Want to learn more about CNC machining and metal 3D printing? This will provide you with everything you need to know about these two popular manufacturing technologies. From their advantages and disadvantages to which process is most suitable for your specific needs, we provide you with services.

CNC machining and metal 3D printing are two of the most advanced manufacturing methods available today. These two techniques are used to produce a wide range of products, from simple prototypes to complex parts for the aerospace industry.

What is CNC Machining?

CNC machining, also known as computer numerical control machining, is a manufacturing process that uses computer programs to control machine tools. This process allows for precise control of cutting tools, resulting in high-quality finished products.

CNC machining is commonly used to produce parts for the automotive, aerospace, and medical industries. The process is also used to create prototypes, as well as one-off parts and small production runs.

What is Metal 3D Printing?

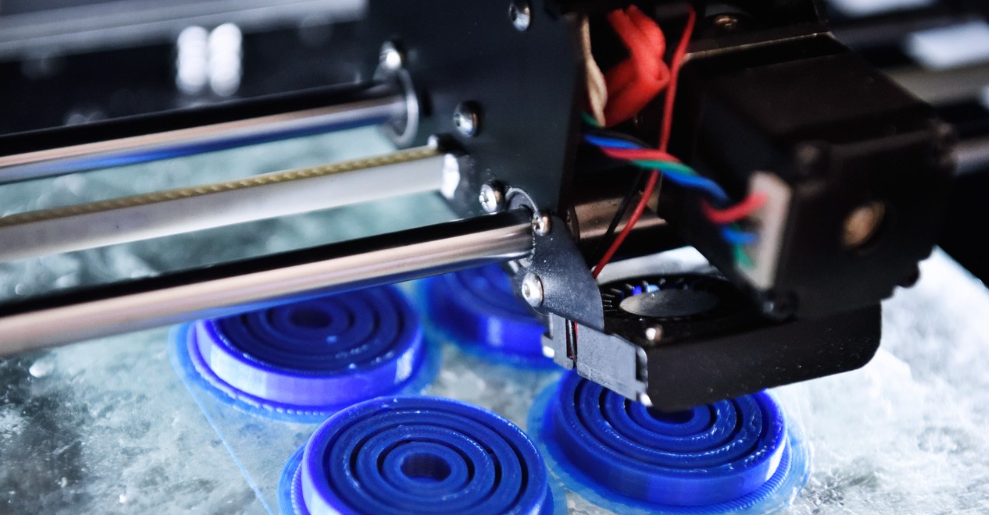

Metal 3D printing, also known as additive manufacturing, is a process of building three-dimensional objects by adding layers of material. This process allows for the creation of complex geometries that would be impossible to produce with traditional manufacturing methods.

Metal 3D printing is commonly used in the aerospace, medical, and defense industries. The process is also used to create prototypes, as well as one-off parts and small production runs.

Difference Detween CNC Machining and 3D Metal Printing

CNC machining and 3D metal printing are two of the most popular manufacturing processes used to produce metal parts with high accuracy and precision. Although they share some similarities, there are some significant differences between the two processes that distinguish them from each other.

The main differences between online CNC machining and 3D metal printing are:

1.Process

CNC machining is a subtractive process, while 3D metal printing is an additive process. This means that CNC machining removes material from a solid block to create a part, while 3D metal printing adds material layer by layer to create a part.

2.Material

CNC machining can work with a wide range of metals, including aluminum, brass, copper, titanium, and stainless steel, while 3D metal printing is limited to a few types of metals such as titanium, stainless steel, and aluminum. This is because the melting point of the metal must be low enough to be melted by the laser or electron beam used in 3D metal printing.

3.Accuracy and Surface Finish

CNC machining produces parts with higher accuracy and better surface finish than 3D metal printing. This is because CNC machines use cutting tools to remove material in a controlled way, resulting in a smoother surface finish and higher accuracy. 3D metal printing, on the other hand, can produce parts with a rougher surface finish and lower accuracy due to the layer-by-layer additive process.

4.Cost

CNC machining is generally more expensive than 3D metal printing for small production runs, but becomes more cost-effective for larger production runs. This is because CNC machines require more setup time and specialized tooling, while 3D metal printing requires less setup time and can produce more complex geometries without the need for specialized tooling.

