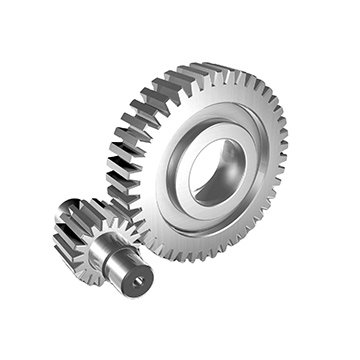

Instant Quoting for Custom Gear Machining & Manufacturing

LS Manufacturing delivers fast, precise quotes for custom gear machining requirements. Backed by a robust material portfolio, comprehensive surface finishing solutions, and high-precision manufacturing capabilities, our quoting system generates tailored, cost-competitive quotes in minutes.

Select industry-grade materials (carbon steel, bronze, aluminum alloy, ductile iron, nylon) for optimized gear performance and long-term durability.

Our surface treatments (quenching, electroplating, lapping, etc.) feature 2-4 day lead times, elevating gear performance and service life.

Achieve tight tolerances for key gear types (parallel shaft gears, spiral gears, miter gears) to ensure precise fit and reliable functionality.

Gear Machining & Manufacturing for Low-Volume Production & Rapid Prototyping

LS Manufacturing specializes in gear machining for low-volume production and rapid prototyping—enabling fast new design validation and efficient functional prototype fabrication. Our flexible lead times and high-precision manufacturing ensure gears meet exact specifications, regardless of design complexity.

Prototypes and small-batch gear units can be manufactured in just 2–3 days, accelerating your product development timeline.

Achieve precise gear tooth profiles with tolerances as tight as ±0.01mm, guaranteeing optimal operational performance.

Choose from over 50 surface finishing options to enhance gear durability and minimize friction, extending service life.

Gear Machining & Manufacturing for High-Volume Production

LS Manufacturing leverages advanced gear machining capabilities to efficiently handle high-volume production—without compromising consistent quality or precision. Our optimized, streamlined workflows ensure every gear aligns with your specifications, while meeting on-time delivery and budget targets.

Maintain uniform tight tolerances and strict quality standards across all high-volume gear orders, ensuring reliable, consistent operational performance.

Reduce production costs and lead times via streamlined, automated workflows—optimizing efficiency for large-scale gear manufacturing.

Enhance gear performance and service life with specialized thermal treatments and coatings (including carburizing, nitriding, etc.).

Start Your CNC Machining Quote

Get instant pricing, project lead times, and DFM feedback.

STEP | STP | SLDPRT | STL | DXF | IPT | X_T | X_B | 3DXML | CATPART | PRT | SAT | 3MF | JT files

File size: ≤15MB All uploads are secure and confidential.

All uploads are secure and confidential.

Gear Machining

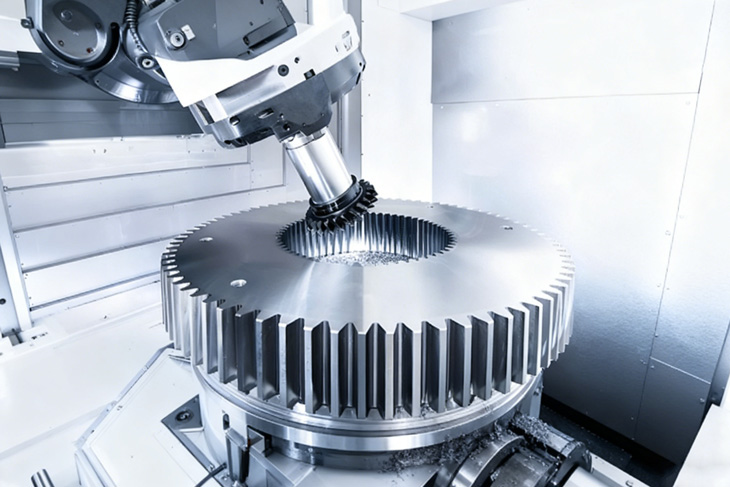

LS Manufacturing specializes in gear machining for complex geometries, delivering extreme precision via simultaneous 5-axis machining. This capability reduces setup steps for intricate parts, ensuring tight tolerances and superior surface finishes—supporting both prototyping and large-scale production requirements.

