What comes to mind when you hear the word “tap”? Is it the faucet that controls the flow of water at the kitchen sink? Or the tap that flows golden beer at the bar? These everyday objects do share the name “tap”. However, in the world of manufacturing and precision engineering, “tap” carries a completely different but crucial mission – it is not a switch for fluids, but a metal engraving tool, the creator of precision internal threads. This is the protagonist we are going to discuss today: the machining tap.

Understanding this special tool used to cut precision threads on the wall of a hole is one of the cornerstones of mastering CNC machining technology and even the entire field of modern mechanical manufacturing. Let’s uncover the precision world hidden behind this seemingly ordinary name.

Common Tap Types Core Comparison Table

| Tap Type | Alias/Nickname | Key Feature | Best For |

|---|---|---|---|

| Hand Taps | Set of 3 | Usually a set of three taps: head tap (cone tap), second tap, bottom tap (fine tap). The head tap has the largest taper to guide the cut; the second tap has a moderate taper; the bottom tap has almost no taper and is used to complete the thread or calibrate. | It is suitable for manual tapping operations, repairing damaged threads, through holes and blind holes (especially suitable for blind holes, the three taps are cut in steps to reduce the risk of breakage). |

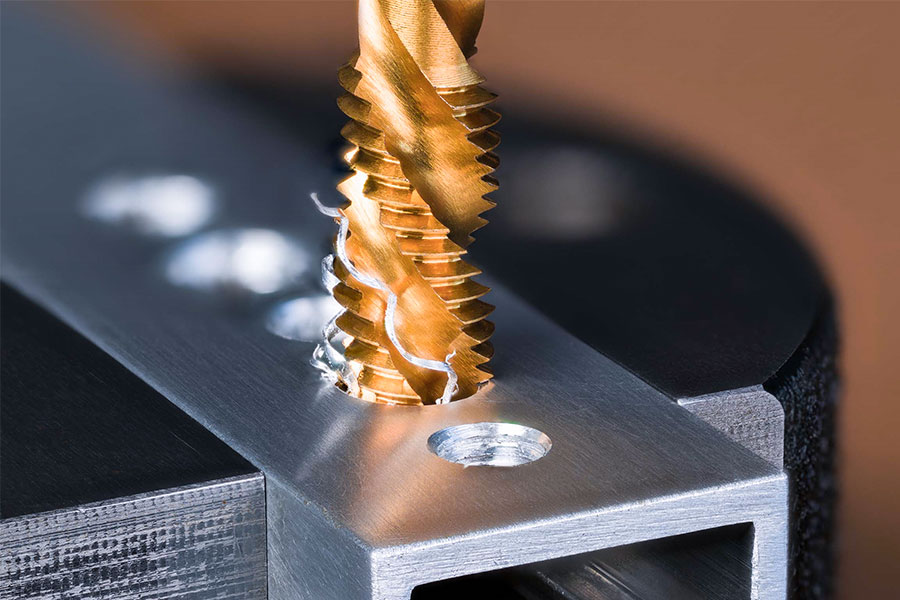

| Spiral Flute Taps | Blind Hole Taps | Taps The flute is spiral (like a drill bit) and is designed to discharge chips upward out of the hole. | Ideal for tapping blind holes (holes with no bottom), especially in soft materials that produce long chips (such as aluminum, mild steel, plastics). It can effectively prevent chip blockage and tap breakage. |

| Spiral Point Taps | Gun Taps | The front end of the cutting edge has a large helix angle (bevel), designed to push the chips forward into the front of the hole. | Through hole (through hole) tapping. Very suitable for high-speed machine tapping, high efficiency. The chips are pushed forward and will not wrap around the tap. Not suitable for blind holes (chips will accumulate at the bottom of the hole). |

| Forming Taps | Chipless Taps | There are no cutting edges and chip grooves. The thread is formed by extruding the material to cause plastic deformation without generating chips. | Soft materials with good ductility (such as aluminum, copper, brass, mild steel, some stainless steels). The formed thread is stronger (the material fibers are not cut), the surface finish is good, and there is no chip handling problem. Requires higher torque and good lubrication. |

| Pipe Taps | (usually no common alias, directly called by the standard, such as NPT Tap, G Tap) | With tapered (e.g. NPT, BSPT) or parallel (cylindrical) threads (e.g. G/BSPP, BSPF). Tapered threads are used for tight connections. | Processing threaded joints used in pipelines, hydraulic and pneumatic systems. Tapered threads (NPT, BSPT) rely on thread deformation to achieve sealing; parallel threads (G/BSPP, BSPF) require sealing rings. |

