Medical Device Industry

If you are looking for a reliable medical equipment precision parts machining company, please contact us. We look forward to working with you to provide you with the highest quality service and products.

- Manufacturing on demand

- High precision medical components

- Tolerances down to +/- 0.005mm

Why LS for Medical Industry

LS is committed to providing you with reliable medical device prototype design and manufacturing services, covering various medical components from simple to complex. With our advanced technology and excellent manufacturing expertise, we are able to turn your medical products into reality in the most efficient way possible.

Quick Quotation

Simply upload CAD files and you can quickly understand manufacturing costs within 2 hours. You can also keep up with the latest information on order status at any time.

Rapid Prototyping

LS has extensive experience in prototype manufacturing, ensuring that your components are completed with high quality in the later stages of the design and manufacturing process.

ISO Certification

LS is a manufacturing company certified by ISO 9001, which means we adopt internationally recognized best practices to develop your products and ensure they meet standard requirements, regardless of the complexity of the design.

On Demand Custom

Our automotive parts manufacturing process is fully customizable, based on your specifications, dimensions, materials, and surface requirements to ensure that your unique needs are met.

Fast Delivery

We are committed to providing fast manufacturing and delivery to meet your production needs, while also providing you with greater flexibility to quickly respond to market changes. Longsheng is your partner for automotive parts needs.

