CNC prototype machining does indeed play a crucial role in overcoming product development bottlenecks. However, 3D-printed parts often lack the strength for practical testing, and outsourcing traditional parts typically involves long lead times and opaque pricing, delaying the validation process. The problem stems from the rigidity and inefficiency of traditional manufacturing processes, causing teams to miss market opportunities while waiting.

LS Manufacturing further integrates online instant quoting with professional manufacturing services. Therefore, it helps to get your functional prototypes ready for testing in just a few days, accelerating your time-to-market significantly. This article will dive into this path of efficiency and see how it can fundamentally change your experience of prototyping.

CNC Prototyping Full-Text Quick Reference Table

| Module Theme | Key Takeaways Overview |

| Core Value | Rapidly create high-precision, high-strength functional prototypes for real-world testing and validation. |

| Applicable Scenarios | Solves problems like the insufficient strength of 3D printed parts and long lead times of traditional manufacturing to meet the demands for rapid iteration development. |

| Key benefits | Variety of materials to use; high precision; prototype performance very close to final products, which greatly reduces development risk. |

| LS Manufacturing Solutions | Offer a full spectrum of integrated services, ranging from instant online CNC machining quotes and professional DFM analysis to rapid manufacturing. |

| How to Get Started | Upload your 3D model file to get a transparent quote and lock in a production schedule in minutes. |

What is CNC prototype machining? It is, overall, an essential bridge from innovative designs to reliable products. Collaboration with companies like LS Manufacturing enables integrated services to digitally enhance and directly translate efficient manufacturing capability into advantages in development speed—a key factor that keeps you ahead of the competition.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

This handbook draws on the LS Manufacturing team’s fifteen years of technical work experience in high-end manufacturing. We have developed many unique insights into precision control, material properties, and process optimization through our cross-disciplinary practical experience.

What makes this guide unique is the transformation of practical experience into a reusable methodology. Based on more than 50,000 complex 5-axis machined parts, we developed a systematic technical methodology with the goal of providing not just machining services but robust technical solutions.

By integrating authoritative industry standards such as ASTM B117 and SAE J404 with our extensive hands-on expertise, this guide delivers innovative and highly dependable professional support tailored to your prototype development needs. This dual approach bridges the critical gap between theoretical benchmarks and practical application, ensuring your prototypes are both rigorously validated and commercially viable.

Why is CNC prototyping the generally accepted gold standard in functional verification?

When your project requires rigorous functional verification, CNC prototyping machining is undoubtedly the preferred solution. In comparison with technologies like 3D printing, it establishes its “gold standard” status for functional verification along three core dimensions:

Material authenticity

The materials employed in the manufacturing process of prototypes with CNC machining are the same as the engineering plastics and metal materials of the final mass-produced product. Because of this consistency in materials, in essential mechanical properties such as strength, temperature resistance, and fatigue resistance, the prototype is highly consistent with the final product, giving highly predictive and reliable test results.

Structural Integrity

Traditional 3D printed parts have anisotropy and weak interlayer bonding, hence leading to the structural fragility of the part. A CNC prototype, because of the machining from a single piece of material, will reflect a uniform and isotropic internal structure, meaning there is no risk of delamination. This can well reflect real performances that the designed structure will put up under stresses, thus guaranteeing the accuracy of verification.

