CNC (Computer Numerical Control) machining has become increasingly popular in the manufacturing industry due to its numerous advantages over traditional machining methods.

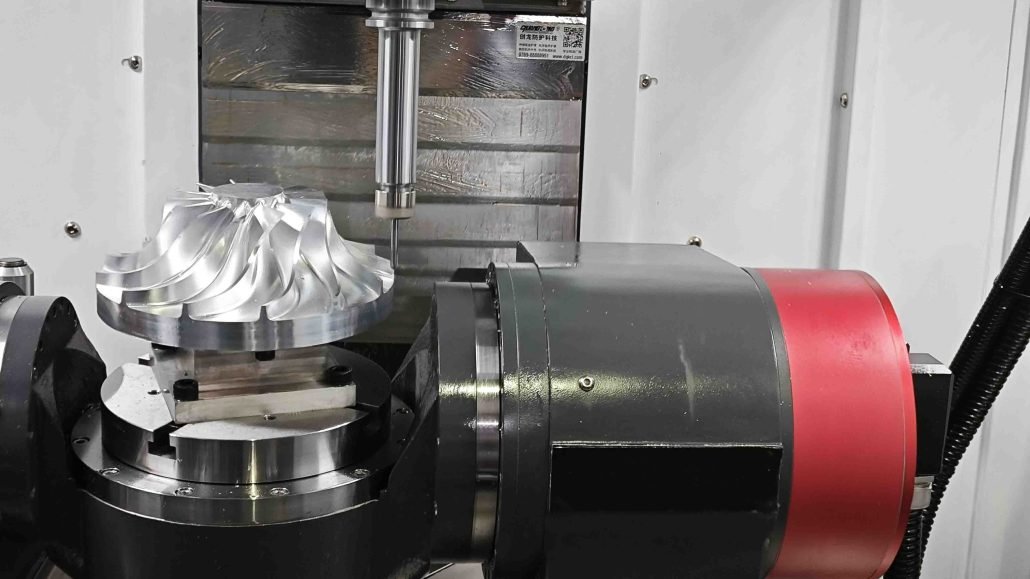

One of the key advantages of CNC machining is its ability to produce precise and complex parts with a high degree of accuracy and repeatability. By using computer-controlled machines, the process is automated and eliminates the need for manual labor, reducing the possibility of human error and increasing output. This is particularly beneficial for manufacturing parts that require a high level of precision and consistency, such as those used in the aerospace and medical industries.

Another reason CNC machining has gained popularity is its ability to produce parts quickly and efficiently. CNC machine parts are able to operate continuously, 24/7, and can produce large quantities of parts with consistent quality. This is particularly beneficial in industries that require high volume production, such as automotive, electronics, and consumer goods. The speed of production also means that parts can be manufactured and delivered to customers more quickly, leading to faster turnaround times and increased customer satisfaction.

CNC machining also allows for greater design flexibility. CAD (Computer-Aided Design) software can be used to create 3D models of parts, which can then be input into the CNC machine to produce the desired part. This enables manufacturers to produce custom parts quickly and more affordably than traditional manufacturing methods. With CNC machining, manufacturers can easily make modifications to a design without having to create new tooling, which can be costly and time-consuming. This flexibility is particularly beneficial for the prototyping phase of a project, where design changes are common and frequent.

Finally, CNC machining is also environmentally friendly. CNC machines produce less waste than traditional machining methods, as the machines are able to use raw materials more efficiently. This reduces the amount of material that needs to be disposed of, lowering the environmental impact of the manufacturing process. Additionally, because CNC machines are highly automated, they require less energy and labor to operate, making them a more sustainable and cost-effective manufacturing solution.

Overall, the numerous advantages of precision CNC machining have made it a popular choice in the manufacturing industry, offering increased efficiency, precision, and design flexibility while also reducing waste and environmental impact. As technology continues to evolve, it is likely that CNC machining will become even more advanced, making it an even more attractive option for manufacturers looking to stay competitive in today’s market.