What’s Nylon 3D Printing?

Nylon, also referred to as Polyamide, is a robust and versatile 3D printing materials that’s ideally suited for a variety {of professional} functions. It’s recognized for its energy, sturdiness, and flexibility, making it a best choice for hobbyists and professionals alike.

Printing with Nylon:

- Moisture Sensitivity: Nylon filament is extraordinarily delicate to moisture. Due to this fact, you will need to take drying measures throughout storage and instantly previous to printing utilizing desiccant, vacuum, or elevated temperature for finest outcomes .

- {Hardware} Necessities: Earlier than 3D printing with Nylon, you will need to be sure that your 3D printer meets the {hardware} necessities to make sure the very best print high quality .

- Mattress Adhesion: Correct mattress adhesion is essential when printing with Nylon, because it tends to warp and curl throughout printing. Utilizing a heated mattress with a layer of adhesive materials akin to PVA glue or a nylon-specific adhesive sheet is beneficial, together with a brim or raft to assist with mattress adhesion .

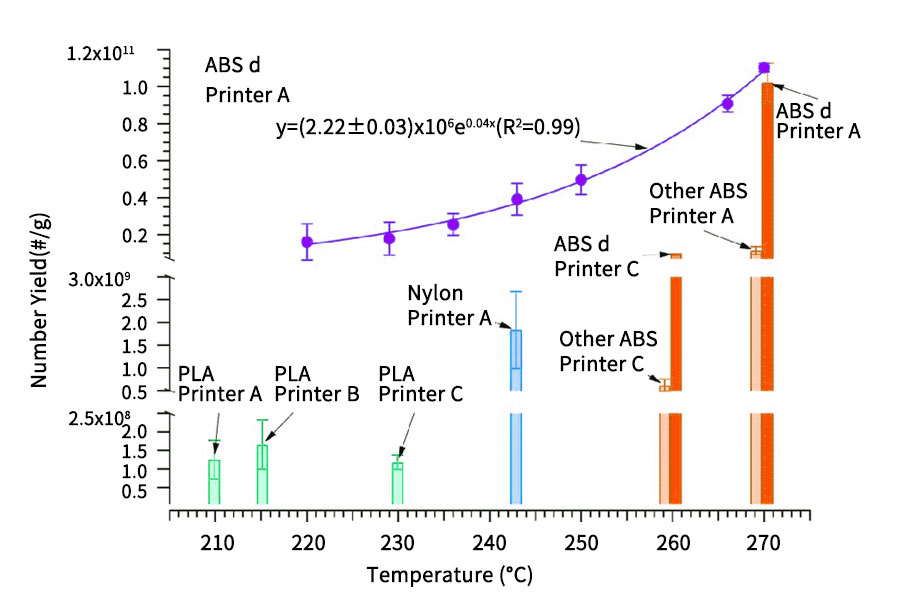

- Printing Temperature: Nylon requires a excessive printing temperature, usually between 240-260°C. Nonetheless, the precise temperature can fluctuate relying on the model and sort of nylon getting used, so it is vital to check with the producer’s suggestions .

what’s PLA 3d printing?

Stronger Examine:Nylon vs PLA in 3D Printing

| Property | Nylon | PLA |

|---|---|---|

| Tensile Power | Excessive | Reasonable |

| Impression Power | Excessive | Low |

| Fatigue Power | Excessive | Reasonable |

| Chemical Resistance | Excessive | Low |

| Abrasion Resistance | Excessive | Low |

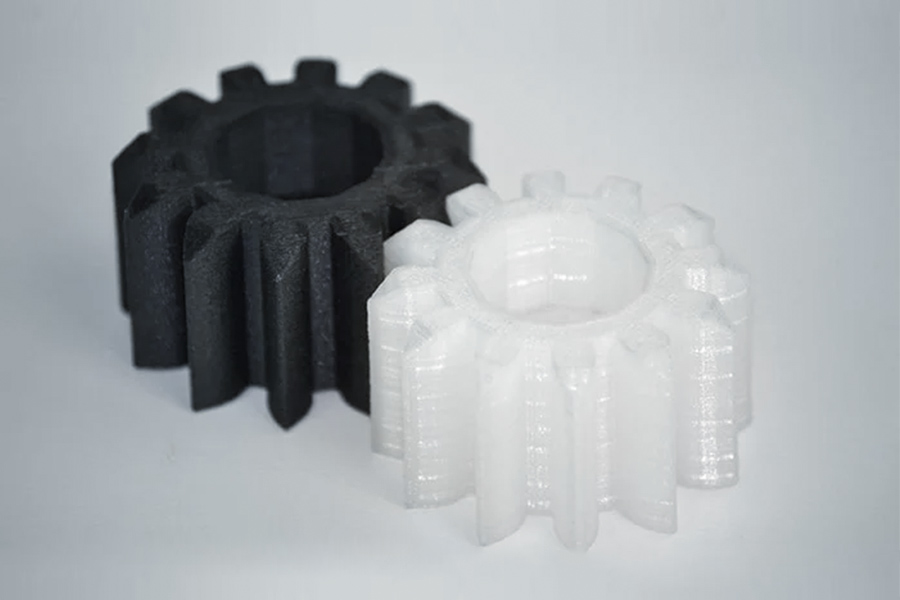

Nylon is a robust, sturdy, and versatile materials that’s well-suited for parts that want to face up to put on and tear, akin to gears and bearings. It has excessive tensile, affect, and fatigue strengths, making it a good selection for practical parts. It additionally has excessive chemical resistance and abrasion resistance, making it appropriate for parts that will likely be uncovered to harsh environments or friction.