Gear Machining Service

Gear Design

Gear Milling

Gear Grinding

Gear Hobbing

Gear Machining Tolerances

LS Manufacturing delivers industry-leading precision tolerances for high-demand gear applications. Backed by rigorous quality control protocols, our gear machining aligns with global standards (AGMA, JIS, DIN), covering both standard and high-performance gear requirements to ensure reliability and accuracy across diverse industrial use cases.

| Precision Level | USA AGMA | Japan JIS | Germany DIN |

|---|---|---|---|

| 1 | - | - | DIN 1 |

| 2 | - | - | DIN 2 |

| 3 | - | - | DIN 3 |

| 4 | - | - | DIN 4 |

| 5 | - | JIS 0 | DIN 5 |

| 6 | - | JIS 1 | DIN 6 |

| 7 | AGMA 16 | JIS 2 | DIN 7 |

| 8 | AGMA 15 | JIS 3 | DIN 8 |

| 9 | AGMA 14 | JIS 4 | DIN 19 |

| 10 | AGMA 13 | JIS 5 | DIN 10 |

| 11 | AGMA 12 | JIS 6 | DIN 11 |

| 12 | AGMA 11 | JIS 7 | DIN 12 |

| 13 | AGMA 10 | JIS 8 | - |

| 14 | AGMA 9 | - | - |

| 15 | AGMA 8 | - | - |

| 16 | AGMA 7 | - | - |

| Precision Level Range | Standard | ||

| USA AGMA | AGMA 8 to AGMA 13 (High Precision) | ||

| Japan JIS | JIS 2 to JIS 6 (High Precision) | ||

| Germany DIN | DIN 5 to DIN 9 (High Precision) |

LS Manufacturing’s CNC part maximum dimensions vary by material type. Reach out to our team for detailed, material-specific size specifications tailored to your requirements.

