Precision CNC turning will be the key to solving manufacturing bottlenecks in automotive electrification and lightweight components. The above-mentioned industrial pain points of unstable precision, poor consistency in mass production, and so forth are rooted in traditional supply chains that cannot offer enough flexibility and are limited in technology.

This article draws upon experiences from process control experts of the AS9100 aerospace grade quality management system at LS Manufacturing to construct a highly reliable turning system. This work aims at zero-defect delivery in mass production, striking at the very heart of the current manufacturing challenges.

Systematically solving these bottlenecks thus means redefining precision CNC turning’s strategic value within automotive manufacturing. To save you time, here’s a quick overview of the core conclusions.

Precision CNC Turning Full Text Quick Reference Table

| Module | Core Content Summary |

| Strategic Value | Redefining it as a core strategic link in ensuring the quality and efficiency of the automotive supply chain. |

| Technological Advantages | Achieving micron-level precision and mirror-like finish through high-rigidity machine tools and advanced toolpath planning. |

| Quality Assurance | Integrating SPC statistical process control and real-time monitoring to ensure consistent quality in mass production. |

| Materials Application | Mature processing of lightweight materials such as aluminum alloys and composite materials to meet the special needs of electrification. |

| Intelligent Inspection | Utilizing online measurement and intelligent inspection technologies, this system enables full-process quality data traceability. |

| Core Value | Ultimately achieving the goals of reducing overall costs, improving assembly efficiency, and strengthening brand reputation. |

This quick reference guide systematically shows how precision CNC turning, as a systemic solution, comprehensively addresses the pain points in the manufacturing of automotive precision parts-from strategic positioning, through technological implementation, quality control, to ultimate value, thus providing essential support in building up robust supply chain competitiveness.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

What gives this book its phenomenal value is the practical production line experience. For more than a decade and a half, we have processed vital components for the very exacting aerospace industry to the highest standards laid down by the International Aerospace Quality Group, while also supplying key components to global Tier 1 suppliers at the very pinnacle of the automotive world with a quality management system fully compliant with IATF 16949 specifications.

In the last ten years, our team has completed more than 50,000 pieces of 5-axis and complex customized parts processing and delivery. The accumulation of experience of this kind inevitably deepened the following understanding: how to develop the best cuttings for Incon 718 alloy, ensure dimensional and positional accuracy during high-speed milling of thin-walled parts, and find an optimal balance among quality, efficiency, and cost in rapid R&D with many varieties and small batches.

Our objective is simple: to be able, chapter by chapter, to give you practical knowledge earned through sweat and wisdom so that the reader will avoid various traps that we fell into and really go to the core of manufacturing. Believe me, what you read here is our reliable methodology for serving top global clients.

Precision CNC Turning: The Cornerstone of Reliability in Automotive Manufacturing

Modern precision CNC turning has long surpassed the scope of a simple cut; it is, in its core, a “digital quality carrier.” The core value is vested in the fact that it converts design intent into a predictable and reproducible set of digital directions that root out the risk of variation owing to human error or equipment fluctuations. It lays the very foundation for automotive grade component manufacturing.

Consistency Assurance

It does this by using digital codes that provide precision control for every motion parameter. From first-piece verification all the way to the 100,000th precision automotive CNC turning parts in high-volume mass production, it creates a very consistent dimension and performance level. This fully meets the most rigid requirements of IATF 16949 for process capability and statistical control.

Traceability and Zero-Defect Pursuit:

Because every part’s machining data can be traced in a digital manufacturing system, even minute deviations can be quickly found, analyzed, and corrected to form a continuously optimizing closed-loop quality system that infinitely approaches the ultimate goal of “zero defects.”

Therefore, precision CNC turning has risen to the strategic core in the supply chain resilience. It provides indispensable reliability assurance for automotive electrification and lightweight, “programming” quality requirements into the DNA of manufacturing that forms the key pillar supporting efficient and high-quality development in modern automotive grade component manufacturing.

Why do leading manufacturers consider CNC turning as a core strategy?

