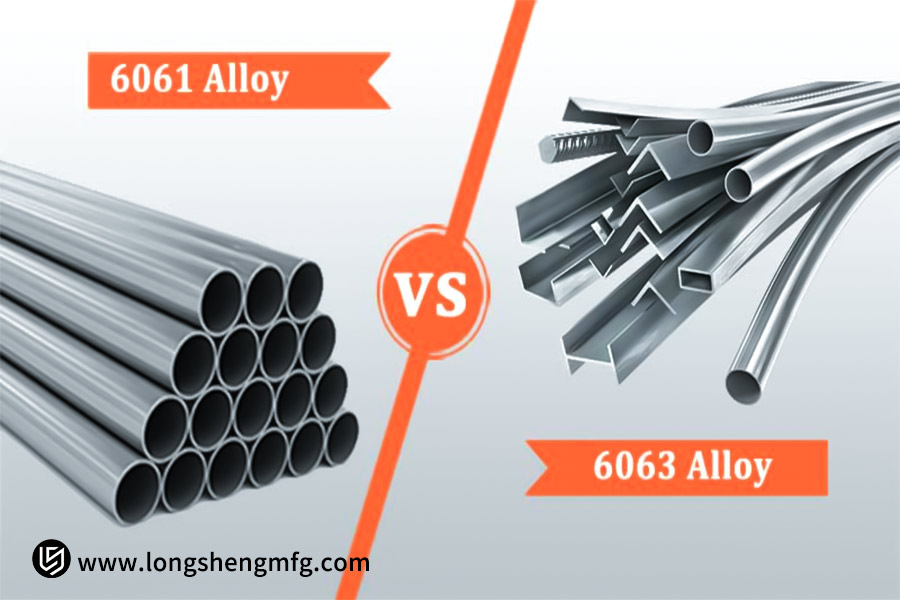

Aluminum, with its remarkable lightness, strength, and modern metallic sheen, has long been the preferred material for electronic product housings, industrial components, bespoke nameplates, and even designer ornamentation. It is nearly every modern industrial material’s dream: strong, light, beautiful, and highly versatile.

Yet when designers and manufacturers attempt to use laser engraving technology to produce legible, detailed, and durable marks on this eye-catching metal surface, aluminum’s unique physical properties—particularly its extremely high reflectivity and excellent thermal conductivity—have a tendency to interfere. Reflected laser beams are ineffective and can damage equipment, and the speedy dissipation of heat makes it difficult to precisely manage engraving depth and contrast. These challenges deter many from pursuing this technique or prevent them from achieving the desired results.

So, which aluminum material overcomes these limitations and becomes the ideal canvas for laser engraving? The answer may surprise you—not all aluminum is created equal, and there are clear and effective options for specialized applications. This manual will reveal the professionals’ secret sauce, the science underlying it, and material and process selection for high-end projects with meticulous care, unlocking brilliant clarity and timeless results on this reflective metal surface. Let’s get started.

Key differences in popular aluminum laser engraving

| Aluminum Type | Engraving Quality/Sharpness | Difficulty/Speed | Contrast | Recommended Applications |

|---|---|---|---|---|

| Anodized Aluminum | Very High | Easy, Fast | Very High (Typically white/light gray) | Brand logos, serial numbers, custom faceplates, artwork, high-end signage, buttons, medals |

| Bare Aluminum, e.g., 6061 | Medium (requires auxiliary processing) | Difficult, Slow | Medium (Typically dark gray/black) | Industrial markings, part traceability codes, tool markings, decorative parts requiring a matte black finish, applications requiring deeper engraving |

| Coated/Painted Aluminum | High | Easy, Fast | High (depending on coating color) | Promotional items, signage, custom gifts, control panels, instrument housings, personalized items |

Here’s What You’ll Learn:

- A Core Decision Framework: Allows you to determine in 60 seconds whether anodized aluminum or bare aluminum is best for your application, founded on the two key challenges of reflectivity and thermal conductivity.

- Key Differences Between Three Laser Systems: Learn the fundamental capabilities and limitations of fiber, CO₂, and diode lasers when processing aluminum materials of differing types (bare vs. anodized aluminum).

- Real-World Solutions to Marking Bare Aluminum: Discover professional methods for achieving crisp, permanent marks on bare aluminum, such as 6061, using laser marking agents or fiber lasers.

