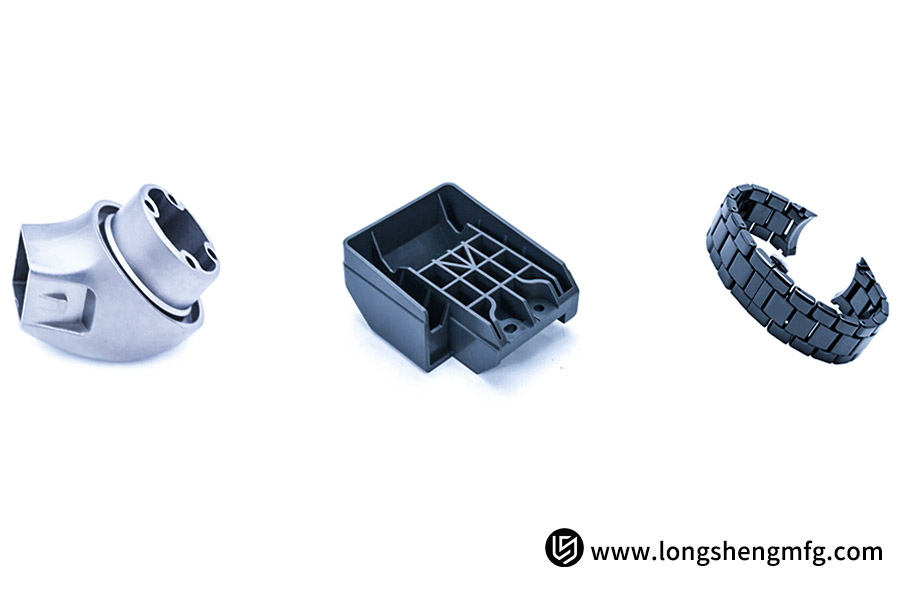

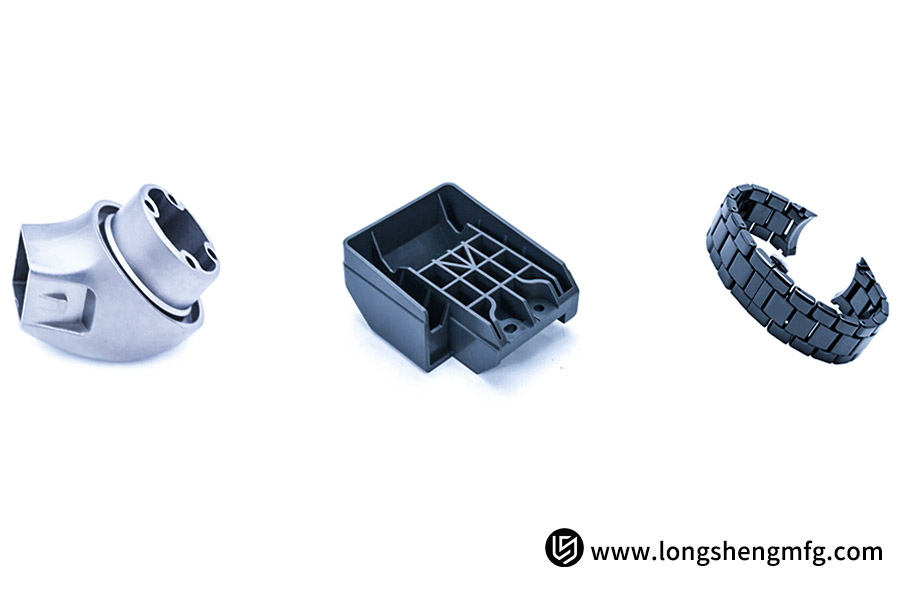

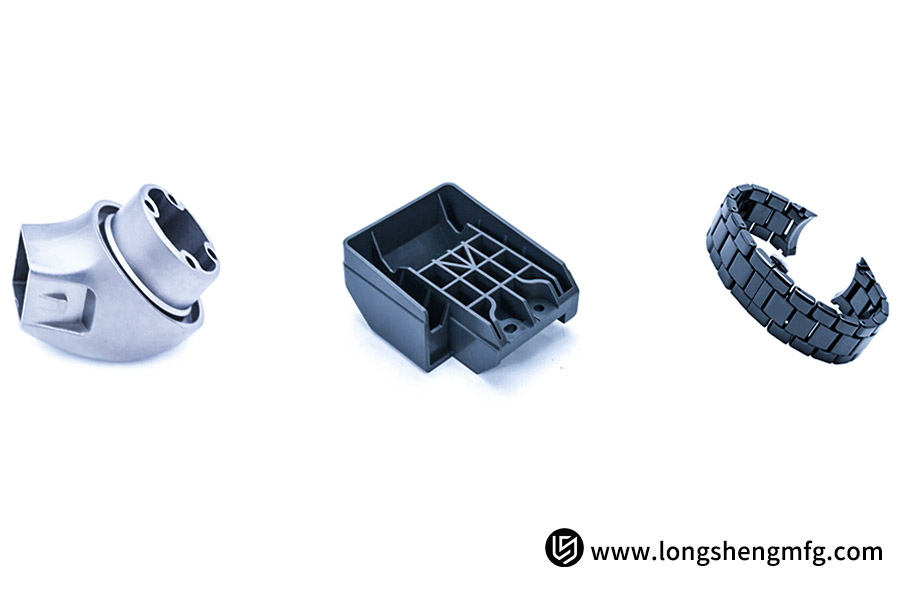

With contemporary manufacturing, the value of custom injection molded components becomes increasingly significant.

Not only do they contribute to precise product realization but also become a major determining factor in making a business competitive and responsive to market needs. LS Technology, with its passion for innovation and commitment to

precision injection molding, takes charge of providing extremely uniform, complex plastic part solutions with advanced processes and innovative production systems. Technology being our platform and teamwork being our approach, we help customers realize optimum product performance, complete cost management, and expedited project deployment. We build reliability and value day-to-day into consumer electronics, automotive, and medical. I will then provide a more in-depth overview of custom injection molding. I hope this would be helpful.

Top 10 Companies Comparison Quick Check Table

| Company Name |

Core Strengths/Focus |

Typical Application Areas |

Case Highlights or Technical Features |

| LS Company |

AI-driven injection molding |

numerous industries |

Patented AI injection molding system |

| Xometry |

Massive online marketplace for on-demand manufacturing |

Automotive parts, home appliances, etc. |

AI-driven intelligent pricing engine and distributed manufacturing network |

| Qingdao Zhongxin Huamei |

Low-odor modified PP expert, customization and environmental protection |

Automotive interiors, electronics, LED lighting |

Low-odor PP with VOC emissions far exceeding industry average, supports full-process customization |

| Kingfa Technology |

Leading domestic modified plastics, large-scale production |

