Insert molding, a sophisticated manufacturing process, has revolutionized the production of intricate components.

This article delves into the depths of insert molding, exploring its history, the intricacies of the process, its applications across industries, and the challenges it overcomes. Join us on a journey to understand the nuances of insert molding and its significance in modern manufacturing.

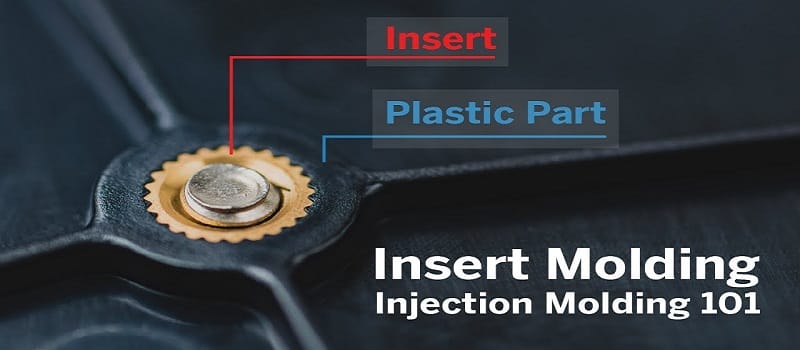

What Is Insert Molding?

Insert molding is a sophisticated manufacturing process that involves integrating inserts, such as metal or plastic components, into a molded part during the injection molding process. This technique allows for the creation of complex and precision components by encapsulating inserts within the molding material.

The process enhances the structural integrity of the final product and offers advantages like cost efficiency, improved product quality, and design flexibility. Insert molding finds applications in various industries, including automotive, electronics, and medical devices, making it a versatile and widely adopted manufacturing method.

How Insert Molding Works

Insert molding is a precise and intricate manufacturing process that involves several steps to create complex components with enhanced structural integrity. Here’s an overview of how it works:

Material Selection:

The process begins with the careful selection of molding materials. The base material, usually a plastic resin, is chosen for its compatibility with the insert material and the desired characteristics of the final product.

Insert Placement:

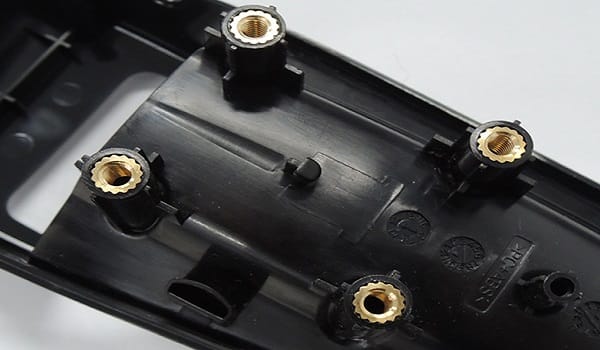

Inserts, which can be made of metal or plastic, are strategically placed in the mold. These inserts may serve various functions, such as reinforcing specific areas, adding strength, or facilitating additional features in the final product.

Mold Closure:

The mold, typically made of two halves, is closed, securing the inserts in their designated positions. This step is crucial for ensuring that the inserts will be encapsulated correctly during the injection molding process.

Injection Molding:

The closed mold is injected with molten plastic resin under high pressure. The plastic flows around and encases the inserts, taking the shape of the mold. The precision and speed of this injection are key factors in achieving a high-quality final product.

Cooling and Solidification:

After injection, the molten plastic cools and solidifies around the inserts. This phase is carefully controlled to prevent defects and ensure the final product’s dimensional accuracy.

Mold Opening:

Once the plastic has solidified, the mold is opened, revealing the newly formed component. The inserts are now securely embedded within the molded part, creating a unified structure.

Ejection:

The finished part is ejected from the mold, and any excess material, known as flash, is trimmed away. This step is crucial for achieving the desired level of precision and surface finish.

The entire insert molding process demands meticulous attention to detail, as variations in material properties, mold design, and injection parameters can impact the final product’s quality.

Through this method, manufacturers can produce components with intricate designs, improved strength, and a seamless integration of diverse materials, making insert molding a preferred choice for various industries.

Considerations Before Insert Molding

Before engaging in an insert molding project, it is essential to meticulously consider various factors to ensure the success of the manufacturing process. These considerations play a pivotal role in determining the feasibility, efficiency, and overall quality of the insert molding endeavor.

1. Material Compatibility

One of the foremost considerations is the compatibility between the base molding material and the inserts. Different materials may react in unpredictable ways during the molding process, potentially leading to adhesion issues or degradation of materials.

It is crucial to select materials that not only work well together but also meet the specific requirements of the final product, such as durability, heat resistance, or conductivity.

2. Insert Design

The design of the inserts is a critical factor influencing the effectiveness of insert molding. Considerations should include the size, shape, and material properties of the inserts.

A well-designed insert ensures a seamless integration with the molding material, contributing to the structural integrity and functionality of the final product.

