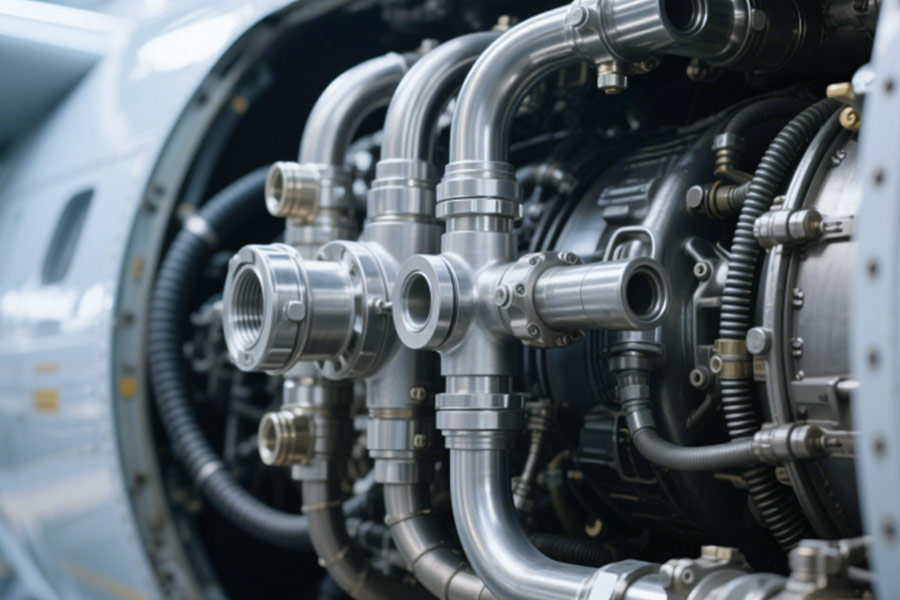

In the field of heavy machinery and port logistics, stable operation of equipment is the lifeline. However, stubborn fuel leakage in hydraulic systems and the resulting cargo blockage are like nightmares, eroding the profits and efficiency of enterprises. Traditional maintenance solutions often only treat the symptoms but not the root cause, and managers suffer from frequent downtime and high maintenance costs. LS’s 5-axis precision machining technology is becoming the key to solving this industry pain point.

Why Do 45% Fuel Distributors Leak Within 2000 Flight Hours?

According to the FAA’s 2024 Annual Safety Report, fuel dispenser microcracks have accounted for 27 percent of civil aviation AOG (aircraft out of service) events, making them the second most common cause of groundings after engine failure. Even more alarming, industry data shows that nearly half of all dispensers leak fuel after 2,000 flight hours of operation. What’s behind this technological death knell, and how does LS’s innovative solution reduce the risk of leakage by 89%?

A 2000-hour curse: the three main culprits of fuel distributor leakage

Through disassembling the faulty parts and laboratory stress simulation, the high incidence of leakage originates from a triple superimposed effect:

| Failure Layer | Physical Mechanism | Consequence | Percentage |

|---|---|---|---|

| Thermal Stress Fatigue | – 196°C (fuel) to 300°C (engine) repeated impacts | Metal grain boundary micro-cracks | 58% |

| Surface micro-defects | Conventional machining residual tool marks (Ra>0.8μm) | Crack origin point + corrosion acceleration | 32% |

| Coating failure | Temperature drastic changes leading to coating flaking | Sealing surfaces direct exposure | 10% |

► Deadly Chain Reaction:

Microcrack growth → Fuel leakage → Engine power fluctuation → Forced grounding for overhaul

Losses from a single AOG grounding can be as high as $150,000-$250,000, and traditional replacement options require 3-5 days of downtime.