Automotive, home appliances, building materials |

Annual production capacity exceeding 800,000 tons, stable supply to large customers |

| Weike Technology |

Integrated precision injection molds and molded parts |

Electronics, automotive, home furnishings, health appliances |

Integrated molding capabilities |

| Changhong Technology |

Precision plastic molds for medical and office equipment |

Medical devices, office automation |

Provides precision instruments and plastic consumables to international giants |

| Yinbaoshanxin |

Large-scale precision molds for automotive parts |

Automotive, communications, electronics |

Comprehensive service solutions for mold, equipment, and parts manufacturing |

| Shanghai Rizhisheng |

Special high-performance modified PP |

Outdoor equipment, precision electronics |

Highly weather-resistant PP maintains stable performance in extreme temperatures |

Why Trust This Guide? LS Experts’ Practical Experience

At LS, our technical team has years of experience in

custom injection molding and has abundant professional experience.

Our engineers not only possess profound knowledge of materials and processes, but also take a leading position in integrating advanced manufacturing with user demands. Amidst the rapid development of new energy vehicles, precision injection molded parts such as

battery pack brackets and charging port housings have exceedingly high demands for high-temperature resistance, flame retardancy, lightweight design, and assembly reliability. Based on our rich experience in material selection and mold design, LS has been able to supply many new energy vehicle manufacturers with highly consistent and age-resistant tailor-made parts, shortening R&D cycles and reducing costs for customers effectively.

