CNC turning parts‘ sourcing strategy directly determines project success, yet the market still faces challenges like vague pricing, delayed delivery, and inconsistent quality—particularly with complex materials and high-precision requirements. These issues often stem from suppliers’ insufficient technical expertise, inadequate quality control systems, and lack of customer-centric management.

Excellent manufacturing of CNC turning parts relies on deep technical expertise, rigorous end-to-end quality control, and close customer collaboration. These three guarantees enable LS Manufacturing to make sure every part meets the standard for precision. So, how do you identify a true expert in turning? This article will provide you with everything you need to know about CNC turning.

Quick Reference Table for CNC Turning Parts Technology

| Module Classification | Core Content Summary |

| Range | It deals with rotating parts, shafts and disks in a diameter ranging between 1-500mm. |

| Material Capabilities | Machined more than 30 types of metal materials, such as stainless steel, aluminum alloy, and titanium alloy. |

| Accuracy Grade | Dimensional tolerance ±0.01mm, surface roughness Ra0.8-1.6μm. |

| Configuration | Equipped with Swiss-type/slip-type machining center, supporting integrated turning and milling. |

| Process Characteristics | In this process, hard turning technology replaces the grinding with turning. |

| Test Methods | Equipped with online measuring instruments and CMMs, with full inspection of the first piece. |

| Delivery Time Standard | Small batches within 3-7 days; large batches within 2 weeks. |

| Certifications | ISO 9001, IATF 16949, and other quality system certifications. |

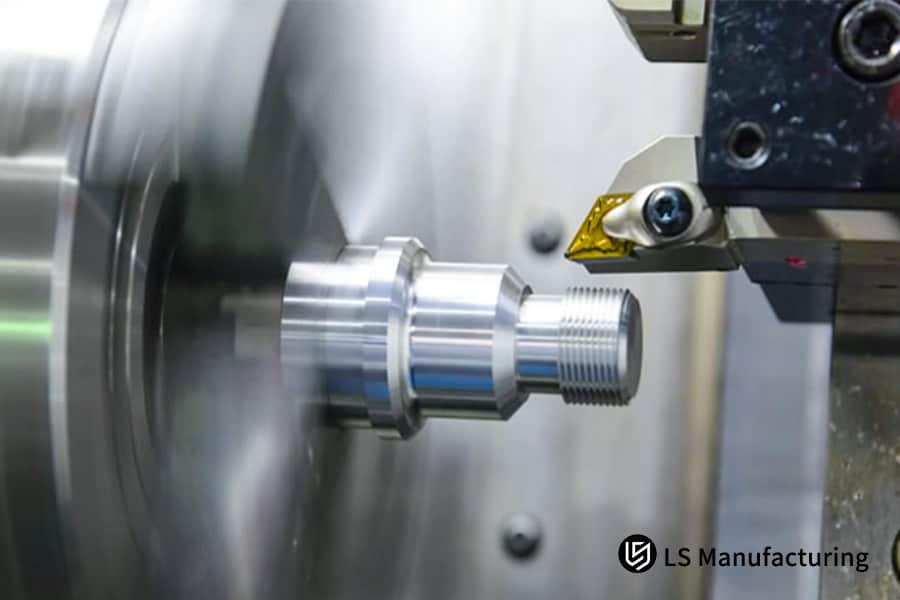

CNC turning is one of the elementary processes in precision manufacturing to efficiently machine intricate rotating parts under digital control. Modern turning has overcome a number of drawbacks that existed traditionally in machining by implementing mill-turning composite processes, which have succeeded in several machining operations all in one setup. Even in hard turning technology, CBN/ceramic tools perform direct finishing of hardened parts.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

With fifteen years of experience, LS Manufacturing offers the CNC turning service in extremely broad industries-from aerospace to medical and semiconductor products. Core component machining solidifies LS’s position as a source of technologies like high-temperature alloy cutting or deformation prevention of thin-walled parts.

Our technology adheres to Society of Manufacturing Engineers(SME) turning standards and International Aerospace Quality Group (IAQG) aerospace specifications. By integrating mill-turn, composite machining, and online measurement, we deliver complete solutions covering materials, tools, and precision control—solving challenges like deep-hole vibration and thin-wall deformation.