Here’s What You’ll Learn:

- The core definition and key role of taps: More than just a tap! Learn how it creates a precise, reliable fixing foundation for bolts and screws in CNC machining.

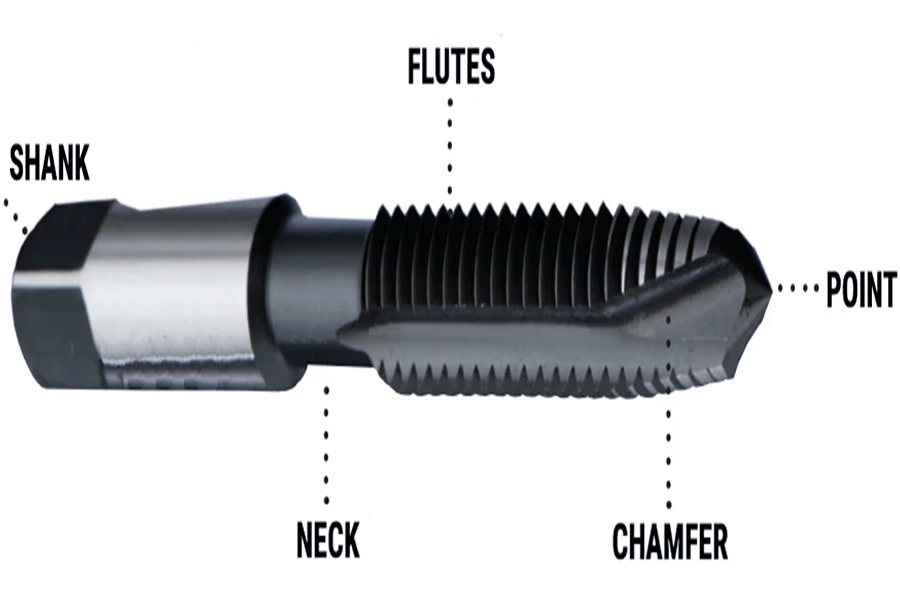

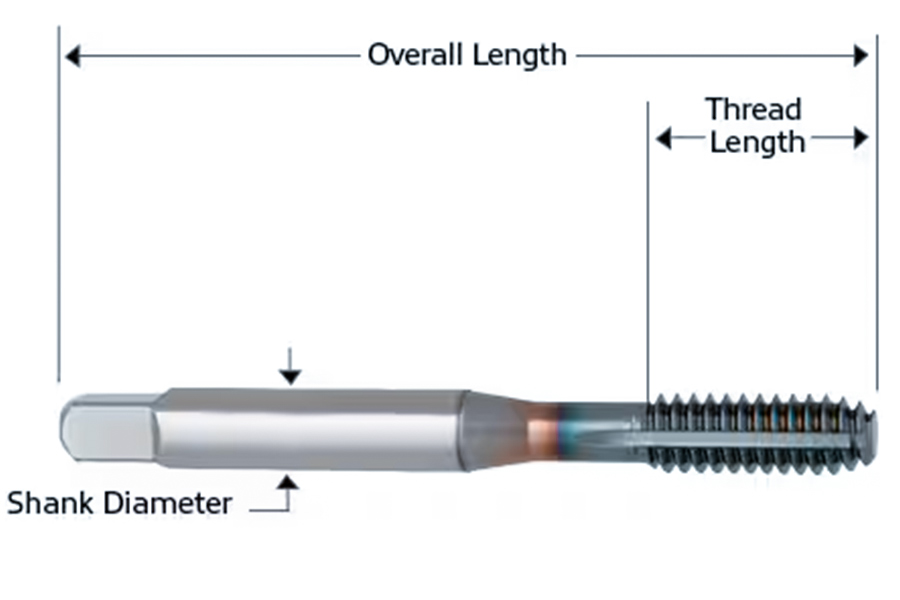

- The precise anatomy of a tap: Understand the key parts and indispensable functions of the shank, square head, groove, threaded portion and chamfer/cutting cone.

