due to acid and alkali resistance and ease of cleaning).

- Home Appliances: Refrigerator linings, dishwashers, and casings of microwave ovens.

Architecture and Decoration

- Outdoor Decoration: Railings, security windows, curtain walls (weather-proof).

- Indoor Decoration: Stair railings, skirting boards, light fixtures (aesthetically pleasing and tough).

Industrial and Medical

- Food Industry: Storage tanks, pipes, and conveying systems (hygiene requirements).

- Medical Equipment: Surgical tools and sterilizing containers (corrosion-resistant and easy to clean).

Other Industries

- Chemical equipment, car exhaust pipes, sea accessories, etc.

4. Drawbacks of 304 Stainless Steel

Not suitable for very corrosive environments (such as sea climate or high-chloride environments). 316 stainless steel is to be used instead.

Extended exposure to acid or salt-like substances may cause pitting corrosion and requires regular maintenance.

304 stainless steel, highly corrosion resistant, easily machinable, and environmentally friendly, is an ideal material for homes, industry, buildings, and other uses. When selecting, consider its suitability in consideration of the specific demands of the environment. For even greater corrosion resistance, use 316 stainless steel. Under proper usage and care, it will last a very long time!

What is 316 stainless steel? Why is it called “marine steel”?

316 stainless steel is a next-generation type of 304 stainless steel and falls under the austenitic stainless steel category. The inclusion of the critical alloying component, molybdenum (Mo), gives it corrosion resistance several times greater than 304 stainless steel, particularly in the presence of chlorides. LS Precision will delve deep into the composition and characteristics of 316 stainless steel and explain why 316 stainless steel has the nickname “marine steel” and upper-level applications.

1. Fundamental composition and characteristics of 316 stainless steel

(1) Fundamental composition: Molybdenum (Mo)

316 stainless steel is a modification of 304 stainless steel (18% Cr, 8% Ni) with 2-3% molybdenum added. Molybdenum significantly increases the material’s resistance to pitting and crevice corrosion in chlorides (e.g., seawater, acid and alkali solutions) by forming a stable passivation film.

(2) Basic properties

Higher resistance to chloride corrosion: It can withstand corrosion from seawater, disinfectants, salt, etc. and is a higher grade of 304 stainless steel.

Improved high-temperature strength: It has good oxidation resistance and strength in high-temperature conditions.

Environmental protection and safety: It is pollution-free and non-toxic and can withstand rigorous certification (such as medical grade ISO13485, food grade GB4806.9).

2. Why is 316 stainless steel referred to as “marine steel”?

The “marine steel” of 316 stainless steel is 316 is also called “Steel”, which is named openly because it is indispensable in the marine environment:

(1) Suppression of marine chlorides

Marine atmosphere and seawater contain a lot of chloride ions. Regular stainless steel (such as 304) will suffer pitting corrosion (local perforation) due to chloride ion corrosion, while the molybdenum element of 316 can reasonably prevent this action.

(2)Strict demand of the shipping sector

Hull fittings: Seawater immerses ship railings, pumps and valves, and piping systems for long durations and must utilize 316 stainless steel against corrosion.

Navigation aids: Radar brackets, anchor chains, rudders, etc. are exposed to salt spray and must rely on the hardness of 316.

(3)Global standard acceptance

ASTM (American Society for Testing and Materials) and others have classified 316 as “marine grade stainless steel”, further reinforcing its industry position.

3.316 stainless steel Luxury application fields

Due to corrosion resistance, 316 stainless steel finds widespread application in harsh environments:

(1) Marine engineering and shipbuilding

Seawater desalination plant pipelines, coastal guardrails, submarine components.

Ship propellers, propeller shafts, offshore platform installations.

(2) Chemical and energy equipment

Chemical reactors, acid storage tanks, petroleum refining pipes (sulfuric acid, hydrochloric acid, etc. proof).

Nuclear power plant cooling systems, flue gas desulfurization units.

(3) High-grade medical devices

Scalpels, implants (e.g., bone screws), MRI equipment (due to non-toxicity and biocompatibility).