Based on the real data of 50,000 pieces, a complete process library has been established. We will share mass production verification technologies like hard turning and mill-turning collaboration. In this guide, you will learn key points to grasp, defects to avoid, and how to get stable batch quality.

What is True Precision CNC Turning?

Manufacturing modern precision CNC turned parts has long since evolved into a highly complex systems engineering project. The true value of the CNC turning service is about the comprehensive integration of equipment, processes, and controls. The core objective is to achieve micron-level turning parts machining accuracy with a superior surface finish. To deeply understand what is CNC turning, we have to understand the following key dimensions:

High-performance CNC lathes are the cornerstone

Equipment rigidity, spindle accuracy, and thermal stability are the physical bases for determining machining accuracy. High-precision bearings, structure of low thermal deformation, and a stable cooling system all function to ensure the machining process is first stable, providing hardware guarantee for micron-level tolerance.

Advanced CAM programming strategies are the brain

This would include smart algorithms for toolpath planning, cutting parameter optimization, and vibration suppression, in turn, effectively controlling the forces of cutting and accumulation of heat. The use of machining strategies according to material properties will guarantee dimensional stability and surface quality right from the source.

Scientific tool management and wear control are key

The proper selection of tool material, geometry, and coating technology with respect to different properties of materials, as well as implementing rigid tool life monitoring with compensation, are some core technical keys to the mass production consistency guarantee.

Thermal deformation control and online detection are essential for ensuring safety

Precise cooling by cutting fluid, environmental temperature control, and real-time online probe detection and compensation effectively offset the thermal deformation effects during machining so that the parts maintain stable tolerances over long-term machining.

Today’s CNC turning requires suppliers to organically combine the performance of the equipment, process planning, and process control into an integral whole in order to transform a simple action of cutting into reliable, precision manufacturing capability. This is precisely the core competitiveness of high-end CNC turning services.

Why is CNC turning still the cornerstone of modern manufacturing?

With the development of intelligent manufacturing technology in modern times, CNC turning still plays an irreplaceable core role in it. Through digital and automation upgrades, this traditional process has been providing a solid foundation for modern manufacturing systems all these years. Three major advantages underpin its enduring vitality: first, it is far superior to other methods of machining in particular fields; second, it comes out especially outstanding in mass production and manufacturing high-precision CNC turned parts.

- Outstanding efficiency and economy: Turning can realize the highest material removal rate among all the machining processes for a rotating part, including shafts, sleeves, and discs. If the cutting parameters are optimized and automation is employed for loading and unloading, the unit cost can be minimized. Therefore, turning is especially appropriate for mass producing small to medium-size batches of precision parts.

- Unrivaled ultra-high precision stability: Precision IT6-IT7 stability in the processing of rotating workpieces, equivalent to within ±0.013mm, indeed represents an important advantage in every modern CNC lathe. Consistent long-term turning parts machining accuracy is possible through closed-loop control systems and online measurement compensations.

- Wide material adaptability: From the alloys of aluminum and stainless steel to high-temperature alloys, titanium alloys, even engineering plastics like PEEK, CNC turning provides an effective method of machining. A growing database of cutting parameters for different materials keeps providing process support to the application of new materials.

Thanks to continuous technological development, CNC turning has been positioned in a very precise role within modern manufacturing: it is the most efficient way to machine rotating parts and can boast comprehensive advantages with regards to precision, cost, and material adaptability.

How to Identify Top CNC Turning Parts Suppliers?