In conclusion, both CNC machining and 3D metal printing are valuable manufacturing processes that have their own unique strengths and weaknesses. The choice between the two processes ultimately depends on the specific needs of the project, including the desired material, accuracy, surface finish, and production volume.

Compared With CNC Machining, What are the Advantages of 3D Metal Printing

When it comes to metal fabrication, there are several methods to choose from, including CNC machining and 3D metal printing. While both have their benefits, 3D metal printing offers several advantages over CNC machining:

1.Flexibility in Design

One of the biggest advantages of 3D metal printing is the ability to create complex and intricate designs that would be difficult or impossible to achieve with CNC machining. With 3D printing, designers can create parts with internal structures and features that would be impractical to produce with traditional machining methods.

2.Faster Prototyping

Another advantage of 3D metal printing is the speed at which prototypes can be produced. CNC machining requires a significant amount of time to set up and program, whereas 3D printing can produce a prototype in a matter of hours or even minutes.

3.Reduced Material Waste

CNC machining often results in significant material waste, as parts are cut from larger blocks of material. In contrast, 3D metal printing uses only the necessary amount of material to create the part, reducing waste and helping to conserve resources.

4.Cost-Effective for Small Production Runs

For small production runs, 3D metal printing can be a cost-effective alternative to CNC machining. With CNC machining, the cost per part decreases as the production run size increases, while 3D printing offers a consistent cost per part regardless of the production run size.

Overall, 3D metal printing offers several advantages over CNC machining, including greater design flexibility, faster prototyping, reduced material waste, and cost-effectiveness for small production runs.

Compared With CNC Machining, What are the Disadvantages of 3D Metal Printing

Metal manufacturing is a complex process that involves multiple methods, including CNC machining and 3D metal printing. Although both have their own benefits, it is crucial to understand the limitations of each method before deciding which one to use for the project.

In this section, we will discuss the drawbacks of 3D metal printing compared to CNC machining.

1.Limited Material Options

One of the most significant drawbacks of 3D metal printing is the limited range of materials available. Currently, 3D metal printing is limited to a relatively small range of materials, including stainless steel, titanium, and aluminum.

In contrast, CNC machining can handle a wider range of materials, including plastics, composite materials, and foreign metals. This limitation may be an important factor in determining which method to use in the project, especially if you need specific materials that are not compatible with 3D metal printing.

2.Lower Accuracy and Surface Finish

While 3D metal printing has come a long way in terms of accuracy and surface finish, it still falls short of CNC machining in many cases. CNC machines can produce parts with extremely high levels of accuracy and a smooth surface finish, which may be necessary for certain applications.

While 3D metal printing can produce parts with a reasonable level of accuracy and surface finish, it may not be suitable for applications that require high precision and a flawless surface finish.

3.Limited Production Volume

Another drawback of 3D metal printing is that it is not very suitable for large-scale production. Although it may be cost-effective for small-scale production operations, it is less cost-effective for large-scale production.

CNC machining is more suitable for mass production and can usually produce parts faster than 3D printing. This limitation may be an important factor in determining which method to use for a project, especially when a large number of parts are required.

Overall, although 3D metal printing has several advantages over CNC machining, its limitations must be considered before deciding which method to use in the project.

Compared with CNC machining, 3D metal printing has significant drawbacks such as limited material range, low accuracy and surface finish, and limited production capacity.

However, if your project requires complex design, faster prototyping, reduced material waste, and cost-effective small-scale production, 3D metal printing may be your better choice.

Compared With 3D Metal Printing, What are the Advantages of CNC Machining

CNC machining and 3D metal printing are two popular manufacturing processes used in modern industry. Both processes have their own set of advantages and disadvantages, and choosing the right process depends on the specific application.

CNC machining is a subtractive manufacturing process that uses computer-controlled machines to remove materials from workpieces and produce finished products. This process is renowned for its high precision and accuracy, making it an ideal choice for producing parts in industries such as aerospace and healthcare.

On the other hand, 3D metal printing is an additive manufacturing process that builds parts layer by layer using metal powder and a laser. This process is typically used for prototyping and small-scale production runs.

Here are some advantages of CNC machining as compared to 3D metal printing:

1.Speed: CNC machines can produce parts at a faster rate than 3D metal printers. This is because CNC machines are designed for mass production, whereas 3D metal printers are typically used for prototyping.