In a real-world case study, LS effectively addressed a customer’s sink mark and dimensional instability issues in connector housings through optimized flow channel design and intelligent process control, with improvement in part yield being dramatic and overall vehicle safety.

- We always stick to the principle of “responding to individualized demands with process innovation,” depending on AI-assisted injection molding systems and one-stop molding services to supply total control from design to mass production.

- Choosing LS is choosing a reliable partner backed by realistic experience, which keeps you in front of the fiercely competitive market.

What Are The Most Significant Factors For Selecting A Plastic Injection Molding Service Provider In 2025?

Amidst the backdrop of accelerating technological change and increasing market demand for customization solutions, the selection of a service provider offering

high-value injection molding solutions with consistency has become a prime imperative for organizations to ensure product competitiveness, total cost management, and time-to-market reduction.

As we approach 2025, organizations must focus on the following basic criteria in selecting partners:

At the top of consideration is technical capability and intelligence

Good suppliers must have proven experience

in multi-material, high-precision, and complex structural parts, and be able to incorporate artificial intelligence, real-time process monitoring, and digital management systems into production processes to improve molding stability and product yield.

A rigorous quality control system is also essential

From material inspection and mold design and manufacturing to injection molding process parameter optimization and post-production testing, suppliers need to

establish a systematic and traceable quality control system to ensure the consistency and reliability of batch production.

Increasingly important as well are collaborative flexibility and response agility of services

Faced with the market’s requests for

small lots, diverse lots, and short lead times, suppliers must be able to collaborate effectively with customers on product refinement and trial production within a short period, becoming true extended partners in

R&D and manufacturing.

- An injection molding service provider must not be chosen on the basis of price or size but based on the depth of their technology, quality professionalism, and customer-focused service system.

- LS, by its unwavering dedication to precision injection molding, capitalizes on AI-powered intelligent injection molding systems, one-stop mold services, and cross-industry proven case studies to provide customers with stable, efficient, and highly customized solutions. If you need a professional and trustworthy injection molding partner, LS is committed to helping you accurately bring your product ideas to life with its project experience and technical competence.

How Are The Top Ten Companies Innovating Plastic Injection Molding?

Global top injection molding enterprises are driving the

plastic injection molding industry towards high precision, high efficiency, and sustainability through multi-dimensional innovations covering material innovation, process intelligence, equipment renovation, and green manufacturing. These enterprises are not only breaking through technological bottlenecks but also reshaping the modern manufacturing paradigm through cross-disciplinary integration and digitalization.

Materials science and process optimization are the core of this innovation

- Ruilu Plastics, for example, is deeply engaged in precision injection molding of special engineering plastics (e.g., PEEK) for core components of humanoid robots. Through material modification, mold flow analysis, and precise process control, they are replacing steel with plastic, achieving lightweight, wear-resistant, and economic results.

- Intelligent equipment and process automation are also significant. Changhong Molding, taking its 4,100-ton ultra-large injection molding machines as the foundation, has developed technologies such as zoned filling and clamping force control, achieving the precise molding of ultra-large structural parts over 100 inches. Steam highlighting technology improves quality and reduces energy consumption.

- Yizumi, through the application of patented technologies such as “sandwich injection molding,” achieves efficient composite molding of multiple layers, expanding the application boundaries of injection molding.

- SABIC’s Megamolding platform, which combines materials science and processing technology, enables the faster, more cost-effective, and more sustainable production of large battery casings, heavy truck parts, and other products than with conventional metals.

Green manufacturing and smart upgrading is another fundamental innovation direction

Changhong Molding applies

steam highlighting technology to integrate energy consumption, improve quality, and actively put low-carbon concepts into practice. Intelligent and digital integration of new processes such as in-mold cutting, for instance,

using industrial IoT, AI, and digital twin technologies to optimize

cutting paths and molding cycles, significantly improves production efficiency and product consistency and reduces material waste.