- The key difference between the “three big” major taps: In-depth analysis of design principles, chip evacuation mechanisms (upward vs. forward) of hand taps, spiral groove taps (spiral taps) and spiral tip taps (screw-tail taps), and their profound influence on cutting forces, alignment accuracy and final thread quality.

- Beyond cutting magic: The enigma of taps making: Learn to create stronger, chip-free threads by “extruding” instead of “cutting”, and its unique advantages (strength, chip-free, life) and applicable conditions (materials, bottom holes).

- Practical Selection Guide: Three Steps to Lock the Perfect Tap: A simple and effective system that allows you to quickly (in 60 seconds or less!) make accurate decisions based on hole type (through hole/blind hole), material (soft and tough/hard and brittle) and process method (manual/machine).

- The hidden power of coatings and materials: Discover how high-speed steel (HSS), cobalt-alloyed high-speed steel (HSSE), cemented carbide, and TiN and TiCN coatings significantly affect the life, performance and application conditions of taps.

- Actual Case: Challenge of Blind Hole Tapping of Aluminum Radiator: A practical analysis in our processing workshop to see how forming taps can meet the needs of blind hole chip-less, high efficiency, and high quality, and ultimately overall cost saving, showing how theory can be transformed into actual value.

- Experts Talk: Tapping problems at high frequencies FAQ: Simple answers to all those confusing questions, such as “How big should the bottom hole be drilled?”, “Why do taps always break?”, “What is the fundamental difference between cutting and forming taps?” and “Where can tapping professionals be found?”.

Now, let us clear the fog and get into the precise world of taps in a thorough manner, master this basic skill of part joining, and become a true tapping master!

Defining Taps in a CNC Machining Context

1. Basic definition: the nature and structure of taps

A tap is a precision cylindrical cutting/forming tool for machining internal threads in pre-drilled holes (bottom holes). Its primary features are:

- Cutting edge structure: A number of longitudinal or helical cutting grooves (Flutes) are placed on the circumference of the cylinder, and between the grooves, sharp cutting teeth (Threads) are formed that are utilized for cutting metal to form the thread profile. Some taps (e.g., extrusion taps) form threads by plastic deformation without the formation of chips.

- Geometrical accuracy: Thread size, tooth profile and lead of tap thread rigorously follow international standards (e.g., ISO, ANSI) for the machined thread to exactly match the standard bolt/screw.

- Drive mode: The tail is usually a square head (Shank Square) or a cylindrical drive plane, for clamping firmly in the tool holder of the CNC machine tool (e.g., elastic tapping tool holder) or hand wrench.

2. Clarify misunderstandings: clarify the industrial background of “Tap”

In engineering and CNC machining, “Tap” has a specific and sole meaning and should be rigorously distinguished from everyday language:

- Machining Tap: refers to thread processing tools. The picture is a thin metal cylinder with accurate spiral grooves or straight grooves and a square handle at the end.

- Bathroom Tap: A domestic water control valve. The photo is of a bathroom fixture with a knob/handle, mounted on a water pipe, and an outlet at the end.

- Main conclusion: In process documents, engineering drawings, CNC programming instructions (for example, G84 tapping cycle) and workshop technical communications, “Tap” almost always refers to thread processing tools. Confusing the two can lead to serious production errors or communication barriers.

3. Major functions: the foundation of strong threaded connections

Tap is used to create the foundation of strong mechanical connections in CNC part manufacturing:

- Direct producer of internal threads: It is the major method of creating internal threads in holes precisely and efficiently in CNC machine tools. The machined threaded holes are used to receive bolts, screws, threaded inserts, etc.

