Do you have a common occurrence of these problems with small-lot or low-production quantities: low order totals yield high unit price, costly tooling is difficult to amortize over, and old habits lack economies of scale? These are core issues that we thoroughly understand, and they represent the very definition of “high cost in small batch manufacturing.”

As professionals dedicated to addressing these problems, LS Precision recognize cost considerations of all of your customers. LS Precision guarantee, no more trade-offs. This article describes seven key ways to address blind spots in cost control for systematic low-volume production, so you can save money efficiently, significantly improve return on investment (ROI), and transform production drawbacks into competitive advantages. To save your time, the following is a brief summary overview of the main conclusions.

Quick Reference: Choose Your Tap at a Glance

| Strategies | Core Objectives | Key Points |

| Cost Factor Analysis | Understand the cost structure and identify cost reduction targets. | Lack of economies of scale, difficulty amortizing mold costs, poor process adaptability, and limited purchasing bargaining power. |

| Design for Manufacturing (DFM) | Eliminate waste at the source to reduce manufacturing costs. | Simplify the structure, reduce the number of parts, avoid complex processes, and adopt designs that are easy to process. |

| Material and Process Matching | Pursue the best price-performance ratio, not the best. | Select materials based on demand (not high performance), explore composite materials/alternative materials, and choose low-threshold molding processes. |

| Modern CNC machining technology | Enable efficient, flexible, and economical production. | Eliminate the need for expensive molds, achieve high precision and flexibility, enable rapid iteration, and support complex geometries. |

| Standardization and Modularization | Reduce customization and increase production runs. | Use standard parts, common interfaces, and modular functional designs for reuse to reduce unit costs. |

| Scientific Supply Chain Management | Control external costs through collaborative procurement strategies. | Centralize procurement, establish long-term strategic partnerships with suppliers, and implement VMI (Vendor Managed Inventory). |

| Value Engineering (VA/VE) Analysis | Ensure maximum cost-effectiveness for each functional area. | Analyze the relationship between functionality and cost, eliminate redundant functionality, and identify lower-cost implementation solutions. |

| Choose the suitable partner | Take advantage of the application of third-party expertise to cut costs incrementally. | Choose a seasoned manufacturer like LS Precision, a small batch production specialist with better technical and advisory skills. |

Reducing the cost of producing small lots is not a one-time compromise but an optimized process engineered in design, material and process choice, and supply chain planning, thereby relying on a partner able to provide technical assistance and subject-matter knowledge.

By integrating these seven strategies, you are able to move cost control from passive to active control, ultimately resulting in huge savings and greatly enhanced return on investment (ROI). Selecting LS Precision Manufacturing is an important step in successfully executing these strategies.

Why Trust This Guide? Practical Experience From LS Experts

Given their experience of decades in low-volume production, not only does LS Precision Manufacturing possess multi-process integration capabilities (from CNC precision machining to 3D printing and injection molding optimization), but also directly confronts exorbitant costs of small-batch production through technology integration (like modular design enabling mold sharing rates in excess of 80%).

LS Precision is dedicated to applying lean manufacturing principles to small-batch production. Through scientific supply chain management and value engineering analysis, we help customers reduce the cost of production by as much as 30%, each recommendation based on a formal, field-tested methodology.

In the typical scenario, LS Precision reassessed material compatibility and production processes for a customer and used metal 3D printing technology rather than traditional mold creation. Not only did this bypass the exorbitant expense of tools, saving 90% of the cost in the first place, but it also sped up prototyping cycles from weeks to less than 24 hours, enabling the customer to rapidly iterate and test.

Moreover, with the use of flexible fixture systems and dynamic scheduling, LS Precision helped another customer achieve a 30% cost reduction in machining and significantly enhance equipment utilization for small-batch machining.

Such experiences assure that LS Precision’s claimed method is not lip service but a proven technique refined by thousands of projects.

Why Are Unit Costs Typically Higher For Small-Batch Production?

More often than not, customers are shocked by the sky-high quotes they receive when they initially hear of small-batch manufacturing processes. The reason for this is that unit prices do not merely encompass raw material and working hours; more importantly, they are watered down by fixed opening investment and inefficiencies.

