CNC milling begins as a direct response to the core challenges in high-end manufacturing: achieving extreme part precision and consistency while managing complex designs, tight deadlines, and cost pressures. This is where the frustration of many engineers and procurement leaders lies: limitations in supplier capability and unstable quality, hence diminished project success.

CNC milling at a number of elite practitioners, such as LS Manufacturing, overcomes the variability of artisan-based CNC milling vs manual milling. Further, schedules for advanced processes involving new materials and geometries are put in jeopardy due to opaque project management. Only elite practitioners make it an ultimate tool that changes blueprints into flawless results through technical mastery along with transparency. Learn how you can unlock the full potential that it has in store for your project.

Quick Guide to CNC Milling

| Section | Key Point |

| Core Challenge | Provides unrivaled accuracy, coupled with sophisticated designs, tight deadlines, and budgetary pressures. |

| Pain Points | Supplier inability leads to variation in quality and causes project delays. |

| Root Cause | Most of the traditional approaches are based on a lot of manual skills where sophisticated capabilities are not present. |

| Solution | CNC milling ensures digitally correct, consistent, and automated processes. |

| Tech Advantage | Reliability in machining complex geometries and advanced materials. |

| Key Success | Process requires proper programming together with the right toolpath strategy and proper fixture design. |

| Partner Value | A supplier like LS Manufacturing provides the necessary capability with transparency of project. |

| Final Output | Turns digital blueprints into high performance, precision physical parts. |

CNC milling solves high-end manufacturing problems digitally because there is an elimination of human inconsistency. Complicated geometries can now be allowed alongside advanced materials. Success will then depend on professional execution regarding programming and control of toolpath. Specialized partners like LS Manufacturing ensure that technical expertise and transparent project management are catered to, seeing that quality is maintained. The company manufactures designs into reliable, high-performance parts with efficiency.

Why trust this guide? Practical experience from LS Manufacturing experts

Of course, there are a thousand and one articles on CNC milling online. Why should this interest you? The reason being, we do not just write about theories but what works on the factory floor. We solve real-life problems at our factory day in and day out, whether difficult alloys or tight tolerances. In fact, the insights herein have their root in solving real-life problems with verifiable results.

Our experience emanates from the capability to provide more than 50,000 custom-machined parts into critical industries. Each part, from high-stress aerospace brackets down to biocompatible medical implants, has honed our approach. This level of experience allows our processes to be sound and reproducible, supported by quality systems that are structured to assure process discipline according to the IATF16949 standard.

From feed and speed optimization in titanium to thermal distortion control in aluminum, every recommendation is tested under real cutting conditions. It’s the underlying principles we use that are checked through measurement practices traceable to the National Institute of Standards and Technology (NIST). It is this commitment to verification that enables us to take complicated blueprints and create flawlessly finished physical parts time and time again, truly precision CNC milling.

What is CNC milling, and how does it reach such a degree of precision and efficiency far beyond manual milling? What is involved in doing CNC milling in reality?

