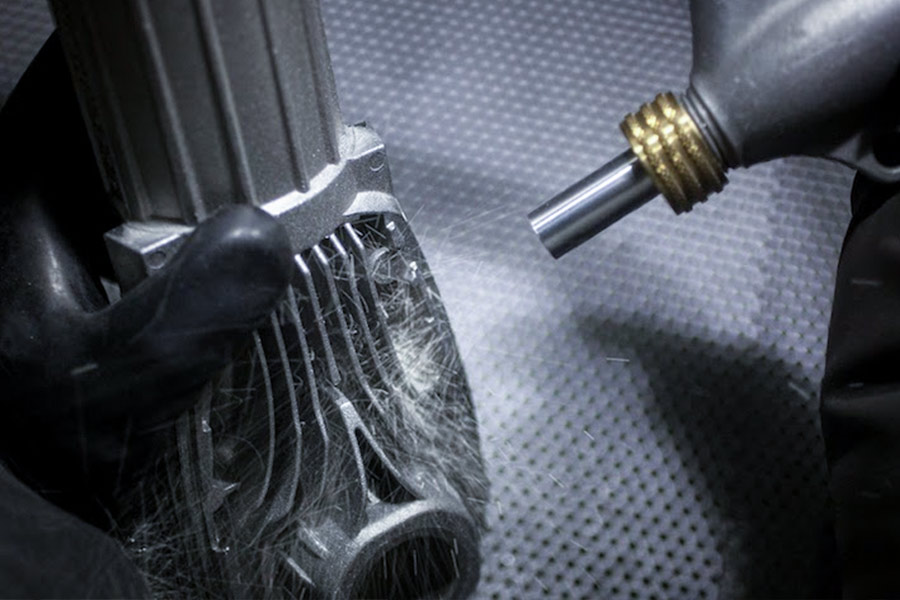

Bead blasting is a process that includes eradicating floor deposits by making use of superb glass beads at a excessive strain with out damaging the floor. It’s utilized in quite a lot of industries, together with automotive, aviation, and manufacturing, for cleansing, ending, and floor preparation functions.

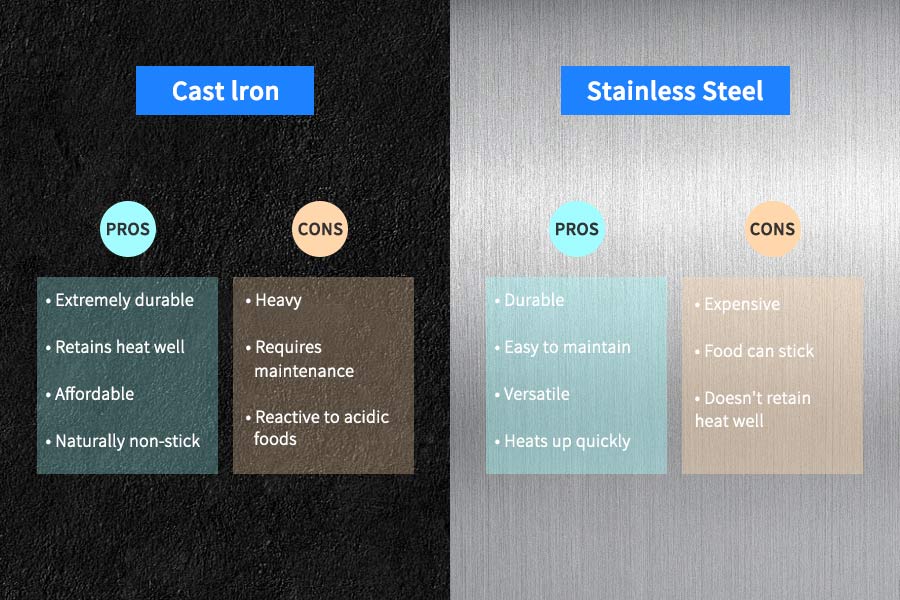

The selection between plastic, stainless steel, and cast iron bead blasting companies will depend on the precise necessities of the duty. Every kind of bead has its personal properties and is appropriate for various functions:

Plastic Bead Blasting

This methodology is often used for delicate duties the place it is essential to not injury the underlying materials. Plastic beads are softer than steel beads, making them much less prone to trigger injury.