- Parameter Tuning Basics: Explain how power, speed, and frequency (fiber laser) work together to create optimum engraving results on anodized or treated bare aluminum.

- Winning Case Studies from the Production Line: Outline how to convert 6061 aluminum enclosures into high-end branded products through the “anodizing + laser engraving” process.

- Laser Engraving Aluminum FAQs: Answers to fundamental questions about cutting possibility, the influence of material strength, and post-processing.

Let’s dive into the details and determine the ideal laser engraving solution for your aluminum project.

Why trust this guide? Derived from the practical experience of LS experts

When it comes to laser engraving aluminum, theory and practice are two different things. The findings in this guide are a product of the LS team’s daily experience in a diverse variety of projects in our precision machining workshops:

- Tested with 10,000+ samples: We’ve personally lasered tens of thousands of aluminum parts (including common alloys like 6061 and 7075, and bare/ anodized aluminum). We’ve iteratively tested and optimized the solutions provided here with real laser beams, learning from our mistakes.

- Beating basic challenges: We’re familiar with the aggravations of engraving caused by bare aluminum’s high reflectivity and thermal conductivity, and we’re experienced in practical solutions, from the meticulous use of laser marking agents to the optimal combination of fiber laser parameters (power, speed, and frequency) for stability and reliability.

- Practical experience with anodizing: Not only do we recommend anodizing aluminium, but we also directly involve ourselves with the entire process from pre-treatment, oxidation, dyeing, to laser engraving. We precisely know how oxide layer thickness and dye impact engraving results (contrast and detail). Our case studies speak for successful mass production.

- Multi-laser Field Measurement: We possess standard CO2, fiber, and diode machinery in our workshop and are well aware of their capabilities. For example, we are clear about the power limit of fiber laser marking on bare aluminum annealing, or the precision limit of CO2 laser engraving on anodized aluminum.

Simply put, you gain from the LS team’s hands-on experience, correlating aluminum properties, laser physics, and process parameters with customer requirements by actual production, testing, and optimization. We want to allow you to rapidly come to crisp, durable, and cost-effective aluminum laser marking solutions.

Why is laser engraving aluminum challenging?

In order to understand what type of aluminum is best, it is useful to understand first why it is difficult to engrave. There are two main reasons:

1. High Reflectivity:

- Phenomenon: Uncoated (naked) aluminum is extremely shiny with a mirror-like appearance. This translates to it being highly reflective to light, and more specifically, infrared light (the 10,600 nm wavelength which most CO2 lasers utilized in industrial engraving emit).

- Problem: When a laser beam strikes bare aluminum, most (typically over 90%) of the laser energy is reflected rather than absorbed by the material. Consider pointing a laser pointer at a mirror in an attempt to heat it up—most of the light bounces off.

- Consequence: Insufficient laser energy is available for the material to absorb and convert to heat for engraving (melting, vaporizing). This results in extremely poor engraving efficiency, or no useful mark whatsoever being created on the surface. This effect is particularly evident with conventional CO2 lasers.

2. High Thermal Conductivity:

- Phenomenon: Aluminum is an excellent conductor of heat, with a thermal conductivity well above that of normal metals like steel. Heat is conducted very quickly and evenly in aluminum.

- Problem: Even if a small amount of laser energy is absorbed at the surface of aluminum and converted to heat (which can occur because of microscopical surface imperfections or at a very high laser power), the resulting heat is not effectively concentrated at the point of incidence of the laser. Instead, it conducts and diffuses extremely rapidly into the surrounding aluminum and the workpiece.

- Consequences:

- Challenge in achieving phase transition temperature: The laser has to heat the aluminum quickly to its melting point (about 660°C) or even vaporizing point (about 2470°C) in a very localized, small spot to get the desired engraving result. High thermal conductivity makes it hard to reach and sustain the high temperature needed in this localized spot. Heat is drawn away quickly.

- Large heat-affected zone: To achieve the desired engraving effect, significantly more laser power or longer exposure times may be required. This, nevertheless, makes the heat spread over a greater area, resulting in a large heat-affected zone. This deforms the material (warps), compromises local mechanical properties, or generates an undesired, fuzzy edge effect (enlarged melted area) rather than a sharp, crisp mark.