The intricacies of the insert design should align with the desired outcome, whether it involves reinforcing specific areas, enhancing strength, or facilitating additional features.

3. Precision Requirements

Different applications demand varying levels of precision. Insert molding excels in scenarios where intricate details and high tolerances are crucial.

Before initiating the process, it’s imperative to define the precision requirements of the components. This includes evaluating the tightness of tolerances needed and ensuring that the insert molding process can meet these specifications reliably.

4. Production Volume

The scale of production is a vital consideration in determining the feasibility of insert molding for a particular project.

While insert molding offers advantages in terms of efficiency and reduced assembly time, its cost-effectiveness is influenced by the production volume. Small-scale productions might not fully capitalize on the process’s efficiency gains, making it essential to strike a balance between the advantages of it and the overall scale of production.

5. Tooling Design

The design of the molds used in the insert molding process is a key factor influencing the success of the operation.

The molds should be intricately designed to accommodate the inserts and allow for their precise placement during the injection molding process. Meticulous tooling design ensures that the inserts are encapsulated correctly, preventing defects and contributing to the overall quality of the final product.

Consideration of these factors collectively contributes to the successful implementation of insert molding.

Manufacturers must navigate these considerations with careful planning and attention to detail to harness the full potential of insert molding for creating high-quality components. Each consideration is interconnected, and a comprehensive approach ensures a smooth and efficient insert molding process.

Advantages of Insert Molding

Insert molding offers a myriad of advantages that contribute to its widespread adoption in various manufacturing processes. These advantages not only enhance the efficiency of production but also result in high-quality components with improved structural integrity. Let’s delve into the details of the key advantages of insert molding:

1. Cost Efficiency:

- Labor and Assembly Savings: One of the primary advantages of insert molding is the reduction in labor and assembly costs. By integrating multiple manufacturing steps into a single process, it minimizes the need for additional assembly steps, leading to cost savings.

- Material Efficiency: The process minimizes material waste by precisely encapsulating inserts within the molding material. This efficiency in material usage contributes to overall cost-effectiveness.

2. Enhanced Component Strength:

- Reinforcement: Inserts, which can be made of metals or plastics, serve to reinforce specific areas within the molded part. This reinforcement enhances the overall strength and durability of the component, making it suitable for applications with high mechanical stresses.

3. Design Flexibility:

- Complex Geometries: Insert molding allows for the creation of components with complex geometries and intricate designs. This versatility is particularly valuable in industries where components need to meet specific design requirements, offering designers greater flexibility in realizing their visions.

- Multi-Material Components: The process enables the molding of components with multiple materials, allowing for the incorporation of various material properties into a single part. This is advantageous when specific areas of the component require different characteristics.

4. Reduced Assembly Time:

- Streamlined Production: Insert molding streamlines the production process by combining multiple steps into one. This reduction in the number of assembly steps results in faster production cycles, contributing to quicker turnaround times for manufactured components.

5. Improved Product Quality:

- Precision and Consistency: The precision of insert molding ensures consistent and repeatable results. The process provides tight control over the molding parameters, reducing the likelihood of defects and variations in the final product.

- Elimination of Secondary Operations: As inserts are encapsulated during the molding process, the need for additional secondary operations is minimized. This elimination of extra steps further contributes to maintaining high product quality.

These advantages collectively position insert molding as a robust and efficient manufacturing process. From cost savings to design flexibility and enhanced component strength, insert molding addresses various manufacturing challenges, making it a preferred choice for industries seeking high-quality, customized components.

Manufacturers embracing insert molding can leverage these advantages to stay competitive and meet the demands of an ever-evolving market.

Applications of Insert Molding

Insert molding finds diverse and extensive applications across various industries, leveraging its unique advantages to create components with enhanced functionality, precision, and durability. The versatility of insert molding makes it a preferred choice in the following key sectors:

1. Automotive Components:

- Connectors and Terminals: Insert molding is widely used in the automotive industry for manufacturing connectors and terminals. The process ensures precise encapsulation of metal inserts, providing robust electrical connections.

- Interior Components: Components such as dashboard switches, knobs, and handles often involve intricate designs and benefit from the structural reinforcement that insert molding provides.

2. Electronics and Electrical Devices:

- Sensor Housings: In electronic devices, insert molding is employed to create sensor housings. This application requires the precise encapsulation of delicate sensors within a protective molding material.

- Cable Assemblies: The process is used to encapsulate cable assemblies, offering strain relief and protection for delicate wires and connectors.

3. Medical Devices:

- Surgical Instruments: Insert molding is crucial in the production of surgical instruments where precision and cleanliness are paramount. The process allows for the creation of intricate, sterile components for medical applications.

- Disposable Devices: Components for disposable medical devices, such as diagnostic tools or drug delivery systems, often involve insert molding to ensure a reliable and hygienic end product.