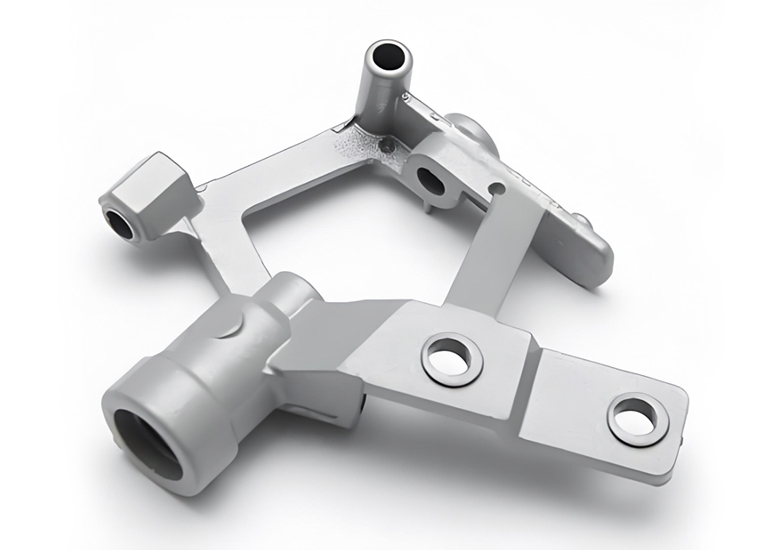

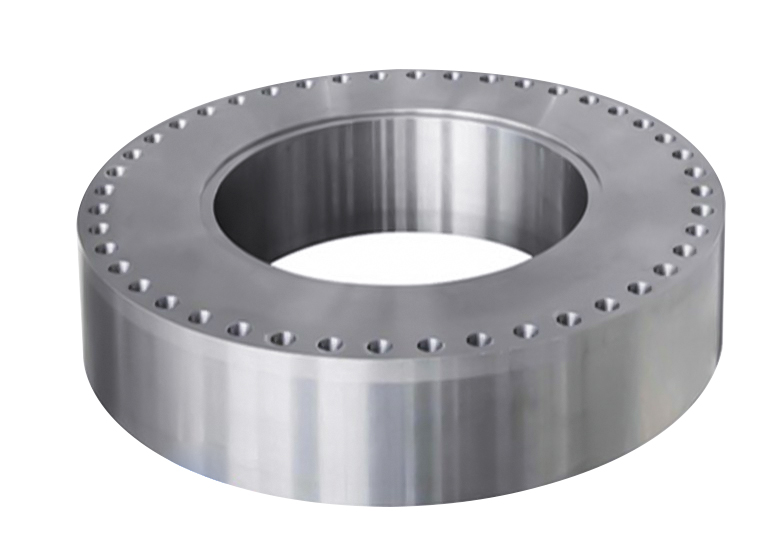

Gear Machining Material Selection

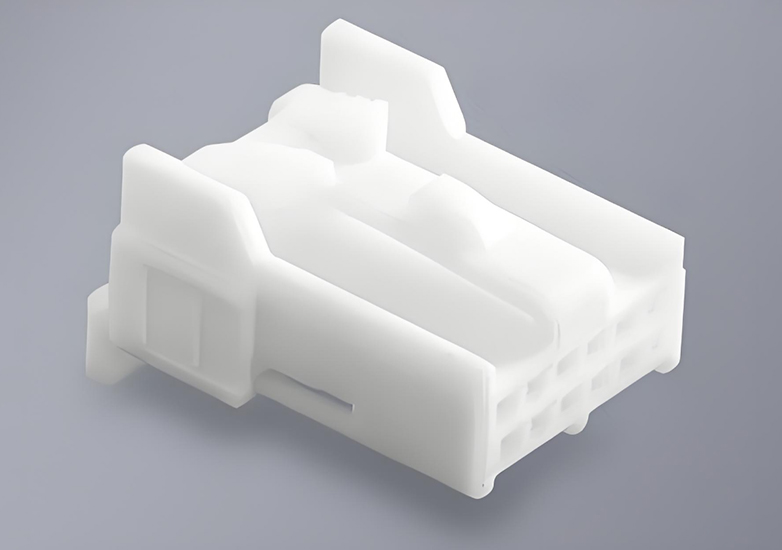

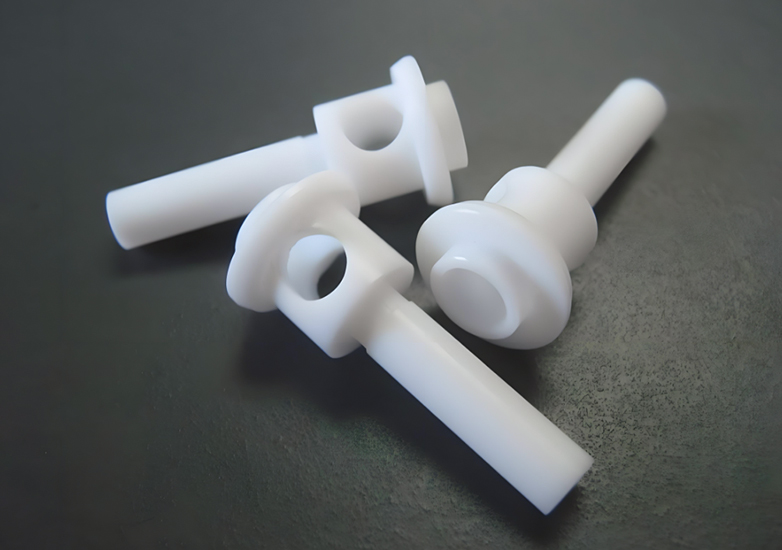

LS Manufacturing offers a diverse portfolio of materials for gear machining, tailored to the unique demands of various industries. Our range includes metals, plastics, and composites—ensuring each gear is manufactured with the optimal material for your application. Below are key materials we specialize in:

Metals

Plastics

The materials above represent our core offerings. For specialized material requirements (including custom alloys or composites), connect with our team to source and process the exact material tailored to your gear application.

These are just a few examples of the materials we work with. If you have a specific material requirement, please contact us to discuss your needs.