- In short, innovating companies such as Changhong Molding, Yizumi, SABIC, and Ruilu Plastics are leading the way in injection molding transformation through their technological autonomy, intelligent manufacturing, and R&D of green products.

- LS also leverages its AI-powered intelligent injection molding system and one-stop molding services to continuously innovate in precision injection molding and provide customers with stable, efficient, and highly customized solutions that allow them to achieve competitive advantage in a competitive market.

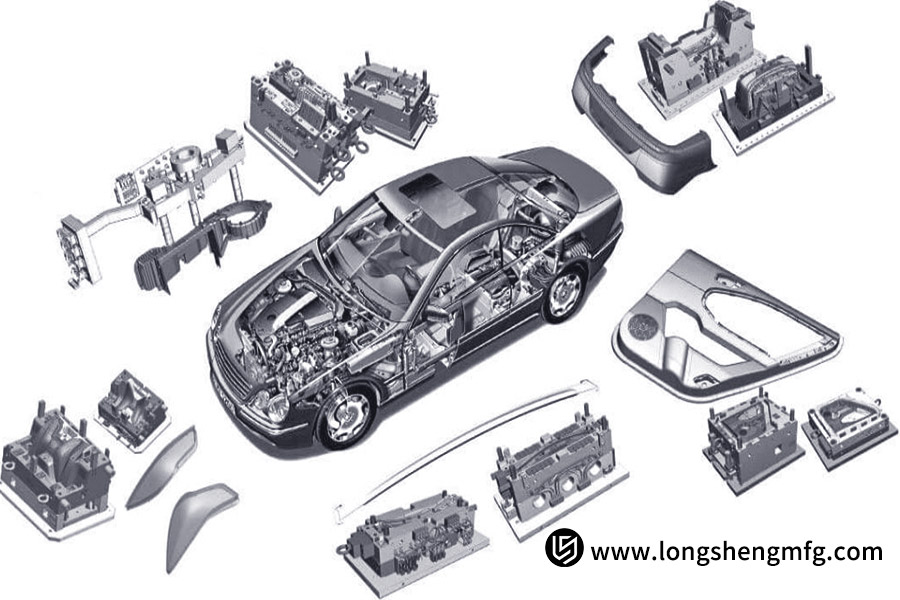

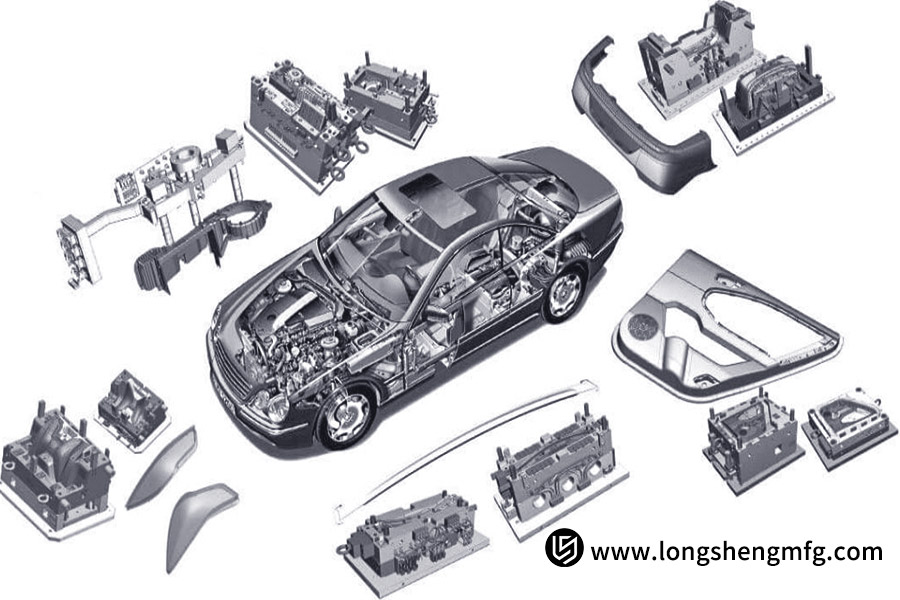

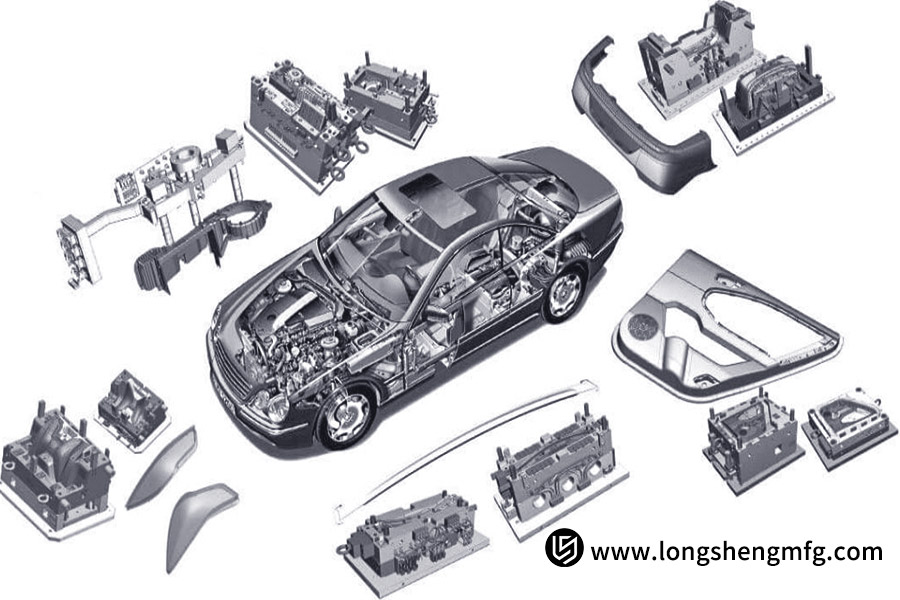

How Are The Special Demands Of Automotive Plastic Injection Molding Met?

The automotive industry places extremely

stringent demands on plastic injection molded parts, besides high strength, high precision, and weather resistance, also light-weighting, safety, and economy. To meet these special demands, systematic innovation and rigorous control in many aspects such as material technology, process design, and quality management are necessary.

High-performance engineering plastics selection and modification are extremely significant

For harsh environments like

high temperature and

oil corrosion in the engine compartment,

high heat-resistant materials like PA and PPS are typically used. Interior and exterior trims require UV resistance, aging resistance, and aesthetics, so modified PP and ASA are widely utilized. Material suppliers like Kingfa Technology utilize special modification techniques to improve the mechanical strength and environmental adaptability of their materials.

Precision molds and intelligent process control are the major enablers

Automotive components possess complicated structure and high dimensional precision, requiring

CAE mold flow analysis to optimize the gating system and reduce sink marks and internal stress.

Multi-cavity molds and high-speed injection molding machines improve production efficiency while closed-loop sensing systems control injection parameters in real time to deliver batch consistency. For example, LS has unveiled an AI process optimization system that dynamically regulates injection speed and holding pressure, with the result of improving dimensional stability and yield.

Comprehensive and rigorous quality management is implemented throughout

From incoming material inspection to measurement of dimension after molding and environmental reliability test (such as high and low temperature cycling and chemical resistance), it is a must to comply with the requirements of

automotive quality management systems such as IATF 16949. Visual inspection and SPC statistical process control are also applied by many companies to enable real-time early warning and traceability of quality issues.

- Briefly, meeting the unique requirements of automotive injection molding entails the sequential integration of three fundamental competencies: material, process, and quality control.

- Based on its extensive know-how in automotive injection molding, integrated molding service, and intelligent production lines, LS continues to provide customers with highly reliable and high-performance injection molded parts, rendering itself a long-term supplier of most major automakers.

How Does LS Precision Manufacturing Achieve zero-Contamination Production Of Medical-grade Components?

