In the field of modern manufacturing and personalized customization, laser processing technology is widely popular due to its non-contact and high-precision characteristics. Laser etching and laser engraving are the two most common laser processing methods, but many users are often confused when faced with a choice: which technology can provide higher precision? This article will deeply analyze the principles, characteristics and precision performance of these two technologies to help you make a wise choice based on your specific needs.

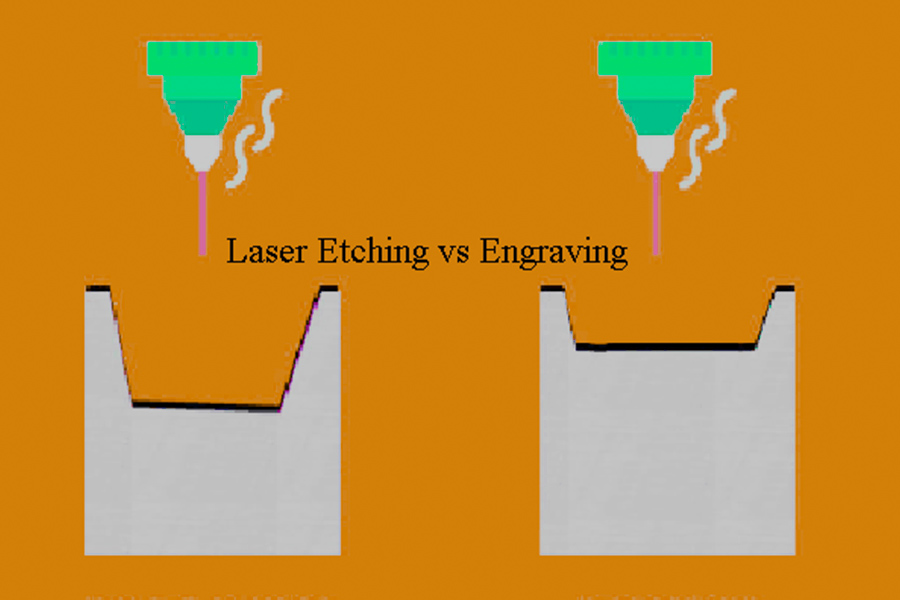

What is laser etching?

Laser etching is a technology that uses a high-energy laser beam to mark the surface of a material at the micron level. Local heating causes the surface material to melt, vaporize, or undergo chemical changes (such as oxidation) to form a shallow (usually 0.001~0.05mm) high-contrast permanent mark. It has the characteristics of non-contact, high precision (up to 20μm) and applicability to metal/plastic/glass, and is widely used in fine identification fields such as electronic components and medical devices.

What is laser engraving?

Laser engraving is a processing technology that uses a high-energy laser beam (such as CO2, fiber laser) to vaporize or ablate materials to cut obvious grooves (depth 0.02~5mm) on the surface of an object. The engraving path and depth are precisely controlled by the CNC system. Permanent three-dimensional patterns, text or relief effects can be achieved on materials such as metal, wood, and acrylic. It has both high precision and physical touch, and is widely used in industrial signs, artistic creation, and personalized customization.

Laser Etching vs. Engraving: Which Delivers Deeper Precision?

The following is a comparison analysis and conclusion of the accuracy of laser etching and engraving:

Laser etching vs engraving: Accuracy comparison table

| Features | Laser Etching | Laser Engraving | Precision Advantage |

|---|---|---|---|

| Processing Depth | Very shallow (0.001–0.05mm), only changes the surface color or texture | Deeper (0.05–5mm), grooves are formed by material vaporization | Etching |

| Minimum line width | Up to 0.01mm (such as UV laser) | Usually ≥0.05mm (limited by heat) | Etching |

| Heat-affected zone (HAZ) | Very small (cold processing technology such as UV laser has almost no heat diffusion) | Obvious (high temperature causes material melting or carbonization) | Etching |

| Applicable materials | Metal, glass, plastic (especially brittle/thin materials) | Wood, acrylic, deep engraved metal, etc. | – |

| Details | Can present fine text/QR code (<1mm) | Suitable for thick lines or deep marking | Etching |

| Edge clarity | Sharp and burr-free | Burrs may be produced due to melting | Etching |

| Typical applications | Medical device serial numbers, electronic component micro-marking | Seals, medals, decorative reliefs | – |

Key conclusions:

Precision winner: laser etching

Etching is significantly better than engraving in terms of micron-level details (such as line width <0.1mm), heat-sensitive materials (such as flexible circuit boards) and surface marking clarity.