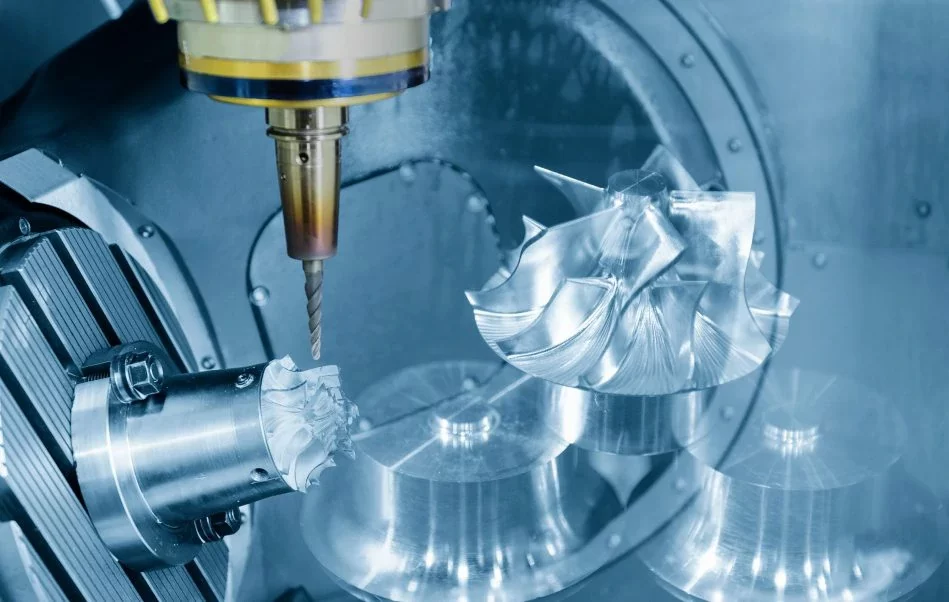

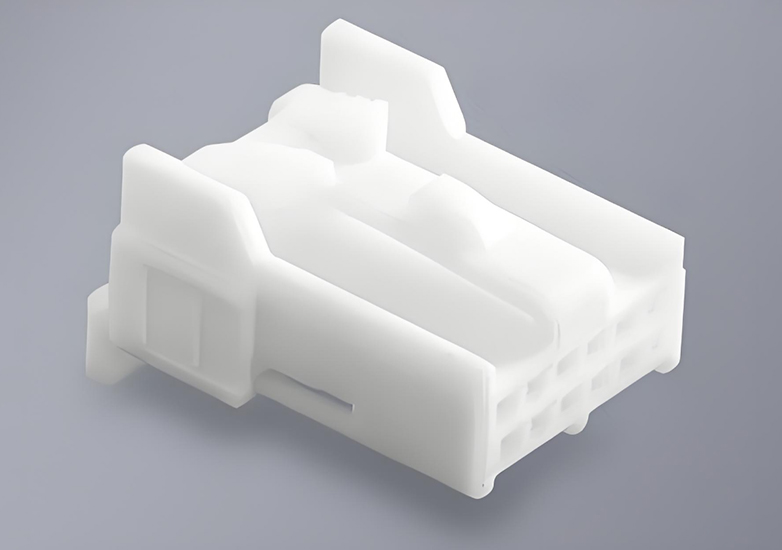

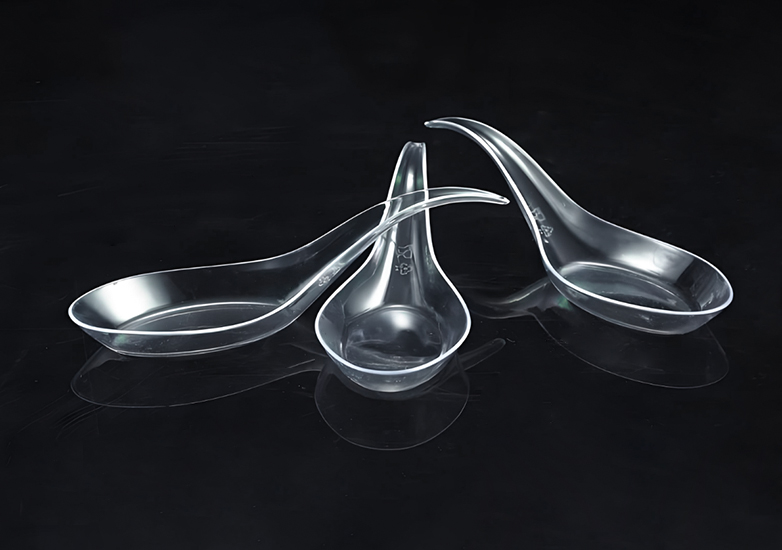

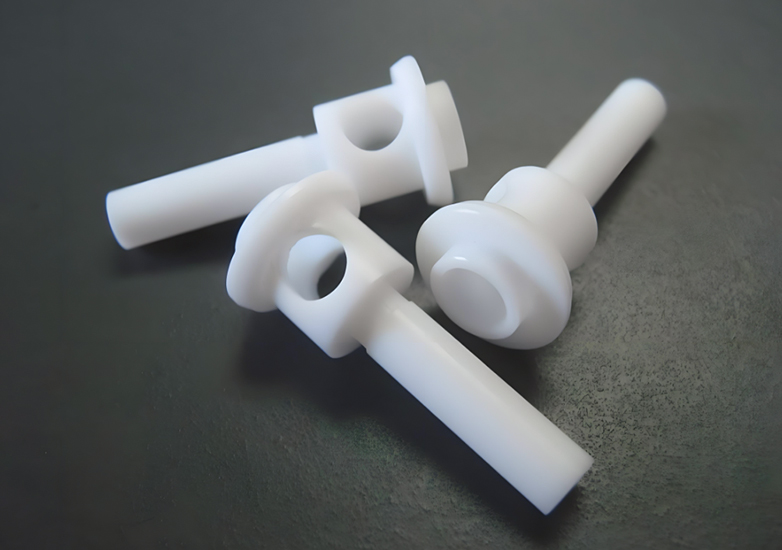

Medical equipment parts machining services

We offer high-quality medical equipment parts machining services that are tailored to meet the specific needs of our customers. Our machining services are precise, efficient, and cost-effective, making us the go-to choice for medical equipment manufacturers and suppliers.

Order quantity

We do not have a minimum order quantity. We can accommodate orders of any size, including single-piece orders.

100% full inspection shipment

– material report

– Hardness test report

– Dimension inspection report

– Salt Mist test report

Mass production

We are capable of mass production and can accommodate orders of any size, including large-volume orders.

