Precision-bent pipes are the lifeblood of many high-stakes systems in modern manufacturing-from sophisticated automotive exhaust systems to the delicate fluidic systems of medical devices. Where millimeter-level accuracy, perfect repeatability, and high-volume production are key considerations, CNC pipe bending (Computer Numerical Controlled pipe Bending) is a key solution.

It has since evolved far beyond the guise of simple “bending” and become a sophisticated, highly technical art form incorporating computer science, mechanical engineering, and material mechanics. With the assistance of computer-controlled precision tube bending machines in conjunction with special dies and springback compensation, CNC technology precisely shapes metal tubes into the desired three-dimensional shape.

This handbook will provide a thorough overview of CNC pipe bending, its operation principle, its main advantage, and how it collaborates with precision processes like gear machining to form the foundation of modern industry.

Summary table of basic knowledge of CNC pipe bending

| Core Questions | Concise Answers | Key Technologies |

|---|---|---|

| What is CNC pipe bending? | A manufacturing process that uses computer numerical control technology to automatically and accurately bend pipes at multiple angles and radii. | Computer-aided design (CAD), 3D coordinate measurement, servo motor control, mandrel bending technology |

| What is the difference with manual pipe bending? | CNC pipe bending far surpasses manual tube bending in accuracy, repeatability, efficiency, and the ability to achieve complex shapes. | CNC programming vs. manual measurement and operation |

| What are the main advantages? | Extremely high accuracy (up to ±0.1°), perfect consistency, the ability to create complex spatial geometries, and high production efficiency. | Data-driven and automated. |

| Core application areas? | Automobile, aerospace, furniture manufacturing, medical equipment, petrochemical pipelines, etc. | Any industry requiring precise fluid delivery or structural framing |

Here’s What You’ll Learn:

- The Essential pipe Bending Process Using CNC: Expose the whole process from YBC coordinate coding and CAD modelling to machine automation and tool selection (mandrel, press die, clamping die, bending die).

- Three Main CNC Bending Technologies: In-depth description of the working principle and application situation of roll bending (arc with large radius), spin bending (best for high precision), and press bending (practical and economic).

- The Ultimate Advantages of CNC pipe Bending: Why is it superior to mandrel-free and hand bending? Highlight its unparalleled accuracy and repeatability, ability to form complex multi-plane geometries, reduced material waste, and extremely high productivity.

- Widespread Use in Major Industries: Understand how CNC pipe bending is transforming the automotive (exhaust/oil lines), aerospace (hydraulic/fuel lines), construction and furniture (metal frames), and medical device (beds/wheelchairs) industries.

- The Synergy of Precision Manufacturing: Following a case study on a racing exhaust system, discover how CNC pipe bending works in harmony with operations like gear machining to stay one step ahead of the twin challenge of space constraints and high-performance requirements.

Let’s go deeper now into the basic engineering technology by which metal tubing is made into intricate and precise shapes.

Why Trust This Guide? Real-World Experience from LS Experts!

You can depend on this guide to the extent that it is constructed upon the broad-based knowledge and practical project experience of our LS engineering team who has been deeply involved in tube bending technology for decades.

- Practice Over Theory: We’re not just reading text book verbosity. All the considerations, solutions, and major points in this manual derive from our experience built up from processing actual production shops with diverse materials (carbon steel, stainless steel, aluminum alloy, titanium alloy, etc.), specs (from capillary tubing to heavy-walled tubing with diameters ranging up to a few feet), and complex geometries. We’ve executed thousands of trial runs, optimizations, debugging, and quality improvement.

- Solving Industry Pain Points: We are well familiar with the pain points our customers suffer from in tube bending: unstable accuracy, difficult control of springback, low productivity rate, material loss, difficult achievement of complex shape, and intricate equipment maintenance. This guide addresses precisely these pain points and provides tried and tested solutions.

- Philosophy of LS Technology: The concepts, advantages, and principles contained in this manual represent LS’s underlying tube bending technology and machine philosophy. We are publishing the basic rationale for the effective and precise operation of our machines.

- Regular Revisions and Verification: Pipe bending technology continuously advances, and materials, processes, and standards are routinely updated. Our LS engineering department persistently invests resources in R&D, incorporating the most recent technological advancements and field experience into our knowledge base to keep this guide state-of-the-art and current.

