In the fields of manufacturing and engineering, 7075 aluminum and 6061 aluminum are common aluminum alloy materials. They each have their own characteristics and advantages, and are suitable for different application scenarios.

This article will compare the chemical composition, mechanical properties, heat treatment characteristics, corrosion resistance, and wide application fields of these two aluminum alloys in detail, to help you make wise decisions when selecting materials.

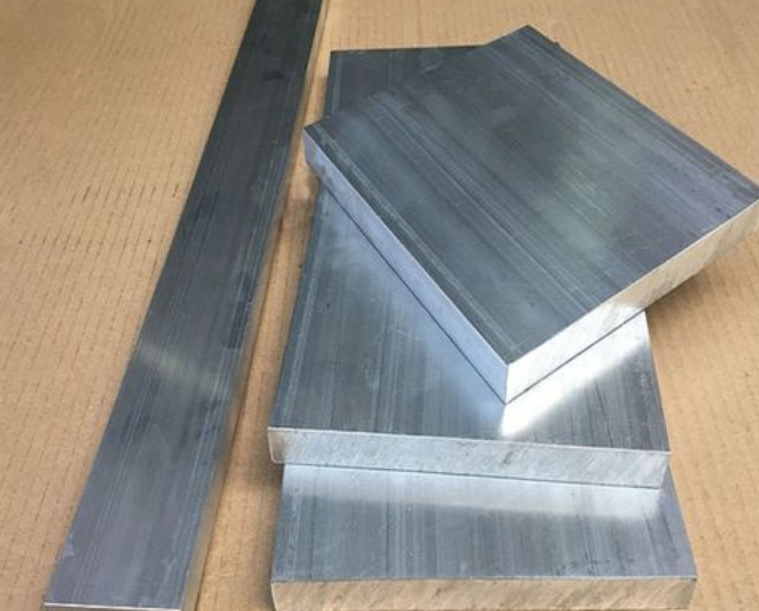

7075 aluminum

7075 aluminum alloy has excellent strength characteristics and corrosion resistance. Due to the addition of an appropriate amount of elements such as zinc, copper, and chromium, 7075 aluminum can maintain stability in various corrosive media and exhibit high corrosion resistance to most common corrosive media.

Although 7075 aluminum alloy is relatively hard, it still has good machinability. It can be operated through various machining methods such as cutting, milling, stamping, and welding, making it easier to form complex parts and structures.

6061 aluminum

6061 aluminum has good processability and corrosion resistance compared to 7075 aluminum, and it can resist the erosion of most common corrosive media, including water, air, acid, and alkali. It can be formed through machining methods such as cutting, milling, stamping, and welding, while maintaining high accuracy and surface quality.

It can also be connected by various welding methods, such as TIG welding, MIG welding and Electric resistance welding. This provides more flexibility and convenience for the manufacturing process.

Compare 7075 Aluminum vs 6061

Let’s take a brief look at the difference between 6061 and 7075 aluminum? In this section, we will compare based on several different parameters.

7075 Aluminum vs 6061 Chemical Composition

7075 aluminum and 6061 aluminum are two common aluminum alloys that differ in multiple aspects. Please continue reading to learn more. Below are their comparisons in terms of strength, density and weight, corrosion resistance, processability, and price and availability:

7075 aluminum vs 6061: strength comparison

The following table compares the strength of 7075 aluminum and 6061 aluminum:

| Strength Parameter | 7075 Aluminum | 6061 Aluminum |

|---|---|---|

| Yield Strength(MPa) | 524 – 572 | 276 – 310 |

| Tensile Strength(MPa) | 572 – 607 | 276 – 310 |

| Elongation(%) | 11 – 17 | 8 – 12 |

7075 aluminum has higher strength and is a high-strength aluminum alloy commonly used in applications with high load and strength requirements. 6061 aluminum also has good strength characteristics, but is slightly lower compared to 7075 aluminum.