Pharmaceutical devices: culture plates, sterile vessels.

(4) Food and daily chemical industry

High-salt or acidic food process equipment (soy sauce fermentation tanks, etc.).

Cosmetic tanks, high-grade kitchenware (more anti-rust situations).

By incorporating molybdenum, 316 stainless steel has “enhanced corrosion resistance” in abrasive environments, making it the best choice for top-quality applications such as marine, chemical, and medical. That it’s also known as “marine steel” is a testament to its resistance to chloride corrosion. For selecting materials, 316 stainless steel is undoubtedly a more reliable investment when working in seawater, acid or alkaline concentrations, or high pressure and temperature environments.

Is 304 or 316 stainless steel superior?

When choosing stainless steel, the most often compared are 304 and 316. Most individuals incorrectly assume that “the higher the number, the better the performance,” but that’s incorrect. Neither is completely “better,” just “more suited.” Your specific application scenario and budget are what decide the right stainless steel to choose.

LS will provide straightforward comparison tables and a comprehensive analysis to help you quickly understand the differences between the two and make the most appropriate choice.

Key Differences at a Glance: Comparison Table

| Characteristics Dimensions | 304 Stainless Steel | 316 Stainless Steel | Winner |

|---|---|---|---|

| Core Composition | 18% Chromium, 8% Nickel (18/8 Stainless Steel) | 18% Chromium, 10% Nickel, 2-3% Molybdenum | 316 |

| Corrosion Resistance | Excellent: Resists most common organic compounds and acids and alkalis. | Excellent: Due to the addition of molybdenum, it offers excellent resistance to pitting corrosion from chlorides (such as seawater and salt). | 316 |

| Strength and Hardness | Good | Slightly higher in strength and hardness than 304 due to the addition of molybdenum. | 316 |

| High Temperature Resistance | Good: Withstands intermittent high temperatures of approximately 800°C. | Better: Withstands intermittent high temperatures of approximately 900°C. Has better oxidation resistance. | 316 |

| Processability | Excellent: Easy to stamp, draw, and weld. | Good, but slightly more difficult to process than 304. Tougher. | 304 |

| Cost | Affordable, high value for money. | Expensive: Due to the high cost of nickel and molybdenum alloying elements, it is typically 20%-40% more expensive than 304. | 304 |

| Common Applications | Home kitchenware, home appliances, water pipes, building decoration, food equipment | Marine vessels, chemical equipment, medical equipment, coastal buildings, high-end kitchenware | – |

1. Corrosion Resistance: Molybdenum is the Ace

- 304: It can be used in normal environments, such as air, water, and regular chemicals (excluding strong alkalis and acids). It’s best for sinks, plates, and home decor.

- 316: Its trump card is the presence of molybdenum (Mo). Molybdenum forms a more resilient passivation film, effectively resisting pitting and crevice corrosion caused by chlorides.

That’s why it’s a must-have in sea and chemical atmospheres.

2. Processability and Mechanical Properties

- 316 is a bit stronger and harder but not very much and not the major reason for choosing.

- 304 is more formable and weldable and hence a better choice to shape complex pieces.

3. Cost: The most practical factor

316 is very expensive compared to 304. Using 316 on non-critical applications will only increase costs. So, determining your budget is a crucial step.

Conclusion: There is no better, only more appropriate

(1) Use 304 stainless steel if your application scenario is:

- Domestic use on a daily basis: kitchen utensils, such as pots and pans, sinks, cabinets, home appliance covers, indoor stair railings.

- Regular buildings: building decoration, doors and windows, exterior railings in inland buildings.

- Food industry: non-corrosive storage in transport devices such as brewing and milk products.

Limited budget and not a special corrosion environment requirement.

(2) Choose 316 stainless steel if your application environment is:

- Marine and saltwater environment: marine ship parts, coastal guardrails, seawater desalination equipment, offshore operating platforms.

- Chemical industry: containers, pipes, valves in contact with acids, alkalis, chemical solvents.

- High-end medical: surgical instruments, implants, high-stability apparatus that is necessary in a sterilized environment.

