Plastic extrusion technology is indeed a critical and foundational component of the vast landscape of modern manufacturing. A constant, efficient molding process, it warms, melts, and plasticizes raw plastics before exposing them to precision mold, yielding mass production of products with uniform cross-section. From standard pipes, doors, and windows to thin medical catheters and fiber optic casing, its applications permeate nearly every industry and aspect of daily life.

As a plastic extrusion specialist, LS Manufacturing, with its extensive experience and technological strength, sets the industry standard. This handbook not only gives a comprehensive technical introduction, exploring the principles of extrusion, materials, and processes, but shows how LS Manufacturing, from its high-level equipment and engineering proficiency, provides clients with one-stop, high-precision, made-to-measure extrusion solutions from design to production, bringing your ideas to life. To save you time, here’s a quick overview of the core conclusions.

Plastic Extrusion Technology Core Quick Reference

| Core Dimensions | Key Points Summary |

| Core Principle | Solid plastic pellets such as PE, PVC, PS, and PP are melted and then further heated. The screw continuously forces them through a mold under high pressure, cooling and shaping them to create a constant cross-section of continuous profile. |

| Key Materials | Engineering plastics: ABS and PC (structural components of high demand); General-purpose plastics: PVC (profiles for doors and windows), PE (pipes). The choice of material will influence the performance and price of the product. |

| Key Processes | 1. Feeding → 2. Heating and Plasticizing → 3. Forming the mold → 4. Cooling and Shaping → 5. Traction and Cutting. Proper control at every step is the foundation for ensuring product quality and dimensional stability |

| Major Applications | Pipes, profiles (door and window), plates/sheets, films, cable sheathing, etc. Due to its consistent high-efficiency production, it also finds several applications in construction, automotive, packaging, and consumer goods industries. |

| Major Strengths | Consistent high-efficiency production, low production cost, high product consistency, easy to produce customized complex cross-sections, and flexibility in processing a wide majority of thermoplastics. |

With an experienced partner like LS Manufacturing, you get a one-stop, customized solution, from material choice and mold design to process improvement. This is the formula for bringing your product to concept through mass production.

Plastic extrusion is an economical and very flexible continuous molding process whose success is entirely dependent on precise control over materials, equipment, and process parameters.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The depth and breadth of this guide are the result of over 20 years of hands-on experience within the plastics extrusion business at LS Manufacturing. We don’t give you theoretical data; rather, we couple our day-to-day production operations, technical problems, and customer solutions with the expert information you’ll discover here.

LS Manufacturing operates the newest co-rotating and counter-rotating twin-screw extrusion lines and has successfully processed hundreds of material formulations from commodity plastics to high-performance engineering plastics. We have personal experience with plasticizing effect of different materials in the barrel and the flow nature at the die mouth.

For example, we helped a client overcome the long-standing corner shrinkage and dimension stability issue with their PVC profiles through optimizing screw design and optimizing the cooling process, increasing qualification of the product by 25%.

Such hands-on experience, gained in resolving hundreds of unique issues, such as surface finishing requirements for medical tubing, heat resistance for car air ducts, and sealing by co-extrusion for door and window profiles, forms the foundation of LS Manufacturing’s expertise.

Every one of the major points laid out here has been stringently verified and substantiated by LS Manufacturing, trying to offer information which is not merely accurate but helpful in day-to-day work of production.

What Is Plastic Extrusion?