- Energy requirements shoot up: To counteract the rapid heat removal, the engraving process requires very high peak power density (usually requiring fiber lasers or high-power CO2 lasers with special technology) in an effort to complete material removal before the heat is conducted away.

Therefore, the knowledge of what aluminum is best suited for laser engraving includes a close understanding of the inherent difficulties of high reflectivity and high thermal conductivity of aluminum. The “best” aluminum is often one that has been surface-treated to modify its properties (reducing reflectivity and modifying thermal conductivity), or an aluminum alloy which, under some conditions (combined with high-performance lasers and process parameters), can reduce these challenges to a certain extent.

The #1 Choice: Why Anodized Aluminum is King?

Anodized aluminum is the best laser engraving choice. This is because the laser does not engrave the aluminum, but rather reacts with the anodized layer.

How it works:

- Oxide layer formation: The anodizing process causes the creation of a hard, dense, and porous ceramic film of aluminum oxide (Al₂O₃) on the aluminum surface.

- Dyeing properties: Pore structure of the oxide layer absorbs dyes (e.g., black, blue, red), bright variety of colors.

- Laser action process mechanism: When irradiated by a low-power CO₂ or diode laser, thermal energy selectively degrades/vaporizes the dye in the oxide layer or alters its molecular structure (“bleaches”), completely without causing damage to the underlying aluminum substrate and revealing the silvery-white/light-gray aluminum oxide background.

Advantages

- Ultra-High Contrast and Clarity: The dark color oxide layer offers an extreme visual contrast with the substrate that has been exposed, creating clear, high-contrast impressions. It is particularly ideal for high-precision applications like QR codes and microtext.

- Permanence and Durability: The mark is beneath the oxide layer, so there are no physical impressions left. It is corrosion-resistant, wear-resistant, and Fade-resistant, with the same life expectancy as the oxide film itself.

- Energy Efficient: Operates with low-power laser (typically less than 30W) to perform high-speed engraving, significantly improving processing time while reducing equipment cost and power consumption.

- Process Flexibility and Cost Effectiveness: Compatible with general laser sources (CO₂/fiber/UV), without additional consumables (such as inks) required, with good yields, and suitable for bulk industrial processes.

Anodized aluminum, possessing a tightly controlled surface oxide structure, supports efficient, non-destructive laser marking with high-contrast, permanent marking. Combined with low cost, this extent of performance has made it the “king” material for industrial signage.

Working with Bare Aluminum: Procedures for 6061 & Others

For bare aluminum workpieces that must remain so (such as the widely used 6061 alloy), while its native reflective nature is a limitation to laser marking, specific methods can reliably achieve clean, high-quality, and long-lasting marks regardless.

Summary of Bare Aluminum Laser Marking Techniques

| Method | Core Principle/Applicable Processes | Marking Results | Brief Procedure | Key Benefits |

|---|---|---|---|---|

| Laser Marking Agent | Laser-induced chemical reaction | Permanent black ceramic layer | 1. Spray/apply marking agent 2. Laser engraving 3. Clean excess agent |

Achieve high-contrast black marks on conventional lasers |

| Fiber Laser | High-absorption laser applied directly to aluminum | Dark gray annealed mark or physical engraving depression | 1. (Optional) Clean the surface 2. Laser parameter setting and engraving |

No additional chemicals required, commonly used in industry, supports multiple marking modes |