Injection molded parts applied to

medical applications directly affect the safety of patients and therapeutic effects, laying extremely stringent demands on cleanliness, biocompatibility, and batch consistency. LS Precision Manufacturing has established a fully controlled production system, systematically

ensuring zero-contamination production on four key dimensions:

environment control, material, process innovation, and quality traceability. This ensures that products possess stable compliance with the rigorous requirements of medical device regulations.

LS has introduced a high-grade clean production environment and automatic production lines

The key medical production lines are within

ISO Class 7 or higher cleanrooms, with stringent control of airborne particulate and microbial counts.

Automated robotics ensure materials and personnel separation, minimizing the risk of contamination due to human contact.

Rigorously Implementing Material Compliance and Process Cleanliness Control

LS only uses

medical-grade raw materials, which are

USP Class VI and ISO 10993 certified. There are also enclosed

stainless steel hoppers and conveying systems, which are regularly cleaned and sterilized. For injection molding, there is a dedicated screw, mold temperature controller, and drying system used for removing residual degradation products as well as cross-contamination for a clean and stable plasticizing process.

On the basis of a comprehensive quality monitoring and traceability system

Each batch of products carries

an individual traceability code, recording data from incoming

raw materials, process parameters, and sterilization packaging. Through the application of such technologies as

laser marking, clean packaging, and particle monitoring, the entry of external contaminants can also be ruled out, ensuring total adherence to regulatory quality requirements such as GMP and MDR.

Briefly, LS Precision Manufacturing achieves “zero-pollution” production of medical injection molded parts in a systematic combination of clean environment, compliant material, anti-contamination process, and digitalized quality control. The company always prioritizes patient safety and has been a trusted partner to numerous medical device companies with its extremely consistent production capability.

How Does Customized Injection Molding Strike A Cost-batch Flexibility Balance?

In the production world driven by growing demand for customization, one of the essential challenges for

customized injection molding is

how to trade off costs and flexibility against divergent batch production demands. In order to achieve the above goal, systematical support from technology optimization, supply chain coordination, and intelligent manufacturing systems is required.

Standardization and modularization principles in the design phase

By creating bespoke designs around standard frameworks and shared modules, the necessity for new mold creation can be reduced,

lowering upfront investment and production complexity significantly. With the application of

DFM (Design for Manufacturing) analysis, costly process problems can be designed out beforehand, shrinking development cycles.

Improving responsiveness through flexible manufacturing and process innovation

Through the application of

quick mold change (QMC) systems and multi-cavity mold assembly technology,

small batches are manufactured economically. Through the introduction of intelligent injection molding and real-time monitoring systems, process parameters can be controlled with precision, machine adjustment losses can be minimized, and consistent quality can be ensured for a series of batches.

Supply chain optimization and lean management are very important

Stable long-term cooperative relationships with material suppliers reduce procurement costs and improve supply stability. Accurate demand forecasting and inventory management prevent overproduction and material waste, and increase flexibility in adjusting to fluctuations in customer order volumes.

- To summarize, attaining cost and batch flexibility in custom injection molding is the seamless integration of three basic strategies: design optimization, flexible production, and supply chain coordination.

- LS leverages its modular design ability, intelligent line configuration, and lean production to allow customers to achieve highly customized products with end-of-life costs under control. This ramp-up from prototype to volume production so smoothly enables them to remain competitive in a volatile market.

What Are The Technological Breakthroughs In Consumer Electronics Injection Molding Miniaturization?

Consumer electronics become lighter, thinner, shorter, and smaller, imposing extremely high requirements on precision injection molding. Miniaturization must break through some technical bottlenecks in

structural design, material performance, mold precision, and molding processes. The key is collaborative innovation with high-precision micro-forming technologies to achieve functional integration, mechanical strength, and mass production stability in very limited space.

Breakthrough Point 1: Precision Molds and Microstructure Forming Capabilities

Ultra-precise mold technology is the basis of microinjection molding. The molds are created by

mirror polishing, micro-drilling, and nano-machining processes to ensure the realization of complex structures such as micropores, thin walls (e.g., less than 0.2mm), and narrow tooth positions. Multi-cavity and stacked mold structures also help to improve production efficiency and reduce costs. For example, LS significantly improves micro-gear injection molding dimensional stability and filling integrity by its hot runner balancing system and high-rigidity mold core.