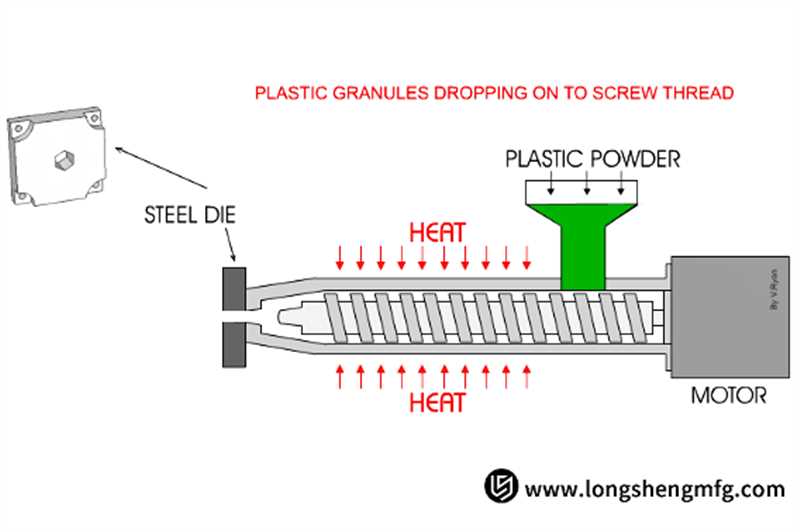

Plastic extrusion is a productive and widely used process of continuous molding that utilizes custom machinery and equipment to convert solid plastic feedstock into constant profiles with uniform cross-section. Simply put, its basic concept is pretty much like a high-tech “noodle machine,” which melts and presses powder or granular material and then extrudes it into the desired form with the help of a mold. Plastic extrusion consists of two principal phases:

- Plastic plasticization: Solid plastic powder or pellets are fed into the extruder, where they melt slowly into a uniform, viscous fluid by the shear heat of the heater and rotating screw.

- Shaping and forming: The plastic melts, spearheaded by the screw, and is pushed through a die (die head) with a pre-determined pattern of holes to give it the intended shape. The continuous profile is then transferred into a shaping and cooling unit (e.g., water bath) where it cools and retains its precise size and shape.

Plastic extrusion methods are either “dry” or “wet” depending on whether chemical reactions or solvent evaporation occurs. Dry extrusion is more common and relies exclusively on heat melting and cooling to establish the shape; wet extrusion employs solvents and requires subsequent heating and solvent evaporation to evaporate the solvent and complete the shape.

We at LS Manufacturing utilize precision extrusion machinery with advanced temperature control and pressure monitoring. This enables us with real-time closed-loop monitoring of screw speed, zone temperature, and cooling rate, enabling proper plasticization and consistent flow of material.

What Are The Core Components Of A Plastic Extruder?

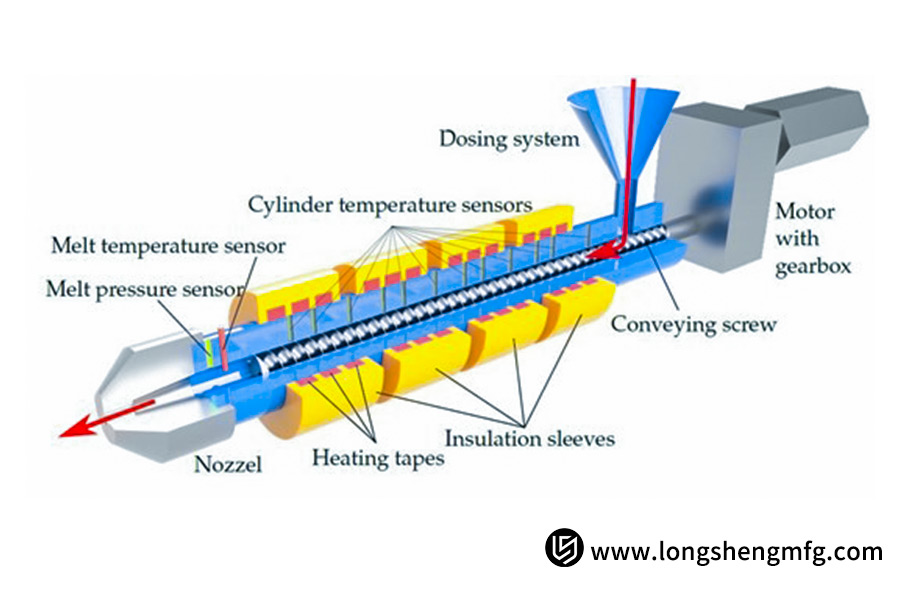

A complete plastic extruder is a sophisticated system operating as a combined entity. Its stability and effectiveness are because of the exact coordination of its primary components. It typically consists of three primary components: the primary extruder system, supporting equipment, and a smart control system.

1. Main extruder system:

The main extruder is the “heart” of the extruder, and it primarily consists of the hopper, barrel, and screw. The hopper gives uniform feeding of the material; the barrel is an external heating chamber and works in association with the high-speed rotating screw. The screw shears and mixes the solid material, plasticizing it uniformly to a melt. The precision of manufacture and construction of the screw directly affects the quality of plasticization and yield.