- Problem-Solving Attitude: We don’t only tell you “what”; more importantly, we teach you “how to do it” and “how not to get stuck.” This is based on our invaluable experience of helping many customers to successfully implement projects and solve hard problems.

Beyond Bending: How CNC Pipe Bending Really Works

The crux of CNC pipe bending is “computer numerical control,” which translates complex three-dimensional bending operations into precise, reproducible, automated processes. The underlying process itself can be described in the below table:

| Phase | Core Content | Key Elements |

|---|---|---|

| Design and Programming | Converting the 3D tube model into machine-executable instructions. | CAD design, CAM programming, YBC coordinates (Y-feeding, B-rotation, C-bending), G-code |

| Machine Setup | Configuring physical tools based on tube characteristics. | Dies (bending, clamping, and pressing dies), mandrels (for wrinkle prevention), and tube parameter settings |

| Automated Execution | The machine precisely controls the movement of each axis, completing all bending operations according to the program. | Servo motor control, multi-axis linkage (feeding, rotation, and bending), and unattended operation |

Design & Programming:

Engineers then use CAD software to create a precise 3D model of the pipe. CAM software interprets important geometric data from the model (that is, Y-axis feed length, B-axis angle of rotation, and C-axis bend angle) and compiles it into a G-code program that is directly understandable and executable by the tube bending machine. This process digitalizes the design intent.

Machine Setup:

Depending on the specific parameters of the pipe to be bent (i.e., diameter, thickness, and type of material), the operator selects the proper set of tools (such as the bend die to define the radius of bend, the clamping die to clamp the tube in position, and the pressing die to prevent flattening), and not least, the crucial mandrel (which is placed inside the pipe to serve as a support for the wall of the tube while bending and to prevent wrinkling or collapse). Proper installation and parameter setting of these physical machines are the solution to ensuring high-quality bends.

Automated Execution:

Once the program is started, the high-precision servo motor drive of the CNC pipe bending machine is in charge. The servo motors execute G-code commands to the precise letter, synchronously controlling the motion of the feed (Y), rotation (B), and bending (C) axes (and possibly additional auxiliary axes). The pipe is fed automatically into the machine, rotated to the right angle, and bent to the right angle. All phases of the pre-programmed bending are simultaneously and continuously carried out in a closely automated process without any intervention by human beings.

The principle of CNC pipe bending lies in the precision control of the various axes by digital programming, translating design data into fine physical bends smoothly.

The 3 Most Widely Used Types of CNC Bending Processes

CNC pipe bending technology, given its accuracy and potential for automation, is widely used in modern manufacturing. It primarily involves three basic processes: roll bending, press bending, and rotary draw bending.

| Technology Type | Key Features | Typical Applications |

|---|---|---|

| Roll Bending | The tube is progressively formed using three or more rotating rollers. | It is used to create large-radius curves, spirals, and slow-bend components. |

| Compression Bending | The pipe is pressed against a fixed bending die. The cost is low and the operation is relatively simple. | Applications where accuracy requirements are not high and cost is sensitive. |

| Rotary Draw Bending | After the pipe is clamped, it is rotated and stretched around the bending die with an internal mandrel for support. This allows for high precision and minimal cross-sectional deformation. | High quality, complex shapes, and small radius bending requirements. |

Roll Bending:

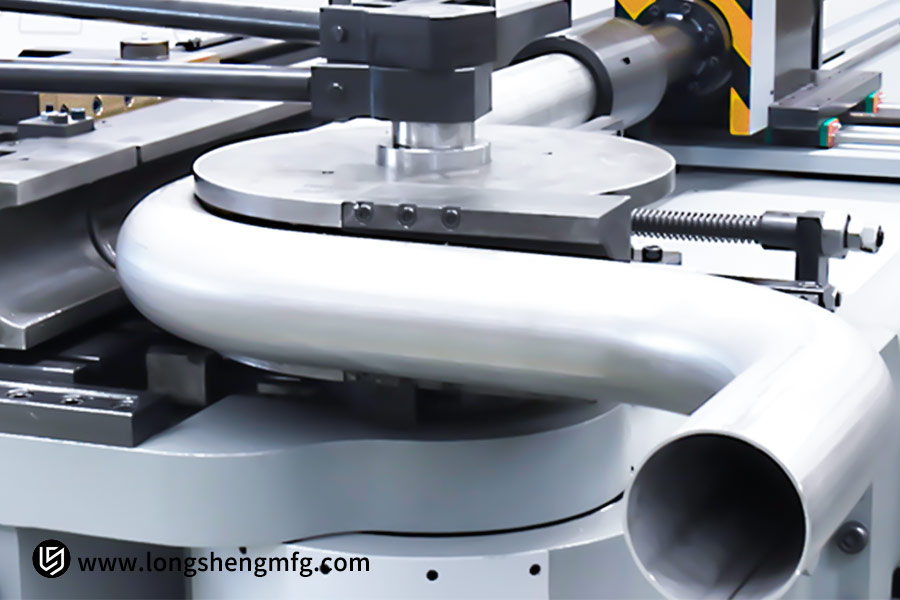

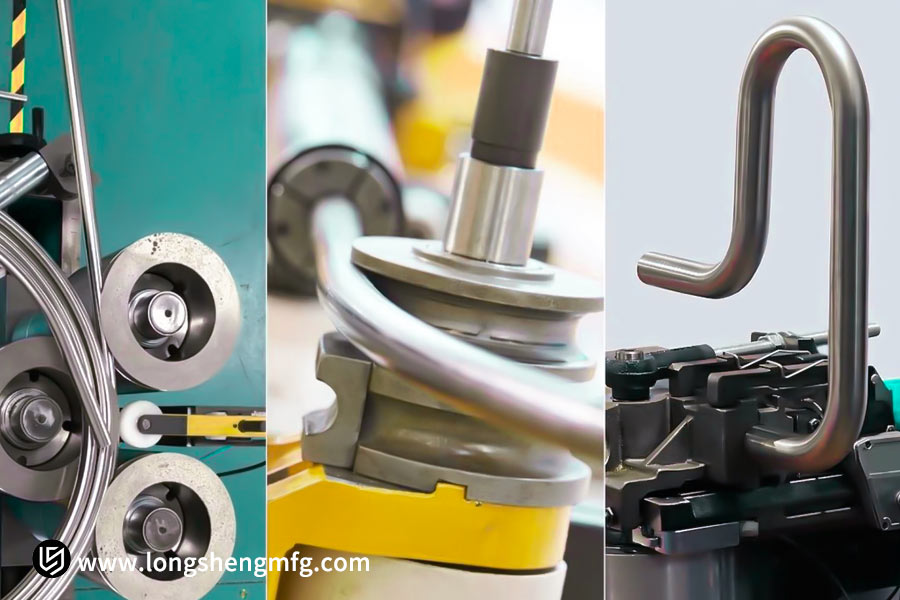

This technique uses multiple (usually three) adjustable rollers. Pipe is led through the rollers. By displacing the rollers with respect to one another and adjusting the rollers’ angle, the pipe is bent slowly and smoothly into the specified large-radius curve or spiral form while passing. It is particularly good at forming smooth, unbroken curves.

Compression Bending:

Similar to pipe bending machines, the pipe is positioned astride a fixed bending die, and a pressure arm (or slide) compresses the pipe against the die to bend it. The operation has simple equipment expenses and procedures, but the inner pipe surface may become slightly puckered or deformed (ovalized) due to compression as it is bent. Therefore, it is ideal for applications where accuracy and appearance are not demanded.

Rotary Draw Bending:

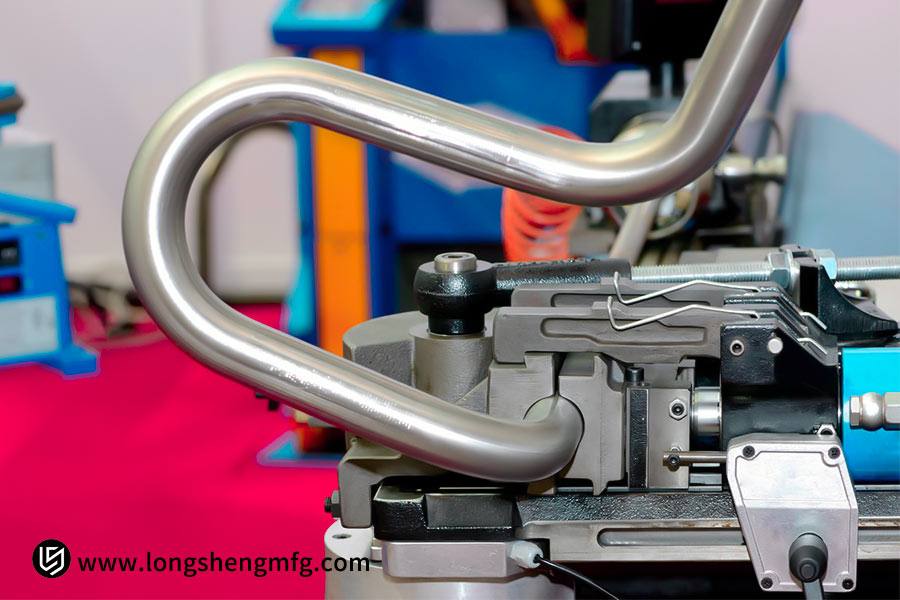

This is currently the most widely used and most accurate CNC pipe bending process. Pipe is fixed at one end, with tension provided at the other end by a compression die. Clamping block and pressure die both work in collaboration during bending to bend pipe around a precision-machined bending die (bending die). Concurrently, a mandrel shaped to the bend die form is pushed into the pipe at the bend location to provide internal support and in effect eliminate pipe collapse, wrinkling, or severe ovalization. The method is used to bend pipes at complex angles and small radii without compromising very high dimensional tolerance and excellent cross-sectional roundness.

Roll bending, press bending, and rotary stretch bending are the core technology group of CNC pipe bending. All three possess unique advantages and serve different manufacturing needs with varying levels of accuracy, cost, and shape requirements. Rotary stretch bending, due to its high accuracy and quality control, is the preferred choice for high-quality pipe bending.

Key Advantages Compared to Manual and Mandrel-less Bending

In this new search for efficient, precise, and complex manufacturing, why has CNC pipe bending technology replaced mandrel-less and manual pipe bending to become an essential core process in modern industry?

Overview of the Core Benefits of CNC Pipe Bending:

| Core Advantages | CNC pipe Bending Performance | Traditional pipe Bending Limitations | Core Value |

|---|---|---|---|

| Precision and Repeatability | Computer control eliminates human error, ensuring first-to-ten thousand parts are identical. | Highly dependent on operator experience, resulting in poor consistency and prone to errors. | Stable and reliable quality assurance. |

| Complex geometry capabilities | Easily achieve complex bending in multiple planes and with variable radii. | Almost impossible or extremely difficult, costly. | Unlocks innovative design possibilities. |

| Material loss | Precise calculation and control, minimal trial and error, and extremely low scrap rates. | Relying on trial bends, resulting in significant material waste. | Significantly reduces production costs. |

| Production efficiency | Once programmed, processing is fast, significantly shortening lead times. | Each bending step requires manual operation, resulting in slow results. | Quickly respond to market demands. |

- Unparalleled Precision and Repetition: The spirit of CNC is the computer-driven control of the bend axis’ motion (location, angle, and velocity) with unerring precision. After a program has been tried, it can be accurately replicated an infinite number of times, completely eliminating the strain, variation in feel, and human factor of manual control. Servo motor drives and measurement feedback for accuracy ensure angular precision to ±0.1° or even better, and millimeter-range positioning.

- Capability for Sophisticated Geometry: CNC pipe bending machines (particularly multi-axis ones) precisely manage multiple motion axes (i.e., bending, feeding, rotation, and clamping). Through programmable combinations of various bend angles, directions of rotation, and feed distances, they precisely shape complex pipes in three dimensions, such as multiple bends in different planes and variable radius bends (e.g., involutes). It’s simply not possible to accomplish with manual or rudimentary machine bending.

- Reduced Material Waste: CNC software replicates bending process with great accuracy, computes constants such as material stretch and springback compensation, and exercises precise control in the actual processing (e.g., the springback compensation function). This reduces repetitive “trial bends” to determine the best parameters in traditional pipe bending, thereby eliminating waste and scrap of expensive tubing (e.g., stainless steel and titanium alloys) directly.

- Very Efficient: After being programmed, the CNC pipe bending process is very mechanized. The machine recurrently performs actions such as feeding, bending, and revolving the pipe over and over, working at rates multiple times that of manual labor. This advantage is particularly significant in mass production, significantly lowering the overall product design-to-delivery process and answering the calls for rapid response in modern industry.