7075 aluminum vs 6061: density and weight comparison

Below is the table comparing the density and weight of 7075 aluminum and 6061 aluminum:

| Parameter | 7075 Aluminum | 6061 Aluminum |

|---|---|---|

| Density (g/cm³) | 2.81 | 2.70 |

| Weight (g/cm³) | 2.81 | 2.70 |

The density of 7075 aluminum is about 2.81 grams per cubic centimeter, which is relatively high. The density of 6061 aluminum is about 2.70 grams per cubic centimeter, which is relatively low. Due to differences in density, 7075 aluminum in the same volume is heavier than 6061 aluminum.

7075 aluminum vs 6061: comparison of corrosion resistance performance

Here is a table comparing the corrosion resistance of 7075 aluminum and 6061 aluminum:

| Corrosion Resistance Performance | 7075 Aluminum | 6061 Aluminum |

|---|---|---|

| General Corrosion | Moderate | Moderate |

| Atmospheric Corrosion | Good | Good |

| Chemical Corrosion | Moderate | Moderate |

| Galvanic Corrosion | Moderate | Moderate |

| Stress Corrosion Cracking | Prone to effect | Strong resistance |

7075 aluminum has good corrosion resistance and exhibits high corrosion resistance to most common corrosive media.6061 aluminum also has good corrosion resistance, but it is slightly inferior to 7075 aluminum.

7075 aluminum vs 6061: machinability comparison

Here is the comparison table of machinability between 7075 aluminum and 6061 aluminum. Please note that machinability can be influenced by various factors, including alloy composition, heat treatment condition, and machining methods. Therefore, the following data is for reference only.

| Property | 7075 Aluminum | 6061 Aluminum |

|---|---|---|

| Strength | High | Medium |

| Forgeability | Good | Good |

| Machinability | Moderate | Good |

| Weldability | Poor | Good |

| Formability | Fair | Good |

| Rivetability | Good | Good |

| Drawability | Good | Fair |

| Machining Stability | Poor (Prone to deformation and cracking) | Good |

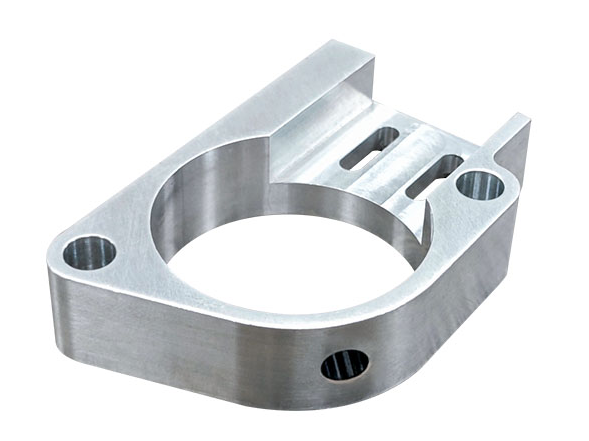

6061 aluminum has good machinability and is suitable for various machining methods, such as cutting, milling, stamping, and welding, to form complex parts and structures.7075 aluminum is relatively hard and difficult to machine, but it still has a certain degree of machinability and can be machining through professional machining methods.

7075 aluminum vs 6061 price and availability

Here is the comparison table of price and availability between 7075 aluminum and 6061 aluminum, covering the price ranges in recent years.

| Year | 7075 Aluminum (USD/pound) | 6061 Aluminum (USD/pound) | Availability of 7075 Aluminum | Availability of 6061 Aluminum |

|---|---|---|---|---|

| 2018 | 2.5 – 3.0 | 1.8 – 2.2 | Moderate | Wide |

| 2019 | 2.3 – 2.8 | 1.6 – 2.0 | Moderate | Wide |

| 2020 | 2.0 – 2.5 | 1.5 – 1.8 | Moderate | Wide |

| 2021 | 2.2 – 2.7 | 1.6 – 2.0 | Moderate | Wide |

| 2022 | 2.5 – 3.0 | 1.8 – 2.2 | Moderate | Wide |

| 2023 | 2.3 – 2.8 | 1.6 – 2.0 | Moderate | Wide |

6061 aluminum has a lower price compared to 7075 aluminum, is more common and widely used, and is easy to obtain and supply.The price of 7075 aluminum is relatively high and the supply is relatively small, usually used for specific high-strength and demanding applications.

Application fields of 7075 aluminum and 6061 aluminum

The following are examples of common application parts for 7075 aluminum and 6061 aluminum in different industries:

7075 aluminum

1.Aerospace industry: aircraft structural parts, aircraft wings, fuselage parts, satellite components.