The key to automotive CNC machining strategy lies in understanding its total cost of ownership (TCO): it is not just a technological upgrade, but also a key measure to improve production efficiency and build long-term cost advantages.

| Comparison Dimensions | Traditional Machining Mode | Precision CNC Turning Strategy |

| Tooling and Fixture Cost | Dedicated tooling is usually required; this typically involves large upfront investments with long cycles. | General-purpose fixtures combined with programmed settings greatly reduce the upfront investment. |

| Changeover Efficiency | Product changeover involves an adjustment of the tooling; this may take hours or longer. | Rapid changeover via program calls reduces this to mere minutes. |

| Material Cost Control | Large machining allowances signify a great deal of material waste and high unit cost. | Near-net-shape machining enables maximum efficiency in cutting paths and thus allows tremendous improvement in material utilization. |

| Quality and Consistency | Relying too heavily on the skills of operators implies high fluctuation in quality, together with increased hidden costs. | Under digital control, batch products would have zero defects and significantly reduce the risk of after-sales service. |

Precision CNC turning systematically reduces the total cost of ownership by optimizing the initial investment, reducing non-machining time, enhancing material added value, and ensuring consistency in quality. All of these factors indicate an all-around production efficiency improvement and therefore are not a simple replacement but a strategic option for leading manufacturers to build core competitiveness in supply chain management.

Three Major Advantages: How does CNC turning reach a win-win situation in quality, cost, and efficiency?

CNC turning advantage matrix has managed to solve the industrial challenge in the pursuit of manufacturing excellence today, which can achieve quality, cost, and efficiency all at once. Systematic advantage is one of the strategic choices for the production of high quality automotive parts:

Quality Dimension

CNC turning is able to reach ultra-high precision of ±0.005mm through digital programming control, providing parts with excellent surface integrity. Such extreme control means that each product will surely meet even the most critical automotive standard for zero-defect, high quality automotive parts that are fundamental to key assemblies such as powertrains and steering systems, basically raising the safety and reliability of the whole vehicle.

Cost Dimension

Considering the cost benefit analysis, high automation in the case of CNC turning reduces human intervention and variation while greatly improving resource utilisation by means of intelligent scheduling and material optimization. While the investment per machine is high, low scrap rates, high capacity, and low management cost in large-scale production enable significant optimization of total lifecycle costs.

Efficiency Dimension

It can support both continuous and stable operation 24/7, with high-speed changeover, whereby the production line switches seamlessly between prototype verification and large-scale mass production. It greatly compresses the product development-to-market cycle through this flexibility, enabling the manufacturers to seize market opportunities in time, thus enhancing their ability to resist supply chain fluctuations.

The benefits of CNC turning in automotive are not isolated but form a self-reinforcing closed-loop system through the digital core. Thus, it is the guarantee of high precision that ensures quality; stable quality reduces after-sales costs, while automation increases efficiency to further lower fixed costs. It is such a three-dimensional win-win model that constitutes the core of its ability to create sustainable competitiveness for modern automobile manufacturing.

Quality Fortress: How to ensure consistency in millions of units produced?

In mass production quality control, high consistency of the millions of products cannot rely on final inspection; it must be rooted in the quality culture of prevention that covers the whole process. This constitutes the core of the LS Manufacturing quality system: through systemic process control, superior quality is embedded into every stage of manufacturing.

Real-time Monitoring and Early Warning: Application of SPC Process Control

The real-time collection and input of the data on the line for critical dimensions’ tolerance into the SPC system enable it to act as a tireless “quality radar” to dynamically analyze process capability indices through control charts. The warnings come out right away when even minor abnormalities are detected, and thus engineers can in due course make proper adjustments to processes before defects take place, thereby realizing a fundamental shift from “post-production inspection” to “pre-production prevention.”

100% Online Inspection & Full-process Traceability

With this, core quality characteristics at the production line are checked 100% automatically by integrated probes, ensuring that each and every product is qualified when it leaves the line. Meanwhile, applying blockchain technology institutes an immutable traceability chain for raw material batches, processing parameters, and inspection data, making any product traceable to its original production state.