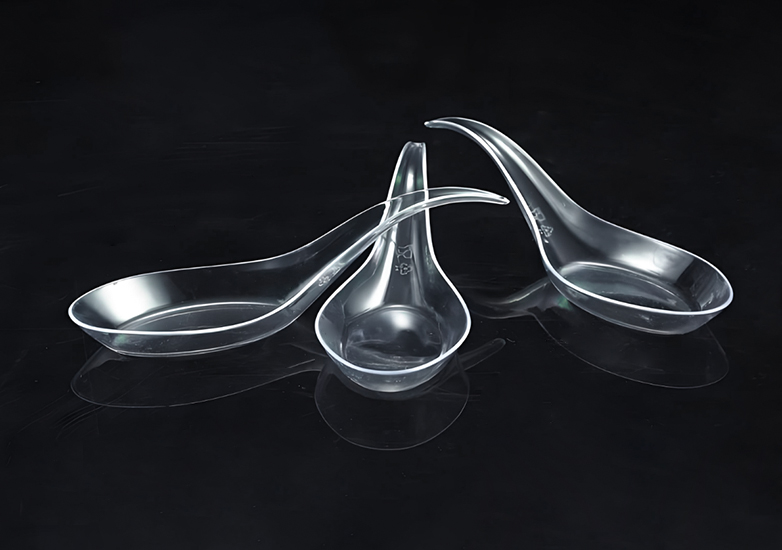

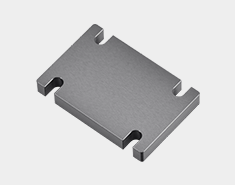

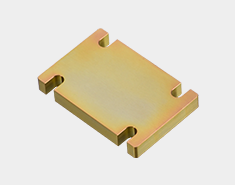

Gear Machining Surface Finishing

surface finishing Surface finishing is a mission-critical step in gear machining—elevating part appearance, operational performance, and service life. LS Manufacturing offers a comprehensive range of surface finishing solutions (including anodizing, powder coating, sandblasting, and polishing) tailored to your application needs. These treatments deliver dual value: enhancing aesthetic appeal while adding functional benefits like corrosion resistance, wear protection, and extended gear longevity.

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Anodizing

Anodizing

|

Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

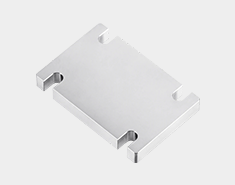

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Chromate

Chromate

|

Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

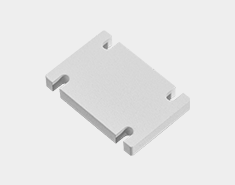

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

The above represent core surface finishing solutions from LS Manufacturing. For specialized surface treatment requirements tailored to your gear application, connect with our team to determine the optimal finishing solution for your project.

Gear Machining Advantages & Features

Our gear machining services integrate industry-leading precision, streamlined efficiency, and rigorous quality control to deliver tailored solutions for your gear production requirements. Discover why we’re the trusted partner for high-performance gear machining.

High Precision and Accuracy

Powered by advanced CNC gear machining equipment and specialized tools, we deliver ultra-high machining precision with tolerances controlled to ±0.005mm—ensuring smooth gear operation and reliable performance.

Fast Turnaround Times

Our streamlined production workflows enable fast delivery without compromising quality: typical lead times range from 1–5 days (from prototyping to mass production), aligning efficiently with your project timelines.

Wide Range of Materials

We offer over 100 gear-specific materials (including metals like steel, aluminum, brass, and plastics like nylon, POM), precisely matching material requirements for diverse applications.

Custom Gear Finishes

We cover 20+ custom surface treatments (e.g., carburizing, nitriding, anodizing), balancing gear durability and aesthetic finish to enhance both functional and visual performance.

Scalability from Prototypes to High-Volume Production

Our services accommodate full production scalability: supporting orders from single prototypes to 50,000-unit mass production, flexibly meeting needs across all project phases.

Comprehensive Quality Assurance

We implement a rigorous quality control process, with in-process and final inspections via precision equipment (CMMs, gear measuring machines). Backed by ISO 9001, IATF 16949, and AS9100D certifications, we uphold uncompromising quality standards.