2. Auxiliary equipment:

After leaving the main extruder, the melt flows through the die (mold) to assume a specified cross-sectional shape. It is then transferred into the shaping and cooling equipment (e.g., vacuum shaping chamber and water cooling tank) for controlled cooling and solidification to achieve product dimension stability. Continuous winding or cut-to-length shearing is then permitted by the haul-off and cutter.

We understand at LS Manufacturing the fundamental importance of the main extruder. That is why we use high-performance extruders. Their deeply optimized screw design and precision-matched barrel improve plasticizing efficiency and mixing performance significantly, which gives superior operating stability and output from the very beginning.

Combined with LS Manufacturing’s intelligent control system, with full control over all process parameters, this offers a productive and reliable precision extrusion system.

How Does Screw Design Affect Extrusion Quality And Efficiency?

Of the requisite components of a plastic extruder, the screw is termed the “heart.” Its design directly affects material plasticization uniformity, stability of extrusion, and quality of the product. Design of an optimized screw plays a significant role in controlling the extrusion process parameters precisely and achieving efficient production.

Major screw design parameters include aspect ratio, compression ratio, and segment structure, all of which contribute to defining the overall extrusion process:

| Major Parameters | Influence on Extrusion Quality and Efficiency | Appropriate Applications |

| Aspect Ratio (L/D): | An increase in aspect ratio increases the residence time of material in the barrel, resulting in more uniform plasticization, better mixing, and uniform extrusion pressure; however, this consumes more energy. | An aspect ratio of between 18:1 and 25:1 is typical for general-purpose plastics; for engineering plastics or applications where effective devolatilization is required or fine mixing, a higher aspect ratio (e.g., 32:1 or higher) may be required. |

| Compression Ratio | The compression ratio must be matched to the plastic’s bulk density. It expels bubbles and volatiles from the melt, yielding a dense, bubble-free material. An erroneous compression ratio may result in overloading or wasteful plasticization. | Crystalline plastics such as PP and PA require a greater compression ratio (~3.5:1); amorphous plastics such as PS and PVC prefer a low compression ratio (~2.5:1). |

| Segmented Screw Structure | The screw is typically divided into a feeding section, compression section, and homogenizing section. Depth-to-length ratio in each section controls the material conveying, compression, shearing, and melting characteristics. | A gradual-step screw: Suitable for heat-sensitive products (e.g., PVC), providing mild plasticization. A sudden-step screw: Suitable for crystalline plastics (such as PA and PE), with a rapid phase transition in the compression area. |

LS Manufacturing optimizes all the design parameters of the screw, such as aspect ratio, compression ratio, and structures of important segments, based on the cross-sectional intricacy of the product at hand. This ensures that your plastic extruder system is always running at peak capacity for quality and efficiency optimization.

LS Manufacturing offers custom screw design service, including comprehensive research of your material’s properties (e.g., melting point, viscosity, heat stability).

What Are The Key Design Considerations For Plastic Extrusion Dies?

While if the screw is the “heart” of the extruder, then the plastic extrusion die is the “throat” which dictates the shape of the end product. It has a primary role to well and continuously transform the uniformly plasticized melt into a continuous profile in the desired cross-sectional shape. The design perfection exerts instant influence on the product’s dimensional accuracy, surface finishing, and manufacturing efficiency. A good mold design must adhere to the following fundamental points:

1. Runner design is the core:

The runner from the entrance of the mold to the die lip exit must ensure smooth flow of the melt and balanced distribution. Excellent flow channel design prevents material stagnation and scorching, effectively eliminates weld marks, and maintains consistent discharge speed, which is important in getting an even cross-sectional shape.

2. Precise Shaping Device:

The just-spun-out profile that is still hot and molten must be put into the tightly coupled vacuum shaping and cooling machine forthwith. This machine is tasked with precisely cooling the profile to its ultimate dimension, and its design affects directly product tolerance control and deformation.

LS Manufacturing utilizes advanced-technology flow channel simulation (CAE) to predict and optimize melt flow during the design phase. Combined with modular plastic extrusion die and shaping device design, we provide quick response to fluctuating demands, providing efficient and precise conversion from drawing to end product, whether for complex profiles or high-gloss finishes.

Die design is viewed as a key component of providing custom extrusion solutions by LS Manufacturing.

How Can We Optimize Extrusion Process Parameters To Improve Product Quality?