When it comes to mass production, the cost disadvantage of small-batch manufacturing processes is primarily due to a few glaring areas:

1. Commissioning and programming equipment expenses:

No matter how many the machine produces, one or 1,000, there is the same involved commissioning, programming, and first-article inspection. All this front-end expense is distributed over comparatively low volumes of products in small-batch production, resulting directly in unit cost inflation.

2. Inadequate amortization of unit labor hours:

A disproportionately high percentage of “non-productive time” for startup of production and changeovers displaces productive cutting time and generates astronomic average unit labor costs.

3. Disadvantages in material procurement scale:

Raw material and run-of-the-mill parts will not be able to reap economies of high-volume production and therefore will have a higher unit cost.

4. Mismatch between process and economic batch size:

Most traditional processes (such as die casting and injection molding) involve expensive molds, which are high barriers to achieve “economic batch size.” Drive manufacturing into small batches doesn’t accommodate recovering mold expenses.

It is these inherent differences in cost structure that generate different cost models for low-volume versus high-volume production. Grasping this underlying cause is the secret to cost control.

Strategy 1: Design Optimization–How To Reduce Manufacturing Costs At The Source?

In constrained production volume, the maximum cost is fixed at the beginning at the design level. Even a small design modification has significant leverage effect on the ultimate total cost. Thus, adherence to the DFM (Design for Manufacturing) principles is the most economical and least expensive way of source cost reduction.

Cost reduction with no performance loss is achievable and maximizes manufacturing efficiency through intelligent design. Some of the most effective methods include:

- Reduce geometry: Removing unnecessary intricate curved surfaces, deep cavities, and special shapes can significantly reduce CNC machining time and scrap material.

- Avoid close tolerances: Appropriately mark core dimensions tolerances and loosen specifications on non-mating surfaces. Each escalation in tolerance classes can mean a gigantic escalation in time to machine and inspect.

- Standard Parts first: Apply standard apertures, threads, flanges, and stock available parts to the maximum extent possible to avoid expensive custom developments.

- Consider Assembly Logic: Designing for assembly simplicity, minimizing overall part number and specialty tooling, can decrease future labor costs substantially.

Optimization design is the ultimate guard against cost problems in low-volume manufacturing.

LS Precision’s skilled staff of engineers offers free Design for Manufacturing (DFM) analysis services, reviewing your design from a manufacturing perspective and offering suggestions for optimization to save your time and money, having your project productive and cost-effective from start.

Strategy 2:How to accurately match materials and processes to optimize cost-effectiveness?

With small-batch manufacturing, employing the most sophisticated processes and high-end materials is not always optimal. True intelligence lies in discovering the most economical blend to meet product functionality without overkill and costly cost overkill.

Various material-process combinations yield wildly varying cost-effectiveness. LS Precision, through its ability to multi-process integrate, offers expert matching suggestions:

1. Aluminum Alloy + CNC Machining:

This is the most traditional pairing for small-batch CNC machining. Aluminium alloy is simple to machine, light, and inexpensive, and so it is a great choice to utilize when producing high-strength, high-precision functional parts and prototypes. It is the go-to for rapid iteration and budget-friendly efficiency.

2. Stainless Steel + CNC Machining/Sheet Metal:

Stainless steel is the optimum selection when more strength, corrosion resistance, or superior appearance has to be realized. In the case of highly structured parts, precision is ensured by small batch CNC machining. For thin-walled products like enclosures and chassis, sheet metal processing is cost-effective.

3. Engineering Plastics (e.g., POM/Nylon) + 3D Printing/CNC:

If the requirement is insulation, weight reduction, or low friction, metal is best substituted by engineering plastics. CNC machining or 3D printing (for complex shapes) can be employed sparingly to dispense with the wastefulness of injection molds altogether.

4. Photosensitive Resin + 3D Printing:

Most suitable for visually high-fidelity validated prototypes that need to be assembled and tested. It is extremely quick and cheap but mechanically defective.

No single process or material is superior, only the optimum match.

LS Precision engineers can objectively review your requirements (strength, appearance, cost, and cycle time) and connect you with the optimum material for small-series CNC machining, 3D printing, sheet metal stamping, and other processes, locking in cost savings ahead of time.

Strategy 3:How to use CNC machining to improve small batch production efficiency and flexibility?