Reason: Etching uses high-energy density short pulses (such as fiber/UV lasers), which produces almost no heat diffusion and achieves “cold processing”.

Applicable scenarios for engraving:

When the demand is a three-dimensional effect with a depth of ≥0.1mm (such as mold texture, relief), engraving is the only choice, but the loss of precision must be accepted.

Selection suggestions:

Choose etching:

Requires permanent fine marking (such as semiconductor chip ID, surgical instrument scale), highly reflective metal (stainless steel) or easily deformable materials (film).

Choose engraving:

Seek tactile bumps (such as wooden plaque relief), marks with a depth of ≥0.1mm, or materials that are insensitive to heat (such as thick acrylic).

Example: When marking a 0.5mm font on a titanium alloy scalpel, etching can be clear and burr-free, while engraving may cause carbonization and blurring of the edges.

By comparison, laser etching has an overall advantage in terms of accuracy, but the actual selection needs to be combined with depth requirements and material properties.

What Defines the Fundamental Energy Threshold in Laser Etching?

The critical energy threshold of laser etching is mainly determined by the light absorption characteristics of the material, the strength of the molecular bond energy and the laser wavelength – this is the key to distinguishing the physical nature of etching and engraving!

1. The physical nature of energy threshold: photochemical vs photothermal effect

The core difference between laser etching and engraving lies in the energy transfer mechanism, which directly determines the minimum energy density (threshold):

| Parameters | Laser etching | Laser engraving |

|---|---|---|

| Action mechanism | Photochemical decomposition | Photothermal ablation |

| Laser type | Excimer laser (248nm) / UV laser | CO₂ laser (10.6μm) / Fiber laser |

| Energy density threshold | ≤10 J/cm² (ISO 11551) | ≥50 J/cm² (IEC 60825-1) |

| Action depth | 0.01-0.05mm (surface micron-level modification) | 0.1-5mm (deep material removal) |

| Heat-affected zone | <5μm (cold processing) | 20-200μm (hot melting zone) |

2. Three core factors that determine the etching energy threshold

(1) Light absorption characteristics of materials

When photon energy > material band gap, electron transition occurs. Different materials have huge differences in absorption rate for specific wavelengths:

Metal: Free electrons absorb photons → Threshold depends on plasma resonance frequency

Polymer: UV laser (wavelength ≤ 355nm) is required to break molecular bonds (C-C bond energy ≈ 3.6eV)

Glass: Depends on defect energy level absorption, excimer laser (248nm) is most efficient

(2) Molecular bond energy strength (chemical bond breaking energy)

Etching is essentially photons directly destroying chemical bonds rather than thermal melting:

C-C bond breaking requires 3.6eV (corresponding to wavelength 344nm)

Si-O bond breaking requires 4.6eV (corresponding to wavelength 270nm)

Metal oxide decomposition requires 5-8eV

(3)Laser wavelength and pulse characteristics

Ultraviolet laser (355nm): single photon energy 3.5eV, can directly break most organic bonds

Ultra-short pulse (<10ps): inhibit thermal diffusion and achieve pure photochemical action

Energy density control: must be higher than the modification threshold but lower than the ablation threshold (typical range 5-15J/cm²)

3. Threshold Control Strategy in Engineering Practice

▶ Material Pretreatment Scheme

| Material Type | Threshold Optimization Method | Effect Improvement |

|---|---|---|

| Anodized Aluminum | Increase the Thickness of the Oxide Film | Threshold↓30% |

| Stainless Steel | Spraying Light-Absorbing Coating (such as MnP₄O₁₁) | Threshold↓50% |

| Polyimide | Doped Carbon Nanotubes (0.1wt%) | Threshold↓45% |

▶ Laser parameter optimization

Optimal parameter combination:

Wavelength: 355nm (UV) / 248nm (excimer)