– 98% on-time delivery rate

– Delivery in one day at the earliest

– Quick proofing of parts

– One-stop machining

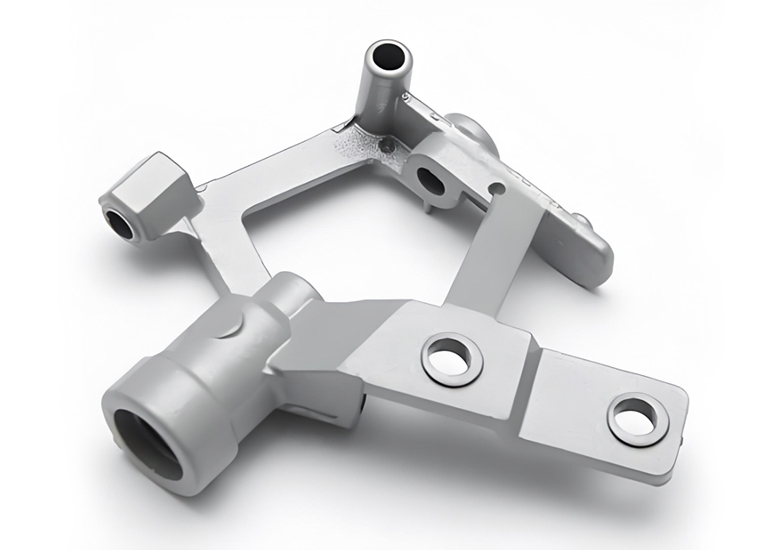

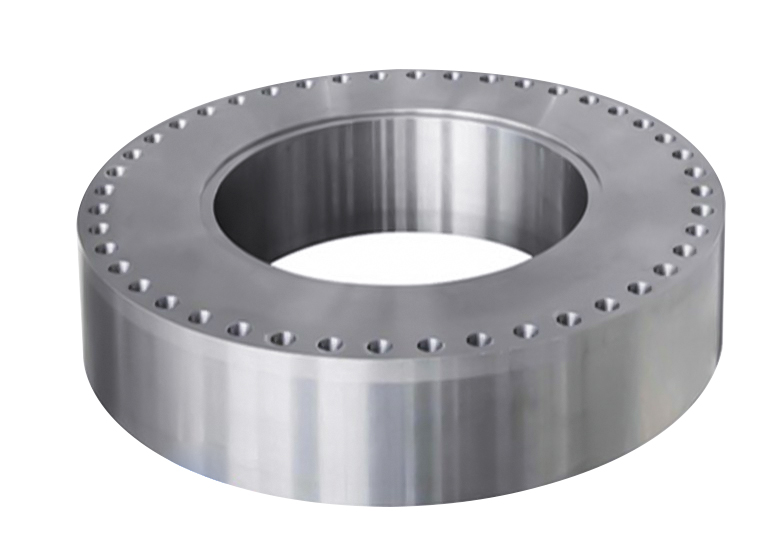

Manufacturing of Medical Device Parts

The medical field relies on carefully developed products to ensure effective protection of human health. We are committed to providing precision medical components that meet regulatory and quality standards, ensuring their accuracy and quality reach the highest level. We provide customers with reliable and professional medical device manufacturing solutions to meet the highest quality standards of customized products.

Materials for Medical Product Parts

LS can source any other material on request for prototyping and production runs of custom parts. If you have special material needs, please contact us to provide you with a reliable solution.

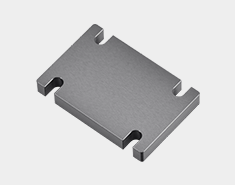

Metals

Plastics

We offer customization based on your specific material requirements. If you need a material not listed here, our team can source and process it to meet your exact needs.

These are just a few examples of the materials we work with. If you have a specific material requirement, please contact us to discuss your needs.

Surface Finishing for Aerospace Parts

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Anodizing

Anodizing

|

Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Chromate

Chromate

|

Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

Medical Device Industry Applications

When it comes to the production of medical equipment, our extensive production capacity also covers the following areas:

– Medical Imaging Equipment

– MRI Scanners

– CT Scanners

– Medical ENT Equipment

– Medical Electronic Devices

– UV Sanitation Components

– Dental Instruments

– Medical Delivery Systems

– Monitoring Instruments

– Electronic Medical Devices

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

Medical industry parts machining FAQ

What materials do you work with?

We are equipped to work with a wide range of materials commonly used in the medical industry, including stainless steel, titanium, aluminum, and plastics such as PEEK and Ultem. Our team has extensive experience working with these materials, and we have the expertise to handle even the most challenging projects.

What tolerances can you achieve?

Our state-of-the-art equipment and skilled machinists allow us to achieve tight tolerances as low as +/- 0.002 inches. We understand the critical importance of precision in medical industry parts, and we take great care to ensure that every part we produce meets our customers’ exact specifications.

What materials do you work with for medical equipment parts?

We handle a wide range of materials commonly used in the medical industry, including stainless steel, titanium, aluminum, and medical-grade plastics such as PEEK and Ultem.

What tolerances can you achieve in machining medical parts?

Our advanced equipment and skilled machinists allow us to achieve tight tolerances as low as +/- 0.002 inches, ensuring precision for critical medical applications.

How do you ensure quality control in medical parts manufacturing?

We implement rigorous inspection processes throughout production, utilizing tools like CMMs, height gauges, and micrometers to ensure all parts meet high standards before shipment.

How do you ensure quality control?

We take quality control seriously and have implemented rigorous inspection processes throughout our production. Our inspection equipment includes CMMs, height gauges, and micrometers, among others, and we use these tools to ensure that every part meets our high standards before it is shipped to our customers. We also have a dedicated quality control team that oversees our processes and ensures that everything we produce meets our customers’ expectations.

What is your lead time for medical industry parts machining?

Lead times vary depending on the complexity and quantity of the parts being machined. However, we strive to provide quick turnaround times and can provide expedited services if needed. We understand that our customers often have tight deadlines and we work hard to ensure that we meet those deadlines while still delivering high-quality parts

Do you offer any additional services for medical industry parts machining?

Yes, we offer a range of additional services to meet the needs of our customers. We can provide design and engineering support to help our customers bring their ideas to life, and we also offer assembly services to simplify the production process. Additionally, we offer finishing services such as anodizing and passivation to ensure that our parts meet our customers’ exact specifications.

What is your lead time for medical parts machining?

Lead times vary based on part complexity and quantity. However, we strive to provide quick turnaround times and can offer expedited services if needed to meet tight deadlines.

Do you offer additional services for medical parts?

Yes, we provide design and engineering support, assembly services, and surface finishing options such as anodizing and passivation to meet specific requirements.

Can you accommodate both small and large production runs?

Absolutely, we can handle orders ranging from single-piece prototypes to large-scale production runs, offering flexibility to meet your project needs.

Customer Satisfaction Evaluation

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.They highly recognize our professional services and high-quality results.

Put your parts into production today

- All information and uploads are secure and confidential.

More of The Industries We Support

Click on the links below to learn more about our services and case studies.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.