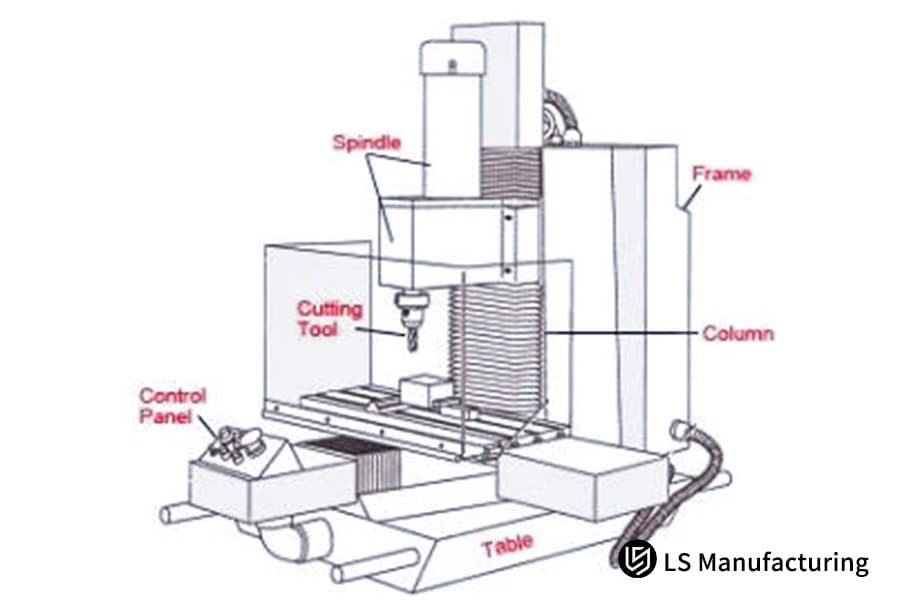

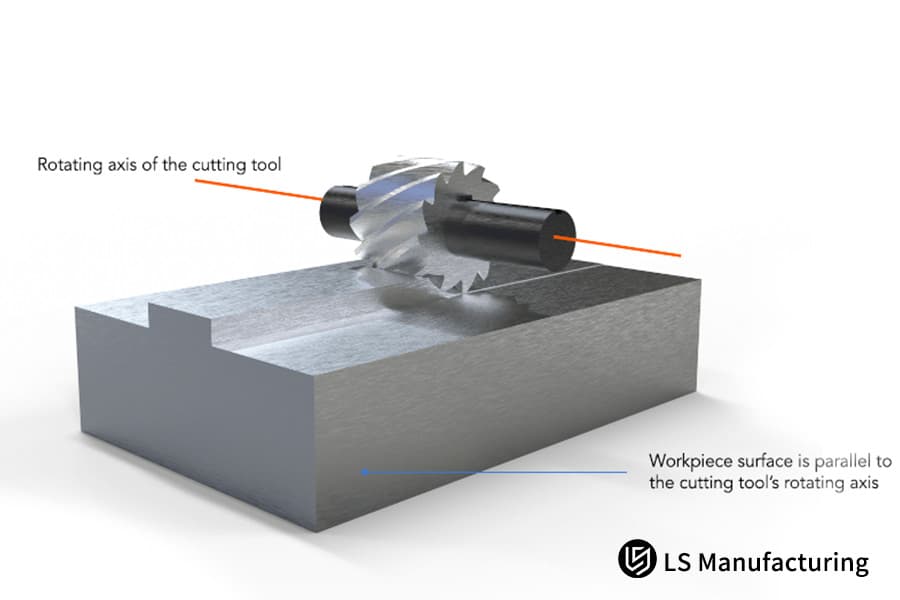

At its core, what is CNC milling?It is basically a computer-controlled subtractive manufacturing process. Inherent to the digitally programmed and instruction-driven nature lies itself the very backbone for accuracy and repeatability, constituting the heart of modern precision CNC milling. Here is where the LS Manufacturing CNC guide makes all the difference: we actually do not just follow the instructions but understand the principles and applications behind them.

- How it works: Multi-axis CNC machining machine units, guided by advanced CAM software and sophisticated CNC control systems, interpret digital designs into precise cutting paths. This shuts out human variability, so micron-level accuracy and repeatable performance are achievable.

- Comparison of the process: While manual milling relies on the operator’s skills, it is very inconsistent in CNC. As a matter of fact, what happens is a precision execution following programmed toolpaths to ensure efficiency and reliability are guaranteed, whether it be to do complicated jobs or high-volume outputs. ·

- Professional Implementation: Advanced multi-axis CNC systems utilized in the facilities at LS Manufacturing are combined with sophisticated CAM software. The combination allows us to realize what is truly synonymous with precision CNC milling: tight tolerances, complex geometries, and superior surface finishes.

What this essentially means is that CNC milling epitomizes the revolutionary leap in manufacturing where digital certainty replaces manual variability. It converts “what is CNC milling” as a technical question into a practical means whereby unparalleled accuracy and efficiency can be achieved. This is what precision CNC milling in modern times epitomizes, and this is how we at LS Manufacturing help bring into reality even your most demanding designs.

When selecting CNC milling services, what are the three core capabilities of the supplier that must be examined?