- High-end or special kitchenware: high-end kitchenware that is in close contact with condiments such as salt and vinegar, or coast hotel kitchen utensils.

Final Advice:

Before you make the decision, think carefully through your conditions of operation (will it be exposed to salt, acid, or alkali conditions?), your budget, and product lifespan. Using the chart above as a guide, you can make the most economically intelligent and cost-saving decision.

Are there substantial price differences between 304 and 316 stainless steel? Why is the cost difference?

Yes, the difference is relatively significant. The price of 316 stainless steel tends to be 20% to 50% higher than that of 304 stainless steel, depending on market conditions, the volatility of the prices of alloying elements (mainly nickel and molybdenum), as well as on product shape (e.g., sheet, pipe, profile, etc.). The cause of this price difference is primarily based on fundamental differences in raw material costs as well as processing intricacy.

The principal explanation is simply the addition of molybdenum (Mo), which adds cost in three aspects:

- Raw material cost increase: Molybdenum is a strategically short metal and therefore expensive. The 2%-3% additional Mo in 316 stainless steel is the most direct reason why its material cost is significantly higher compared to that of 304 stainless steel, which contains chromium (Cr) and nickel (Ni) as the sole additions.

- High performance premium: This premium is paid for the superior performance provided by Mo. Molybdenum significantly enhances the passive film stability of stainless steel, providing 316 stainless steel with one of the best resistance to corrosion, particularly against chloride pitting. It therefore finds use in aggressive environments such as the marine and chemical industries, and its superior reliability and long lifespan warrant its higher price.

- Increased processing hardship: Molybdenum also causes 316 stainless steel to work-harden harder. What this means is that during cold working processes such as forming and cutting, it hardens and becomes resistant to wear, resulting in increased tool wear, more equipment power requirements, and increased overall production costs.

| Characteristics | 304 Stainless Steel | 316 Stainless Steel | Cost Impact |

|---|---|---|---|

| Core Composition | 18% Cr, 9% Ni | 17% Cr, 12% Ni, 2-3% Mo | The addition of expensive molybdenum to 316 significantly increases raw material costs. |

| Corrosion Resistance | Good, suitable for general environments. | Excellent, especially resistance to chloride pitting. | High performance premium, suitable for harsh environments, higher value. |

| Machinability | Relatively easy to machine. | Strong tendency to work hardening, rapid tool wear. | Higher manufacturing costs (tools, energy consumption, time). |

| Applications | Household goods, architectural decoration, kitchenware. | Marine, chemical, medical, coastal construction. | More critical applications allow for higher price points. |

The economic difference between 316 and 304 stainless steel is mainly an expense paid for the “molybdenum” alloy. The expense covers:

The premium price of the molybdenum metal itself.

The extra corrosion resistance and high-temperature service (performance premium) provided by molybdenum.

The increased processing complexity and tool wear caused by the molybdenum content.

Therefore, when choosing a material, if your area of use is likely to be exposed to excessive corrosion risks from chemicals, seawater, or salt, it is essential and a good investment to use 316 stainless steel. It ensures the long-term performance and safety of your equipment and avoids the costly maintenance and replacement based on corrosion. For normal dry or indoor use, 304 stainless steel is less expensive.

LS Precision Case: How to Properly Choose Materials for Medical Clients?

1. Strong Challenge: The Uncompromising Task of Medical Safety

A high-quality medical device manufacturer had to produce a shipment of precision surgical instrument trays that would survive repeated high-temperature, high-pressure steam sterilization on a daily basis as well as corrosion from a broad spectrum of aggressive chemical disinfectants (such as chlorine-containing agents). The client initially considered using the standard 304 stainless steel option.

2. Expert Judgment: Predicting and Controlling Risks through the Power of Technology

After intense scrutiny, the LS technical team rejected the 304 option. They noted that 304 stainless steel is chlorides sensitive and most susceptible to pitting and crevice corrosion under the stringent medical sterilization conditions, posing a serious safety hazard of bacterial growth and instrument contamination. LS strongly recommended and employed 316L stainless steel.