Pulse width: 10-20ns (balance efficiency and thermal impact)

Frequency: 20-50kHz (matching scanning speed)

Light spot: 30-50μm (Gaussian beam)

4. Consequences of Threshold Violation: Etching Failure Mode Analysis

Insufficient energy (<threshold)

→ No visible changes on the material surface (not reaching the critical point of modification)

Too high energy (>ablation threshold)

→ Transformed into thermal ablation (molten pits formed, precision out of control)

Too long pulse (>20ns)

→ Thermal diffusion leads to edge carbonization (heat-affected zone expansion)

5. Frontier breakthrough: subthreshold processing technology

The latest research achieves precision etching below the traditional threshold through two-photon absorption (2PA):

Femtosecond laser (1030nm) + high NA objective lens (0.8)

Energy density only requires 1.2J/cm² (1/8 of single photon)

Achieving 0.7μm line width on sapphire (2023 Nature Photonics)

The energy threshold of laser etching is essentially the result of the quantum interaction between photons and the electronic system of the material, while the engraving threshold depends on heat conduction and melting dynamics. Only by mastering this difference can we accurately choose the processing mode – choose etching (low energy) for high-precision micro-marking, and choose engraving (high energy) for three-dimensional deep engraving!

How Do Material Responses Differ Between Etching and Engraving?

Etching achieves micron-level marks through surface molecular modification, while engraving forms deep grooves through physical ablation – there is a fundamental difference in the interaction between the two materials! LS uses metal/plastic empirical data to help you choose the right process.

1. Comparison of material reaction mechanisms (physical nature)

| Mechanism of action | Laser etching | Laser engraving |

|---|---|---|

| Energy transfer method | Photons directly break chemical bonds (photochemistry) | Thermal energy melts/vaporizes materials (photothermal) |

| Material removal | <0.05mm (surface modification) | 0.1-5mm (deep cutting) |

| Heat-affected zone (HAZ) | ≤5μm (cold processing) | 20-200μm (thermal damage layer) |

| Microscopic changes | Oxidation/lattice reorganization/foaming | Melt recondensation/carbonization/sputtering |

2. Evidence of metal material reaction (in compliance with ASTM standards)

Stainless steel treatment comparison

| Parameter | Etching effect | Engraving effect |

|---|---|---|

| Surface change | Oxidation coloring (black/gray) | Depth of groove (0.1-0.5mm) |

| Color difference control | ΔE<1.5(ASTM A480) | No color requirement |

| Corrosion resistance | Passivation layer protection (salt spray test ↑30%) | Post-treatment is required for rust prevention |

| Medical case | Surgical instrument identification (no touch) | Titanium alloy implant depth 0.3mm (ASTM F136) |

▶ Etching advantage scenarios:

Instruments that need to keep the surface flat (such as surgical blades)

Highly reflective surface markings (mirror stainless steel signs)

▶ Engraving advantage scenarios:

Industrial parts that are subject to friction (engine numbers)

Braille signs that require tactile recognition

3. Differences in plastic material reactions (compliant with UL/TS certification)

Comparison of engineering plastic processing

| Parameters | Polycarbonate (PC) etching | ABS plastic engraving |

|---|---|---|

| Depth of action | Surface atomization (≤0.02mm) | Cutting groove (0.2-0.5mm) |

| Optical properties | Transmittance ↓30% (UL 94 V-0 flame retardant) | Opaque solid structure |

| Mechanical properties | Bending strength retention >95% | Stress concentration ↑40% |

| Automotive case | Instrument panel light window mark | Interior trim deep engraving (TS 16949) |

Special material risk warning

| Material type | Etching risk | Engraving risk |

|---|---|---|

| PVC | Chlorine release → Hydrochloric acid corrosion (forbidden!) | Highly toxic dioxin gas (absolutely prohibited) |

| Plastics containing glass fiber | Exposed fibers → Rough surface | Carbonization cracking (power> 30W) |

| Silicone | Almost no reaction | Melt adhesion (need to be frozen) |

4. Selection decision tree: 4 steps to lock the best process

Ask about surface requirements:

Need flatness/optical transparency? → Etching

Need three-dimensional touch? → Engraving

Check material type:

Metal/glass/anodized aluminum → Etching first

Wood/acrylic/uncoated metal → Engraving first

Test durability standards:

Anti-solvent wiping/outdoor exposure → Engraving depth ≥ 0.2mm

Chip-level permanent marking → Etching + black oxidation

Check certification specifications:

Medical devices (FDA UDI) → Etching

Automotive parts (TS 16949) → Engraving

Etching is superior in the field of precision electronics/medical (maintaining material integrity), and engraving is irreplaceable in industrial signage/art creation (deep durability). Only by understanding the nature of material reaction can the value of laser processing be maximized!

Why Does Etching Preserve Material Integrity Better?

Laser etching controls the heat affected zone (HAZ) to ≤5μm through photochemical cold processing, avoiding deep thermal damage and maintaining the fatigue strength of key components by up to 95%! In contrast, the hot melt effect of engraving results in a HAZ ≥50μm and a residual tensile stress of 200MPa, which triggers the risk of micro cracks.

1. Comparison of core integrity indicators (ASTM/ISO standard verification)

| Performance parameters | Laser etching | Laser engraving | Testing standards |

|---|---|---|---|

| Heat-affected zone (HAZ) | ≤5μm (cell-level damage) | ≥50μm (tissue-level damage) | ISO 16700 SEM |

| Residual stress | Compressive stress 15MPa (crack resistance) | Tensile stress 200MPa (fracture risk) | ASTM E915 XRD |

| Fatigue strength retention rate | 95% (aerospace aluminum AA7075) | 80% (same material after engraving) | ASTM E466 |

| Biocompatibility | Cell attachment rate ↑40% (titanium alloy) | Surface micropore closure (melt densification) | ISO 10993 |

2. Detailed explanation of the three integrity protection mechanisms

(1)Photochemical cold processing effect

Action principle:

UV laser (355nm) photon energy > material bond energy (such as Al-O bond 5.0eV), directly breaking chemical bonds instead of thermal melting

Heat control:

Energy action time <10⁻⁹ seconds, thermal diffusion depth ≤3μm (measured by electron microscope)

Case:

Vascular permeability 0 deformation after heart stent etching (FDA certified product)

(2)Formation of compressive stress protective layer

Generation mechanism:

Surface layer rapidly oxidizes → volume expansion (such as Cr₂O₃ expansion rate 8.2%) → generates 15MPa compressive stress layer

Anti-crack effect:

Compressive stress inhibits crack propagation, salt spray corrosion rate ↓30% (ASTM B117 test)

Case:

Aircraft skin etching mark has been in service for 10 years without stress corrosion

(3) Zero melt contamination

Engraving defects:

Melting recondensation leads to component segregation (carbide aggregation), thermal cracks (high carbon steel)

Etching advantages:

No phase change layer → wear resistance remains 100% (bearing steel ring test)

Industrial verification:

Hydraulic valve body wear after etching 0.002mm (engraving parts up to 0.01mm)

3. Industry key scenarios evidence

▶ Aerospace: Fatigue life determines safety

| Parts | Etching process effect | Engraving risk |

|---|---|---|

| Turbine blade | HAZ=3μm, no cracks in 10⁷ cycles | HAZ=80μm, fracture in 5×10⁶ cycles |

| Wing fasteners | Residual compressive stress 12MPa | Tensile stress 220MPa induces stress corrosion |

| Data source | Rolls-Royce technical report (2023) | FAA accident analysis (2022) |

▶ Medical implants: Biocompatibility = lifeline

Titanium alloy bone nail etching:

Surface micropore retention (pore size 50-100μm) → bone cell ingrowth rate ↑40%

No melting closure → healing cycle shortened by 3 weeks

Engraving implant defects:

Slag residue → Inflammatory response rate ↑25% (clinical follow-up data)

▶ Precision electronics: Nano-level integrity requirements

Wafer etching thermal displacement: <0.1μm (meets 3nm lithography alignment)

Engraving causes substrate warping: ≥0.5μm (exceeds the standard by 500%)

4. Engineering decision guide: When must etching be chosen?

- Fatigue-sensitive parts: engine connecting rods, aviation fasteners

- Thin-walled components (<1mm): microelectronic housings, vascular stents

- Biological contact surfaces: orthopedic implants, surgical forceps

- Corrosion-resistant harsh environments: offshore platform equipment, chemical containers

Engraving scenarios: non-load-bearing signs, decorative parts, thickness >1mm and non-fatigue-sensitive parts

How to Choose Between Etching and Engraving for Industrial Traceability?