2.Accuracy: CNC machines are known for their high level of accuracy, which is critical for parts used in industries such as aerospace and medical. 3D metal printers, on the other hand, may produce parts that require post-processing to achieve the desired level of accuracy.

3.Material selection: CNC machines can work with a variety of materials, including metals, plastics, and composites. 3D metal printers are limited to metal materials, which can be costly and may not be suitable for all applications.

4.Surface finish: CNC machining can produce a smooth surface finish without the need for post-processing. 3D metal printing may produce a rough surface finish that requires additional steps to achieve a smooth finish.

5.Strength: Parts produced using CNC machining tend to be stronger and more durable than those produced using 3D metal printing. This is because the material is not subject to the high temperatures and stresses associated with 3D metal printing.

In summary, while 3D metal printing has its advantages, CNC machining is often the preferred manufacturing method for producing high-quality, accurate, and durable parts at a faster rate. CNC machining offers greater material flexibility, speed, accuracy, and strength as compared to 3D metal printing.

However, it is important to note that both processes have their own unique advantages and disadvantages, and the choice of process ultimately depends on the specific application and requirements of the part being produced.

Compared with 3D Metal Printing, What are the Disadvantages of CNC Machining

Metal manufacturing is a complex process that involves multiple methods, including CNC machining and 3D metal printing. Although both have their own benefits, it is crucial to understand the limitations of each method before deciding which one to use for the project.

In this section, we will discuss the drawbacks of CNC machining compared to 3D metal printing.

1.Limited Design Flexibility

One of the biggest drawbacks of CNC machining compared to 3D metal printing is limited design flexibility.

CNC machining is limited to producing parts with straight edges and simple curves. Complex and complex designs are difficult or impossible to achieve with CNC machining

3D printing allows designers to create parts with internal structures and features, which are impractical to produce using traditional machining methods.

2.Slower Prototyping

Another disadvantage of CNC machining is the time it takes to produce a prototype. CNC machining requires a significant amount of time to set up and program, making it slower than 3D printing, which can produce a prototype in a matter of hours or even minutes.

3.Higher Material Waste

CNC machining often results in significant material waste, as parts are cut from larger blocks of material. In contrast, 3D metal printing uses only the necessary amount of material to create the part, reducing waste and helping to conserve resources.

4.Cost-Ineffective for Small Production Runs

For small production runs, CNC machining can be a cost-ineffective alternative to 3D metal printing. With CNC machining, the cost per part increases as the production run size decreases, while 3D printing offers a consistent cost per part regardless of the production run size.

Overall, although CNC machining has several advantages over 3D metal printing, its limitations must be considered before deciding which method to use in the project.

Compared to 3D metal printing, limited design flexibility, slower prototyping, higher material waste, and cost-effectiveness of small-scale production are significant drawbacks of CNC machining.

However, if your project requires simple design, higher accuracy, and perfect surface finish, then CNC machining may be your better choice.

Choosing the Right Manufacturing Method

When deciding between CNC machining and metal 3D printing, several factors need to be considered. This includes the complexity of the parts, required accuracy, materials used, and production volume.

CNC machining is best suited for producing parts with high accuracy and tight tolerances. The process is also ideal for producing parts in large volumes.

On the other hand, metal 3D printing is most suitable for producing parts with complex geometric shapes and medium to low yield. This process is also very suitable for producing parts that require customization or are difficult to produce using traditional manufacturing methods.

In short, CNC machining and metal 3D printing are valuable manufacturing methods with unique advantages. By understanding the advantages and limitations of each process, the correct method can be selected for a given project.

FAQ

If you’re interested in getting started with CNC machining or 3D metal printing, there are a few things you can do. First, research local manufacturers or service providers who offer these services. You can also look into purchasing your own CNC machine or 3D metal printer if you have the resources and expertise to do so. Additionally, there are many online resources and tutorials available to help you learn more about these processes and how to use them effectively.You can also contact Longsheng Technology directly, we are professional in providing cnc machining services and 3d printing services, contact us today to start the quotation

The process you choose depends on your specific needs and requirements. If you need high precision and accuracy, a wide range of materials, and high production speed for large quantities, CNC Machining may be the best option. If you need highly intricate geometries, design flexibility, and less material waste, Metal 3D Printing may be the best option.