Complete Quality Data Package Delivery

We supply qualified parts supported by a full quality data package for every batch of products. This detailed report includes dimensional reports, material certifications, and process capability analysis, providing the customer with clear, verifiable quality assurance. This greatly simplifies the incoming material inspection and vehicle assembly processes.

In a nutshell, the quality fortress of us is not isolated points in inspection, but a dynamic protective network interwoven with technologies like SPC process control, intelligent inspection, and blockchain traceability. The key to LS Manufacturing quality system lies in strict control over every step to pursue absolute consistency, achieve high volume CNC turning, and thus win customers’ solid trust in quality.

Deformation and Tool Wear in Machining Aluminum

As one of the most important players in the machining of aluminum automotive parts, we deeply recognize that controlling deformation and extending tool life is the core challenge in aluminum alloys parts machining. Solutions based on an enormous material processing database turn theory into a competitive advantage for stable productions by systematic process optimization.

| Optimization Dimensions | Traditional Challenges | LS Proprietary Solutions |

| Tool geometry and material selection | General-purpose tools are vulnerable to wear, which could easily lead to tearing or burrs on the material. | Tailor-made diamond-coated tools and rake angles based on aluminum alloy grades provide smooth cutting. |

| Optimization of Cutting Parameters | Conservative parameters result in low efficiency, whereas aggressive ones easily generate high heat and stress. | The balance between efficiency and thermal control is achieved by matching optimum linear speed with optimum feed rate using a database. |

| Control of the Cooling Strategy and Stress | Incorrect cooling can result in thermal deformation, affecting dimensional stability. | Precise cooling at defined pressure and flow rate effectively suppresses machining thermal stress and deformation. |

| Tool-Life Monitoring and Prediction | The tool-changing practice based on experience can result in over or under tooling. | Real-time monitoring of cutting forces will allow predictive tool changing, tool life optimizing. |

By matching the systematic process mentioned above, the life of the tool was extended by over 30%, and the dimensional stability of the aluminum parts was greatly improved. This proprietary technology comes from a material process database; it is a core guarantee that provides us with high efficiency, low cost, and high-quality mass production for our customers as experts in aluminum alloys parts machining.

99.98% Yield: How LS Manufacturing Solves the Mass Production Challenge of Turbocharger Shafts

LS Manufacturing case study aptly illustrates how we turn technical expertise into a real competitive advantage in high-precision turbocharger shaft machining for customers and deliver on a promise of a million-unit yield guarantee.

Customer Challenge

A leading global auto parts supplier was facing severe problems in mass producing a new generation of turbochargers. The stainless steel shaft parts of the customer required ultra-high roundness ±0.008mm; the insurmountable vibration and tool mark problems of the existing supplier kept the mass production yield persistently below 95%, seriously affecting the customer’s production efficiency and costs.

LS Manufacturing Solution

Soon after that, we assembled a professional technical team to analyze not only the equipment but the whole system. We applied dynamic simulation software and found the exact source of chatter during machining, optimized clamping force and tooling fixture layout, and customized a tooling system able to reduce vibration. Meanwhile, we had made fine adjustments to the matching curve of spindle speed-feed rate to eliminate the vibration from its source.

Results and Value

The solution was so effective that it reached the yield rate of 99.98% for the first batch of 500,000 products. This achievement directly helped the customer reduce line downtime due to this part’s quality issue by 90%, saving over 2 million RMB in annual quality costs inclusive of rework, scrap, and losses associated with downtime.

Altogether, success in this case is about attaining near-perfect yield figures, but it is even more about proving the systematic capability of us in solving the most complicated engineering problems. We applied precise root cause analysis, innovative process design, and rigorous process control, gave the customer a significant competitive advantage in the market.

Technology Panorama : Key Applications from Engines to Electric Drive Systems

Ultimately, the value of precision CNC turning technology is reflected in its support for core automotive component manufacturing. For a long time, automotive parts CNC machining applications has become an indispensable underlying process during the key components manufacturing.