How to choose a CNC turning service is directly related to product quality and project success.in today’s extremely competitive manufacturing environment. Besides supplying qualified products, a good turning parts supplier will be a solid technical partner in your supply chain. You can make an informed decision according to the following key evaluation dimensions. These standards form the backbone of our long-standing commitment to quality here at LS Manufacturing:

| Evaluation Dimensions | Capabilities of Best Suppliers |

| Equipment and Technology Platform | Equipped with advanced equipment, including Swiss-type lathes and multi-axis milling and turning centers capable of handling complex structures. |

| Quality System Certification | Recognized certifications by ISO 9001 on Quality Management Systems or ISO 13485 on Medical Devices ensure that standardized procedures are followed. |

| Material Traceability | Full material documentation will be available for traceability, from raw material to finished products. |

| Inspection and Documentation Capabilities | First-article inspection reports and full-dimensional inspection reports will be provided to ensure the transparency of information and quality control. |

| Engineering Support Experience | The team has extensive experience in process optimization and is capable of providing professional manufacturability design advice. |

Supplier selection is thus a project in its own right, which has to be considered comprehensively: equipment, quality, traceability, and technical service. In this respect, a good partner should be able to translate the most rigorous standards into a consistent output of every precision-machined part, precisely the core value that LS Manufacturing has been consistently providing to its clients.

What are key factors determining cost of machined parts?

Accurately understanding the composition of CNC turning prices is the first step in effective budget control and cost optimization. In most cases, when asking for quotations, the client only considers the unit price, whereas in fact, the final price of the machined parts depends on a system process with several key variables. To really lower the cost, one needs to analyze every step right from the very source; the free DFM analysis that LS Manufacturing offers therefore becomes the key service in helping the clients reach their aims. The cost structure mainly includes five elements:

- Material Costs: The cost of raw materials procurement is basic, and huge price gaps exist for different materials like aluminum alloys, stainless steel, and titanium alloys. Machinability directly affects tool wear and machining time of materials.

- Programming and Setup Time: Engineering time costs associated with such CNC programming, process planning, tool preparation, and machine tool debugging for every new part are especially large when prototypes or small batches are being produced.

- Machining Time: The time actually spent cutting the part on the machine tool. Its length depends upon the complexity of structure, dimensional accuracy, and surface finish requirements, and it is a core part of the cost.

- Post-processing Requirements: Other surface treatments like anodizing, sandblasting, and electroplating also involve additional costs, which are directly proportional to the type of process, coverage area, and quality requirements.

- Order Quantity: Batch size is directly related to the amortization of costs per unit. Large batches enable the amortization of one-time costs like programming and setup, hence offering substantial reductions in unit price.

Cost optimization on turned parts is not just about unit price; rather, it is a synergy of technical and managerial factors toward the best cost overall. All customers are invited to take advantage of the free DFM analysis by us in finding the potential for cost savings-right from the design phase-in collaboration and to maximum effect.

Does your project require turning or mill-turn machining?

During the development of many projects in precision manufacturing, one of the important questions is choosing between traditional turning and more advanced mill-turn machining. We will always support you in making a very rational decision as your technology business partner by considering the characteristics of parts. Such a choice will become very important for the complex parts manufacturing which require high precision and multiple processes.

Applicable Scenarios for CNC Turning:

The turning process could be applied to the parts that require rotation, such as shafts and sleeves. This process involves efficiently processing features, including outer diameters and inner holes and end faces through workpiece rotation. Its advantages are high efficiency of processing and controllable costs that will make it fit for those parts with a simple structure and mainly rotary features.

Unique Value of Mill-Turn Machining:

Mill-turn machining can perform turning, milling, drilling, and tapping operations in one setup and is ideal for asymmetrical parts featuring eccentric holes, planes, slots, and angled holes. Without the need for repositioning, this eliminates errors related to multiple setups and increases the general accuracy and positional repeatability of the parts significantly.

Recommendations for process optimization: LS Manufacturing

We recommend that a client provide a part drawing at the very beginning of the project, based on which our engineers will conduct manufacturability analysis. Mill-turn machining ensures accuracy for structurally complex parts and significantly cuts down the delivery cycle due to process integration, resulting in better economic benefits.

The selection of the process should be done according to the geometric characteristics and the precision requirements of the part. Equipped with rich process experience, LS Manufacturing will develop an optimum technical solution for your project and comprehensively optimize quality, cost, and timeline.

How does precision turning solve the reliability challenges of core UAV connectors?