Finally, CNC pipe bending with its unmatched precision, ability to manufacture complex shapes, high productivity, and minimal material wastage has become a crucial core technology for the modern industrial manufacture of complex, high-quality tubular structures.

From Pipes to Power: CNC Bending in Major Industries

From pipes that transport fluids to structures that hold electricity, CNC pipe bending technology, with its precision, efficiency, and reliability, has made an extensive influence on the manufacturing of critical components in a variety of major industries.

Overview of CNC pipe Bending Applications in Major Industries

| Industry | Typical Applications | Key Technical Requirements | Common Equipment Types |

|---|---|---|---|

| Automotive | Exhaust pipes, brake oil lines, air conditioning lines, vehicle frame structures | High production volume, consistency, complex 3D shapes | CNC pipe bender |

| Aerospace | Hydraulic system piping, fuel lines, environmental control system ducting | Extreme precision, lightweight, space efficiency, material performance | High-precision CNC pipe bender |

| Furniture and Architecture | Metal chair frames, armrests, lighting brackets | Design, consistent appearance, mass production | CNC pipe bender |

| Medical Equipment | Bed frames, wheelchair structures, instrument carts | High precision, clean and smooth surfaces, reliability | High-precision CNC pipe bender |

- Automotive Industry: CNC pipe bending is a standard activity for the production of complex exhausts, precise brake/fuel lines, and lightweight yet tough auto frame parts, meeting the high efficiency and consistency requirements of mass production.

- Aerospace: In the aircraft, where space is confined and weight is paramount, CNC pipe bending offers routing of hydraulic, fuel, and environmental control system ducting with the highest accuracy and reliability at the minimum space and weight.

- Furniture and Architecture: With this technology, designers can produce smooth continuous metal curves and therefore it is utilized intensively in mass production of modern metal furniture (chairs, table legs, armrests) and architectural elements (railings, lighting, ornamentation).

- Medical Equipment: For structural elements of wheeled devices such as beds, wheelchairs, and carts, CNC pipe bending provides the necessary high accuracy, structural integrity, and smooth surface finish, ensuring safety, stability, and ease of cleaning.

From the handling of liquids to providing structural support, CNC pipe bending technology with its unprecedented precision shaping continues to be a pillar of the most critical areas of modern industry.

Gear Machining & CNC Bending: Balance of Precision

In manufacturing, procedures are always interlinked. The robotic arm, for example, is so extremely efficient because of the deep synergy between CNC pipe bending and high-precision gear machining:

Lightweight Frame (CNC pipe Bending):

Using CNC technology to precisely bend lightweight, strong alloy tubing into an intricate three-dimensional shape.

Key Advantages: Radical weight saving (hollow design), with stiffness where required, and integrated cable and pipe passageways through the hollow tubing, establishing the robot’s “bones” and “veins.”

Power Core (Gear Processing):

The joint’s core is bespoke, high-accuracy gears and gearboxes (e.g., harmonic gears and planetary gears).

Core Benefits: Online gear processing services ensure the precision of the gear tooth profile, surface finish, material properties, and gearbox assembly. Directly, this ensures the smooth operation of the joint, micron-class accuracy in positioning, high transmission efficiency, and high load capacity, making it the “power heart” of the robot.

Symbiotic Harmony

Ideal performance results from the best balance of the two: the gearbox must be correctly mounted into the tubular casing (interface coordination and stiffness transfer).

Optimization of the three things simultaneously (spatial layout – wiring avoidance, load transmission, and compromise on performance – weight reduction vs. support stiffness) must be carefully considered.

Structural deflections or small gear misalignments affect the entire-arm accuracy.

The “light but strong” nature of the robot arm is derived from the perfect synergy between the light structure/channels realized through CNC pipe bending and precise power/transmission realized through gear machining. This is the hallmark of excellent custom gear producers’ strengths: not only producing extremely high-quality gear machining, but being exceedingly clear on their role in larger systems (e.g., robots with integrated constructions of pipe bending-based structures), providing integrated solutions that merge structure, transmission, space, and performance.

Case Study: High-Performance Racing Exhaust System

Challenge:

We recently assisted an auto racing modification firm with a problematic project: the design of a high-performance exhaust system for their new car in racing. The most important challenges were in two areas: First, the path of air has to be extremely smooth; any wrinkle or deformity in even a single bend would decrease performance significantly. Second, the mounting space was extremely cramped, requiring precise clearance around numerous vehicle and chassis components. This called for extremely close tolerances, placing extremely demanding requirements on piping design accuracy and molding process.