1. Laser Marking Spray/Paste:

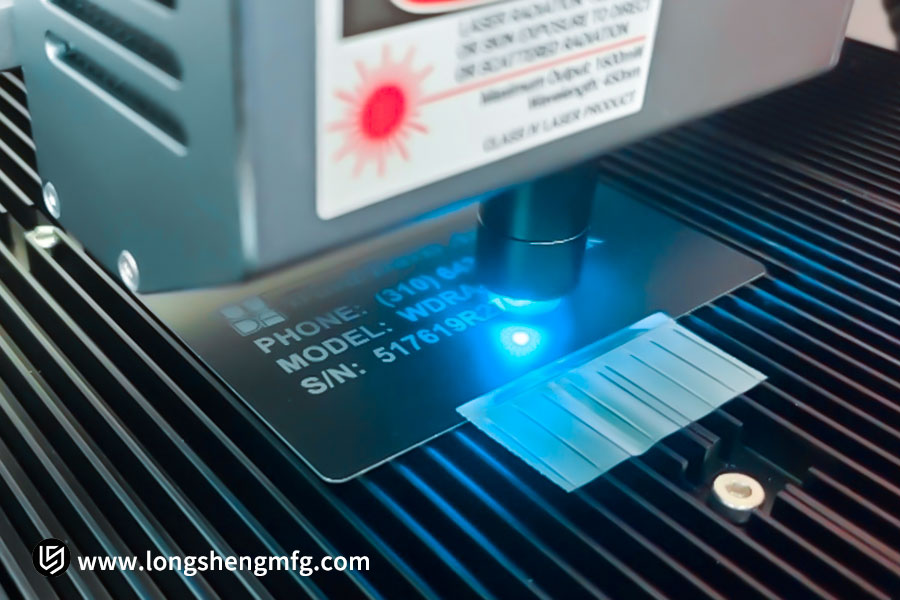

- Principle: A thin layer of proprietary chemical (e.g., Cermark and LaserBond) is deposited evenly on the surface of well-cleaned, bare aluminum (e.g., 6061) before laser processing. When laser beam is applied on it, heat causes the constituents of the marking agent to undergo an energetic thermochemical reaction with the substrate aluminum.

- Result: The marking agent melts in the laser-irradiated zone and is permanently bonded to the surface of the aluminum substrate, thereby forming a solid, high-contrast (usually black) ceramic marking layer. Such a marking layer has superior resistance to wear, corrosion, and weather.

- Post-Processing: After marking, any trace of unused marking agent left on the workpiece surface must be wiped away with a suitable solvent (water, alcohol, or proprietary cleaning fluid as indicated in the product instructions) to create a clear, indelible black mark.

- Advantages: Its biggest advantage is that it achieves a huge black mark on uncoated aluminum using relatively standard lasers (e.g., CO2 lasers, or certain low-power fiber lasers), significantly increasing contrast and readability. The laser itself also requires relatively low metal absorption.

2. Using a Fiber Laser:

- Principle: Due to the fact that 1064nm light from a fiber laser is better absorbed in metals (e.g., aluminum), it exploits its strong power density and pulse control to cut directly on bare aluminum surfaces.

- Main Marking Modes:

Annealing Mark: Accurately controlling laser energy (decreasing power density, raising frequency) only heats up a thin layer near the surface of aluminum, causing oxidation or microstructural change, resulting in a dark gray, gray-black, or even colored oxide layer. The mark is shifted below the surface without altering the flatness.

Deep Engraving: When there is more laser energy (higher power density), the mark is actually physically removed by ablation from the surface of the aluminum, creating a recessed mark. Color depends on natural aluminum color or degree of oxidation, typically light gray.

Benefits: This is currently the most commonly applied and efficient method of marking bare aluminum (including 6061) in manufacturing. It requires no additional chemicals and is a clean, ecologically sound process. Fiber lasers offer fast speed, high precision, and excellent reliability, enabling permanent marking directly on metal. They support a variety of marking effects (color, depth) and are particularly well adapted to automated production lines and high-specification industrial uses.

Whether with laser marking chemicals to deliver high-contrast black marking on general-purpose equipment, or with fiber lasers for chemical-free annealing or deep engraving, the correct method can sidestep the processing challenges of bare aluminum and respond to the necessity of high-quality, durable marking on bare aluminum pieces such as 6061.