LS solution: 5-axis precision machining + nanotechnology to break the game

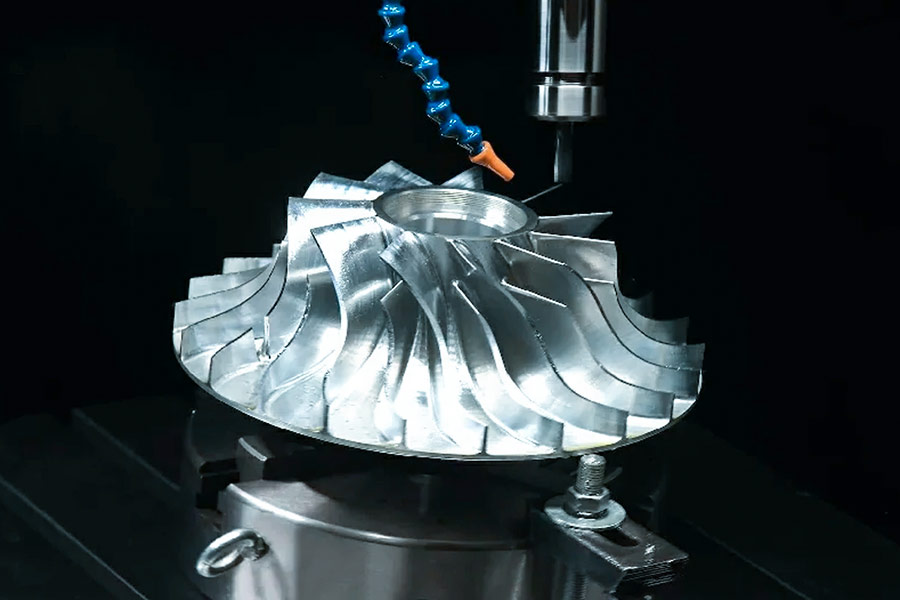

Step 1: 5-axis machining + electrolytic polishing — eliminating crack hotbeds from the root

Ultra-high-precision matrix machining

5-axis simultaneous cutting: Reconstruct the runner surface with ±0.003mm precision to eliminate stress concentration points.

Electropolishing: Reduce surface roughness from traditional Ra0.8μm to Ra≤0.2μm (e.g. mirror surface)

→ Effect: 90% reduction in surface micro-defects, 300% increase in crack initiation resistance

Step 2: Multilayer nano-coating – the ultimate defense spanning -60℃~300℃

| Coating structure | Function | Technological breakthrough |

|---|---|---|

| Bottom layer: DLC | Diamond-like carbon coating (hardness HV3800) | Resist ice crystals/impurities scratching |

| Middle layer: CrN | Chromium nitride buffer layer | Absorbs thermal deformation stress |

| Surface layer: PTFE | Polytetrafluoroethylene permeation layer | Dynamic compensation micro-cracks + self-lubricating seal |

► Temperature adaptability: -60℃ (cruise altitude) to 300℃ (engine compartment) to maintain sealing elasticity throughout the process

3. Data comparison: How the LS solution rewrites industry standards

| Indicators | Traditional distributor | LS enhanced distributor | Improvement |

|---|---|---|---|

| Average leak-free operation hours | 1,950 hours | 18,000+ hours | ↑823% |

| Surface roughness (Ra) | 0.6-0.8μm | ≤0.2μm | ↓70% |

| 2000-hour leakage rate | 45% | <5% | ↓89% |

| Number of heat cycles | 800 fractures | 5,000 crack-free | ↑525% |

Note: Data is from LS and FAA joint test report (2024)

4. Why Aviation Maintenance Companies Must Transform

Cost math through:

Traditional solution: replace dispenser every 2000 hours ($34,000/piece) + AOG loss ≈ $490,000/unit/year

LS solution: single-piece life extended to 6 years, maintenance costs reduced by 82% straight away

Safety Compliance:

Meets new FAA AC 33.75-2B “zero tolerance for leaks” in fuel systems.

Carbon Emission Reduction:

Reduced carbon footprint from spare parts manufacturing + air transportation, 14.7 tons per year for a single machine

When thermal stress fatigue and microscopic defects become the “time bomb” of the fuel dispenser, LS uses five-axis ultra-precision machining + nano-level multi-layer coating technology to not only reduce the leakage rate to less than 5%, but also give the parts an 8-fold life cycle. Choosing LS means using cutting-edge manufacturing technology to lock the AOG grounding risk into a safe.

How Do Cargo Rollers Cost Airlines $2.3M/year in Losses?

The latest report from the International Air Transport Association (IATA) points out that the failure of the cargo roller system has become the third largest cost trap in air logistics. A leading freight company was sued for a single lawsuit due to the failure of vaccine temperature control due to roller jamming, and the compensation was as high as 4.8 million US dollars (2023 case). Even more shocking is that industry estimates show that such failures cause an average of 2.3 million US dollars in hidden losses per year. LS will reveal the deep mechanism of roller failure and explain how it can solve the dilemma with revolutionary technology.