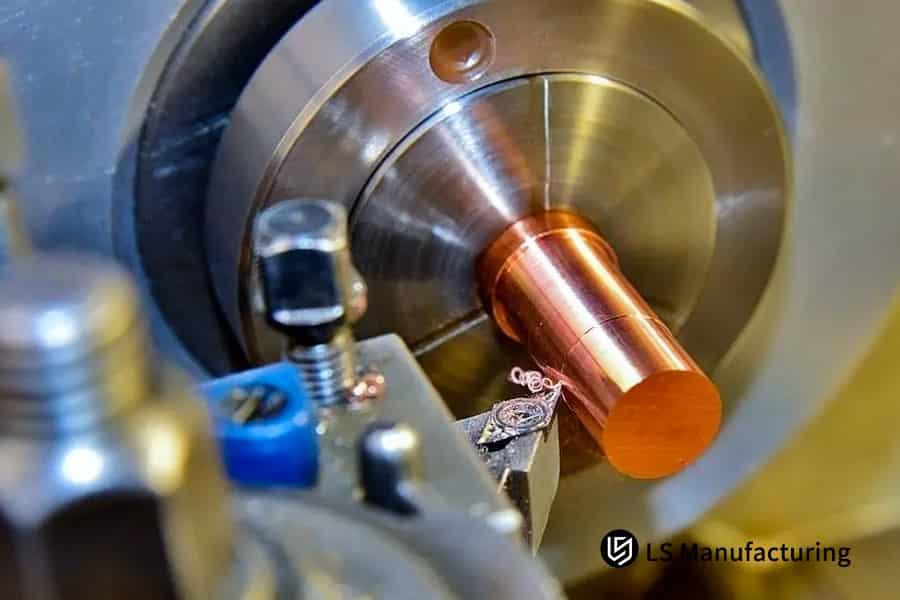

High Precision and Excellent Surface Quality

CNC machining process can easily achieve high dimensional accuracy up to ±0.05mm or higher and good surface finish up to Ra 0.8μm. It can manufacture prototypes that are not only suitable for rigorous assembly and checking of tolerances between parts but can be used directly as demonstration samples without further processing, which shortens the cycle from verification to decision-making.

The realistic material with a dense structure and precision dimensions used in CNC prototyping makes this possible, presenting the engineer with an actual model that is similar to the final product. This means that functional testing, lifespan assessment, and user feedback results are highly instructive and can effectively avoid design errors due to distortion of prototype performance.

Which type of CNC prototyping is suitable for your project?

Defining your prototype goals is the first step in selecting the correct prototype CNC machining type. Prototypes serve vastly different verification purposes during different stages of product development. Choosing the most suitable type will not only accurately verify design assumptions but can save a great amount of development cost and time. The types of CNC prototype manufacturing are as follows:

| Prototype Type | Validation Focus | Process Characteristics | Applicable Stage |

| Aesthetic Prototype | Appearance, color, texture, human-computer interaction | Fine surface treatment, such as high gloss polishing, sand blasting and anodizing | Early conceptual design |

| Functional Prototype | Dimensional accuracy, material properties, assembly reliability | Apply materials consistent with mass production, and focus on structural strength | Engineering verification stage |

| Small-batch trial production | Production process stability, assembling efficiency | Machining parameter verification, production process optimization | Final verification before mass production |

If you are in the conceptual design stage, an appearance prototype will be the most economical and efficient choice; a functional prototype is indispensable when it needs actual working condition testing. A small-batch production prototype would be your best choice to prepare for large-scale mass production.

How do we make a quick physical testable prototype of your design?

Our standardized rapid prototyping methods ensures a seamless transition from digital models to physical prototypes. With an elaborately designed end-to-end process, we can turn your ideas quickly into testable physical products, ensuring quality. The whole process is interlinked, and at every step, it is optimized for maximum efficiency:

| Process Stage | Core Work Content | Value Demonstration |

| Design Analysis and Optimization | The system auto-analyzes manufacturability upon receiving 3D files, and the engineers will provide professional optimization suggestions within 2 hours. | We proactively mitigate manufacturing risks to reduce future modification costs. |

| Intelligent process planning | The machining strategy is automatically matched based on the part characteristics, the optimal toolpath is generated, and the accurate delivery date is estimated | Ensure maximum processing efficiency and controllable delivery time. |

| Precision Machining Execution | Accurate 5-axis CNC machining with real-time monitoring ensures the key dimensions meet the design specifications. | This will ensure the accuracy and consistency of the prototypes. |

| Post-processing & Quality Check | The surface treatment will be finished, and three-coordinate measurement will be taken. When the dimensions are within the standard parameters, the prototype will be packaged and shipped immediately. | Deliver ready-to-use high-quality prototypes. |

Each step has a timeline and quality standard from file upload to prototype delivery. This ensures that your project receives a test prototype of high quality in the shortest time, thus greatly shortening the product development time. Our professional team will support you fully and make prototyping easy, efficient, and reliable.

Precision CNC prototyping plays a major role in what industries?

Precision CNC prototyping is an indispensable part in the course of product development inside high-end manufacturing. It bridges the gap between digital design and physical products. In these high-end fields, CNC prototyping is an indispensable verification process before a product can be successfully launched on the market.

- Aerospace: Some of the important components manufactured by CNC prototyping in the aerospace field include engine mounts and door mechanisms. In prototypes, it is possible to check comprehensive structural strength, vibration characteristics, and fatigue life under extreme temperatures with high pressure to make sure the final product will meet the stringent standards of aerospace regarding safety while achieving optimum lightweight design.

- Medical Devices: CNC prototyping can achieve the precision verification required for the biocompatibility, mechanical properties, and sterilization tolerance of medical-grade titanium alloys or ceramic materials found in such products as orthopedic implants and surgical robot end effectors. This gives crucial data support to clinical approval and reduces medical risks significantly.

- Automotive Industry: The automotive industry relies on CNC prototypes in the production of such basic core parts as turbocharger impellers and transmission gears for severe bench testing. Prototypes can accurately reflect the resistance to wear, fatigue strength, and noise performance of components under high-temperature and high-speed conditions, thus providing reliable engineering data support for mass production.