We started cooperating with a UAV company whose connectors were always made from 7075-T6 aluminum alloy and had the same problem: if parts were to be resistant to high-frequency vibration, extremely high strength and concentricity were demanded for threads. The previous supplier’s yield rate was only 70%, and frequent component failures caused frequent UAV field malfunction events that seriously affected the client’s brand reputation.

Client’s Problem

This is a complicated connector with many precision threads and irregular mating surfaces. Due to the multiple clamping operations in traditional machining methods, there were excessive concentricity deviations and micro-cracks in the thread roots, which could not meet the requirement for service life under high-intensity vibration conditions.

LS Manufacturing Solution

By deeply analyzing the modes of failure, our engineering team adopted a multi-spindle precision turning center. In optimizing the toolpath and cutting parameters, they reached machining of all external diameters, threads, and end face features in one clamping operation. Meanwhile, they introduced high-pressure cooling with a thread inspection instrument to inspect 100% of every product to ensure that the thread root integrity and dimensions were correct.

Results and Value

With the optimization of processes and conducting of end-to-end quality control, part yield rates leaped to 99.9%, while the fatigue life of connectors increased by over threefold. Completely resolving customer failures at job sites with quality stability, this helped them win large-scale inspection orders and establish long-term supply chain partnerships.

In summary, this case study the full-spectrum technical capability of LS Manufacturing in precision turning. We combined process innovation with quality control, transforming what would apparently constitute simple turned parts into reliable products that can operate under extreme conditions and provide trusted solutions for demanding industrial applications.

Let precision turning safeguard the reliability of your critical components!

Why is a precision-turned part particularly favored in the medical device field?

The reason behind such a great demand for medical devices turned parts is that the technology of precision turning meets the requirements of medical applications, with very high standards concerning materials, precision, and traceability. Their main unique advantages for the medical field lie in aspects such as these since these are high-value precision CNC turining parts:

Precision machining capabilities for biocompatible materials

Common biocompatible materials include titanium alloys, 316L stainless steel, and PEEK. All these materials can be challenging to machine and are typically very expensive. Precision turning can manufacture complex implant or surgical instrument components to a high degree of repeatability while guaranteeing that material properties have not been affected by processing heat or mechanical stress.

Extremely high requirements for surface quality and cleanliness

Surfaces of medical parts should be smooth and dead-angle-free to avoid bacterial residue, and ensure complete sterilization. The turning process can achieve a mirror finish with Ra≤0.4μm. Besides, the fully enclosed production environment and cleanroom are able to effectively manage particulate contamination.

A fully traceable quality system

Medical compliance is the cornerstone of the medical manufacturing industry.From material certificates to machining parameters to test reports, precision turning suppliers need to generate comprehensive quality archives that ensure traceability of every batch of parts back to the original production data, adhering to regulations such as FDA and ISO 13485.

Precision turning is vital in medical device manufacturing as it ensures quality consistency and compliance. With our medical manufacturing expertise, we maintain a comprehensive compliance system and precise process control, delivering fully traceable turned medical part solutions from material selection to final delivery.

How can turning services seamlessly integrate between small-batch prototyping and large-scale production?

We achieve consistent high-quality output for both small-batch turning machining and large-scale production with flexible capacity configuration and standardized process systems. The core integration mechanism is reflected in the following aspects:

Rapid response and verification at the small-scale stage

During the prototyping stage, the focus is to quickly respond to design iteration needs using flexible production lines. Small-batch turning is done to verify process feasibility. Meanwhile, standardized processing procedures and testing benchmarks are developed in preparation for subsequent capacity expansion.

Seamless transition to large-scale production and cost optimization

Once the design is finalized, the system automatically switches to large-scale production. Maximum efficiency and minimum unit costs are realized by using validated process parameters, optimized tooling solutions, bulk purchasing, and assembly line operations.

Full-cycle quality traceability and consistency assurance

From the first piece to mass production, we adopt the same quality control system. Through standardized testing processes and data traceability systems, we ensure a very high level of consistency between mass-produced products and prototypes without the risk of quality variation during mass production.