- Foundation of assembly reliability: The quality of the machined threads (dimensional accuracy, surface finish, burr-free) has a direct influence on the strength, sealability and life span of the assembly. Poor threads can result in loosening of fasteners, fatigue failure or seal failure.

- Wide application: From M1.6 threads in microelectronic devices to M30 and above threads in heavy machinery, taps are indispensable tools for manufacturing internal threads on various metal, plastic and composite CNC parts (such as engine blocks, gearboxes, brackets, housings, precision instrument components).

- Automation Integration: CNC machine tools can achieve precise synchronization of tap rotation and axial feed through rigid tapping or synchronous tapping functions, greatly improving tapping efficiency, accuracy and consistency, and is one of the core technologies for mass production.

In the field of CNC machining, a tap is a cylindrical tool that manufactures precision internal threads in pre-drilled holes by cutting or extrusion. Its core value lies in providing a standardized and highly reliable threaded connection foundation for various CNC machined parts, and it is a key process equipment to ensure the realization of mechanical assembly functions. Clarifying its essential difference from the “faucet” used in daily life is the prerequisite for effective engineering communication and technical operations.

The Anatomy of a Machining Tap|

The processing tap achieves reliable clamping and torque transmission through its precisely designed shank and square head, relies on the groove to complete the key chip removal, lubrication and cooling, and form the cutting edge, uses the front chamfered part to guide and bear most of the cutting load, and finally completes the precise cutting or forming of the thread by the thread part. The core components of the processing tap are:

Comparative overview of the core components of machining taps

| Component name | Location | Main function | Key features |

|---|---|---|---|

| Shank | The tail of the tap | Clamping and fixing | Usually smooth cylindrical |

| Square | The end of the shank | Transmits torque and prevents slipping | Square cross section |

| Flute | Runs through the threaded part | Removes chips, contains cutting fluid, and forms cutting edges | Spiral or straight grooves |

| Thread | The middle to the front of the tap | Cuts or forms internal threads | Has a complete thread profile |

| Chamfer/Lead | The front end of the tap | Guides the tap and undertakes the main cutting work | Tapered, with incomplete thread height (gradually increasing) |

1. Shank:

- Position and appearance: The tail of the tap, smooth and cylindrical.

- Core function: The part where the tap is clamped, loaded into the tap wrench or machine tool chuck, the clamping firmness affects the torque transmission and processing stability.

2. Square head:

- Position and appearance: The end of the shank, a short section with a square cross section.

- Core function: When tapping manually, the square hole of the wrench is put on it to transmit torque and prevent slipping, providing a reliable driving point; when the machine tool is tapping automatically, a specific chuck may also be used.

3. Groove:

- Position and appearance: A longitudinal groove extending backward along the thread from the chamfered part, running through the working length, with straight grooves or spiral grooves.

- Core function: Chip removal, avoiding chip blockage, scratching the surface or causing the tap to break; accommodating cutting fluid, lubricating, cooling and assisting chip removal; the front cutting face intersects with the back of the tooth to form a cutting edge.

4. Threaded part:

- Position and appearance: From the chamfer/cutting cone to the end of the effective working length, there is a complete thread profile.

- Core function: The thread teeth of the cutting tap are cutting edges, and the calibration teeth ensure the thread accuracy and finish; the extrusion tap has no cutting edge, and the hole wall metal is plastically deformed by extrusion to form threads, with high torque but high thread strength.

5. Chamfer/cutting tap:

- Position and appearance: the front end of the tap, conical, incomplete thread teeth, and the tooth height gradually increases to complete.

- Core function: guide the tap to align and guide it into the bottom hole; on the cutting tap, the chamfer contains 2-6 incomplete cutting teeth, which complete most of the cutting work, disperse the cutting load, reduce the cutting force, make the tapping stable, low torque, and long life; on the extrusion tap, it is responsible for the initial extrusion deformation guidance.

The “Big Three”: Hand, Spiral Flute, and Spiral Point Taps

Here is a comparison and explanation of the “big three” tap types: hand taps, spiral flute taps, and spiral point taps.