- High-end consumer electronics: Internal precision structures, cooling systems, and electromagnetic shielding effectiveness verified by CNC prototyping ensure the best functionality, the efficiency of heat dissipation, and high structural strength within a compact space that significantly improves product reliability for highly integrated products such as smartphones and wearable devices.

Precision CNC prototyping can provide a physical model consistent in material properties and precision with mass-produced parts. The broad scope of CNC machining applications allows for the completion of comprehensive functional, performance, and environmental adaptability verification before mass production, greatly reducing the risks in product development and lowering production costs.

How did we help a robotics startup win its first round of funding?

For every tech startup, a successful product demo to investors often decides whether a project lives or dies. Two cornerstones that support that performance are speed and reliability. This is precisely where the value of LS Manufacturing lies: this case demonstrates the speed and reliability of LS Manufacturing CNC prototype in supporting innovative businesses.

Client Challenge

A robotics start-up had to demonstrate its core innovation-precision joint components for a robotic arm-in two weeks’ time to investors at a critical funding stage. On the other hand, traditional machining plants, with their complex processes, high prices, and four-week delivery cycles, threatened to derail its funding plans.

LS Manufacturing Solution

In less than ten minutes, the customer confirmed the solution and the price, placing the order on our online intelligent quotation platform. We immediately mobilized our 5-axis machining center, using high-strength aluminum alloy, and through optimized cutting strategies and rigid online inspection, delivered a high-precision functional prototype fully meeting the design tolerances within five business days.

Results and Value

Resulting from perfectly demonstrating the smooth movement and precise positioning of its robotic arm at an investor conference, this startup obtained 5 million RMB of angel-round funding, thanks to the quality prototype we delivered. The mutual trust built from this cooperation also made them identify us as a strategic supplier for the mass production stage of this product.

We not only understand the extreme demands for speed and cost put on startups but also interpret these demands through digital processes and advanced manufacturing technologies into reliable, high-quality prototypes, thereby becoming the most trusted partner for innovative companies at critical moments.

How does an online quotation system make your prototyping process more efficient and transparent?

In medical device prototyping, the usual big bottlenecks to getting a project up and running as soon as possible are budget and timeline. Traditional quotation methods are long-winded, slow to respond, and vaguely defined, which greatly consumes the R&D team’s time and energy. Get a clear budget for your prototype project in minutes using our online CNC machining quote tool.

- Immediacy: Simply upload the 3D model file of your product, and the system intelligently analyzes geometry, machining difficulty, and material usage by algorithms to output a quotation in detail, including price and date of delivery within minutes. This will completely change the traditional model, which involves repeated communication and waiting for days to get the quotation, thus making effective project planning and decision-making possible right away.

- Transparency: The quotation will itemize clearly in detail the material cost, machining hours, and post-processing costs. In this way, you will be able to understand thoroughly the specific composition of cost and avoid any hidden costs or unclear items common in traditional quotations, so as to enable design optimization with a clear cost structure and budget control.

- Convenience: It transcends the boundary of time and location: you can request quotations, compare processes, or directly place orders any time and anywhere. Such smoothness in interaction greatly cuts down communication barriers, allowing you to invest your energy into the design itself rather than tedious coordination work.

It will enable engineers to enjoy unparalleled autonomy and efficiency by turning manufacturing knowledge into instant data insights. This basically lowers the psychological barrier to the initiation of projects and upfront costs, hence turning your innovative ideas into high-quality physical prototypes at the fastest speed with the least risk.

How does one go about optimizing the model to save costs and time before submitting the design?

The major design decisions greatly influence the final cost and timeline for prototyping in this process. A slight change in design could have a quite massive impact on machining difficulty and production efficiency. The core philosophy is: With simple design optimizations, your CNC prototyping projects can achieve better cost and delivery times. For that, consider the following points:

Avoid excessively deep cavities and narrow slots

If the enclosed cavities are too deep, tools with extremely high aspect ratios are required; this leads to poor rigidity, low cutting efficiency, and susceptibility to wear and breakage. If the depth of the cavities can be controlled within a reasonable range or even as modular structures, machining efficiency can be highly improved with costs lowered accordingly.

Standardize and simplify corner radii

Wherever possible, try to standardize corner radii in non-critical areas of the model. Much programming and machining time is greatly extended by continually changing tools of different sizes to machine the different radii. Standardizing corner radii-particularly with the specification of standard tool sizes-effectively reduces tool changes and shortens machining cycles.

Establish reasonable tolerances for the various features

Not all dimensions require very high precision. Clearly differentiate between critical mating dimensions and non-functional dimensions, assigning less strict tolerances for the latter. This would relax the demands on machining processes and sometimes even enable substitution of 5-axis machining with much cheaper 3-axis machining to save considerable cost.