Alternatively, PLA (Polylactic Acid) is a biodegradable and eco-friendly materials derived from renewable sources like cornstarch or sugar cane. It is simpler to print with and does not require a heated mattress, making it a preferred selection for inexperienced persons. Nonetheless, it has average tensile and fatigue strengths and low affect energy, making it much less appropriate for parts that want to face up to excessive stress or affect. Its chemical resistance and abrasion resistance are additionally decrease than nylon’s.

Please notice that the particular properties can fluctuate relying on the precise formulation of the fabric and the printing situations. At all times verify the specs supplied by the filament producer.

Utility

Nylon: Nylon is extensively utilized in 3D printing, particularly for parts that require excessive energy, rigidity, chemical resistance, and abrasion resistance. As an illustration:

- Gears, Bearings, Fixtures: The excessive energy and abrasion resistance of nylon make it the perfect materials for manufacturing these elements.

- Chemical Pumps, Valves: The chemical resistance of nylon permits it to face up to the corrosion of varied chemical substances.

- Automotive, Aerospace Components: The excessive energy and abrasion resistance of nylon make it appropriate for manufacturing parts that want to face up to excessive strain and friction.

PLA: PLA is a biodegradable materials sourced from renewable sources akin to cornstarch or sugarcane. PLA is simpler to print with and does not require a heated mattress, making it a preferred selection for inexperienced persons. Nonetheless, PLA has average tensile and fatigue strengths and low affect energy, making it much less appropriate for parts that want to face up to excessive stress or affect. Its chemical resistance and abrasion resistance are additionally decrease than nylon’s. PLA is primarily used within the following situations:

- Training: PLA is a standard 3D printing materials in faculties and academic establishments because of its ease of printing and renewable sourcing.

- Artwork and Decorations: The excessive printing precision and large coloration vary of PLA make it ideally suited for printing artworks and decorations.

- Prototype Design: The quick printing pace and low price of PLA make it very appropriate for speedy prototype design and idea validation.

Execs and Cons Comparability

| Materials | Execs | Cons |

|---|---|---|

| Nylon | Excessive energy, excessive rigidity, chemical resistance, abrasion resistance | Increased price, harder to print |

| PLA | Decrease price, simpler to print, biodegradable | Decrease energy, rigidity, chemical resistance, abrasion resistance |

The benefits of Nylon lie in its excessive energy, excessive rigidity, chemical resistance, and abrasion resistance, making it very helpful in functions the place these options are wanted. Nonetheless, the price of Nylon is comparatively excessive, and it’s harder to print, probably requiring extra complicated printing settings and better printing temperatures.

In distinction, the benefits of PLA are its decrease price, simpler printing, and biodegradability, making it extremely popular in schooling, artwork and ornament, and speedy prototype design. Nonetheless, the energy, rigidity, chemical resistance, and abrasion resistance of PLA are all decrease, which can restrict its use in some functions.

Choice Information

Power Necessities: In case your half wants to face up to excessive energy, excessive affect, or excessive stress, then Nylon is a better option. The excessive energy and rigidity of Nylon enable it to deal with these pressures, and its chemical resistance and abrasion resistance additionally allow it to carry out properly beneath harsh environmental situations.

Value Issues: If price is your major consideration, then PLA is perhaps a better option. The fabric price of PLA is usually decrease than that of Nylon, and it’s simpler to print, which implies it’s possible you’ll not want to speculate as a lot time and sources in adjusting printing settings or troubleshooting printing points.

Printing Expertise: In the event you’re new to 3D printing or haven’t got a lot printing expertise, then PLA is perhaps a better option. PLA is simpler to print and usually doesn’t require a heated mattress or particular print settings, making it a great selection for inexperienced persons.

Utility Eventualities: Lastly, you need to select probably the most appropriate materials primarily based on the particular use of the half. If the half must be used beneath harsh environmental situations, or wants to face up to excessive strain or friction, then Nylon is perhaps a better option. If the half is primarily for schooling, artwork, and ornament, or must be quickly prototyped, then PLA is perhaps a better option.

Conclusion

when selecting 3D printing supplies, you need to take into account the bodily and chemical properties of the fabric, price, printing problem, and the particular use of the half. Whereas these are normal pointers, the particular selection could fluctuate relying on the particular formulation of the fabric, printing situations, and the particular wants of the half. Due to this fact, when selecting a 3D printing materials, all the time verify the specs supplied by the filament producer and take into account all related elements.

FAQs

Which nylon and PLA supplies are appropriate for 3D printing?

Each nylon and PLA are broadly utilized in 3D printing. For nylon, supplies like Nylon 6, Nylon 66, and Nylon 12 are generally used because of their glorious energy, flexibility, and sturdiness. For PLA, it is normally out there in an ordinary kind, however there are additionally variants like PLA+ which provide improved properties over the usual PLA.

How you can enhance the energy of 3D printed nylon and PLA?

The energy of 3D printed parts could be improved by adjusting the print settings. As an illustration, rising the infill density, layer top, and print pace can improve the energy. Moreover, utilizing design strategies like including ribs or gussets may also enhance energy.

Is 3D printed nylon UV resistant?

Nylon is just not naturally UV resistant. Nonetheless, it may be made UV resistant by including sure components or by post-processing strategies like coating with a UV-resistant materials.

How a lot does 3D printed nylon price?

The price of 3D-printed nylon can fluctuate broadly relying on the kind of nylon, the scale of the print, and the particular 3D printing service used. For probably the most correct pricing, it is best to get a quote from a 3D printing service.

Quotation

The supply used within the article is:

- Markforged. (n.d.). PLA vs ABS vs Nylon – Markforged. Retrieved April 18, 2024, from https://markforged.com/resources/blog/pla-abs-nylon