In plastic extrusion, better product quality is not something that happens by chance; it is a function of meticulous control and continuous optimization of extrusion process parameters. The synergistic interplay among key parameters such as temperature, pressure, and speed has a direct impact on the physical properties, dimensional stability, and appearance of the product.

1. Temperature Control:

The temperature at all sections, from the feed area to the die, must be precisely controlled. Low temperatures can lead to insufficient plasticization, uneven melting formation, and excessive internal stress in the product; excessively high temperatures can lead to material degradation, bubbles, and charring. An optimally designed temperature profile is essential for maintaining a stable and homogeneous melt.

2. Pressure and Speed:

The die pressure must be constant within any reasonable range. Pressure fluctuations may directly generate irregular product dimensions or surface flaws. Further, extrusion velocity must be dynamically coordinated with the speed of pulling off; any desynchronization will lead to stretching, distortion, or dimensional faults.

At LS Manufacturing, we integrate advanced on-line monitoring and closed-loop control systems to track melt pressure, temperature, and screw speed in real time and automatically adjust to even the slightest variations between resin batches. This level of control of the plastic extrusion process ensures extreme stability and highly consistent products from start-up through continuous production, resulting in quality that exceeds customers’ expectations.

Adjusting these interdependent extrusion process parameters is a complex, systematic process, and indeed it is the single most significant condition for selecting a high-quality extruder.

What Are The Characteristics Of Commonly Used Plastic Extrusion Materials And A Selection Guide?

In plastic extrusion production, the materials constitute the building blocks of the product. Different commonly employed extruded plastic materials have vastly different physical and chemical properties, which have a direct bearing on the final performance and fields of utilization of the end product. Correct choice of material is a key towards an optimal balance between product worth and expense. Some of the most common extrusion materials and their key features are listed below:

- PE (Polyethylene): Being odorless and non-toxic with good chemical stability and high flexibility, it is employed in cabling sheathing, packaging films, and tubing types.

- PP (Polypropylene): Its low density and high resistance to fatigue make it useful in heat-resistant sealing strips, food packing, and interior automobile parts.

- PVC (Polyvinyl Chloride): It comes in a broad hardness spectrum, is flame-retardant and weather-resistant, and inexpensive. By means of formulation modifications, it can create a wide variety of products ranging from rigid piping and door and window profiles to flexible cable trunking.

- PS (polystyrene): It is highly transparent, very rigid, and has easy processing, and due to its use in display stands, lamp covers, and foam sheets, it is found to be a popular commodity.

- Nylon (PA): Due to its higher wear resistance, mechanical strength, and oil resistance, it’s the most suitable for auto fuel lines, mechanical gear, and sporting equipment.

LS Manufacturing, which has extensive knowledge of materials, can help you review in detail your product’s service environment (i.e., temperature and chemical resistance requirements), mechanical strength requirements, and your cost. We then recommend the most cost-efficient and appropriate plastic extrusion material from a range of available options so that your product achieves the optimal cost-performance ratio achievable.

The right selection of the widely used extruded plastic material is an art.

LS Manufacturing Success Case Study: Precision Extrusion Solutions For Automotive Sealing Strips

Their dimensional accuracy and durability are subjected to rigorous stresses by the production of automotive sealing strips, with a direct impact on the sealing, quietness, and service life of the vehicle as a whole. We assisted an automobile components supplier in overcoming their sealing strip products’ critical technical issues.

1. Client’s Dilemma:

The sealing strips of the client’s window had been suffering from poor dimensional stability for a long time, causing low assembly fit and cracking due to aging after long-time exposure to sunlight. The qualification rate of the product remained as low as approximately 95%, which could not meet the high requirements of the OEM.

2. LS Manufacturing’s Systematic Solution:

To deal with such a complex problem, we provided an overall precision extrusion solution:

- Material Science Application: We proposed and developed an EPDM rubber compound. Its higher ozone and UV stability and wide temperature range compatibility were the foundation for product’s long-term weather stability.

- Core Component Customization: Targeting the processing characteristics of EPDM, we designed a high-compression ratio screw and multi-layer flow channel mold, ensuring uniform plasticization and stable discharge of the rubber compound, while guaranteeing precise cross-sectional shape from the very beginning.

- Precise Process Control: Our intelligent control system optimizes extrusion speed, temperature zones, and vacuum setting pressure, completely eliminating profile bending and dimensional fluctuations.