- Traditional Powertrains: CNC turning finds its place in the manufacture of turbocharger scroll plates, high-pressure oil pump core components, and many more in engines. All these parts need to maintain their shape and dimensions under extreme conditions of high temperature and high pressure. Any deviation at the level of micrometers directly influences engine efficiency, fuel consumption, and emissions.

- Chassis and Safety Systems: Computer numerically controlled turning guarantees extremely high mechanical strength, wear resistance, and assembly precision in the key components manufacturing, such as steering knuckle ball joints and drivetrain half-shafts. This relates directly to vehicle handling stability, the accuracy of steering, and driving safety-areas where there is absolutely no room for error.

- New Energy Vehicle Electric Drive Systems: Faced with the wave of electrification, the role of CNC turning in components for new energy 3-electric system components is very important and cannot be ignored. It ranges from but is not limited to a few instances like motor shafts, precision connectors inside the battery pack, to controller heat sink casings.

CNC turning technology permeates every core system in automobiles. The wide range of use of in automotive CNC machining proves it is the common key technology supporting performance, safety, and reliability of the whole vehicle and a solid foundation for the development of the auto industry.

Why Choose LS Manufacturing as Your Strategic Supplier?

A choice of partner in such a market environment is a choice about the future competitiveness of the supply chain. As a strategic automotive parts supplier, our core value is not in delivering products, but rather in guaranteeing certainty in quality, cost, and delivery through systematic capability building. The core value of LS Manufacturing automotive is best reflected in three important dimensions.

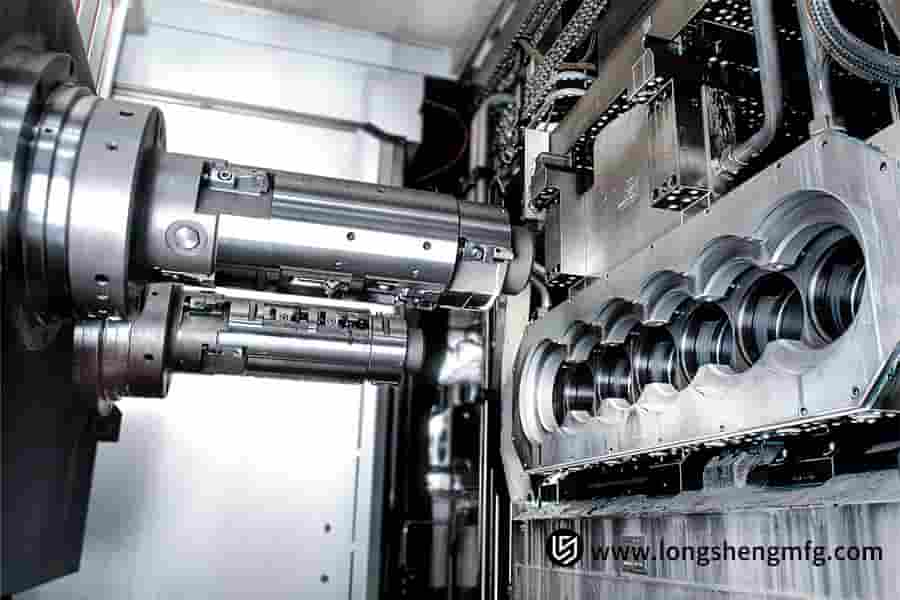

- Technological Leadership: Laying the Foundation for Manufacturing with Advanced Equipment: We invest continuously in state-of-the-art 5-axis milling and turning centers, and high-precision coordinate measuring machines. It means handling more complex geometries, ensuring absolute leadership in process capability from the point of view of hardware, therefore constituting a solid physical foundation for machining complex parts.

- System Assurance: Building a Quality Firewall with Dual Certifications: We implement simultaneously the aerospace quality system, AS9100, and the IATF 16949 automotive industry standard. It is not just a piece of paper but an internalization process of the zero defects and process excellence philosophy into every stage from order to delivery, so that it will form a quality culture system based on prevention and continuous improvement.