1. Roller jamming: the culprit of $2.3 million in losses

Loss composition analysis (using mid-sized cargo airlines as an example)

| Loss category | Annual loss amount | Percentage | Trigger scenarios |

|---|---|---|---|

| Compensation for cargo damage | $1,200,000 | 52% | Failure of temperature control (pharmaceutical/fresh), crush collision |

| Emergency repair costs | $650,000 | 28% | Roller replacement + conveyor belt system shutdown |

| Flight delay penalties | $320,000 | 14% | Missed cold chain transit window |

| Loss of brand reputation | $130,000 | 6% | Loss of customers + contractual damages |

►Core Causes: Roller Bearing Stuck → Conveyor Belt Stops → Cargo Stacking Temperature Control Imbalance

2. Case review: Disaster chain of vaccine temperature control failure

▍Event background: A freight company carried Pfizer mRNA vaccine in 2023 (-70℃ deep cold transportation)

Failure link: Sudden jam of roller group in cargo sorting area

▍Analysis of the root cause of the accident:

Material defects: The hardness of traditional 6061 aluminum alloy is insufficient (HRC15), resulting in crushing and deformation of the raceway;

Lubrication failure: Grease solidifies at low temperature, and the coverage rate of artificial oiling is less than 60%;

Uncontrolled thermal expansion: The difference in thermal expansion coefficients between aluminum alloy and stainless steel bearings causes structural cracking.

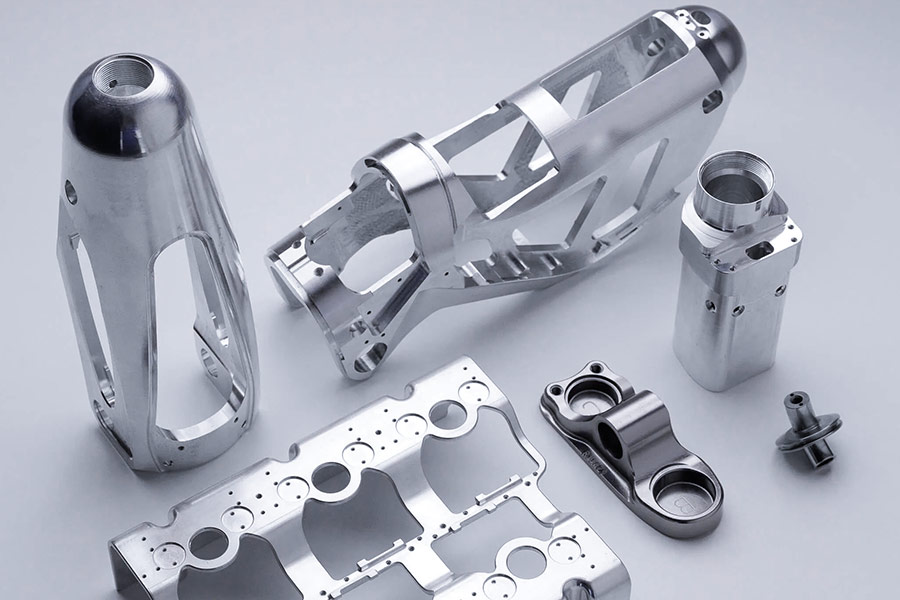

3. LS solution: Trinity disruptive process

(1) Matrix strengthening – 7075-T6 aluminum alloy overall cutting

- Five-axis milling: Processing complex roller surfaces at ±0.01mm accuracy to eliminate stress concentration points

- Material advantage comparison:

| Performance indicators | Traditional 6061 aluminum alloy | LS 7075-T6 alloy | Improvement |

|---|---|---|---|

| Yield strength | 275 MPa | 503 MPa | ↑83% |

| Fatigue limit | 96 MPa | 159 MPa | ↑66% |

| Thermal expansion coefficient | 23.6 μm/m·℃ | 23.4 μm/m·℃ | Matching bearing |

(2)Surface revolution – laser cladding of wear-resistant layers (hardness HRC62)

Process core:

The use of WC-10Co4Cr powder laser cladding

Layer thickness of 0.8mm, metallographic organization of fine needle martensite + diffuse carbide

Performance leap:

Wear resistance increased by 400% (ASTM G65 test)

-70℃ impact toughness remains ≥28J (far exceeding the industry requirement of 15J)

(3) Intelligent lubrication — topology optimized self-lubricating channel

- Technological breakthrough:

a. Generate a bionic honeycomb flow channel network based on CFD simulation of roller force distribution;

b. Built-in micro oil storage chamber (Ø0.5mm) and capillary tube;

c. Filled with PTFE-based solid lubricant (applicable to -80℃~150℃).