When evaluating how to choose a CNC milling service provider, one must look beyond quoted prices and lead times. The real differentiators that ensure project success lie in three critical operational pillars, which we will explore in detail. As a matter of fact, when considering how to choose a CNC milling service provider, prices and lead times quoted represent just a starting point. Real differentiators lie within three critical operational pillars that determine success for any given project, and which we will now consider.

- Knowledge of Equipment and Material: A truly reliable CNC milling partner in precision CNC milling will have multi-axis CNC centers, apart from showing experience in working with hard-to-machine materials, such as titanium and composites. This directly reflects the level of geometrical complexity of the part and achievable quality.

- Technical Process Knowledge: The more experienced a supplier is, the more capable of solving complex issues in manufacturing. Specialized process controls would include the management of distortions for thin-walled components to avoid expensive reworking while ensuring part integrity from the first article.

- Quality Assurance System: Confidence comes from verifiable proof. A well-structured quality system behind LS Manufacturing quality inspection employs tools like CMMs and laser scanners to validate each dimension against the original design for full compliance, ensuring traceability. Indeed, this is the best level of practice in CNC machining USA operations.

Capability and certainty form the cornerstones of selection when it comes to the selection of vendors. Rigorous assessment of equipment scope, applied process knowledge, and quality verification rigor secures for you the reliable CNC milling partner who will take complex designs and translates them flawlessly into high-performance parts executed with consistency.

What Are the Measurable Value Additions That CNC Milling Provides for Your Project?

There is more to manufacturing options than basic specifications. The real competitive advantage of CNC milling is in the direct and measurable impact it creates at the bottom line of your project and therefore drives tangible business value. Let us break these areas of impact down.

Reduced Overall Cost

Among the most important advantage of CNC milling is a contribution to the significant CNC machining cost optimization. This is by greatly reducing scrap rates due to precision repeatability, while at the same time it minimizes secondary operations. In regard to finishing cuts, it cuts down both material waste and labor time, improving your return on investment directly.

Accelerated Time-to-Market

The technology enables 24/7 automated production, thereby greatly compressing lead times. This speed boost to production is one of the fundamental ways wherein CNC milling improves production efficiency, because this truly rapid prototyping and scaling will get your product to market ahead of schedule.

Unlocked Design Freedom

Engineers are no longer constrained by traditional manufacturing limits. The capability of CNC milling to create complex, lightweight, single-piece components that consolidate assemblies means improved performance of better products, reduced part count, and a simplification of supply chains and, as such, adds value outside the shop.

The value of CNC milling has quantitative value-it reduces the total cost systematically and radically shortens development cycles; it also unblocks new, innovative design potential. These tangible benefits, which are reliably achieved for our customers here at LS Manufacturing, directly equate to increased competitiveness in the marketplace and better commercial results on your project.

For What Key Industries And Applications Does The Process Of CNC Milling Become Indispensable?

Considering the normal machining process, it is believed that through driving innovation and precision through the wide spectrum of industries, CNC milling has been a bedrock technology which has become so indispensable. Because of great power it holds regarding handling complex designs with sophisticated materials, it is crucially important in the following applications where performance, reliability, and accuracy are not to be compromised. Below is the table showing key sectors and their specific applications to which CNC milling applications come into play. Industry:

| Industry | Key Applications & Contribution |

| Aerospace | Aerospace CNC milling in aerospace is critical in the manufacturing of structure parts, engine mounts, and turbine blades; all these have to bear very high levels of stress and temperature. |

| Medical | The process provides for precision medical device part machining for implants, surgical tools, and diagnostic equipment where biocompatibility and exacting tolerances are critical. |

| Automotive | It is used to make high-performance prototypes, durable engine parts, and intricately designed molds that allow rapid innovation and mass production. |

| Electronics & Semiconductors | CNC milling fabricates precision housings, heat sinks, and connectors that ensure device integrity, miniaturization, and thermal management. |

For example, from providing the lightweight strength required in aerospace CNC milling to the precision which saves lives in the medical device part machining, these are core manufacturing solutions which prove capable of satisfying the demands imposed by various high-stake fields. This underlines its position as a cornerstone of modern engineering and production.

How To Maximize CNC Milling Benefits With Cost Control By Design Optimization?