Breakthrough Point 2: Microinjection Molding and Precision Process Control

Micro-part injection molding is a matter of managing problems of high shear and rapid cooling. Microinjection molding machines utilize higher injection rates (>800mm/s) and more precise metering control to avoid flow stagnation and short shots. Variable temperature technology is utilized for controlling the mold temperature, reducing weld marks and improving surface quality. LS takes AI-based real-time monitoring and adaptive parameter control to achieve higher yields in micro-molding for products such as

connectors and headphone components.

Breakthrough Point 3: High-Performance Engineering Plastics and Functional Materials

Miniaturization requires materials with a compromise of fluidity, strength, and heat resistance.

High-flow materials such as LCP, PPA, and PEEK are widely used, with excellent filling performance in microchannels and also meeting the reflow resistance of electronic parts. LS uses material property analysis and modification technologies to develop bespoke material solutions with low warpage and high bending strength to guarantee the reliability of micro components in subsequent assembly.

Breakthrough Point 4: Integration of Design and Quality Inspection

Micro injection molding is typically combined with processes such as

insert molding and LDS antenna molding to achieve better integrated device functionality. Injection molding feasibility is considered in the product design stage, and mold flow analysis methods such as Moldflow are used to preempt likely defects. Visual inspection, laser measurement, and CT scanning are used in production for full dimensional control to ensure optimum quality in batches of micro-sized parts.

- Micro injection molding is a highly concentrated integration of precision material, mold technology, intelligent process, and rigorous quality system.

- Relying on its technical advantages in micro-injection molding, LS leverages ultra-high-precision mold, special micro-molding equipment, and comprehensive quality control to help consumer electronics customers successfully achieve smaller, lighter, and smarter product innovations, which continuously enhance their market competitiveness.

What Are The Qualitative Changes Brought About By The IoT Intelligent Monitoring System In Injection Molding Factories?

Driven by Industry 4.0, injection molding factories are transforming from traditional manufacturing to digitalized manufacturing by embracing IoT intelligent monitoring systems. Through

real-time perception, data interconnection, and intelligent analysis, these systems are bringing about multi-dimensional qualitative changes to the production process, significantly improving operational efficiency, quality control, and resource utilization.

The IoT solution offers real-time perception and open management of the entire process

By utilizing multiple sensors on

injection molding machines, auxiliary equipment, molds, and ambient, the solution obtains key data such as pressure, temperature, cycle time, and power consumption in real time, with comprehensive visualization of the producing process. Managers can remotely monitor the operating status of global plants, accurately locate abnormalities, and intervene in time, significantly reducing the likelihood of unplanned downtime.

Predictive maintenance and data-driven process optimization are now a reality

The IoT platform utilizes machine learning algorithms to analyze historical and real-time data, providing early warning of problems such as screw wear, hydraulic system failure, or thermocouple failure, and turning reactive maintenance into proactive prevention. Further, by comparing actual parameters against standard process windows, the system automatically optimizes injection molding parameters, reducing deviations, improving product consistency, and lowering scrap rates.

IoT system significantly enhances energy and resource efficiency

Real-time monitoring of the power, water, and gas consumption of every machine identifies power-hungry parts and performs precise adjustments,

such as automatically reducing the motor speed or shutting down needless loads in standby mode. This not only conserves energy and saves money but also meets the requirements for green manufacturing.

Decision support and quality traceability are greatly enriched

Production data of each batch of products—from raw material input to molding parameters—are automatically recorded and linked to the order number, enabling full lifecycle traceability. Multi-dimensional performance reports (e.g.,

OEE and material utilization) are also generated by the big data analytics-based system, providing management with a scientific basis for continuous improvement.

- Briefly, IoT-enabled intelligent monitoring systems have transformed injection molding factories, bringing about operational transparency, predictive maintenance, optimized energy consumption, and quality traceability.