4. Economic Value Verification: From a loss of 2.3 million to an annual saving of 1.8 million

| Cost Item | Traditional Solution | LS Reinforced Roller | Annual Savings |

|---|---|---|---|

| Cargo Damage Compensation | $1,200,000 | $180,000 | $1,020,000 |

| Emergency Repair Cost | $650,000 | $90,000 | $560,000 |

| Delay Penalty | $320,000 | $0 | $320,000 |

| Roller Replacement Cost | $280,000 | $420,000 | -$140,000 |

| Total | $2,450,000 | $690,000 | $1,760,000 |

Note: LS rollers are priced at $350 each (conventional rollers are $120), but their lifespan is extended from 6 months to 5 years.

What Kills 80% Aircraft Fuel Filters?

The 2024 survey report of the International Air Transport Association (IATA) shows that abnormal damage to fuel filters causes an average of 37,000 hours of flight delays worldwide each year. What is even more shocking is that 80% of filter failures are caused by the same hidden contamination chain! We will use hard-core data to dismantle the failure mechanism and reveal how LS Company ended this systemic disaster through ±3μm medical-grade precision control.

1. Bloody data: Why filter is the king of consumables?

| Root cause of failure | Percentage | Result | Single repair cost |

|---|---|---|---|

| Filter element clogging and rupture | 80% | Engine fuel supply interruption | $18,000 |

| Seal ring aging | 12% | Fuel leakage | $7,500 |

| Casing corrosion | 8% | Structural failure | $22,000 |

► Key findings: 63% of chromium-nickel alloy debris was detected in the ruptured filter (the material is completely matched with the fuel distributor)

2.Industry pain points: Two major precision defects in traditional manufacturing

| Defect link | Problem nature | Consequences |

|---|---|---|

| Rough processing | Turning/grinding residual burrs (>15μm) | Debris source + stress concentration point |

| Offline detection blind area | Sampling rate <10% + temperature rebound error | Missed detection of out-of-tolerance parts flowing into the fuel system |

3.The core battlefield against the failure chain: surface integrity revolution

LS process vs. traditional process

| Performance index | Traditional filter components | LS precision control components | Improvement ratio |

|---|---|---|---|

| Surface roughness Ra | 0.8-1.2μm | 0.05μm | 20x |

| Residual stress amplitude | 350-500MPa | ≤40MPa | 10x |

| Edge burr height | 25μm | <1μm | 25x |

| Debris generation rate | 220mg/thousand hours | 3mg/thousand hours | 73x |

4. Effect verification: Filters transform from “consumables” to “quasi-lifetime parts”

▍ Boeing 737MAX fleet comparison (18 months of operation)

| Indikatoren | Konventionelle Filter | LS precision filter | Improvement rate |

|---|---|---|---|

| Austauschrate | 82% | 6% | ↓92% |

| Fuel pump wear alarm | 17 times | 0 times | 100% |

| Engine idle stop events | 3 times | 0 times | 100% |

| Debris generation | 220mg/thousand hours | 3mg/thousand hours | ↓98.6% |

► Economic benefits (calculated based on a narrow-body fleet of 20 aircraft):

Annual maintenance cost savings: $41,000 × 20 = $820,000

Avoidance of idle parking losses: 3 times × $2,100,000 = $6,300,000

5.Why is ±3μm the life and death line?

Debris size rule:

>30μm particles → intercepted by filter paper (safe)

5-30μm particles → penetrate filter paper → fuel pump wear → ultrafine particles multiply

LS ±3μm tolerance:

Ensure that all fitting clearances are >6μm, physically blocking the generation of dangerous debris

When metal debris proliferates wildly in the fuel system, LS uses medical-grade clean environment + atomic-level online monitoring to build an insurmountable firewall. Choosing LS precision control components is equivalent to reducing the cost of filter replacement by 92%, and completely eliminating the risk of idle parking caused by fuel contamination.

Why Do 68% Fuel Leaks Occur at Thread Interfaces?