Stainless Steel Bead Blasting

Stainless steel beads are tougher and extra sturdy than plastic beads. They supply a powerful cleansing potential and may create a high-gloss end. Nevertheless, they might trigger extra floor roughness and doubtlessly injury the bottom materials if not used correctly.

Cast Iron Bead Blasting

Cast iron beads are even tougher than stainless steel beads. They provide a powerful cleansing potential and are sometimes used for heavy-duty duties. Nevertheless, they will trigger excessive floor roughness and should injury the bottom materials.

Distinction Between Plastic, Stainless Steel, and Cast Iron Bead Blasting Providers

Bead blasting companies make the most of several types of blasting media, which considerably affect the ultimate end and the general effectiveness of the process. The variations between plastic, stainless steel, and cast iron bead blasting companies are as follows:

Plastic Bead Blasting: Plastic bead blasting employs supplies similar to plastic grit, steel grit, steel shot, aluminum oxide, minimize wire, and copper slag. This method is appropriate for delicate or thin-walled functions and is understood for producing very low ranges of mud.

Stainless Steel Bead Blasting: Stainless steel bead blasting sometimes makes use of glass beads, a preferred blasting method for stainless steel. Glass beads can clear, deburr, and put together surfaces with out embedding something into them. They’re additionally recyclable and reusable. Medium-sized beads are the perfect possibility when bead blasting stainless steel.

Cast Iron Bead Blasting: Cast iron might be bead blasted utilizing glass beads, ceramic grit, or crushed glass, which create a softer end splendid for stainless steel. Glass beads are recognized for cleansing, deburring, and getting ready surfaces with out embedding something into them. They’re additionally recyclable and reusable.

In abstract, the selection of blasting media for plastic, stainless steel, and cast iron bead blasting companies will depend on the precise necessities of the fabric being blasted. Glass beads are a preferred selection for stainless steel and cast iron on account of their potential to scrub, deburr, and put together surfaces with out embedding something into them, whereas plastic blasting supplies are appropriate for delicate or thin-walled functions and produce very low ranges of mud.

Selecting the Acceptable Bead Blasting Method

Selecting the suitable bead blasting method will depend on the precise necessities of the fabric being blasted. Listed here are some components to think about:

-

Materials Sensitivity: If the fabric is delicate or thin-walled, plastic bead blasting is likely to be the only option on account of its light nature and low mud manufacturing.

-

Floor End: If a clean, clear end is desired with none materials being embedded into the floor, glass bead blasting (utilized in stainless steel and cast iron bead blasting) can be splendid.

-

Recyclability: If recyclability and reusability are essential, glass beads utilized in stainless steel and cast iron bead blasting are a sensible choice as they are often reused.

-

Utility: The selection of bead blasting method additionally will depend on the appliance. For example, stainless steel bead blasting is commonly utilized in functions the place a excessive diploma of cleanliness and brightness is required.

Working Precept of Plastic Bead Blasting

Plastic bead blasting is a surface finishing process that includes projecting spherical or bead-shaped plastic media in opposition to the floor of a workpiece at excessive strain. The influence of the media leaves a clean, uniform end on the part. This process is comparatively low cost, quick, removes minimal materials, and is eco-friendly. It might cowl a big floor space very effectively and is right for all kinds of supplies, together with aluminum, steel, titanium, brass, copper, and varied plastics.