Comparison table of tap types

| Tap type | Number of cutting taper teeth | Chip removal mechanism | Applicable scenarios |

|---|---|---|---|

| Hand tap – Taper Tap | 8-10 teeth | No special (straight groove) | Initial tapping, easy to start |

| Hand tap – Plug Tap | 3-5 teeth | No special (straight groove) | General tapping, most commonly used |

| Hand tap – Bottoming Tap | 1-2 teeth | No special (straight groove) | Blind hole bottom tapping |

| Spiral Flute Tap | Variable (usually 3-5 teeth) | Upward chip removal | Blind hole processing to avoid chip blockage |

| Spiral Point Tap | Variable | Pushing chips forward | Through hole processing, efficient chip removal |

Note: Hand taps are used to make straight grooves as a general entirety, without using special chip removal devices; spiral point taps and spiral groove taps possess variable numbers of teeth that can be altered, typically referring to the plug tap or being altered according to the specific model.

- Hand Taps: There are three types: cone taps, double taps and bottom taps. Cone taps consist of 8-10 cutting cones of teeth, employed for starting tapping and easy to align; double taps consist of 3-5 cutting cones of teeth, most commonly used general-purpose type; bottom taps consist of 1-2 cutting cones of teeth, employed especially at the bottom of blind holes, but you need to watch out for chip build-up.

- Spiral Flute Taps: The spiral groove structure is utilized to realize the “upward chip removal” mechanism, in which the chips are forced upwards from the hole by the groove body during processing, avoiding clogging of chips at the bottom of the blind hole and hence avoiding the tap breaking, a blind hole processing lifesaver.

- Spiral Point Taps: Spiral point form is used in order to attain the “forward chip push” function. The chips are pushed forward from the hole in the mode of a bullet, suitable for high-efficiency through-hole machining with fewer interruptions and greater efficiency.

These three types of taps have their respective characteristics. Choosing the correct type according to the type of hole (blind hole or through hole) and processing requirements can significantly improve the tapping efficiency and success ratio.

Beyond Cutting: The Magic of Forming Taps

Forming taps or chipless taps or extrusion taps are an innovative process in thread processing technology. It abandons the conventional process of “cutting” metal and, instead, utilizes the plastic deformation of the material for “forming” the thread. The following table elaborates on the basic differences between forming taps and conventional cutting taps:

| Comparison items | Traditional cutting taps | Forming taps |

|---|---|---|

| Working principle | The material is cut through the sharp cutting edge to form a thread groove | The material is extruded through cold forming to form a thread by plastic flow |

| Chip generation | Chip generation | No chip generation |

| Thread strength | Standard thread strength | Significantly enhanced thread strength (more wear-resistant and tensile-resistant) |

| Tap life | Limited by cutting edge wear | Usually longer life (no sharp edge wear) |

| Applicable materials | Wide range, hard and brittle materials are also acceptable | Limited to materials with good ductility (such as aluminum, low carbon steel, copper, soft stainless steel, etc.) |

| Bottom hole requirements | Relatively loose requirements | Extremely strict and precise requirements |

| Main advantage areas | Strong versatility | Chipless requirements, high-strength threads, long life requirements scenarios |

1. Working principle:

Chipless taps/extrusion taps don’t cut material, but are founded on the cold forming concept. Its smooth, raised thread shape closely squeezes the bottom surface of the hole, leading the ductile metal to deform plastically, and the material is displaced from the “valley” area to form a “peak”, thereby forming a full thread.

2. Core advantages:

- Chipless: The biggest advantage. Completely avoid chips and eliminate the risks of pollution, short circuits, and precision field clogging (electronics, oil circuits/aerospace industry circuits, medical treatment, and food). Sign.jp ameliorate efficiency considerably (sparing chip cleaning), and it is the best choice for blind hole machining.

- Stricter thread: Refines grain through extrusion treatment and leads to work hardening. Significantly increase the pull-off strength, wear resistance, and fatigue resistance of the thread, and the surface is more dense and smooth.