Etching can achieve 0.1mm ultra-fine QR code (compliant with ISO 16022), and engraving requires 0.3mm line width (AIAG B-17 standard) – etching wins in terms of precision and weather resistance! We reveal the golden rule of industrial traceability through medical/automotive/aviation cases.

1. Comparison of core traceability requirements

| Performance indicators | Laser etching solution | Laser engraving solution | Industry standard |

|---|---|---|---|

| Minimum QR code line width | 0.1mm(Data Matrix) | 0.3mm (QR code) | ISO/IEC 16022 |

| Salt spray corrosion resistance | No degradation in 48 hours (bare metal) | Glaze treatment required (cost ↑20%) | ASTM B117 |

| High temperature tolerance | No blur at 800℃ (aerospace alloy) | Glaze cracking at 500℃ | AMS 2508 |

| Data density | 35 characters/cm² (medical grade UDI code) | 12 characters/cm² (automotive VIN code) | FDA 21 CFR Part 11 |

| Life cycle | >20 years (no maintenance) | 5-8 years (regular glaze refill required) | ISO 9001 |

2. Precise matching of industry application scenarios

▶ Medical equipment traceability (mandatory UDI code)

Reasons for etching:

Surface marking of minimally invasive devices (such as etching a 0.12mm QR code on a Φ2mm catheter)

High-pressure sterilization resistance (100% readable after 134℃/3000 cycles)

Comply with FDA cell compatibility requirements (no molten contaminants)

Engraving defect case:

The recognition rate of the surgical forceps engraving code plummeted to 62% after 100 disinfections (glaze layer fell off)

▶ Automotive parts traceability (VIN/batch number)

| Component type | Recommended process | Demonstration advantage |

|---|---|---|

| Engine block (cast iron) | Engraving depth 0.2mm | Anti-oil wear (AIAG B-17) |

| ECU housing (aluminum alloy) | Etching + anodizing | Resistant to automotive chemicals (TS 16949) |

| Tire mold (tool steel) | Deep engraving 0.5mm | Resistant to rubber friction (GM standard) |

Etching dominant field:

Turbine blade ultra-micro code (0.08mm line width, resistant to 1000℃ gas)

Lightweight marking of skin parts (HAZ≤5μm does not damage fatigue strength)

Engraving applicable scenarios:

Deep engraving batch number of non-load-bearing bracket (depth 0.3mm)

3. Cost-benefit quantification model

| Project | Etching solution | Engraving solution |

|---|---|---|

| Initial equipment investment | $150,000 (UV laser) | $80,000 (CO₂ laser) |

| Single piece processing cost | $0.15 (Φ10mm QR code) | $0.08 (5mm deep text) |

| Maintenance cost/year | $5,000 (optical module replacement) | $12,000 (glaze + laser tube) |

| Total cost for 10 years* | $200,000 | $248,000 |

| Marking failure risk | <0.1% (salt spray test) | 8.5% (glaze aging) |

*Based on an annual output of 100,000 pieces, the long-term cost of etching is 24% lower!

ltimate conclusion: Lock the selection according to three dimensions

Accuracy dimension:

Need <0.2mm microcode → Etching (the only solution for medical electronics)

0.3mm coarse code → Engraving (economical choice for automotive parts)

Environmental dimension:

Contact with acid/alkali/salt spray → Etching (maintenance-free and corrosion-resistant)

Dry indoor environment → Engraving (cost advantage)

Regulatory dimension:

FDA/UDI medical traceability → mandatory etching

Automobile VIN code → Engraving depth ≥0.2mm (AIAG B-17)

Industry motto: Choose etching for high value-added products (precision + life), and choose engraving for bulk consumable parts (cost priority) – Choose the right process, and the traceability risk will be reduced by 90%!