- LS is currently deploying intelligent injection molding production lines with embedded IoT technology, continuous process optimization via data-driven processes to allow customers to make their operations more profitable and improve their market competitiveness.

FAQs

1.How do I choose the most suitable material for custom plastic injection molded parts?

The choice of the most suitable material for plastic injection molded custom components

relies on the application scenario. At LS, our highly experienced engineering team will choose from over 300 qualified particles in our material library based on application requirements, such as automotive high-temperature resistance and medical biocompatibility, to offer the optimal solution for strength, weatherability, and cost.

2.Why are small-batch custom injection molding orders more expensive?

The reason the unit price is high for small-batch custom injection molding orders is that the initial mold price is high. However, LS’s modular mold technology

will reduce 30% of the cost, and unit prices will be significantly lower after mass production.

We also offer flexible quotation for 50-piece orders. LS reduces prices for your small-batch custom injection molding services.

3.What is the duration of the whole injection molding process, from design to delivery?

LS offers extremely fast and effective whole

injection molding processes, from design to delivery.

We utilize 48-hour rapid prototyping and parallel engineering, such as simultaneous process and mold development.

On standard orders, we guarantee a 15-day delivery time. On rush project orders, we at LS can cut turn-around times to 7 days.

4.How do we realize stable quality of large-volume injection molded parts?

LS has a professional monitoring system for realizing stable quality of large-volume injection molded parts. We have

an IoT online monitoring system that captures 12 parameters per shot and conducts full-size inspection of first-parts every two hours. At LS, we can guarantee a stable tolerance of ±0.01mm for orders in the millions.

Conclusion

The custom plastic injection molding industry is rapidly heading towards

greater intelligence, flexibility, and sustainability today. With ever-quicker iteration of finished goods and rising demand for customization, companies are demanding more of injection molding suppliers than just manufacturing capability. Instead,

they need a complete value proposition incorporating collaborative design, speedy response, lean production, and end-to-end quality.

- Driven by technological innovation, LS comprehensively applies AI process optimization, IoT real-time monitoring, and modular design.

- We are committed to providing customers with one-stop, high-end injection molding services from rapid prototyping to mass production, helping them overcome the problem of producing multiple batches, small batches, and customization.

We cordially invite you to take action now and

send your design drawings to the LS professional team. On the basis of our engineering analysis system and digital manufacturing platform that has been established, you will receive thorough feedback in the shortest time,

including process feasibility analysis, material selection proposals, and cost optimization suggestions.

- LS is always customer-focused, striving to combine technology and service perfectly to help you reduce development risks, shorten project cycles, and effectively achieve your product goals.

- Contact us today with your specifications and work together with us to create precise, reliable, and cost-effective injection molded parts!

Contact an LS expert today or submit your design online to receive your customized, efficient solution!

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:

https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and

types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking

quotes for parts are responsible for defining the specific requirements for those parts.

Please contact to our for more information.

Team LS

This article was written by various LS contributors.

LS is a leading resource on manufacturing with CNC machining,

sheet metal fabrication,

3D printing, injection molding,metal stamping and more.

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Simply desire to say your article is as surprising The clearness in your post is simply excellent and i could assume you are an expert on this subject Fine with your permission let me to grab your feed to keep up to date with forthcoming post Thanks a million and please carry on the gratifying work

I’d need to check with you here. Which is not one thing I usually do! I take pleasure in reading a put up that can make people think. Additionally, thanks for permitting me to remark!

I must say, I feel very honored by your willingness to make an exception and share your thoughts with us! Thank you for breaking the silence; your message has certainly made me think. Please don’t hesitate to share your thoughts and ideas with us again; we always welcome your contributions and participation!

I regard something genuinely interesting about your web blog so I saved to my bookmarks.

I discovered your blog site on google and check a few of your early posts. Continue to keep up the very good operate. I just additional up your RSS feed to my MSN News Reader. Seeking forward to reading more from you later on!…

I truly appreciate this post. I have been looking all over for this! Thank goodness I found it on Bing. You’ve made my day! Thank you again

There is noticeably a bundle to know about this. I assume you made certain nice points in features also.