3. Precise Solution: Recommending the Optimal Material Solution

LS recommended and chose 316L stainless steel (022Cr17Ni12Mo2) most strongly. The most significant advantages of this choice are:

- Principal Element “Molybdenum”: The introduction of 2%-3% molybdenum (Mo) significantly enhances the material’s resistance to pitting corrosion in chloride media, effectively overcoming the essential issue of medical sterilization.

- Low Carbon Content Advantage: The lower carbon content even avoids intergranular corrosion that may occur due to welding and high-temperature sterilization, rendering the product stable and long-lasting.

- Lifecycle Value: The team was successful in convincing the client that although 316L has a slightly higher up-front cost, its longer life span, zero failure rate, and zero risk profile would save the client considerable potential costs of product scrap and medical accidents and allow for a more favorable lifecycle cost profile.

4. Exceptional Results: Establishing a New Benchmark for Medical-Grade Reliability

The finished product fully meets the most severe operation conditions. Under thousands of extreme high-temperature, high-pressure, and chemical sterilization processes, the surface of the tray is not touched, without rust, pitting, or deformation, providing ideal sterile storage and full security of medical appliances. Its outstanding performance won extensive praise and profound trust from customers and became a key strategic supplier of LS.

5. Core Lessons: Evolution from Supplier to Value Partner

The case perfectly embodies the core competitiveness of LS Precision Manufacturing: founded on extensive technical expertise, we always lay emphasis on the final needs of our customers. Not only do we provide precision manufacturing, but we also actively investigate technical risks and deliver value-added solutions. Our willingness to have the courage to say “no” to second-best solutions and our professional leadership to create long-term value for our customers is the answer to LS’s evolution from a “order processor” to a trusted “technical partner,” ultimately safeguarding the lives and health of patients.

How do I make the choice between 304 and 316?

Simply, 316 stainless steel has an additional chemical element called “molybdenum” compared to 304.

This “molybdenum” alloy greatly improves stainless steel’s corrosion resistance against chlorides (seawater, salt, and de-icing salt) and against corrosion from other chemical solvents.

You can obtain it like this:

- 304 stainless steel (18-8 stainless steel): 18% chromium and 8% nickel. It is the most widely used and economical stainless steel, resistant to corrosion in most ordinary exposures.

- 316 stainless steel of marine grade: Its 16% chromium, 10% nickel, and 2% molybdenum composition. The extra 2% molybdenum classifies it as a “naval steel.”

Easy option: What to use?

| Application Scenario | Recommended Choice | Reasoning |

|---|---|---|

| Kitchen sinks and countertops | 304 (in most cases) | In contact with water, detergents, oil, vinegar, etc., 304 is fully sufficient. |

| Home appliance housings (refrigerators, ovens) | 304 | In dry indoor environments, 304 offers excellent rust resistance and aesthetics. |

| Indoor decorations and furniture | 304 | In mild environments, no special corrosion requirements, 304 is an economical choice. |

| Architectural decoration (inland cities) | 304 | For curtain walls, railings, doors, and windows, 304 resists rain and atmospheric corrosion. |

| Coastal building exterior walls and railings | 316 | In salt-rich air, 304 is susceptible to rust, making 316 essential. |

| Marine fittings and seawater equipment | 316 | Direct contact with seawater or marine atmosphere, 316 is a “marine grade” standard. |

| Chemical industry equipment | 316 | Resists corrosion from a variety of chemicals and solvents, offering increased safety. |

| Medical surgical instruments | 316 | It requires frequent high-temperature disinfection and contact with various chemical disinfectants, and has extremely high corrosion resistance requirements. |

| Food processing, brewing, pharmaceuticals | 316 | The equipment needs to withstand acidic food materials, high temperature and high pressure cleaning, and chemical disinfection. |

| Swimming pool components | 316 | When exposed to chlorinated pool water for a long time, 316 has better resistance to chloride ion corrosion. |

Considerations

- Surface treatment is important: Regardless of whether it’s 304 or 316, surface finishes (such as mirror, brushed, or sandblasted) will affect its stain resistance and look but not its inherent chemical resistance.