2.Military applications: military equipment parts, missile parts, fighter and helicopter parts.

3.Sports equipment: mountaineering equipment, bicycle components, shooting equipment.

4.Automotive industry: wheels, steering rods, suspension system components.

5.Compressed gas container: high-pressure gas container, such as compressed air cylinder and Oxygen tank.

6061 aluminum

1.Automotive industry: body components, engine parts, suspension systems, and wheels.

2.Building and building materials: door and window frames, staircase handrails, roof materials, and vertical panels.

3.Ship manufacturing: hull, mast, and internal components of the ship.

4.Electronic products: shell, heat sink, connector.

5.General industrial applications: Machine element, pipes, containers, molds.

machining characteristics of 7075 aluminum and 6061 aluminum

7075 aluminum and 6061 aluminum are commonly used aluminum alloy materials, which have wide applications in industrial and manufacturing fields. There are some differences in the machining characteristics between these two aluminum alloys. The following is a detailed introduction to the machining characteristics of 7075 aluminum and 6061 aluminum:

7075 aluminum vs 6061: cutting performance

Here is the comparison of the machining characteristics between 7075 aluminum and 6061 aluminum in table format:

| Machining Characteristics | 7075 Aluminum | 6061 Aluminum |

|---|---|---|

| Hardness | High | Moderate |

| Machinability | Difficult | Easy |

| Cutting Speed | High | Moderate |

| Cutting Force | High | Moderate |

| Cutting Heat | High | Moderate |

| Chip Formation | Long, continuous chips | Short, manageable chips |

| Tool Wear | High | Low |

Conclusion: There are some differences in cutting performance between 7075 aluminum and 6061 aluminum. 7075 aluminum has high hardness and strength, so it may face higher cutting forces and cutting heat during the cutting process, posing higher requirements for cutting tools and processes. In contrast, 6061 aluminum has better cutting performance, relatively easy control of the cutting process, and lower cutting force and heat.

7075 aluminum vs 6061: welding performance

Here is the comparison of the welding performance between 7075 aluminum and 6061 aluminum in table format:

| Welding Performance Characteristics | 7075 Aluminum | 6061 Aluminum |

|---|---|---|

| Weldability | Poor | Good |

| Welding Methods | Typically utilizes high-energy welding methods such as inert gas shielded arc welding, resistance welding, and laser welding | Typically utilizes standard welding methods such as inert gas shielded arc welding, resistance welding, and laser welding under conventional gas protection |

| Welding Deformation | Prone to occur | Relatively small |

| Weld Seam Strength | High | Moderate |

| Post-Weld Treatment | Typically requires heat treatment to restore the strength and hardness of the welded area | Generally does not require heat treatment, and the performance of the welded area remains relatively unchanged |

Conclusion: 7075 aluminum has poor weldability and is prone to welding deformation during the welding process. It is usually necessary to use high-energy welding methods and undergo heat treatment after welding to restore the strength and hardness of the welding area. In contrast, 6061 aluminum has better welding performance, usually using conventional welding methods, with less welding deformation, and the performance of the welding area remains basically unchanged.

If welding performance and deformation are crucial, then 6061 aluminum is a more suitable choice. However, if higher welding strength and hardness are required, as well as the need for post weld heat treatment, then 7075 aluminum may be more suitable.

FAQ

6061 aluminum alloy is easier to machine because it has good machinability and weldability. 7075 alloy is relatively difficult to machine and requires higher cutting speeds and forces.

Aluminum alloy is usually considered an environmentally friendly material because it can be recycled and can reduce resource waste. However, energy consumption and emissions may vary when producing these alloys. Environmental considerations usually involve the entire production process, not just the characteristics of the alloy.

conclusion

Through the comprehensive comparison and detailed guidance in this article, you should now have a clearer understanding of the characteristics, mechanical properties, application fields, and machining characteristics of 7075 aluminum and 6061 aluminum. Based on your specific project requirements, selecting suitable aluminum alloy materials and considering optimized machining methods will bring the best performance and results to your project. If you need further consultation or customized suggestions, please feel free to contact our professional team at any time.