If you are not sure how to optimize, we recommend that you take advantage of our free DFM service. Our professional engineers will provide a careful analysis report before placing the order. It shall clearly point out the possible problems and optimization proposals for your reference in order to avoid risk, reduce your budget, and ensure that the project moves ahead successfully and at top speed.

Why is LS Manufacturing the ideal partner for your CNC Prototyping Project?

In such a competitive field of innovation, the efficiency and cost, even the final success or failure of product development, depend much on the proper selection of the manufacturing partner for prototyping. Choosing LS Manufacturing CNC Prototyping Services means selecting a manufacturing partner that is efficient, reliable, and detail-oriented. Our unique value is reflected in three core aspects:

- Technical depth and equipment assurance: We have a cluster of high-end CNC equipment covering 5-axis machining, and have cultivated a mature process database in the high-end fields of medical devices and precision transmission. So, no matter how complicated your prototype structure is, or however special the material, we can offer a manufacturing solution that will perfectly combine precision with efficiency and technologically guarantee it’s right the first time.

- Customer-Oriented Service System: From instant, transparent online quotation systems to professional, free DFM-Manufacturability Analysis audits, we have built a seamlessly digital service ecosystem. We understand both speed and budget constraints of startups, and stringent process and documentation requirements for large enterprises, providing you with a tailor-made highly efficient collaboration experience.

- Commitment to Quality and Commitment: We consider “reliability” our lifeline. Each project is managed by a dedicated project manager throughout the whole process, ensuring smooth communication and controllable progress. Our promised delivery dates are our bottom line, which we never give in on. Through rigorous internal quality control, we make sure every prototype delivered to you meets or exceeds your expectation.

Not only are we the executor to make your ideas real, but we are also a strategic partner who will look after the security of your journey of innovation with our expertise and rich experience. With us, you are guaranteed not only high-quality CNC prototypes but a strong success guarantee for your projects and valued time to market.

FAQs

1. How accurate are these on-line quotations?

When the model is well-designed and reasonable, it is possible for our online intelligent quotation system to reach an accuracy rate of over 95%. Accordingly, our system will make a detailed and visualized quotation based on real-time geometric features, material usage, and processing time analysis of your 3D model so that the budget can be clear and controllable.

2. How long does it take from ordering to delivery?

Normally, 3-5 working days are needed after confirmation for the dispatch of orders. Additionally, we have an expedited service channel: if there is an urgent need, precision machining can be finished and shipment arranged within 48 hours to fully guarantee your R&D progress.

3. What materials are supported, and can you provide material certificates?

Ranging from various grades of aluminum alloy, stainless steel, and titanium alloy to over 20 varieties of engineering plastics, the options are very broad. Materials are from legitimate channels, with original manufacturer material certificates provided for every shipment to ensure that material performance is reliable and authentic.

4. How do you plan to keep the design files confidential?

We value information security and are internationally ISO27001 certified. Bank-level encryption technology is applied to all file transfers, while every employee is obliged to a strict confidentiality agreement. We guarantee that all relevant design data will be completely deleted at the end of the project as agreed upon.

5. If the design has manufacturing issues, do you have any suggestions?

Of course, our engineers will actively conduct a free DFM manufacturability foundation analysis for you and prepare an in-depth report to clearly indicate the possible manufacturing difficulties and risks, as well as specific optimization solutions to help improve design quality and save costs.

6. What is the minimum order quantity? Are single-piece prototypes possible?

We totally support single-piece prototype manufacturing without any restriction of minimum order quantity. Whether a single-piece prototype for proof of concept or a small-batch pilot production, flexible and efficient manufacturing is available.

7. Are there also post-processing options such as anodizing and sandblasting?

We provide a complete Post-treatment surface finish services that includes anodizing in various colors, sandblasting of different mesh sizes, passivation, screen printing, etc. Please select the required processes when placing your order, and we will deliver the completed processing.

8. How can I track my order progress?

You can track the whole ordering process in real time through a dedicated online customer portal, including the current processing stage, quality inspection results, and logistics information. Meanwhile, we will automatically send the progress notifications to you at each key milestone through the system.

Conclusion

As an important link connecting innovative design and market products, CNC prototyping provides core value in material authenticity consistent with mass-produced parts, with better structural strength and micron-level machining accuracy. This technological advantage ensures the highest reliability of the prototypes during functional tests, durability verification, and compliance assessment-a solid guarantee for product launch.

You are sincerely invited to upload your 3D design files now for use with our intelligent quotation system or professional DFM analysis service. You may also directly contact our prototyping experts for personalized solutions. Choose LS Manufacturing, and let us accelerate the R&D process for you with our exquisite workmanship and efficient service to seize the opportunities of the market.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.