- Maintenance is imperative: Even the best 316 stainless steel can be problematic if not properly maintained in hostile environments. Proper cleaning and maintenance can significantly increase its lifespan.

- Budget considerations: 316 stainless steel contains molybdenum, and so it is extremely costly as compared to 304 stainless steel. If it is appropriate for your use, 304 stainless steel is less expensive.

Briefly: Employ 304 stainless steel for cost savings and peace of mind; employ 316 stainless steel when acid and salt resistance are needed. Based on your specific application condition and your price point, utilize the above decision tree and scenario descriptions to make the optimal choice.

FAQs

1.Is 316 stainless steel totally rustproof?

Not quite. Due to molybdenum addition, 316 stainless steel is slightly more resistant to corrosion than 304 stainless steel under similar conditions, particularly in chlorided environments (such as sea water and road salt). Nevertheless, pitting and crevice corrosion may occur in extremely severe conditions, or due to mechanical damage or inadequate cleaning and maintenance destroying the surface passivation film.

2.Should I opt for 304 or 316 for a home kitchen sink?

The 304 stainless steel sink is far more than adequate for most households; its resistance to corrosion and price meet everyday needs. If you live in coastal areas (where air is high in chlorides), are accustomed to using highly corrosive cleaners, or want ultimate longevity and looks, you may choose the higher-priced 316 stainless steel, but this is not absolutely necessary.

3.Can you distinguish between 304 and 316 stainless steel with a magnet?

It cannot be depended on to identify. 304 and 316 stainless steels are both non-magnetic or weakly magnetic and austenitic under normal conditions, and thus the magnet attraction technique doesn’t work. Cold working (such as punching and cutting) can produce localized weak magnetism but will not be able to dependably identify the grade. Scientific methods utilize chemical reagents or spectral analysis to analyze the composition.

4.Does LS provide 304 and 316 stainless steel processing services?

Yes, LS Precision Manufacturing is a one-stop full-processing service factory for both 304 and 316 stainless steel. With abundant material inventory and advanced processing equipment, we offer customized one-stop services, ranging from process design consultation and material selection to precision cutting, forming, and surface treatment, to meet the high corrosion resistance and strength demands of customers from various industries.

Conclusion

The above comparison puts the debate over the superiority of 304 vs. 316 stainless steel to rest: there’s no such thing as a superior material, only the option that best suits your specific needs.

Thanks to its molybdenum addition, 316 exhibits exceptional chloride corrosion resistance, making it an ideal choice for harsh environments like chemical and marine applications. 304, on the other hand, offers excellent overall performance and affordability, making it a cost-effective option for most common applications, including food, medical, and household goods.

Your ultimate decision should be based on a delicate balance between the application scenario, budget constraints, and performance requirements. If you’re still unsure about the material selection for your specific project, please contact LS Precision Manufacturing. Our professional technical team will provide free material selection advice and solutions to ensure you achieve the optimal balance between performance and cost.

LS Precision Manufacturing, with its expertise in materials science, precision-casts every product for you.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

I am always browsing online for posts that can benefit me. Thanks!

This is very attention-grabbing, You are an overly professional blogger. I’ve joined your feed and look forward to searching for more of your excellent post. Additionally, I have shared your site in my social networks!

Thank you so much for your attention and for sharing my work; your support means the world to me! I will continue to work hard to create content that meets your expectations.

I absolutely love your blog and find many of your post’s to be precisely what I’m looking for. can you offer guest writers to write content for you personally? I wouldn’t mind creating a post or elaborating on a lot of the subjects you write regarding here. Again, awesome weblog!

I have read some just right stuff here. Certainly value bookmarking for revisiting. I wonder how so much attempt you place to create one of these great informative website.

Pingback: Five Common Myths About 304 Stainless Steel in 2025 - China's top engineering material supplier

Heya i’m for the primary time here. I came across this board and I to find It truly helpful & it helped me out a lot. I hope to provide one thing back and help others like you helped me.