- Service Synergy: Creating Value Beyond Expectations through Deep Collaboration: We offer genuine end-to-end service: right from the very beginning of a project, a committed team is assigned to join the client in conducting DFM analysis. Optimize product design from a manufacturing perspective to achieve maximum productivity, reduce costs, and have smooth communication and speed in each phase of the cooperation cycle.

In sum, with LS Manufacturing, the customer gets a deeply integrated technology partner and not just a supplier. We are ensuring technological leadership for breadth and precision in product realization and system assurance for stability and reliability of process outputs.

Cost Unveiled: How Does CNC Turning Reduce Unit Costs by 15%?

These factors imply that automotive parts cost optimization cannot be achieved by simply squeezing out machining time but requires a systemic approach based on value engineering. This white paper will explain in detail how we apply CNC turning economic analyses to achieve a 15% reduction in overall unit costs without compromise on performance.

Structural Optimization

Our engineers support customers with design reviews, non-load-bearing component analysis, and lightweight and integrated design implementations during the CAD stage. For instance, optimizing a complex component from several pieces into a single turned part directly saves the cost of welding or bolting connections while improving structural reliability.

Material Substitution

By applying value engineering principles with knowledge in materials science, we are able to provide functionality equivalently at lower costs; we recommend materials for applications such as substituting high-performance and free-machining stainless steel for the most expensive materials. It can keep strength and corrosion resistance, greatly reducing raw material procurement costs, prolonging tool life, and improving production efficiency thanks to its outstanding machinability.

Process Integration

Multi-axis CNC turning allows for composite machining; in such a context, the secondary machining that was done through milling and drilling has already been integrated into one setup. This greatly reduces the number of setups required, turnaround times, and special tooling needed. Overall, this compresses cost from a manufacturing process perspective.

Using value engineering with a triple optimization of structure, materials, and process CNC turning economic analysis finds and eliminates redundant value in the manufacturing process. The systematic automotive parts cost optimization strategy culminates in cost savings as high as 15% for customers while maintaining or even improving product quality, building solid market competitiveness.

Forward-Looking Strategy: Manufacturing Technologies for Intelligent Connected Vehicles

In the modern auto industry, which is undergoing profound transformation toward intelligence and connectivity, future automobile manufacturing technologies have become the core driver of innovation. As a technology partner for our customers, LS Manufacturing technology roadmap has clearly specified the R&D directions in the fields of intelligent manufacturing and new materials, laying a solid technological foundation for the birth of next-generation intelligent and connected vehicle components.

AI-Driven Predictive Maintenance

We are deeply integrating artificial intelligence algorithms into our production systems. Through real-time analysis of vibration, torque, and other data of machine tool spindles, AI can make accurate predictions regarding the wear of tools and possible failures in equipment, thus shifting from “routine maintenance” to “on-demand maintenance.” This reduces unplanned downtime, making sure there is continuous, reliable production of intelligent and connected vehicle components.

Digital Twin Technology for Process Optimization

We use digital twin technology to simulate, debug, and optimize the whole process chain in a virtual environment before actual machining. This does not only identify and resolve some key problems, such as machining interference, vibration, or deformation, well in advance and greatly shorten the trial production cycle but also ensures that new materials and structural parts meet design goals from the very first piece, hence fastening the pace of implementing innovation.

Forward-Looking Research and Development of New Material Machining Technologies

We have initiated forward-looking research in turning technologies for the manufacturing of new lightweight and high performance materials like carbon fiber composite, mainly with a focus on overcoming such defects as delamination and burrs, optimizing tool materials, and cutting parameters, with a view to meeting the future manufacturing demand for new materials on key components like car bodies and chassis.

Summed up, the core of the LS Manufacturing technology roadmap is upgrading manufacturing technology itself to intelligent levels, matching and leading the development of future automotive manufacturing technologies. We further invest in AI, digital twins, and new materials processes, shifting precision manufacturing from capability to the ecosystem of the future.

FAQs

1. While choosing an automobile CNC turning supplier, what is the point of evaluation which can be easily neglected but is very important?