4. Consumer Goods:

- Power Tool Handles: The ergonomic design and durability required for power tool handles make insert molding an ideal choice. The process allows for the integration of metal reinforcements, improving the overall strength of the handle.

- Appliance Components: Components in household appliances, like buttons and handles, benefit from insert molding for its ability to combine different materials and create parts with varying properties.

5. Industrial Equipment:

- Machine Components: In the manufacturing of industrial equipment, insert molding is utilized for creating precision components such as gears, bearings, and handles.

- Control Panels: Components of control panels, where a combination of materials and precise molding is often required, can be efficiently produced through insert molding.

6. Telecommunications Devices:

- Connectors and Housings: Telecommunications devices, such as routers and modems, often require components with intricate designs and precise dimensions. Insert molding ensures the creation of such components with the necessary structural integrity.

7. Aerospace Components:

- Avionics Parts: Insert molding is employed in the aerospace industry to manufacture avionics parts with complex designs and high precision requirements.

- Lightweight Components: The ability to combine materials with varying properties makes insert molding valuable for creating lightweight yet durable components used in aerospace applications.

8. Sporting Goods:

- Equipment Handles: Sporting goods, such as bicycle handles or golf club grips, benefit from the ergonomic design and enhanced grip provided by insert molding.

- Protective Gear Components: Components of protective gear, like helmet liners, can be manufactured with a combination of materials for optimal performance and safety.

These applications highlight the versatility of insert molding across a wide range of industries, showcasing its ability to meet the specific demands of each sector. As technology and materials continue to advance, the applications of insert molding are likely to expand further, contributing to innovative solutions in various fields.

Making Custom Insert Molded Parts

Creating custom insert molded parts involves a systematic process that integrates precision design, material selection, and advanced manufacturing techniques. Whether you’re designing components for automotive, electronics, medical devices, or any other industry, the following steps guide the production of custom insert molded parts:

1. Design the Part:

- Define Functionality: Clearly outline the intended functionality and purpose of the part. Consider specific features, dimensions, and any requirements for reinforcement or integration of multiple materials.

- CAD Modeling: Utilize Computer-Aided Design (CAD) software to create a detailed 3D model of the part. This model serves as the foundation for the manufacturing process.

2. Choose Materials:

- Base Molding Material: Select a suitable base molding material based on the specific characteristics required for the part. Consider factors such as strength, flexibility, and resistance to environmental factors.

- Insert Material: Choose the material for the insert based on its function. Inserts can be made of metals, plastics, or other materials, each offering unique properties.

3. Tooling Design:

- Mold Creation: Develop molds that accommodate the inserts and allow for precise encapsulation during the injection molding process. The mold design should account for factors like part geometry, placement of inserts, and the intricacies of the molding material.

- Tooling Material: Select durable and heat-resistant materials for the molds to withstand the injection molding process. Consider the number of cavities needed for efficient production.

4. Injection Molding Process:

- Insert Placement: Carefully place the inserts into the mold. The precision of insert placement is crucial for achieving the desired functionality and strength in the final product.

- Injection: Inject molten plastic resin into the mold under high pressure. The plastic material encapsulates the inserts, taking the shape of the mold. Control injection parameters for optimal results.

- Cooling and Solidification: Allow the molten plastic to cool and solidify around the inserts. The cooling process is carefully controlled to prevent defects and ensure dimensional accuracy.

5. Ejection and Finishing:

- Ejection: Open the mold and eject the finished part. Any excess material, known as flash, is trimmed away to achieve the desired final shape.

- Quality Check: Conduct thorough quality checks to ensure that the final parts meet the specified design tolerances and quality standards.

6. Testing and Validation:

- Functionality Testing: Validate the functionality of the insert molded part through rigorous testing. This may include mechanical tests, electrical tests, or any other assessments relevant to the part’s intended use.

- Iterative Improvements: If needed, iterate the design and manufacturing process based on testing results to optimize the performance of the custom insert molded part.

7. Scaling Production:

- Optimize Production Parameters: Once satisfied with the prototype, scale up production by optimizing injection molding parameters for efficiency and consistency.

- Quality Control Measures: Implement quality control measures to maintain consistency and precision in large-scale production.

Creating custom insert molded parts involves a combination of design expertise, material knowledge, and manufacturing precision. By carefully navigating each step of the process, manufacturers can produce high-quality, customized components that meet the specific requirements of diverse industries.

A Brief Comparison Between Insert Molding Vs Overmolding

While both insert molding and overmolding involve molding additional materials onto a base, they differ in the placement of the added material.

In insert molding, inserts are placed into the mold before injection, while in overmolding, the additional material is molded over a pre-existing part. Both techniques offer unique advantages based on specific project requirements.

Conclusion

Insert molding stands as a versatile and efficient manufacturing process, offering a host of advantages and applications across various industries.

By carefully considering key factors before initiating a project and understanding the benefits and applications, manufacturers can harness the full potential of insert molding for creating high-quality, customized components.