While the CNC milling allows great flexibility, upfront design choices can greatly affect final part quality, lead time, and cost. The best way to ensure value is by following DFM principles. Here is a functional CNC milling design guide that points out some of the major ways you can optimize your design for efficient production. ·

- Optimize Geometry for Machining: Incorporate features like appropriate internal corner radii (matching standard tool sizes) and consistent wall thickness. This avoids specialized tools and reduces machining time, directly helping control CNC machining costs.

- DFM Guideline: Avoid complex setups design parts to be machined in fewer orientations. The fewer number of fixturing setups a part requires in production, the less labor time is used, errors decrease, and delivery speeds up.

- Take Advantage of Standardized Features: In other words, just use standard hole sizes, thread types, and available tool geometries where possible. This eliminates special tooling needs, simplifies the process, and significantly enhances CNC machining cost control. Otherwise stated, intelligent design is the first and most important step in effective manufacturing.

By using these DFM guidelines, you avoid manifold issues while going into production, ensuring better parts more quickly. Furthermore, invite you to draw on that experience by providing a free DFM analysis where our engineers will look at your design and offer detailed suggestions to help optimize your part for performance and value.

LS Manufacturing – Aerospace – Case Study Precision Milling Solution for High Reliability UAV Landing Gear Brackets

Below is the LS Manufacturing case study that represents how systematic engineering coupled with UAV parts processing can solve critical field failures. We would depict how, in real life, addressing a reliability problem of one of its key load-bearing components faced by a maker of high-end industrial drones is addressed.

Customer Challenge

It is a very critical structural part of the customer’s landing gear bracket. A 5% field failure rate was realized from these parts. These failures were supplied by the previous supplier and caused by hidden machining cracks. Such a too-high rate severely compromises product reliability and brand trust; thus, there is an urgent need for a robust solution to drone part machining that will be able to guarantee structural integrity.

LS Manufacturing Solution

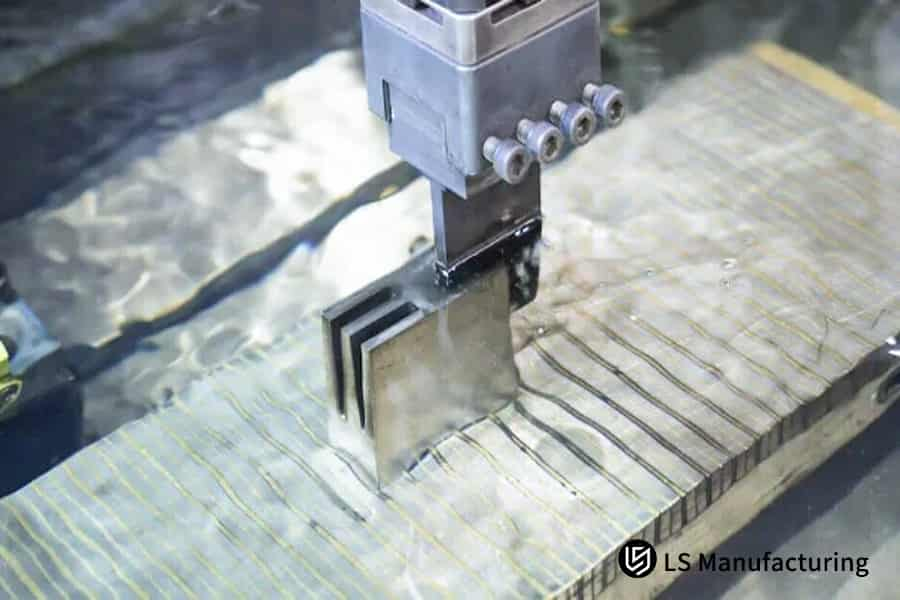

We optimized the design of the bracket by performing finite element analysis. By using our 5-axis simultaneous milling centers, we CNC-machined the optimized part out of high-grade aerospace aluminum alloy to enable the completion in one setup, thereby avoiding re-fixturing errors in the process of the aerospace aluminum part CNC machining. Every part underwent 100% fluorescent penetrant inspection to ensure zero internal defects and thereby offered comprehensive precision milling solution.