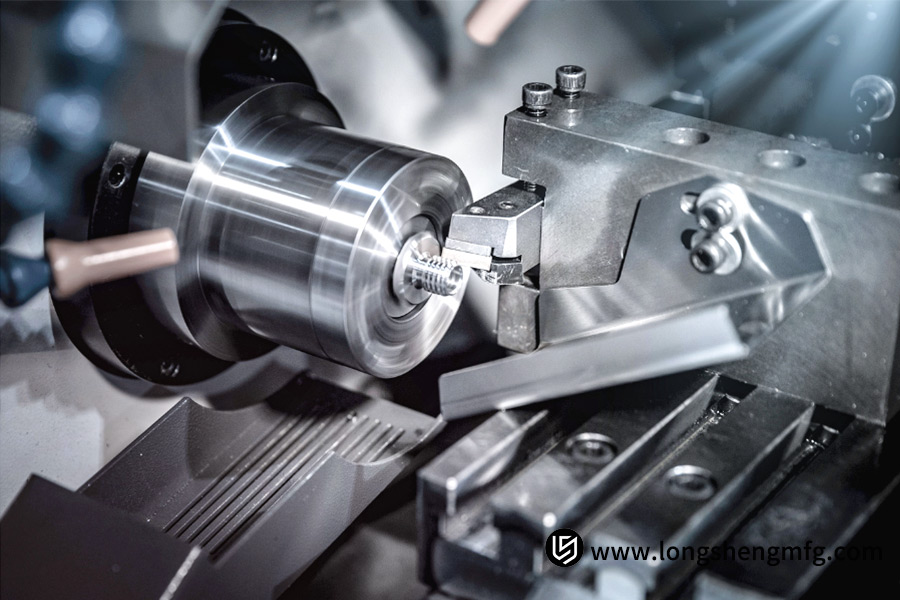

CNC machining has historically been thought to be applicable for high-volume production only. But modern technology in CNC is an excellent way of avoiding the cost restrictions of low-volume production. Through technological progress and process improvement, LS Precision’s low-volume CNC machining achieves efficient use of fixed costs and economic efficiency comparable to high-volume production.

LS Precision’s high efficiency is reflected in the following main features:

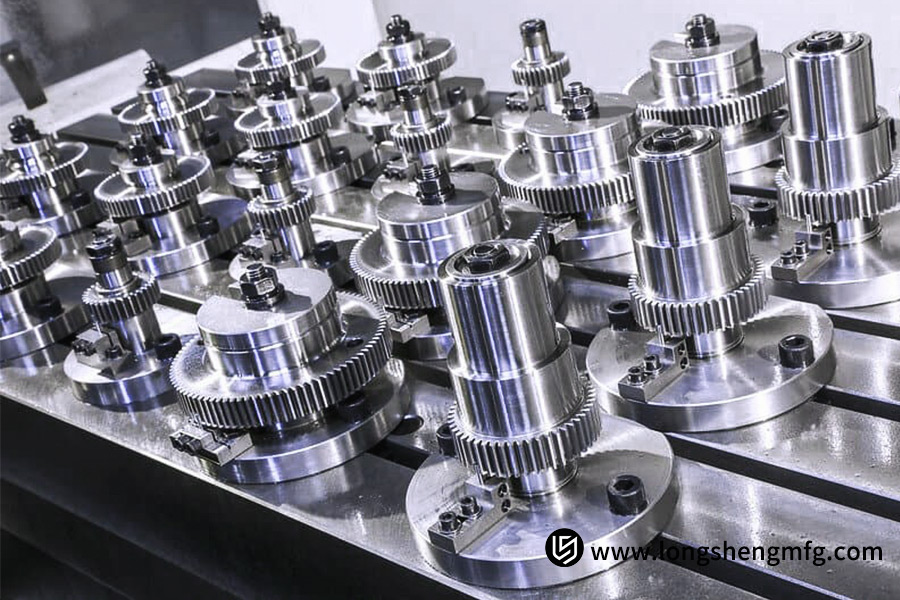

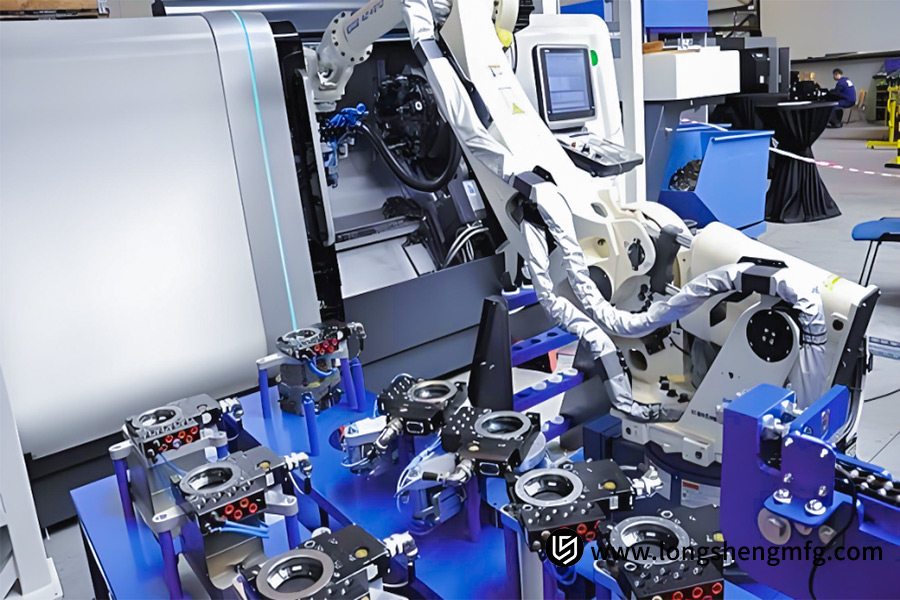

- High-Performance Machining Center Cluster: Equipped with multiple high-speed, high-precision CNC machine tools, LS Precision possess powerful production strength and can process multiple orders of small-volume CNC machining at the same time, cutting processing time per piece.

- Quick Tool Change System and Standardized Fixtures: Significantly cut equipment commissioning and line changeover time, eliminating traditional “unproductive” downtime and significantly improving handling efficiency of small orders.

- Automated Loading and Unattended Production: Enables extended periods of unattended, computer-controlled machining with low labor expenses per part and a decreased need for experienced machinists without compromising machining quality.

- Intelligent Programming and Tool Path Optimization: Programmers utilize sophisticated CAM software to create the most efficient cutting paths, optimize material usage, and reduce cost at each stage.

By investing in top-class equipment and streamlined manufacturing processes, LS Precision transfers its technological advantage straight to cost savings to you. You will receive improved parts at similar costs, and with faster delivery, actually gaining efficiency and flexibility.

With the latest CNC technology now accessible, the low-volume CNC machining business model has been revolutionized.

Strategy 4: Standardization And Modular Design –Can Costs Be Reduced Like Building Blocks?

Faced with economies for small batch production, the most forward-looking strategy is not just to maximize individual orders, but to rethink product design itself. With standardization and modular design, you can construct products in blocks, combining multiple “small batches” into “economic batches,” entirely redrawing cost economics.

The secret of the strategy is to break out of production volume limitation through intelligent design:

1. Part Commonality:

Employ identical screws, bearings, connectors, or PCBs across product lines wherever feasible. This permits one small-batch orders to be grouped together into large purchasing quantities, thereby making the suppliers in a position to offer sizable discounts.

2. Functional Modularity:

Split products into several independent functional modules. Modules can be upgraded and revised individually without a need for a total redesign of the product. This not only reduces the cost and complexity of each small-batch production run, but also accelerates R&D.

3. Interface Standardization:

Define standard mechanical and electrical interfaces to allow simple plugging in and out of various modules. This is the foundation of modular design, and this ensures flexibility and scalability.

Modularization and standardization are strategic solutions to containing small-batch production expenses. They elegantly move production batches through design reuse and assembly, thereby achieving economies of scale.

LS Precision’s technical professionals offer professional consulting and support and help you reconsider product architecture and design more cost-economic and flexible product platforms to achieve long-term cost reduction.

Strategy 5: Scientific Supply Chain Management –How To Control Costs Through Procurement Strategies?