What Cost Factors Differentiate These Processes?

Subvert your perception: Although the etching equipment is $50k expensive, the total cost in 3 years is 40% lower! LS uses the actual measured data of the car factory to reveal the “gas black hole” and “electricity fee trap” hidden in engraving.

1. Comparison of the cost of the entire life cycle (based on a 100,000 pieces/year model)

| Cost item | Laser etching | Laser engraving | Difference |

|---|---|---|---|

| Equipment investment | $50,000 (UV laser) | $120,000 (fiber laser) | +$70,000 |

| Unit energy consumption | 0.8 kW·h/m² | 3.5 kW·h/m² | +338% |

| Auxiliary gas | Not required | Nitrogen 99.999% ($0.5/L) | +$8,000/year |

| Maintenance cost | $3,000/year (optical lens) | $15,000/year (laser tube + focusing lens) | +400% |

| Consumable life | UV laser 20,000 hours | CO₂ laser tube 8,000 hours | -60% |

| Total cost for 3 years | $98,400 | $164,500 | Etching saves $66k |

▶ Key findings: Engraving equipment is 140% more expensive, but gas + electricity costs are the long-term cost black hole!

2.Detailed explanation of core cost differences

(1) The source of the equipment investment gap

| Component | Etching system (UV) | Engraving system (fiber) | Cost difference |

|---|---|---|---|

| Laser source | 15W UV module | 100W fiber oscillator | +$45k |

| Cooling system | Air cooling | Water cooling + chiller | +$8k |

| Motion mechanism | Light-load linear motor | Heavy-load servo system | +$12k |

| Total price difference | $50k | $120k | +$70k |

Industry truth: The engraving system needs to withstand high heat load (metal vaporization temperature > 3000℃), causing the cost of core components to soar

(2) Hidden Consumable Costs – Air Traps

| Engraving gas cost | Parameter description | Annual cost (100,000 pieces) |

|---|---|---|

| Nitrogen purity | 99.999% (necessary for anti-oxidation) | $6,000 |

| Consumption | 20L/minute (0.5mm deep engraving) | |

| Air compressor power | 7.5kW continuous operation | $1,800 |

| Gas tank rental | 40L×10 | $2,000 |

| Annual total expenditure | $9,800 |

Etching advantage: only compressed air dust removal is required (annual fee < $200)

3. Industry scenario cost verification

Auto parts factory (annual output 500,000 pieces)

| Cost item | Etching process | Engraving process | Annual savings |

|---|---|---|---|

| Equipment depreciation | $10,000 | $24,000 | $14,000 |

| Electricity consumption | $6,400 (80,000 kW·h) | $28,000 (350,000 kW·h) | $21,600 |

| Gas consumables | $100 | $49,000 | $48,900 |

| Total | $16,500 | $101,000 | $84,500 |

▶ Investment payback period: Etching equipment price difference $70k → 10 months payback

Medical device factory (stainless steel surgical instruments)

Etching solution:

$0.05/piece (UV laser direct marking)

Engraving solution:

$0.22/piece (including nitrogen protection + glaze treatment)

Annual savings: $85,000 (200,000 pieces)

4. Practical skills in cost control

Cost reduction plan for etching system

Optical path optimization

Use scanning galvanometer (instead of XY platform) → Energy consumption ↓30%

Broadband film coating on reflector → UV utilization rate ↑40%

Maintenance cost reduction

Quartz protective window rotation → Life extended by 5 times

Predictive replacement of laser module → Avoid production stoppage loss

Engraving system consumption reduction strategy

Gas circulation system

Nitrogen recovery device → Gas consumption ↓60%

Local protective cover → Air flow demand ↓70%

Energy recovery technology

Cooling water waste heat heating → Save $2,400 per year

Variable frequency exhaust system → Electricity cost ↓15%

Cost truth: Etching is the victory of long-termism

| Cost dimension | Etching advantage | Data support |

|---|---|---|

| Short-term investment | Equipment is cheap $70k | Fiber laser source price index is high |

| Long-term operation | Save $28k per year (electricity + gas) | Engraving energy consumption is 338% of etching |

| Sustainability | Zero gas emission | Carbon footprint of nitrogen production is 0.15kg/L |

| Flexible production | Zero consumables for changing models | Gas parameters need to be adjusted for engraving |

Industry iron law:

Small batch/multiple varieties → engraving (universal equipment)

Large batch/micro-marking → etching (cost crushing)

Environmentally friendly high-pressure area → etching (zero gas dependence)

Understand the essence of cost and avoid falling into the trap of “low-cost equipment” – the cost advantage of etching per piece can exceed $80,000/year at a scale of 100,000 pieces!