Results & Value

This created transformative value in that the delivered aft section had a 15% weight reduction, increasing structural strength by 20%. The customer failure rate in their assembly line went below 0.1%. Continuing this effort to shorten lead times as much as 30%, our project management firmly placed LS Manufacturing as a strategic manufacturing partner with the client.

The project thus demonstrated that true precision manufacturing encompasses the best available analytical techniques, process control, and tight validation. This work underlined that precision milling solution focused can deal with critical field failures with a view to enhancing performance for its products by building continuing partnerships based on proven reliability and value.

Are you looking for a reliable partner in precision milling? Please do not hesitate to contact us today for an ideal solution as far as CNC milling is concerned.

How does the CNC milling stand in comparison with other current processes like 3-D printing?

Basically, the choice comparison of CNC milling and 3D printing is very crucial where the choice of manufacturing process applies, since each applies to particular scenarios. how to choose the machining process comes down to understanding your project’s particular needs with regard to material properties, precision, volume, and cost. The following chart examines a variety of advantages of CNC milling in those applications where ultimate performance and reliability are required.

| Aspect | CNC Milling (Advantages) | 3D Printing (Common Uses) |

| Material Strength | Provides the parts with isotropic and fully-dense characteristics of the material. Applications best for functional, load-carrying parts. | Parts may show anisotropic properties and possess internal porosity; ideal applications are prototypes and parts that are non-structural. |

| Surface Finish | Can achieve excellent, ready-to-use surface finishes direct from machine with little or no post-processing. | Generally requires heavy finishing in order to achieve smooth surfaces or tight tolerances. |

| Production Volume | Smaller In-cycle times and superior material economics yield significantly better per-part costs at higher volumes | Lower-cost at very low volumes for complicated one-offs, or designs that cannot be machined. |

| Tight Tolerances | Achieves very tight dimensional tolerances combined with very high repeatability from lot to lot. | Capability for tolerance in general is less strict than that of milling; it is more processand material-dependent. |

The key difference is that CNC milling performs better when higher mechanical properties and surface quality, higher accuracy are in need for your application, such as end-use parts for critical industries. That is where the production of bridges and large batches really shines; consistency and speed drive down the cost. Understanding the limitations of CNC milling, such as geometric constraints for internal features, is also part of a thorough process selection. As a comprehensive provider, the best LS Manufacturing solution often integrates both technologies, selecting the ideal process—or combination—to precisely match your technical and commercial goals.

FAQs

1. What is the LS Manufacturing average lead time for CNC milling?

Urgent project needs are met through our capabilities in concurrent engineering management. For example, one of our medical clients received its project 5 days in advance.

2. What is MOQ? Do you support prototyping?

From a single prototype to mass production, everything is supported, flexibly meeting the needs of R&D and production.

3. How would you protect my product design and IP?

LS Manufacturing is ISO27001 certified, and we have signed strict confidentiality agreements, or NDAs, with all our clients, so your intellectual property is 100% secure.

4. What type of material do you specialize in processing?

More than 50 types of metallic and non-metallic materials, including engineering plastics and high-temperature alloys, can be treated in our company. We also provide material selection counseling.

5. What surface treatments are available?

We provide one-stop service for such various surface finishing as anodizing, electroplating, and sand blasting to reinforce performance and appearance.

6. How does your pricing work? How would someone obtain a detailed quote?

Material, processing time, and process complexity are the major price determinants. Please submit your 3D drawings for transparent quotation within one hour.

7. Do you accept orders from other countries?

Yes, we have an exceptionally well-settled logistics system that guarantees safety and punctuality in the delivery of parts from any part of the world.

8. Suppose there is some quality problem with the machined parts?

We promise 100% quality assurance, and one full detailed inspection report will be provided. In case of an issue unmatched to our inspection, unconditional reworks or remakes of the parts would be done.

Conclusion

Besides technology itself, CNC milling is about building partnerships to deliver excellence in product requirements. A partnership with LS Manufacturing offers deep expertise forged in the fire of extensive experience, seamless project management, uncompromising quality defining every stage of production.

Your project requires precision in manufacturing quality that LS Manufacturing provides. Upload your drawings today to get free DFM analysis and instant quote, or schedule a one-on-one consultation with our technical specialists. Let us help push your next project over the top.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.