CNC turning has become a buzzword in the manufacturing industry and it’s essential to know how it works and its benefits. In this article, we will explore everything you need to know about CNC turning, the processes involved, operations and the benefits of using this technique.

What is CNC Turning?

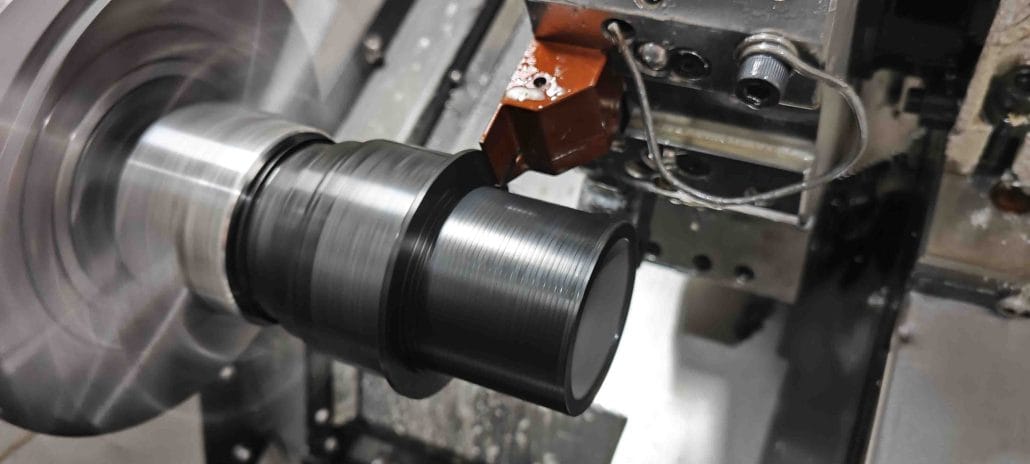

What is CNC turning?CNC (Computer Numerical Control) Turning refers to the manufacturing process whereby a metalwork piece is rotated at high speeds and a cutting tool is used to remove material from the rotating workpiece. The cutting tool is made to conform to the desired shape with precision. This process is automated with the use of a computer to control the machine, hence the name CNC Turning.

History of CNC Turning

CNC turning has come a long way since its inception in the early 1950s. The idea behind Computer Numerical Control (CNC) turning sprang from the need to produce more precise and complex parts. Before then, lathes were operated manually by skilled machinists.

The earliest CNC lathe machines were only capable of making simple parts, but as technology advanced, so did the capabilities of CNC lathes. Today, CNC turning machines can make exceedingly complex designs quickly and with unparalleled precision.

The Basics of CNC Turning

CNC turning is a subtractive manufacturing process that involves the removal of material from a stock piece to create the desired shape. The process begins with a computer-aided design (CAD) file or 3D model of the component, which is then transferred to the CNC machine. The machine then uses a spinning cutting tool to remove material from the stock piece, following the path specified in the CAD file.

The CNC machine is programmed to perform a specific set of movements in order to create the desired shape. This process can be highly complex, with the cutting tool moving in multiple axes and at different speeds and depths. The result is a finished component that is highly precise and accurate, with tolerances of just a few thousandths of an inch.

How CNC Turning Works

CNC turning machines use an incredible amount of technology to cut and shape metal workpieces. A workpiece is inserted into the lathe machine and secured in place. The cutting tool is then initialized by a computer program that directs the tool to cut the workpiece according to the desired design specs.

The process is highly automated, with the computer program controlling all aspects of the machining process. The program translates the design specifications into machine code that directs the cutting tool precisely where and how to cut the material.

Why CNC Turning is Important

CNC turning is an essential technology in modern manufacturing, allowing for faster production times, lower costs, and higher levels of accuracy. This process is particularly well-suited for the production of complex shapes and components, such as gears, shafts, and housings. It is also capable of producing parts in a wide variety of materials, including metals, plastics, and ceramics.

CNC turning offers a number of advantages over traditional manufacturing processes, such as manual turning or milling. One of the biggest advantages is the ability to produce parts with consistent quality and precision, even in large quantities. This is because the CNC machine is programmed to perform the same set of movements for each part, ensuring that they are all identical.

Another advantage of CNC turning is its flexibility. The machines can be programmed to produce parts in a wide range of shapes and sizes, making it ideal for both mass production and custom manufacturing. It is also possible to make changes to the program quickly and easily, allowing for rapid prototyping and design iteration.

Benefits of CNC Turning

CNC turning has become a critical part of the manufacturing process for many industries. This is due to the range of benefits it provides, which include:

- Increased Efficiency

Undoubtedly, one of the most significant benefits of CNC turning is the increase in efficiency. CNC turning removes the need for manual labor, which can be time-consuming, costly, and more prone to errors. By streamlining the manufacturing process, CNC turning saves businesses time and money, allowing for faster production rates without sacrificing quality.

- Flexibility

CNC turning allows for customization and versatility in the manufacturing process, providing greater flexibility. Once the settings are programmed and tested, virtually any shape or size of material can be milled with ease and precision. This means that manufacturers can create parts that are tailored to their specific needs, from complex parts with intricate designs to simple and straightforward ones.

- Increased Accuracy

Precision is a crucial aspect of the manufacturing process. With CNC turning, manufacturers can achieve the highest level of accuracy, far beyond human capabilities. The CNC machine is programmed to produce parts with the exact same specifications every time, ensuring consistency and reducing waste.

- Low Cost

While the initial cost of investing in a CNC turning machine can be high, it’s worth it in the long run. CNC turning provides a higher and more consistent level of quality, making it a more cost-effective solution. Additionally, the process is more energy-efficient, reducing operating costs and increasing profits.

- Reduced Lead Times

CNC turning also reduces the amount of time required to produce parts. Once the settings are programmed, the machine can run continuously, producing parts around the clock. This means that lead times are greatly reduced, getting products to market faster and improving customer satisfaction.

CNC turning has truly revolutionized the manufacturing industry, providing significant benefits that have transformed the way businesses operate. The efficiency, flexibility, accuracy, and cost-effectiveness of CNC turning make it a wise investment for any manufacturer. Not to mention, the reduced lead times mean businesses can meet customer demand and grow their operations.

If your business is looking to optimize its manufacturing process, online CNC machining is the way to go. It’s a game-changing technology that’s sure to improve both your efficiency and profitability.

The Future of CNC Turning

CNC turning is a rapidly evolving technology, with new advances in machine design, tooling, and software being made all the time. This means that the capabilities of CNC turning are constantly expanding, allowing for even greater levels of precision, speed, and flexibility.

One area of particular interest is the use of artificial intelligence (AI) and machine learning algorithms to optimize the CNC turning process. By analyzing data from the machine and its sensors, these algorithms can identify areas where performance can be improved, such as the speed of the cutting tool or the angle of the part. This could lead to even faster production times and higher levels of accuracy in the future.