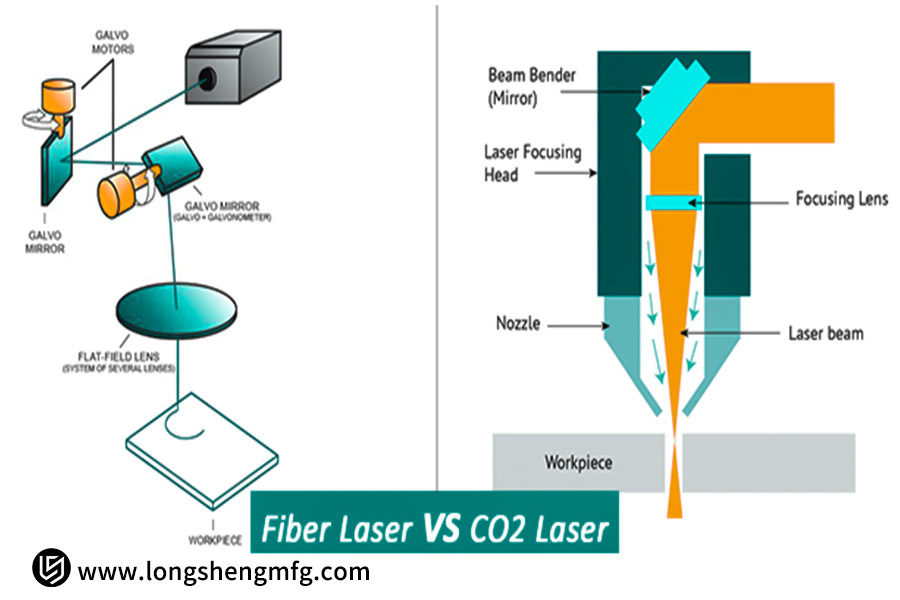

Fiber vs. CO2 vs. Diode: Which Laser is Best?

Choosing the best laser engraver can be challenging. Each of fiber, CO₂, and diode lasers has its own strengths, and the best one for you ultimately depends on your basic application needs—namely what type of material you are engraving.

| Features | Fiber Laser | Carbon Dioxide (CO₂) Laser | Diode Laser |

|---|---|---|---|

| Bare Metal Engraving | Best (all metals, including aluminum) | Unable to engrave | Limited (usually requires pre-treatment) |

| Anodized Aluminum/Coated Metal Engraving | Good | Best | Good (especially anodized aluminum) |

| Non-Metal Engraving/Cutting | Very limited or unavailable | Excellent (wood, acrylic, leather, etc.) | Limited (typically lower power/speed) |

| Power Level | High Power (industrial grade) | Medium to High Power (commercial/industrial grade) | Low Power (entry-level/hobbyist grade) |

| Typical User Groups | Industrial users, professional machining | Commercial users, integrated fabrication shops | Hobbyists, small studios |

Fiber Laser:

If high-speed, high-quality, and durable engraving directly onto bare metal (even hardest aluminium) is your primary requirement, then the fiber laser is the undisputed monarch. Its high power density and metal’s specifically absorbed wavelength create readable, long-lasting impressions without pre-treatment and thus are the industrial-strength metal marking and deep engraving solution of choice. But its processing capacity on non-metallic materials is quite bad.

Carbon Dioxide (CO₂) Laser:

A CO₂ laser is the best choice if most of your work involves non-metallic materials (wood, acrylic, plastic, leather, fabric, glass, stone, etc.) or if you are engraving on anodized aluminum or coated (painted) metals. Its wavelength is well absorbed by these kinds of materials to accurately engrave and cut. However, its big disadvantage is that it won’t correctly engrave on plain metal (especially aluminum) because its wavelength is not absorbed but reflected by the metal surface.

Diode Laser:

As the cheapest entry-level machine, diodes have lower power. Although it performs well with anodized aluminum, plain aluminum requires pre-treatment with a marking chemical (such as CerMark or LaserBond) to create a readable and relatively long-lasting mark. It can also ablate some non-metallic materials (such as leather and wood), but its speed and depth are much poorer than CO2 lasers. Its advantage is being low-cost and compact, and thus it is handy for frugal hobbyists and users of low-volume, low-power applications.

There isn’t one “ideal” laser. Fiber lasers rule bare metal engraving, CO2 lasers for non-metals and anodized/coated metals, and diode lasers are a good starting point for users on a budget.

Secret to Perfect Results: Tuning of Three Basic Parameters

Long-standing secret to flawless engraving results is with precise tuning of three basic parameters, i.e., power, speed, and frequency.

Analysis of Laser Engraving Critical Parameters

| Parameter | Application/Impact | Key Points |

|---|---|---|

| Power | Anodized aluminum: Low power Bare aluminum (fiber laser): High power. |

This controls the laser energy input intensity to prevent burn-through of the oxide layer or ensure effective performance on bare aluminum. |

| Speed | All materials. | This affects the laser action time. Testing is required to find the optimal balance between speed and power. The faster the speed, the shorter the action time. |

| Frequency | Fiber laser only. | This affects the single-point pulse energy and action mode: Low frequency: Strong impact, suitable for deep engraving. High frequency: Delicate effect, suitable for fine, dark annealed marks. |

1. Power:

It is a direct indication of the energy output of the laser. Power is the parameter that governs the energy density imparted by the material surface in unit time.