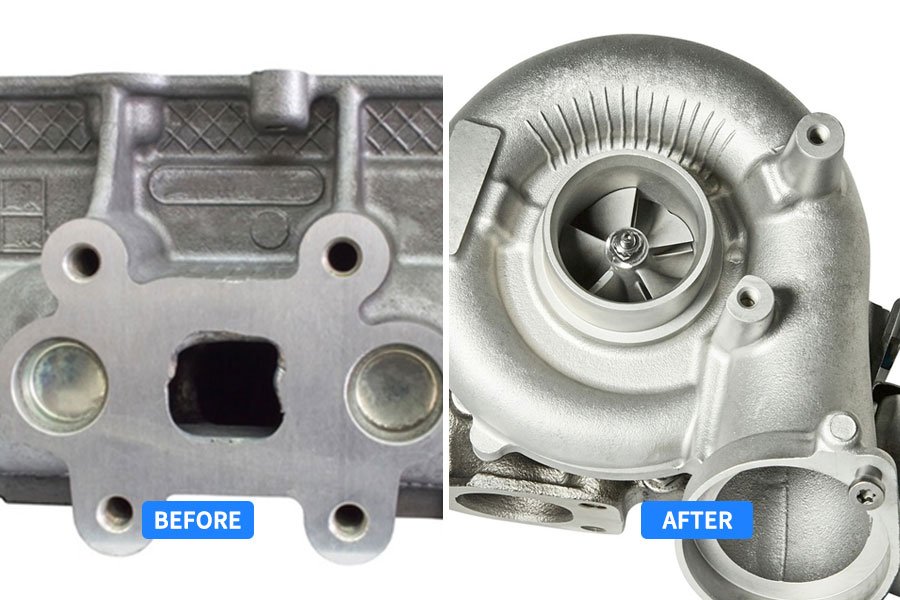

Working Precept of Stainless Steel Bead Blasting

Stainless steel bead blasting includes the process of projecting spherical media in opposition to a stainless steel substrate to situation its floor. This process is used to realize a uniform end by inflicting the spherical media to dimple the floor, leading to a non-directional, uniform matte floor with low reflectivity. The bead blasting process is flexible and may cowl a variety of functions, together with sprucing supplies similar to aluminum, stainless steel, and cast iron. It is usually appropriate for making a non-directional clean and textured floor that’s aesthetically pleasing.

Working Precept of Cast Iron Bead Blasting

The working precept of cast iron bead blasting includes the projection of spherical or bead-shaped media in opposition to the floor of a workpiece, sometimes utilizing compressed air to function the bead blaster gun. The selection of bead dimension and sort, similar to glass beads, performs an important function in reaching the specified floor end for cast iron and different steel supplies.

In abstract, the working rules of plastic, stainless steel, and cast iron bead blasting companies are comparable, however the kind of media used and the precise functions fluctuate. All three processes contain the usage of spherical or bead-shaped media that’s projected in opposition to the floor of a workpiece at excessive strain, leaving a clean, uniform end on the part.

Comparability of Abrasives

| Sort of Abrasive | Options | Relevant Vary |

|---|---|---|

| Sand | Excessive hardness, low price | Elimination of cussed filth, rust |

| Glass Beads | Reasonable hardness, excessive floor gloss | Cleansing, roughening, sprucing |

| Aluminum Oxide | Excessive hardness, robust slicing pressure | Roughening, precision processing |

| Plastic Beads | Low hardness, won’t injury the floor | Cleansing, sprucing |

| Stainless Steel Beads | Reasonable hardness, corrosion-resistant | Cleansing, sprucing |

Bead blasting is a process that makes use of small beads to scrub or polish a floor. The kind of bead used can considerably have an effect on the end result of the process. Here is a comparability of plastic, stainless steel, and cast iron (not talked about within the desk however generally used) bead blasting:

-

Plastic Beads: These have low hardness and won’t injury the floor. They’re appropriate for cleansing and sprucing functions the place sustaining the integrity of the floor is essential.

-

Stainless Steel Beads: These have reasonable hardness and are corrosion-resistant. They’re appropriate for cleansing and sprucing functions, particularly the place resistance to rust is essential.

-

Cast Iron Beads: These are sometimes tougher than plastic and stainless steel beads. They’re usually used for extra aggressive cleansing and floor preparation duties. Nevertheless, they will trigger extra put on and tear on the floor.