Choose LS Manufacturing for your gear machining needs—unlock the benefits of our advanced production capabilities and unwavering quality commitment. Connect with our team today to discuss your project, or secure an instant quote right away.

Gear Machining Case Studies

LS Manufacturing’s gear machining components are trusted across diverse industries. Below are real-world examples of our ability to deliver high-quality,

application-tailored precision gears for specialized sector needs:

Gear Manufacturing Industry

▲Project Background: A leading global gear manufacturer required custom precision gears for its high-performance industrial machinery system—critical to the equipment’s core operational efficiency.

Challenge: The gears demanded tight tolerances (±0.005mm), exceptional durability under extreme operational stress, and seamless integration within a complex mechanical assembly.

Solution: We deployed advanced 5-axis CNC gear machining capabilities, utilizing high-strength alloy steel and aerospace-grade aluminum to optimize the gears’ structural integrity and performance.

Results: The gears were delivered 2 days ahead of the project timeline, fully meeting all tolerance and performance specifications. They enabled 15% improved operational smoothness for the machinery, extending the system’s service lifespan by 20%.

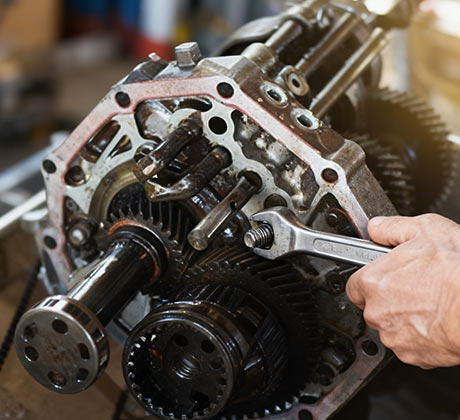

Automotive Gearbox

▲Project Background: A leading automotive OEM engaged LS Manufacturing to supply precision gears for its new fuel-efficient transmission system line—targeting mass production for mid-size passenger vehicles.

Challenge:The gears required a lightweight-yet-robust design (to reduce vehicle curb weight), compliance with IATF 16949 automotive quality standards, and optimized power transmission efficiency to cut fuel consumption.

Solution:We deployed precision CNC gear hobbing + milling, paired with high-strength aluminum alloy (to balance weight and durability), and engineered optimized involute tooth profiles to minimize friction during operation.

Results: The transmission system achieved an 8% reduction in fuel consumption; gear operation noise was cut by 12dB, and the design secured industry recognition for smooth shifting reliability. Our gears supported the OEM’s 50,000-unit annual production target on schedule.

Wind Power Generation Equipment

▲Project Background: A leading 2.5MW wind turbine manufacturer partnered with LS Manufacturing to supply high-precision gears for its main gearbox—critical components for converting turbine rotor torque into grid-compatible electrical power.

Challenge:The gears required structural integrity under continuous 120kN·m load stress, resistance to -40℃~60℃ temperature fluctuations (typical for offshore/continental wind farms), and a 20+ year service life with minimal scheduled maintenance.

Solution: We utilized carburized alloy structural steel (for high fatigue resistance) paired with 5-axis CNC gear grinding (achieving DIN 3-level tolerances), and applied anti-corrosion thermal spray coatings to withstand harsh environmental conditions.

Results: The gearboxes delivered a 2.3% improvement in power generation efficiency; the gears met 25-year design life requirements (exceeding the industry standard 20 years), and maintenance intervals were extended from 12 to 18 months—reducing the turbine operator’s lifecycle costs by 15%.

Robotics & Automation Equipment

▲Project Background: A leading industrial robotics firm engaged LS Manufacturing to supply custom precision gears for its 6-axis collaborative robotic arms—deployed in high-speed electronic component assembly and automotive parts welding (core industrial automation scenarios).

Challenge:The gears required ultra-low backlash (≤0.01mm) for precise motion control, high wear resistance under 1,200+ daily repetitive operations, and compatibility with compact robotic arm enclosures (strict size constraints).