For anodized aluminum, there is a thin oxide layer on the surface that is decorative/protective. So, one requires less power to engrave. Too much power will burn through or much too badly damage this oxide layer immediately and create a blurred whitish engraving area or damage to the material below, so no nice clear high-contrast mark.

For uncovered aluminum (in the case of a fiber laser), where there is no protective oxide layer, more power is required in order to effectively alter the surface of the material. Great power must be applied in order to create effective engraving (i.e., pit creation) or to create noticeable annealing discoloration. Not enough power offers only a faint, unclear impression.

2. Speed

The velocity of the laser head over the material surface. Speed determines the time for which the laser beam is held stationary at a point.

The higher the speed, the lower the laser beam exposure time and hence the less input energy. This will lead to shallow engraving depth or lighter shade.

Reduced speed offers increased laser exposure time and greater energy delivery with potential to overheat the material, over-melt (rocky edges on deep cuts), too dark annealing color, or ablation.

Most critical is the power-speed compromise: additional power will require higher speeds to avoid over-ablation (especially when cutting thick). Low power requires low speeds to achieve appropriate energy input to achieve desired effect (e.g., good crisp annealing color). The best power-speed compromise must be established via trial and error for specific material being processed and desired effect.

3. Frequency (only for fiber lasers):

This is the rate of pulses (Hz) emitted by the laser in a second. It determines whether the laser action is very “spot-impact” or “quasi-continuous” heating.

Low frequency (e.g., 20kHz – 80kHz):

The interval between each pulse is very large, hence generating more energy and higher impact.

Effect: Better for deep engraving, with a greater ability to remove material and produce deeper grooves. It can also induce a high thermal effect on metals, but less sensitive than high frequencies.

High frequencies that are, say, 80kHz – 300kHz or higher:

The pulse period is short, and the energy in each pulse relatively low, but more concentrated and longer-lasting effect.

Effect: Ideal for annealing, especially when thin, smooth edges and dark colors (e.g., black) are required. The high heat input produces a more consistent, denser oxide layer on metallic surfaces (e.g., stainless steel, titanium alloys, and surface aluminum under special parameters), darkening the surface’s appearance. High frequencies also have the effect of producing thinner details and lines, and reducing the heat-affected zone.

The best engraving results do not come from maximizing a single parameter, but rather a dynamic balance and compromise of power, speed, and frequency according to material properties and desired effect. Quality control and testing must be performed in order to find the best combination.

Case Study: Raw Part to Branded Product

1. Client Challenge:

We were presented with a technology startup that involved engraving a clean, very wear-resistant company name and product information on 1,000 6061 aluminum alloy power bank shells. The customer initially attempted engraving raw aluminum directly using a CO2 laser but was not satisfied with the quality of the result, which was short of the desired level of clarity and durability.

2. LS’s Solution:

In order to combat the difficulties of engraving naked aluminum, we undertook an in-depth material properties and process compatibility analysis, proposing and implementing an innovative combination of anodizing pre-treatment and CO2 laser engraving:

Anodizing Pre-treatment: First, we professionally anodize all casings with a black anodizing treatment. Not only does this give the casings a consistent, deep, and beautiful look, but also importantly creates a hard, abrasion-resistant aluminum oxide ceramic layer.

Laser Engraving Accuracy: After anodizing, we employ precision CO2 laser engraving technology, operated with ease through our online laser cutting service platform. We control the laser parameters (high speed with low power), and we ablate black dye from targeted regions of the surface layer to expose the undyed, silvery-white anodized aluminum base layer below. It creates a high-contrast logo and text in a clear way on a black background.

3. Results:

Superb Appearance: The final product possesses a dramatic black-and-white color contrast, and the logo and text appear crisp and forceful, significantly enhancing the product’s high-quality status.

Superb Durability: The logo, lying beneath a hard anodized layer, is plane and smooth, offering exceptional wear, scratch, and corrosion resistance, keeping the brand visible for years to come.