- Longer lifespan: No cutting edge, therefore, no chipping and built-up edge problems. The extrusion surface deteriorates less rapidly, and with surface treatment (nitriding, coating), the life will generally be much longer than for cutting taps.

3. Limitations:

- Material restriction: Particularly suitable for materials with good ductility, i.e., aluminium, copper, low carbon steel, soft stainless steel (apply 304/316 with caution), brass, etc. Not suitable for brittle material (cast iron, carbide) or high-strength low-ductility alloy steel (tears/break easily).

- Highly accurate bottom hole requirements: The bottom hole bore must be as exact as possible (usually nominal diameter + 50%-65% tooth height, refer to supplier specifications). Too large will provide insufficient tooth height and poor strength; too small will provide additional torque, easy to crush the cone, crack the hole wall or affect thread quality. Highly stringent drilling precision requirements.

The principal advantages of chipless working, tap forming, high-strength thread and long life, highlight the “magic” compared to traditional cutting in the conditions of applicable materials and high-precision bottom holes.

Choosing the Right Tap: A Practical Guid

Choosing the proper tap is central to thread working quality, efficiency and tool life. For the best choice under specific working conditions, follow the three steps below

Step 1: Establish the type of hole and ascertain the chip removal direction

- Through hole: In the work, the first choice is a spiral tip tap, which pushes the chips forward out of the hole. There is minimal resistance to chip removal, excellent efficiency, and minimum torque. It suits high-speed machining but for through holes only.

- Blind hole: Not in the workpiece, an initial choice is a spiral groove tap. The spiral groove leads the chips upward, a safe and effective chip removal method of blind holes. Large helix angles have high chip removal and are suitable for long-chip materials; small helix angles have high strength and are suitable for short-chip materials or high-strength applications.

Step 2: Remember the material selection processing rule and coating

- Soft and hard materials (e.g., aluminum, copper alloy, etc.): Cold extrusion taps are recommended. Cold extrusion plastically deforms the material to form threads, without chips, with durable threads, very good surface finish, extended tool life, and high processing rate. Material should be ductile, with large bottom hole diameter and raised tapping torque. If the material is extremely brittle, employ a spiral groove cutting tap.

- Hard, hard or hard-to-cut materials (e.g., cast iron, high-hardness steel, etc.): Cutting taps must be used to form threads by cutting the material through the cutting edge. Coating selection is most critical. TiN is general-purpose and low cost; TiCN is higher in hardness and wear resistance; TiAlN is higher in high-temperature stability; special coatings provide additional lubricity for specialty materials.

Step 3: Select the method of processing and the tap structure and precision

- Manual tapping: The substitute first is a three-piece hand tap set, which is batch cut, low torque, good feel, and fault tolerant high. Or a single spiral groove tap can be used to avoid using a spiral tip tap.

- Machine tapping: Use a spiral tip tap for through holes and a spiral groove tap for blind holes. Soft, hard, and tough materials and corresponding hole types are best tapped with extrusion taps. Synchronous/rigid tapping must be used to ensure that the tap shank type is suited for the machine tool. Ground taps are best used for threads with high accuracy. Tap life and thread quality need to be cooled and lubricated.

The key to efficient and repeatable tap selection is to adequately understand the hole type (blind/through), workpiece material properties (soft and tough/hard and brittle) and process route (machine/manual) and match the optimum suitable tap type.

Tap coatings and materials significance in machining

Tap materials and coatings introduction

| Classification | Type | Features | Applicable scenarios |

|---|---|---|---|

| Tool materials | High-speed steel (HSS) | Most common, cost-effective | General processing |

| Cobalt-containing high-speed steel (HSSE) | Add cobalt, better red hardness | Difficult-to-process materials such as stainless steel | |

| Solid carbide | Extremely hard, wear-resistant, but brittle | Mass production, cast iron, abrasive materials | |

| Common coatings | Oxide layer (Bright/Steam Oxide) | No coating or black oxide layer | Non-ferrous metals (aluminum, copper, etc.) |

| Titanium nitride (TiN) | Gold coating, good versatility, improve lubricity and wear resistance | General processing (steel, alloy steel) | |

| Titanium carbonitride (TiCN) | Blue-gray coating, harder than TiN | Difficult-to-process materials such as cast iron and stainless steel |

Importance of tool materials:

- High-speed steel (HSS): As the most economical choice, it has an acceptable combination of hardness, toughness and cost, and is sufficient to handle tapping operations of most common materials. It is the preferred choice for general-purpose taps.