The essential benefit of LS Manufacturing is to organize prototype development and mass production under one management umbrella. By collaborating smoothly from early process verification through flexible mid-stage transition into standardized final-stage production, we really achieve seamless transition from prototype to mass production; thus, we assist the clients in significantly shortening product launch cycles with consistency in quality.

What is the collaboration process with LS Manufacturing from inquiry to delivery?

With LS Manufacturing as your CNC turning service provider, you will experience an efficient, transparent, and professional collaboration process. We have standardized the customer journey so that all steps-communication to delivery-will be clear and smooth, ultimately saving you time and reducing project risk. Here are our core steps of service:

| Stage | Key Activities and Customer Value |

| Submission and review of drawing/requirement | You submit the drawing/requirement online and our professional technical team will then review it online immediately to develop a correct basis for pricing. |

| Price and DFM Analysis | We’re offering transparent pricing, free DFM-manufacturability analysis suggestions to help optimize your design and control costs. |

| Order Confirmation & Production Scheduling | The production plan will start right after confirmation; it will assign a project manager to coordinate the whole process and ensure that information is synchronized. |

| Precision Machining & Quality Inspection | The parts are made under the strict control that combines online testing together with final inspection to ensure that quality is within specifications. |

| Packing and On-Time Delivery | Qualified parts will be properly packed. Shipment will be on time. A logistics tracking number will be provided. |

| Follow-up after Sale and Continuous Support | The team will follow up with technical consultation, further iteration, or even mass production after delivery. |

LS Manufacturing’s core strength lies in integrating prototype development and mass production under unified management. By ensuring seamless transitions from process verification to standardized production, we help clients significantly shorten product launch cycles while maintaining consistent quality.

FAQs

1. What is the least amount of tolerance you can accept?

Thanks to the imported precision CNC lathes and a temperature-controlled workshop environment, we can reliably guarantee the control of tolerance as small as ±0.005mm (5 micrometers). All dimensions in the critical area are checked with a coordinate measuring machine. An inspection report is provided to ensure batch consistency.

2. What is the MOQ of small batch orders?

We support single-piece prototyping and small-batch production. No limit on the minimum order quantity exists with flexible production lines responding to R&D and trial production; the quality of small batches maintains at the level of large lots.

3. What are the material options?

The stock materials include aluminum alloy, stainless steel, titanium alloy, brass and so on, besides engineering plastics including PEEK, nylon and polyoxymethylene Delrin. We can also support customers with special grades required. Material certification can be provided.

4. How do I safeguard design drawings and information against disclosure?

We will sign the NDA before working on your project, adopt encrypted data transmission and partitioned access control during the production process, and destroy all the documents relevant to the production after it is finished according to the agreement.

5. What is the average estimated time of delivery?

Can it be expedited? The normal time to deliver a prototype is about 5-7 business days. However, for a bulk order, this depends on the quantity and the complexity of the process. Of course, there’s an expedited channel where, if urgent, it could be delivered within 3 days. Please consult your project manager for more information.

6. Do you offer surface treatment?

One-stop surface treatment: anodizing includes coloring, electroplating, sandblasting, passivation, and electrophoresis to meet the functional and aesthetic requirements of parts strictly according to industrial standards.

7. If the part does not pass the quality check,

We check quality at all levels-from raw material to finished goods. Immediately, the defective products are isolated and cause analysis is started. Meanwhile, the rapid replenishment mechanism ensures that on-time delivery is made with qualified products complete with inspection records.

8. How can I get a detailed quotation?

You can fill in the form on our official website or email us to submit your 2D/3D drawings and technical requirements about materials, quantity, processes, etc. Then, we will send a detailed quotation within 2 hours, including the price, delivery time, and process solution.

Conclusion

Choosing CNC turning parts LS Manufacturing involves much more than just choosing any one machine tool; it’s about choosing a strategic partner who can truly understand your needs and have solid process expertise with a relentless pursuit of quality. This will directly influence performance, reliability, and the market success rate of your products.

Waste no more resources and time on unreliable suppliers. Just upload your part drawings now for professional free DFM analysis and rapid quotation service here at LS Manufacturing! Let us provide the strongest guarantee for your projects with our solid precision manufacturing capability. Get expert support to ensure your success.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.