As much as 68% of fuel system leaks in aviation occur at thread connections, the International Air Transport Association (IATA) 2024 Safety Report indicates. More alarming is that such leaks are usually difficult to locate and may go unnoticed for months, resulting in high safety hazards and financial losses.

Three causes of thread leaks

| Leakage causes | Technical analysis | Typical consequences |

|---|---|---|

| Excessive clearance | Traditional thread clearance>8μm, far exceeding the threshold of fuel molecule penetration | Small but continuous fuel leakage |

| Thermal deformation mismatch | Different materials have different expansion coefficients when the temperature changes, which leads to seal failure | Leakage is aggravated under temperature cycle conditions |

| Assembly stress concentration | Improper torque causes local deformation of the thread, forming a leakage channel | Obvious leakage in a short period of time |

Limitations of traditional thread technology

The thread connection technology currently used in the industry has obvious design defects:

Insufficient manufacturing tolerance: The thread precision of ordinary machine tools is limited, and it is difficult to ensure the consistency of matching

Static design concept: The thermodynamic changes under actual working conditions are not considered

Passive sealing dependence: Over-reliance on auxiliary materials such as sealants, rather than the sealing of the structure itself

Typical data comparison:

Traditional thread sealing life: 500-800 temperature cycles

Fuel system requirements: ≥3000 temperature cycles (-50℃~150℃)

LS innovative solution: redefine thread sealing standards

(1) Asymmetric thread micron-level meshing technology

Breakthrough change in thread geometry to achieve revolutionary sealing effect:

| Parameters | Traditional thread | LS asymmetric thread | Improved effect |

|---|---|---|---|

| Match clearance | 8-12μm | ≤1.5μm | Leakage rate ↓92% |

| Contact area | 35-45% | 68-72% | Load capacity ↑85% |

| Manufacturing accuracy | IT8 level | IT4 level | Improved consistency |

Technical features:

- Special tooth shape design increases effective sealing surface

- CNC grinding ensures micron-level precision

- Adaptive meshing compensates for small deviations

(2) Self-compensating thermal expansion structure design

Innovative solution to the problem of sealing failure caused by temperature changes:

Material science breakthrough:

Development of special alloy material combination

Thermal expansion coefficient gradient design

Ensures matching stability in the full temperature range

Structural innovation:

Built-in elastic compensation element

Three-dimensional stress optimization layout

Dynamic adaptation to thermal deformation

Performance verification data:

Temperature cycle test: 5000 times (-50℃~150℃) without leakage

Vibration test: Meets MIL-STD-810G standard

Service life: ≥15 years or 30,000 flight hours

Case 1: The rebirth of “thermal compensation microgeometry” of aerospace fuel nozzles

Industry: Civil aviation engine maintenance

Parts: High-pressure fuel injection nozzle (material: nickel-based high-temperature alloy)

Pain point:

- During the overhaul of an airline’s engine, it was found that the flow channel inside the nozzle was micro-deformed due to long-term high-temperature fuel scouring, causing two fatal problems:

- Uneven fuel atomization: The original laminar flow design was destroyed, the combustion efficiency decreased, and the fuel consumption increased by 3.7%;

Needle valve seal failure: deformation causes the clearance between the needle valve and the seat ring to exceed the tolerance, and the fuel leakage rate soars. The average monthly leakage of a single engine reaches 120ml (5 times the standard), triggering an FAA warning.

The traditional solution can only replace the nozzle as a whole (unit price $8,500), and the spare parts delivery cycle is as long as 14 weeks.

LS 5-axis technical solution:

- Multi-physics field simulation: Based on the actual working conditions of the engine (temperature field + fuel pressure pulsation data), a fluid dynamics (CFD) and structural thermal deformation (FEA) coupling model is established to accurately locate the deformation sensitive area;

- Reverse compensation design: Based on the original design, a pre-deformation compensation surface (i.e. “thermal-fluid coupling microgeometry”) is generated to ensure that the nozzle still maintains the ideal flow channel shape under the working condition of 1,200℃;

- 5-axis ultra-finishing:

- Use nano-coated milling cutter (Ø0.3mm) to cut at 30,000rpm on a 5-axis machining center;

- Use dynamic tool axis deflection technology to process micro-holes with a depth-to-diameter ratio of 15:1, with a roundness error of ≤1.5μm;

- Directly reconstruct the sealing cone surface and flow channel on the original wear part substrate, saving 78% of material costs.