- Cobalt high-speed steel (HSSE) has: The cobalt content significantly increases the material’s ability to retain hardness at high temperatures (red hardness). This allows the tap to retain a sharp edge longer, reduce wear and sticking, and extend life in machining difficult-to-machine materials such as stainless steel and high-temperature alloys that generate a lot of cutting heat and work harden.

- Solid Carbide: It has extremely high hardness and wear resistance and is particularly well-suited for high-speed, large-volume production and applications with extremely high wear resistance requirements, e.g., cast iron machining, powder metallurgy parts, reinforced plastics and other highly abrasive materials. However, its brittleness also makes it more susceptible to impact and abuse, and the cost is also comparatively higher.

Importance of coating:

- Bright/Steam Oxide: It is essentially a surface treatment (or no coating) at minimum cost. It has a microporous structure that can hold a small amount of cutting fluid, which has a certain lubrication and chip removal effect. It is ideally suited for non-ferrous metals of low viscosity (such as aluminum and copper alloys) for chip adhesion prevention.

- Titanium nitride (TiN): Most widely used coating. It successfully reduces the friction coefficient between the tap and work material and improves the surface hardness and wear resistance. The gold coating also makes it possible to visually monitor wear. TiN coating can significantly extend the life of the tap and can be applied to a wide steel and alloy steel processing range.

- Titanium carbonitride (TiCN): Carbon is added to TiN, which has higher hardness (usually more than 30% higher than TiN) and higher wear resistance. It is most suitable for cutting hard or abrasive materials that would cause normal coatings to wear rapidly, such as cast iron, stainless steel, titanium alloy, etc. Its blue-gray appearance is the identifying factor.

Selecting the proper tap material and coating is one of the most significant aspects of optimizing tapping efficiency, thread quality, tool life and reducing cost. It must be chosen according to the specific workpiece material, process conditions and production requirements.

LS Case: Chip-free Solution for Blind Holes of Aluminum Radiators

1. Project Background:

Recently, we successfully carried out mass production of an aluminum heat sink for a major electronic product for a client. The heat sink design required the processing of a large number of M3 blind holes for installation, and was faced with a particularly acute difficulty: any small metal chips falling into the small heat sink fin gaps would cause the device to short circuit and fail. Accordingly, the process of processing must be chip-free.

2. Challenge and First Cut Solution Evaluation:

- Basic Challenge: Huge blind hole processing needed + absolute zero chip requirements (avoid fin contamination).

- Traditional Solution Limitations: Our first thought was to utilize high-performance spiral groove taps (blind hole type). Although it is good for chip removal, it still cannot completely eliminate the risk of very tiny chips in mass production. That would require more complicated and uncertain cleaning processes to be added later, not just increasing cost, but also bringing in potential quality risks. This solution was abandoned.

3. LS’s professional solution:

After detailed process analysis and deliberation, we strongly decided on the M3 Forming Tap technology as the final solution.

4. Attainments and value:

- Zero chips, zero risk: Forming taps produce threads by plastic deformation of materials, without the generation of any chips at all, inherently eliminating the risk of chips falling into the heat sink fins, and ensuring the absolute reliability of the product.

- Dramatically improved efficiency: Extrusion molding can typically provide a faster processing speed than traditional cutting, significantly shortening the single-piece processing cycle and improving overall production efficiency.

- Better thread quality: Threads made by extrusion have better material strength and surface integrity, and the joint is stronger and longer-lasting.

- Total cost saving: Although the cost of a single forming tap is slightly higher than that of a cutting tap, by eliminating the cleaning process, reducing the potential risk of scrapping, and greatly improving processing efficiency, we successfully maintained the overall CNC machining cost of the project at a more competitive level.