For independent small-batch producers or start-ups, occasional purchasing of raw material and generic components normally entails compromise with a higher market price, thus directly cutting into profit margins of a project.

The principle of scientific supply chain management lies in consolidating scattered demand through aggressive purchasing strategies, rendering scale benefits and negotiating power. As an expert manufacturing service platform, LS Precision holds unique advantages over independent small-batch producers:

1. Scale Purchase Advantage:

LS Precision combine the dispersed orders of numerous customers into bundled, fixed purchase orders enabling us to achieve lower wholesale prices from raw material suppliers and standard parts manufacturers.

2. Long-Term Supplier Network:

LS Precision have formed long-term, stable strategic relationships with upstream suppliers. Having this foundation of trust allows us to have priority allocation of capacity, better delivery schedules, and better pricing—resources most small manufacturers are unable to secure on their own.

3. Professional Material Suggestion Recommendations:

LS Precision Manufactuuring are aware of market trends as part of our purchasing and engineering staff and can recommend alternative materials or stock items with comparable function but lower cost and faster delivery, saving you initial costs.

Cost control goes far beyond the process of maximizing production steps. Partnering with us in LS Precision is your means of avoiding the disadvantages of sole-sourcing while reaping the immediate benefits of our experienced and efficient supply chain system, material procurement at better-than-market prices, and a significant reduction in your total small-batch production costs.

Strategy 6: Value Engineering Analysis – Is Every Feature Measure Worth The Cost?

Of all the activities involved in controlling cost of low-volume production, the most vital to do in a lot of instances is to return and examine the value of the product design itself: Does every non-functional and functional requirement offer commensurate value? Are there overperforming or overcosted designs?

Value Engineering (VE) seeks to consistently deliver the demanded product function at the lowest total cost through the application of systematic analysis. LS Precision advocate collaborative intensive work with clients to co-execute value engineering analysis, focusing on:

- Function-Cost Correlation Analysis: Examine the cost of each design feature individually to see if it is matched by the functional value it represents, and cut out “excessive features” which are costly but trivial.

- Solution Search: Determine other cost-saving measures to implement necessary functions. For example, can adopting more generic materials replace specialty alloys? Can altering design to the structure simplify manufacturing?

- Standardization and Versatility Evaluation: Determine whether or not non-critical components possess the capability for using standard components or universal designs in order to avoid undue customization costs for specialized purposes.

Value engineering analysis is not merely tradeoff in quality terms; it’s about finding the optimum balance between function and cost. This analysis is particularly valuable for low-volume cost control, ensuring that every investment is worth the effort.

LS Precision’s engineering experts will assist in doing this, cooperating to optimize your design and uncover where significant cost reductions can be made without compromising on your fundamental requirements.

Strategy 7: Why LS Precision Manufacturing Is The Best Choice For Your Small-Batch Projects?

By including all the above methods, the one thing that is the most successful cost-control tactic is choosing a truly professional manufacturing partner. For most companies, using an average small-batch manufacturer too often means adopting all potential risks and cost burdens all by itself. Choosing LS Precision is, in itself, a cost-saving choice. The value LS Precision deliver is much greater than the numbers on the estimate:

1. Systematic Cost Optimisation:

LS Precision integrate the six approaches described above into every single project execution process, from design, materials, and processes, to supply chain, and offer you total cost control—a professional service unavailable from typical fabricators.

2. Dedicated Quality and Delivery Guarantee:

Ensured quality means lower defect rates and rework hazards, while assured delivery averts potential project delays and losses, all of which directly add to your net return on investment (ROI).

3. Value of Expert Consulting:

LS Precision are not just a producer; we are your strategic consultant. Our engineers proactively provide you with professional analysis, including design optimization (DFM) and value engineering (VE), translating our knowledge into a competitive asset.

With small-batch manufacturing, the real cost is the total cost of ownership of the entire process, not per unit price.

LS Precision Manufacturing, with its complete experience, can be your trusted, extended family, turning inherent cost issues into marketplace advantage and providing maximum worth return on every project.

LS Success Story: How To Reduce Small-Batch Production Costs By 30%?