As Extremely Cost-Effective: The process employs tried-and-tested anodizing and CO2 laser technology, eliminating the need for any expensive fiber laser machines or time-consuming, complex chemical marking procedures, strictly controlling the cost per part.

4. LS Value

Backed by our vast experience in materials science and laser processing, we’ve created this affordable, effective, and reliable marking solution for our customers. The solution solves the challenge of bare aluminum engraving and allows them to bring high-quality, professional products to market.

FAQs

1. Do lasers cut aluminum?

Yes, lasers are capable of cutting aluminum, but it requires a very powerful fiber laser since aluminum’s high reflectivity and thermal conductivity make it difficult to process. Normal CO2 or diode lasers won’t cut aluminum efficiently as they are not powerful or do not possess a proper wavelength and can result in low-quality cuts or material damage. Special capability and adjusted settings equipment must therefore be used when cutting aluminum to avoid issues. Fiber lasers are generally better in most situations, but precautions for safety and efficiency should be taken with caution.

2. Does laser engraving weaken aluminum?

Laser engraving of anodized aluminum only creates the image by altering the surface dye, not removing material. Fibre laser deep engraving does remove a minute amount of aluminum physically, although in most applications, for instance, signage or decoration, this is insignificant as the removal is minor and extremely localized to the surface. Generally speaking, unless excessive depth engraving or precision parts are involved, the strength of the aluminum is not significantly affected. The designs should be such that the location and depth of the engraving are considered to leave the structural integrity intact.

3. What post-engraving treatment is required?

Anodized aluminum is typically simply wiped with a damp cloth to clean off residue or dust after engraving. Chemical marking processes (such as some laser processes) must be cleaned in order to remove the excess chemicals so that they will not lead to corrosion or coloration. Water or a cleaner is employed for this. Post-processing is easy and quick, just to maintain a clean and good-appearing surface, with no need for such complex processes as polishing or coating. Overall recommendations vary depending on the specific engraving type and material condition, ensuring proper safety and environmental protection.

Conclusion

In summary, there’s no single answer to the “best” aluminum material for laser engraving. It depends on your core goals and the capabilities of your equipment.

Seeking superior visuals and high contrast? Anodized aluminum is the undisputed king. Its surface coating, when lasered, produces clear, sharp, durable, and high-contrast marks. Whether it’s detailed logos, intricate patterns, or elegant text, it perfectly renders them, making it the top choice for enhancing product appearance and brand recognition.

Needing durable, industrial-grade bare metal marking? Then combining a high-power fiber laser with bare aluminum is a must-have solution. It can directly engrave deep, wear-resistant, and permanent marks directly onto the metal, meeting stringent requirements for industrial traceability and part numbering.

Understanding the inherent relationship between different aluminum material properties (especially surface treatments) and corresponding laser processes (such as fiber lasers) is key to unlocking ideal engraving results and avoiding blurring or material damage. Matching process and material can illuminate the essence of your design.

Let professional lasers illuminate your brand with precision!

Say goodbye to blurry, fuzzy engravings! Whether your project calls for stunning, detailed art on anodized aluminum or requires industrial-grade permanent marking on complex metal parts, our dedicated team and advanced laser equipment are the solution.

No need to wait, act now!

Upload your CAD file now.

Get an instant quote and experience professional and efficient laser processing services. Let us use our precise craftsmanship and deep understanding of materials to help you perfectly realize your creative ideas and make precise laser engraving a shining star for your brand!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

I’ve been browsing on-line greater than 3 hours today, but I never found any interesting article like yours. It is pretty worth enough for me. In my view, if all web owners and bloggers made good content as you did, the web will probably be a lot more helpful than ever before.

Glad to be one of many visitants on this awing web site : D.

Haha, we’re so glad you’ve joined us! Welcome!

This is a topic close to my heart cheers, where are your contact details though?

Thank you for the auspicious writeup. It in fact was a amusement account it. Look advanced to far added agreeable from you! By the way, how could we communicate?

Its wonderful as your other articles : D, thankyou for putting up. “The present is the necessary product of all the past, the necessary cause of all the future.” by Robert Green Ingersoll.

Our contact information is below the conclusion of the article