3. Results and Value:

Lastly, the dimensional tolerance of the sealing strip product was controlled to ±0.15mm, and the pass rate significantly enhanced to 99.8%. Not only did this end a long-standing quality issue with the customer, but it produced weather resistance far exceeding industry standards, successfully winning orders for a number of new car models and building a firm, long-term relationship with us.

This case study best shows LS Manufacturing’s competence in providing customized extrusion solutions and transforming the customers’ issues into business advantages.

What Are Some Common Problems And Solutions In Extrusion Production?

In plastic extrusion manufacturing, regardless of the precision control of parameters, there can still be some issues. The earlier the cause is determined and the more precise measures are implemented, the better it is for constant and consistent production.

1. Scorch (degradation):

Yellow lines or black spots on the product due to yellowing and thermal decomposition of the material by local overheating:

- Causes: Excessively high temperature settings, excessively high screw speed, resulting in excessive shear heating, or material stagnation areas in the flow channel.

- Solutions: Optimize temperature profile; decrease screw speed; inspect and clean dead corners of the mold flow channel to avoid stagnation areas.

2. Poor Plasticization:

Uneven melting of the material, forming unmelted particles in the product, which acquires weaker mechanical properties:

- Causes: Reduced processing temperature, insufficient screw compression ratio, or screw wear, forming insufficient shear mixing.

- Solutions: Correctly increase the processing temperature, especially in the compression zone; inspect and replace a screw suitably designed for the material.

3. Bubbles:

Bubbles appear inside or on the surface of the product, weakening appearance and strength:

- Causes: Gross over-saturation of raw material; excessive temperature leading to breakdown and gas evolution; or low compression ratio resulting in air entrainment.

- Solutions: Pre-dry the raw material properly (e.g., by using a dehumidifier); regulate temperature controls so that overheating is not done; and see to it that the compression ratio of the screws is okay.

4. Dimensional Fluctuation:

Product dimensions are out of tolerance and unsteady:

- Causes: Mismatched traction and extrusion velocities; poor cooling and shaping system or unsteady vacuum; unbalanced feeding.

- Solutions: Calibrate and match traction and extrusion velocities; maintain stable cooling water temperature and flow, check vacuum system leaks; use a forced feeder to offer uniform feeding.

These issues generally are interdependent, and separate changes would have limited effectiveness. LS Manufacturing, through its total quality control system, has established a preventive and rapid response system, from incoming raw material inspection and process parameter standardization to online real-time monitoring.

When problems emerge, LS Manufacturing engineers systematically examine sequences of data like temperature, pressure, and speed to determine the root cause, ensuring root-level correction and ensuring product consistency and ease of production.

Why Choose LS Manufacturing As Your Extrusion Partner?

With a highly competitive market, it is vital to choose a technically capable and responsive extrusion partner. LS Manufacturing’s all-round strengths have made it the preferred choice among industry leaders. We are committed to taking your product ideas to high-grade reality.

1. End-to-End Customization Capabilities:

LS Manufacturing understands that generic solutions always don’t meet all the requirements. Therefore, we deliver one-stop, bespoke extrusion solutions, from material choice and bespoke screw and mold design to process parameter optimization, to achieve your products the optimum performance cost and delivery time.

2. Leading Technology and Equipment:

LS Manufacturing’s production facilities also receive state-of-the-art co-rotating and counter-rotating twin-screw extrusion lines that feature high-precision temperature control and pressure feedback systems. Not only does this ensure seamless production but also serves as the foundation of achieving precision extrusion molding and preventing complex process problems.

3. Seamless Quality and Service Guarantee:

LS Manufacturing has built a complete quality control system, tracking the entire process from raw material receiving to finished product shipping. Most importantly, our skilled engineers provide responsive services, ranging from project appraisal to post-production service, to ensure trouble-free production.

Choosing LS Manufacturing is more than acquiring a plastic extruder or mold; it’s gaining a very collaborative, dependable partner. We’re committed to ensuring your project’s success through our vast technical expertise and creative engineering solutions.

Contact LS Manufacturing’s expert staff today for your custom solution!

What Are The Future Trends In Plastic Extrusion Technology?