LS Solution:

Faced with this demanding requirement, we utilized LS’s value as an end-to-end provider and adopted a multi-process collaborative approach:

- Precise Surveying: We initially used advanced 3D scanning technology to survey the dimensional data of the chassis and surrounding components accurately, creating a high-accuracy baseline for design.

- Optimized Design: From the scan data, our engineers designed a complex, multi-radius, multi-angle 3D exhaust path that optimized airflow efficiency with constrictive space limitations.

- High-Accuracy Tube Bending: To provide wrinkle-free, constant-diameter bends (critical for fluid airflow), we utilize core mandrel-bending technology. This results in a smooth inner tube surface, even on complex bends, to minimize airflow resistance.

- Precision Machining: High-precision CNC milling is used to make the flange, a very critical component that connects the exhaust system to the engine. This ensures ideal flatness, hole location, and tightness, which provides a leak-free, secure joint.

Results:

This end-to-end solution comprising precise mapping, optimized design, mandrel-bending tube bending (cutting-edge), and high-accuracy CNC machining was capable of delivering the following successfully:

- Perfect Fit: The exhaust system was installed correctly and immaculately, with a clean fit into the tight chassis space without conflict.

- Performance Enhancement: Most notably, the new system significantly improved engine performance under close space conditions, with a measured 15 horsepower power output increase over the stock system.

LS’s Value:

This case study depicts how LS blends core competencies such as 3D scanning, complex piping design, mandrel bending, and precision CNC machining in harmony to generate innovative solutions for customers’ complex engineering challenges bound by twin constraints of space and performance, to provide high-performance solutions exceeding expectations.

FAQs

In what way is CNC pipe bending different from CNC plate bending (press bending)?

CNC pipe bending is mainly used to bend hollow profiles or tubular (roundpipes and squarepipes), while CNC plate bending (press bending) is used to form flat metallic sheets. Due to the natural differences in the aims of processing, the two require completely different specialized machines and tooling (tube bending machines and press bending machines), and the forming principles and methods are also completely different.

Can all metal pipes be CNC bent?

Not all metalpipe can be utilized. Ductility of the material is a key factor: ductile stainless steel, aluminium alloys, copper alloys, and mild steel can be bent beautifully; however, brittle materials (such as cast iron) fracture during bending easily and are not appropriate for CNC bending.

What is a mandrel, and why is it so critical?

A mandrel is a rigid support tool that is placed inside the pipe before bending. Its basic function is to give support to the pipe’s inner wall in real time during bending, thereby eliminating wall collapse, wrinkling, or cross-sectional deformation that can occur while processing thin-walled pipes or small bend radii, and forming a smooth, round, and highly accurate bend.

How is CNC pipe bending cost calculated?

Price is decided primarily by four factors: 1. Material type and unit price; 2. Pipe diameter and wall thickness (affecting difficulty); 3. Number of bends, angle complexity, and required precision; 4. Order quantity (volume affects unit price). We take these factors into comprehensive consideration when quoting.

Conclusion

CNC pipe bending is not just metal bending, but one of the most important precision technologies for forming the skeleton of an industrial product. It forms complex three-dimensional shapes through digital control, combining high precision, high repeatability, and material adaptability, and also requiring scientific control over constraints such as springback and bend radius. As a key link in today’s manufacturing chain, it works in concert with processes such as gear machining to realize product development—from transmission mechanisms to fluid pipes, overall building high-performance, high-reliability engineering systems. Mastering this technology is a strategic turning point in driving light-weight design and innovation breakthroughs.

Whether your project requires high-precision gear machining parts for core power trains or complex three-dimensional tubing for product skeletons and fluid paths, we have the deep knowledge and state-of-the-art manufacturing capabilities to provide definitive, end-to-end solutions.

Don’t wait, just do it!

- Upload your design plans now: from pipe bending designs to gear machining specifications.

- Get a tailored proposal and quote: Our engineering team will quickly provide you with:

- A thorough, feasible, and optimized manufacturing solution.

- Competitive, accurate quotes (Gear machining price and pipe bending quote).

- Experience professional collaboration: From design optimization recommendations to efficient production delivery, we’re with you every step of the way.

Let’s make your next innovative product together with impeccable precision and reliable manufacturing capability!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.