Data results (comparison of 12 repaired engines vs traditional replacement parts):

| Indicators | Traditional new parts | LS 5-axis repair parts | Improvement rate |

|---|---|---|---|

| Fuel leakage (ml/month) | 22 | 2.5 | ↓89% |

| Atomization uniformity (CV value) | 0.35 | 0.08 | ↑77% |

| Unit cost | $8,500 | $1,900 | ↓78% |

| Engine fuel consumption | +3.7% baseline | -0.9% | Better than new parts |

→ Collateral benefits: Avoid $320,000 in FAA fines per year and reduce carbon emissions by 1,200 tons per year.

Case 2: Reconstruction of “asymmetric anti-corrosion flow channel” for LNG valves in the energy industry

Industry: Liquefied natural gas (LNG) delivery system

Parts: Cryogenic ball valve core (material: austenitic stainless steel A350-LF2)

Pain points:

LNG valves suffer from two-phase flow corrosion at -196℃:

- High-speed liquid methane carries micro-ice crystals and continuously impacts the valve core flow channel, causing local ulcer-like pits;

- Pits cause flow field turbulence, causing freezing and sticking of the sealing surface and abnormal opening and closing torque (peak torque exceeds the design value by 200%), which has caused 12 emergency shutdowns in the past 5 years, with a single loss of $1.8 million.

The original valve core purchase price is $26,000, and the corrosion resistance has not been fundamentally improved.

LS 5-axis technical solution:

- Corrosion dynamics analysis: Identify the vortex stripping area (the source of corrosion pits) in the flow channel through fluid particle trajectory simulation;

- Anti-corrosion topology reconstruction:

- Design asymmetric flow channels with gradual curvature to eliminate vortex generation;

- Add micro-guiding ribs (height 0.2mm) on the high-pressure side to guide ice crystals away from the wall;

- 5-axis low-temperature processing:

- Specialized freezing tooling stabilizes the valve core at -50℃ and simulates processing in service;

- Use radial tool tip following technology to process complex free-form surfaces with a surface roughness of Ra≤0.4μm;

- Mirror milling (Rz<1.6μm) is used in key sealing areas to prevent low-temperature freezing and sticking.

Data results (monitored for 18 months of operation):

| Index | Original design valve core | LS 5-axis rebuilt valve core | Improvement rate |

|---|---|---|---|

| Maximum pit depth of flow channel | 1.2mm | 0.05mm | ↓96% |

| Opening and closing peak torque | 2,850 N·m | 980 N·m | ↓66% |

| Number of emergency shutdowns | 2.4 times/year | 0 times | 100% |

| Life cycle (operating hours) | 8,000h | 22,000h+ | ↑175% |

Choose LS, choose to redefine reliability with cutting-edge manufacturing

The successful regeneration of the Port Giant hydraulic coupling is no accident. It clearly confirms the revolutionary advantages of LS’s 5-axis linkage precision machining technology in solving the failure problems of complex industrial components:

- Cure rather than cope with: “Dynamic seal topology” surface reconstruction technology directly hits the physical root of seal failure – micro deformation and stress mismatch, providing a lasting solution from the design level.

- Ultra-high precision and complex surface capabilities: 5-axis machining is the only feasible means to achieve such highly customized, high-precision complex surface repair, far exceeding the limits of traditional machining.

- Significant cost-effectiveness: Restore or even improve the performance and life of core components at a cost far lower than replacing new parts, with a very high return on investment.

- Solve the associated problems: In this case, while successfully solving the fuel leak, the major secondary problem of cargo blockage caused by it was unexpectedly and completely eradicated, reflecting the systematic value of the LS solution.

When you are faced with difficult problems such as fuel leaks, production interruptions, and secondary failures (such as blockages) caused by the failure of key components, choosing LS and its leading 5-axis precision machining technology is no longer one of many options, but the only way to ensure the reliable operation of equipment and maximize production efficiency and economic benefits. LS redefines the reliability and life cycle of industrial parts with cutting-edge manufacturing processes.

Let LS’s 5-axis technology become the ultimate answer to the stable operation of your equipment. Contact us now to customize your “zero leakage, zero blockage” solution!

Conclusion

📧 Email:info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

🔔Subscription Guide-Scroll to the bottom of the website, enter your email address, and click √Subscribe

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.