The plastic extrusion technology is evolving at a fast pace towards higher accuracy, intelligence, and environmental friendliness to meet the demands of global industrial upgrading. LS Manufacturing, being a market leader, has made serious commitments in the new and high-tech areas and is committed to providing customers with incredible value in the form of breakthrough technologies. Future trends are highlighted in the following four ways:

1. Precision and High Speed:

The market’s demand for the precision of products and efficiency remains unabated. Technologically, co-extrusion technology is getting better, and products with five layers or more complex structures are increasing gradually. Concurrently, high-speed extrusion is the focus of increasing competitiveness.

With the world’s top line speeds, 250m/min has already been reached in production line speed, putting maximum demands on precision control of extrusion molding. LS Manufacturing invests in high-precision control systems and high-performance extruders to gain ±0.01mm tolerances even at high speeds, up to the requirements of high-end medical and film production.

2. Intelligence and Digitalization:

Extrusion manufacturing is becoming increasingly “data-driven” rather than “experience-driven.” Artificial intelligence (AI) and big data technologies are being increasingly embedded to optimize extrusion process parameters, bringing commissioning times down from weeks to days, and enabling reliable product quality predictions.

LS Manufacturing is completely leveraging this transition, including an end-to-end data management system to allow for real-time closed-loop control and optimization of screw speed, temperature profile, and pressure, greatly improving production stability and product consistency.

3. Energy Saving and Green Environmental Protection:

The international agreement on sustainable manufacturing is targeted at promoting circular economy and reducing the environmental footprint. These trends primarily appear in materials and processes.

- Various advances in research and application of degradable and bio-based materials (e.g., thermoplastic starch).

- Advanced processes such as reactive extrusion can achieve zero solvent emissions, eliminating pollution issues at source and reducing energy usage significantly.

LS Manufacturing has integrated green philosophy into its technology development to help customers achieve their ESG goals through improved equipment energy efficiency and the use of environmentally friendly materials. Relying on these trends as the company’s technology direction, LS Manufacturing will further expand R&D input in precision extrusion, intelligent control systems, and environmental solutions to make sure that our customers are ahead of industry development and together create the future of plastics manufacturing.

In the future, plastic extrusion technology will be a profound integration of precision, intelligence, and ecogreen.

FAQs

1. What is the typical production cycle for plastic extrusion products?

The plastic extrusion products‘ production cycle is determined by product complexity, material properties, and order volumes. LS Manufacturing has shortened the production cycle for standard products to 5-7 days through process layout simplification and parallel processing. In emergency situations, we implement an accelerated response system, planning manufacturing resources, prioritizing production, minimizing lead times without compromising quality, and ensuring uninterrupted progress on customer projects.

2. What size range of extruded products can you handle?

Our extrusion equipment has wide dimensional flexibility for the stable production of any form of profiles, tubes, and rods from 1mm to 300mm in size. We provide custom molds and process solutions for specialty uses, offering careful molding for products ranging from fine medical catheters to giant structural engineering parts, covering multiple application fields in electronics, automotive, and construction industries.

3. How do you ensure the dimensional stability of extruded products?

We achieve dimensional stability by a three-in-one control system: precision flow channel mould design, on-line temperature and pressure monitoring, and multi-stage vacuum cooling. Through dynamic adjustment of process parameters, product dimensional tolerances are within ±0.1mm, preventing material shrinkage variations and batch-to-batch consistency in a practical manner.

4. What kind of after-sales technical support does LS Manufacturing provide?

We have established a closed-loop after-sales service system: from equipment installation and commissioning, standardized operation training, to process optimization consultation in production. LS Manufacturing technical support team provides 24/7 online response to solve on-site issues in a timely manner and regular visits to optimize the parameters of production, allowing customers to continuously improve product quality and production efficiency and ensure long-term stable running.

Conclusion

This piece delves deeply into the basic concepts of plastic extrusion technology—ranging from the material science underlying principles, to finely controlled process parameter manipulation, to innovative mold and equipment design. Optimization of all these factors in the end is the key to high-quality extrusion output.

As your trusted extrusion solutions partner, LS Manufacturing leans on its long history of material choice expertise, process optimization, and customized solutions to provide full technical support, from concept through finished product.

If you’re looking for a reliable extrusion supplier or need information on specific technical specifications, we can assist. Contact LS Manufacturing and inform us of your specific needs. We will tailor a technical solution to your needs. We would be pleased to welcome you personally to visit our factory and personally experience the state-of-the-art technology and outstanding services of LS Manufacturing.

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.