In the domain of smart hardware innovation, magnificent designs are often handicapped by costly manufacture for low-volume production. Many companies, especially start-ups, tend to find that quotes for small-lot precision parts are far more than their imagination can handle. The following real-life case illustrates how LS Precision Manufacturing helps customers overcome this with its expertise and optimization system.

1. Client Challenge:

In the field of intelligent hardware, startups typically have to contend with prohibitive low-volume production expenses. A technology firm that was developing a smartwatch had to produce 500 aluminum alloy cases with complex structures and tight tolerances. After speaking to a number of suppliers, their quotations all exceeded the project budget, creating significant stress on product commercialization.

2. LS Precision’s Innovative Solution:

To enable the company to get through this challenge, the team at LS Precision Manufacturing proposed a comprehensive solution:

- LS Precision’s designers conducted a rigorous DFM (Design for Manufacturing) analysis of the design of the customer and discovered that the tolerance for a non-critical structural component (±0.05mm) was too tight. To guarantee product functionality and quality, we recommended relaxing this tolerance to ±0.1mm and optimized CNC’s milling path to substantially improve processing efficiency.

- Considering the process selection aspect, we recommended 6061 aluminum alloy, a material that possesses performance advantage and cost advantage. We also utilized five-axis CNC machining technology to achieve multi-faceted machining in single setup to conserve labor hours and cumulative error and avoid multiple setup costs.

- With LS Precision Manufacturing’s bulk buying advantage, we helped the customer source raw materials at a cheaper rate, ongoing costs management.

3. Final Result:

By implementing these different steps, LS Precision were successful in helping the customer reduce the cost of low-volume production of their smartwatch case by 30% and the lead time by 15%. It not only allowed the client’s product to be launched successfully, but also attained their long-term trust in our good service and excellent products with several follow-up orders.

This case completely demonstrates how having LS Precision Manufacturing as your partner can truly add so much value to your small-batch CNC machining projects.

FAQs

1. Can LS Precision offer competitive pricing for small-batch production?

Yes. LS Precision acknowledge the cost issue of small-batch production and implement a number of precise approaches to reduce costs and optimize efficiency: using effective small-batch CNC machining technology to reduce time per item; leveraging scaled raw material purchasing to secure better pricing; and reducing waste by lean production management. LS specializes in providing cost-effective solutions for small-batch orders so that you can enjoy quality products while efficiently managing low-volume production costs.

2. Does my design file need modification? Can LS Precision help?

Yes, LS Precision offer free Design for Manufacturability (DFM) services. Our engineers, armed with their many years of small-run manufacturing experience, will scrutinize your design upfront, identify possible process pitfalls and cost pitfalls, and offer suggestions for optimization, such as modifying tolerances, simplifying structures, or selecting lower-cost materials. LS Precision want to save you money and accelerate production without compromising product quality.

3. What is the typical lead time for small-batch orders?

For standard small-batch NC orders for machining with regular materials, LS Precision generally complete the manufacturing and arrange shipping within 7-15 working days. The actual lead time will be determined based on the complexity of the project, schedules of outstanding orders, and requirements of the manufacturing process. LS Precision, having armed itself with its high-performance production scheduling system and huge reserves of manufacturing capacity, aims to ensure timely and guaranteed delivery for your small-batch manufacturing needs with quality assurance.

4. Besides CNC machining, does LS Precision offer other small-batch services?

Yes, LS Precision offer a genuine one-stop service. Apart from basic small-batch CNC machining, LS Precision also offer several processes, including metal/plastic 3D printing (for prototype and high-complexity components), sheet metal production (for chassis and boxes), and vacuum casting (for small-batch duplicates). Thus, you can select the most economical and efficient solution based on your product needs at each phase, and LS Precision will handle it all, saving you time and worry.

Conclusion

Effective optimization of low-volume production costs doesn’t rely on corner cutting in a single process; it’s an optimized process that works across design, processes, materials, supply chain, and partner.

From design optimization (DFM) and value engineering (VE) research, to proper process matching and ideal utilization of advanced CNC technology, to promotion of standardization of modularization and scientific supply chain management, each link has tremendous cost optimization potential.

If you’re struggling with low-volume cost and quality issues, don’t struggle alone. Contact LS Precision today, upload your 3D design drawings, and receive an instant quote and a free, exclusive DFM (Manufacturability Analysis) report!

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.