5. LS’s professional value:

This case perfectly demonstrates LS’s basic strengths as an online CNC machining professional service provider: we not only have advanced processing equipment and process know-how, but also clearly understand customer product’s key quality requirements (such as total chiplessness in this case), and choose the best and sometimes non-standard technical solutions (such as extrusion taps) accordingly, while offering the highest quality, achieving efficiency improvement and overall cost optimization. We are committed to transforming challenges into value and to delivering customers consistent, efficient and cost-reducing manufacturing solutions.

FAQs

1. What size hole should I drill for tapping?

Drilling for tapping needs you to select the correct bottom hole size for realizing thread quality. For each thread size (e.g., M6 or 1/4-20), there is an ideal bottom hole diameter, and it can be found from the standard “Tap Bottom Hole Size Table”. A hole that is too small in diameter risks tap breakage, and one that is too large results in less thread depth and lower strength. Use accurate measuring tools or consult the manufacturer’s manual to avoid common mistakes, such as ignoring the influence of material hardness. Proper size can increase tapping efficiency and thread quality, and is typically slightly larger than the thread minor diameter by 0.1-0.3mm.

2. Why does my tap always break?

The common reasons for tap breakage include: the bottom hole size is too small and the tap gets stuck and overloaded; the tap and hole are not concentric and produce eccentric forces; the wrong type of tap is selected, i.e., a spiral tip tap is used in a blind hole (a spiral groove tap is to be used); insufficient cutting fluid causes frictional overheating; and tap wear or blunting reduces the cutting efficiency. To avoid these problems, you must match the bottom hole, use guide tools, use the right tap type, lubricate properly, and change worn-out taps regularly to enhance tool life as well as to prevent accidental breakage.

3. What is the fundamental difference between “cutting taps” and “extrusion taps”?

The fundamental difference between cutting taps and extrusion taps is the working mechanism: cutting taps machine materials with sharp cutting edges to produce threads, produce chips, and can be used for various materials such as steel or cast iron; extrusion taps move materials by cold extrusion plastic deformation to produce threads, without producing chips, and are widely used for ductile materials such as aluminum or copper, with higher thread strength and surface finish. Material properties must be considered when choosing – extrusion taps save chip cleaning but require good material ductility.

4. Where can I buy high-quality custom tapping services?

High-quality custom tapping services are usually provided by professional CNC processing factories. They have various kinds of taps (for example, cutting or extrusion taps) and advanced CNC equipment, which can accurately control speed, torque, feed and cooling conditions to ensure thread size accuracy, consistency and surface finish. These factories are suitable for machining complex workpieces or batch production, one-stop service from material choosing to after-processing, with assured reliability and high efficiency. Reputable suppliers can be found on industry websites or through local suppliers.

Conclusion

Taps are the essential tools for creating reliable threaded connections in machining and are much more complex than their everyday names suggest. The correct choice of tap type, base material, and coating is key to ensuring part quality, maximizing production efficiency, and controlling costs. Ignoring these factors can lead to thread defects, tool wear, and scrapped parts.

Remember: the quality of every thread relates to the success or failure of the final product. Don’t waste time and money on speculation.

Upload your CAD file to our smart manufacturing platform. Thread features will be automatically detected by our DFM system, and our team of experienced engineers will accurately match you with the optimal tapping solution and provide instant, transparent CNC machining quotes. No trial and error, and enjoy expert tap application solutions!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

naturally like your web site however you have to take a look at the spelling on several of your posts. A number of them are rife with spelling problems and I find it very troublesome to tell the reality then again I’ll surely come back again.

Thank you so much for your honest feedback! Proofreading is indeed my weak point, and your comments are invaluable to me. I truly appreciate them. I will immediately review and correct my recent articles. Thank you for taking the time to offer such helpful suggestions to help me improve. Please feel free to check my work again in the future!

My brother recommended I might like this blog. He was entirely right. This post actually made my day. You can not imagine simply how much time I had spent for this info! Thanks!

I used to be suggested this website via my cousin. I’m now not positive whether this put up is written by him as no one else know such distinct about my difficulty. You are incredible! Thanks!