Instead of an equipment list, it is the process control capability that is important. Of course, top-of-the-line equipment is required, but the key to manufacturing good quality parts every time is process control. Please note that SPC reports and Cpk data for the critical dimensions given by the supplier are what really represent the stability and reliability of their mass production. We can provide customers with transparent process capability documentation.

2. Can the easily deformable and high-requirement conductive component, such as a copper busbar of a new energy automobile, be processed by CNC turning?

Yes, this is one of our key strengths. Proprietary toolpath strategies, special tools, and following electropolishing processes that ensure flatness, cleanliness, and conductivity of the electrical connection surfaces have been developed to address the tool sticking or deformation because of processing stresses in highly conductive copper. This has already been successfully applied by a number of major battery manufacturers.

3. How does your AS9100 aerospace-grade quality system help me specifically reduce the risks in my supply chain?

The “traceability” and “prevention” aspects are the cornerstones of our AS9100 system. In other words, every act, from raw material warehousing to finished product delivery, is traceable. Any part can be traced back to the specific production batch, equipment, and even an operator. This system makes sure that deviations are signaled at the most initial stage possible, allowing for speedy problem isolation and corrections, hence greatly reducing the risks of product recalls and production line downtime.

4. Can LS Manufacturing respond quickly to sudden capacity demands, and how can it ensure that quality is not sacrificed?

Our flexible production cells and intelligent scheduling systems are designed to handle fluctuations. When urgent orders arise, we don’t just “speed things up.” We make sure quality is maintained by activating reserved capacity, establishing parallel processes, and supporting directly our experienced engineering team. All expedited orders undergo complete first-article inspection and sampling; speed never supersedes quality.

5. How do we ensure that designs and patent information, when entrusted to LS Manufacturing, are strictly protected?

Our lifeblood is intellectual property protection. Complementing the signing of standard NDAs, physical and digital information isolation management is implemented: independently encrypted project data sits on servers, and access is allowed only for the core members of the project team. We welcome customer audits into our information security management processes, since this is the base for long-term trust.

6. Does LS Manufacturing support small-batch trial production in the early stages of new projects? What are the MOQ requirements?

We would consider the first phase of growth very important, wanting to grow with our customers. Therefore, we have a Rapid Prototyping and Trial Production department supporting small-batch projects. This way, MOQs can go as low as hundreds of pieces to allow you to validate your designs and our capabilities with the least initial investment for a solid foundation in terms of future large-scale collaborations.

7. In collaborating with LS Manufacturing, is this just “processing based on provided drawings” or do we also receive optimization suggestions from the manufacturing side?

We advocate Collaborative Design-Focused Manufacturing (DFM) and Collaborative Manufacturing-Based Manufacturing (DfMA). Our engineers will have already actively analyzed your drawings during the quotation stage, with manufacturability suggestions, cost optimization, and performance improvements-such as subtle structural changes that can greatly enhance strength or reduce machining difficulty. We won’t be mere executors; we’re expert consultants for your manufacturing process.

8. What are the core differentiating advantages of LS Manufacturing over major state-owned enterprises or international giants?

Our key competitive advantages are “focus, agility, and in-depth service.” Compared to giants, we specialize in CNC turning for automotive industry, doing more deeply and precisely. You will reach faster response times because of shorter chains of decision making, get more focused expert team services, and process solutions adapted to your projects. We want to be a valuable and responsive strategic partner that you can rely on with your supply chain.

Conclusion

In the light of unprecedented changes, reliability, agility, and technological depth of the supply chain have developed into the most crucial competitive advantages. The precision turning process is one of the cornerstone procedures to create this aim and is increasingly vital. LS Manufacturing endeavors to be your best manufacturing partner through solid engineering technology, stringent quality control, and forward-looking technological planning.

Get your customized “Automotive Parts Cost and Process Optimization Assessment Report.” Please contact us provide part drawings and requirements now, and our professional team will offer a comprehensive report including DFM analysis, precise pricing, and potential optimization points within 24 hours.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.