Comparability of Advantages and Disadvantages

| Know-how | Advantages | Disadvantages |

|---|---|---|

| Sandblasting | Sturdy cleansing potential, low price | Excessive floor roughness, might injury the bottom materials |

| Bead Blasting | Sturdy cleansing potential, excessive floor gloss, won’t injury the bottom materials | Cleansing potential weaker than sandblasting, increased price |

Based mostly on the above data and normal information, this is a comparability of plastic, stainless steel, and cast iron bead blasting companies:

1. Plastic Bead Blasting

This methodology makes use of plastic beads, that are softer than steel beads. The benefit is that it is much less prone to injury the bottom materials, making it appropriate for delicate surfaces. Nevertheless, its cleansing potential is likely to be weaker than different strategies, and the fee may very well be increased.

2. Stainless Steel Bead Blasting

Stainless steel beads are tougher and extra sturdy than plastic beads. They supply robust cleansing potential and excessive floor gloss. Nevertheless, they might trigger extra floor roughness and doubtlessly injury the bottom materials if not used correctly.

3. Cast Iron Bead Blasting

Cast iron beads are even tougher than stainless steel beads. They provide a powerful cleansing potential and are sometimes used for heavy-duty duties. Nevertheless, they will trigger excessive floor roughness and should injury the bottom materials.

Bead Blasting Providers: Plastic vs Stainless Steel vs Cast Iron

Bead blasting is a floor remedy process utilized in quite a lot of industries. The selection of bead materials – plastic, stainless steel, or cast iron – can considerably influence the effectiveness, price, and suitability of the process for particular functions. Here is a comparability of those three varieties of bead blasting companies primarily based on the translated data:

-

Plastic Bead Blasting: This methodology is right for cleansing precision parts or when a excessive floor gloss is required. It is also an appropriate selection when the bottom materials is tender, because it minimizes the danger of injury. Nevertheless, it might not be as efficient in eradicating cussed filth and rust.

-

Stainless Steel Bead Blasting: This methodology can ship a high-gloss end and is efficient for cleansing precision parts. Nevertheless, it might not be the only option for tender supplies because of the potential threat of injury. It is also sometimes costlier than sandblasting, which may very well be a consideration if funds is a constraint.

-

Cast Iron Bead Blasting: This methodology is often used for heavy-duty duties and is efficient in eradicating cussed filth and rust. Nevertheless, it may end up in a excessive floor roughness and should injury the bottom materials, particularly if it is tender. Like stainless steel bead blasting, it is sometimes costlier than sandblasting.

Conclusion

The selection between plastic, stainless steel, and cast iron bead blasting companies will depend on the precise necessities of the duty. Elements to think about embrace the cleansing necessities, the character of the bottom materials, the funds, and the specified floor end. Every methodology has its strengths and potential drawbacks, so it is essential to decide on the one that most closely fits the wants of the precise software.

FAQs

Which supplies are appropriate for sandblasting and bead blasting?

Sandblasting is usually appropriate for tougher supplies like steel, stone, and glass. It is usually used to take away rust, paint, and different floor contaminants. Bead blasting, then again, is often used on softer supplies like plastic, aluminum, and stainless steel. It is usually used for cleansing, ending, and floor preparation functions.

What blasting media to make use of on plastic?

Plastic bead blasting is often used on plastic supplies. Plastic beads are softer than steel beads, making them much less prone to trigger injury to the plastic floor.

What’s the finest media for sandblasting cast iron?

For sandblasting cast iron, tougher media like aluminum oxide or silicon carbide are sometimes used. These media are efficient in eradicating rust and different floor contaminants from the cast iron.

What’s the distinction between sandblasting and bead blasting?

Sandblasting makes use of sand particles because the blasting media and is often used for eradicating rust, paint, and different floor contaminants. It is usually appropriate for tougher supplies. Bead blasting, then again, makes use of glass or plastic beads because the blasting media. It is sometimes used for cleansing, ending, and floor preparation functions, and is commonly used on softer supplies.

Can sandblasting take away paint?

Sure, sandblasting can successfully take away paint from quite a lot of surfaces. Nevertheless, it is essential to make use of the suitable blasting media and strain to keep away from damaging the underlying materials.

Supply Quotation

The supply used within the article is:

- Ending Programs. (n.d.). Abrasive Blasting Media Information: Which Blasting Media Is Greatest? Retrieved April 18, 2024, from https://www.finishingsystems.com/blog/abrasive-blasting-media-guide/