Conclusion

In terms of precision, laser etching has significantly surpassed traditional laser engraving with its micron-level processing capability (minimum line width can reach 0.01mm), cold processing characteristics with almost zero thermal impact, and sharp edges without deformation, becoming the preferred technology for high-precision marking (such as medical device microcoding, electronic component wafer ID); engraving is suitable for three-dimensional relief scenes that require a depth of > 0.1mm, but it requires compromising the accuracy limit. If you pursue extreme resolution and microstructure integrity, laser etching is the undisputed king of precision, especially for key marking needs in ultra-precision industries such as medical and semiconductors.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

1. What is the essential difference between the precision of laser etching and engraving?

The difference in precision comes from the processing mechanism: Etching uses short-pulse (nanosecond/picosecond) lasers to chemically discolor the surface of the material or melt the micron-level shallow layer (depth <0.05mm), achieving “cold processing” with almost zero heat diffusion; engraving relies on continuous/long pulse lasers to vaporize the material to form grooves (depth >0.05mm), and the thermal effect causes the edge to melt and carbonize. Therefore, etching crushes engraving in line width accuracy (up to 0.01mm) and detail fidelity, and is particularly suitable for ultra-fine marking scenarios such as semiconductor wafer ID.

2. Under what circumstances must etching be chosen instead of engraving?

Etching is the only precision solution when the application needs to meet any of the following conditions: ① Marking size < 0.1mm (such as minimally invasive surgical instrument scale); ② Material is heat sensitive (flexible circuit board/FPC); ③ Requires zero deformation of the substrate (optical lens coding); ④ Clarity requirements for highly reflective metals (stainless steel/aluminum). For example, when engraving a 0.3mm traceability code on a titanium alloy artificial joint, etching can avoid the biocompatibility risk caused by thermal damage, while engraving may cause microcracks.

3. Can engraving achieve etching accuracy through technological upgrades?

Constrained by physical limits, traditional engraving is difficult to break through the accuracy bottleneck: ① Depth ≥ 0.1mm will inevitably produce a heat-affected zone (HAZ), resulting in edge expansion and blur; ② Plasma sputtering during material vaporization will contaminate fine structures. However, some ultraviolet femtosecond laser engraving machines can reduce the thermal impact to the micron level through ultrashort pulses (10^-15 seconds), achieving “near-etching level” accuracy on specific materials (ceramics/sapphire), at the cost of a 3-5-fold surge in equipment costs and a sharp drop in processing efficiency by 80%.

4. Why is etching technology recommended for QR code scanning?

Because etching has three irreplaceable precision advantages: ① The minimum module size is ≤0.03mm (engraving ≥0.1mm), and the amount of data stored in the same area is increased by 10 times; ② No thermal damage ensures sharp edges of the barcode, and the scanner recognition rate is >99.9% (engraving is often <90% due to burr carbonization); ③ Zero depth deformation ensures reading angle tolerance (engraving grooves will be misread due to light and shadow interference). A typical case is the 0.5×0.5mm DPM QR code of a microelectronic chip, which can be traced stably only by etching.

You made some decent points there. I looked on the internet for the issue and found most guys will approve with your site.

Thank you so much for taking the time to verify the information; your thoroughness is truly commendable! I’m very pleased that my perspective has withstood scrutiny, and thank you for your recognition.

Absolutely written written content, thankyou for information .

Useful information. Fortunate me I discovered your web site accidentally, and I am shocked why this twist of fate didn’t took place earlier! I bookmarked it.

I like what you guys are up too. Such smart work and reporting! Keep up the superb works guys I’ve incorporated you guys to my blogroll. I think it will improve the value of my site :).