Solution: We applied precision CNC worm grinding + hobbing (achieving AGMA 14-level accuracy), used carburized alloy steel (for high fatigue strength), and added low-friction nitriding surface treatment to meet space and performance demands.

Results: The robotic arms’ repeat positioning accuracy improved by 32% (to ±0.02mm), cycle time per assembly task was reduced by 18%, and gear service life extended to 50,000+ hours—supporting the client’s 2,000-unit annual robotic arm production target.

Agricultural Machinery

▲Project Background: A top-tier agricultural equipment brand partnered with LS Manufacturing to supply robust gears for its new line of 120HP tractors and self-propelled combine harvesters—deployed in large-scale grain planting and harvesting operations.

Challenge:The gears needed to withstand extreme outdoor conditions (mud, dust, -25℃~45℃ temperature fluctuations), sustain continuous 5-ton traction loads (for tractors), and maintain reliability through 800+ hours of seasonal harvesting operations.

Solution:We manufactured gears using high-carbon hardened steel (via CNC hobbing + carburizing treatment) to boost load-bearing capacity, and added anti-corrosion zinc-plated coatings to resist harsh field environments.

Results: Gear durability improved by 40% (extending service life to 1,200+ operating hours); maintenance intervals were extended from 200 to 350 hours, cutting seasonal downtime by 22%. The combine harvesters’ operational efficiency also rose by 12% during peak harvesting periods.

Gear Machining Quality Control

At LS Manufacturing, quality is the foundation of our gear machining services. We enforce rigorous, end-to-end quality control—spanning design validation, production, and post-manufacturing—to ensure every gear meets uncompromising standards for precision, structural strength, and long-term reliability. Our system combines proactive oversight with advanced tools to deliver consistent, high-caliber output.

In-Process Inspections

We conduct targeted checks at critical production stages (machining, heat treatment, surface finishing) to verify alignment with design specifications. This proactive approach identifies and resolves deviations early, minimizing rework and keeping projects on track while upholding precision.

Final Inspections

Before shipment, every gear undergoes 100% batch inspection using high-precision tools (e.g., coordinate measuring machines, gear profile analyzers). These audits confirm full compliance with dimensional, tolerance, and performance benchmarks for your application.

Precision Measurement Tools

Our quality lab is equipped with specialized equipment: coordinate measuring machines (CMMs), gear tooth vernier calipers, and surface roughness testers. These tools validate micron-level tolerances and surface quality, ensuring gears perform as engineered.

ISO 9001, IATF 16949 & AS9100D Certifications

Our quality management system is certified to global standards: ISO 9001 (general quality), IATF 16949 (automotive-specific), and AS9100D (aerospace). These credentials confirm our processes align with industry-specific requirements for reliability and consistency.

Continuous Improvement

We maintain leading standards through quarterly process audits, staff upskilling programs, and adoption of the latest machining/inspection technologies. This cycle of refinement ensures our quality control evolves alongside evolving industry demands.

Choose LS Manufacturing for gear machining—our rigorous quality control delivers reliable, high-performance gears tailored to your needs. Contact our team today to discuss your project, or get an instant quote to launch production with confidence.

Need Assistance? We’re Here to Support You.

If you have gear machining questions or support needs, our team assists 24/7. Reach out via the methods below.

We’ve compiled answers to common gear machining questions to clarify our capabilities and processes. If you need further details, our team is standing by to help.

What types of gears can you manufacture?

Our gear machining services integrate industry-leading precision, streamlined efficiency, and rigorous quality control to deliver tailored solutions for your gear production requirements. Discover why we’re the trusted partner for high-performance gear machining.

What is the minimum order quantity for gear machining?

No MOQ—we accept single prototypes to 50,000+ unit runs. Pricing scales with volume; low-volume/prototype orders are welcome.

Can you produce custom-designed gears?

Custom gear manufacturing is our specialty. Our engineering team works with your specs (or provides design support), including DFM recommendations and 3D modeling/prototype validation.

What quality control measures are in place?

We use in-process inspections, gear measuring machines, CMMs, hardness testing, and tooth contact analysis. Our processes are ISO 9001, IATF 16949, and AS9100D certified.

How do I provide my gear design for manufacturing?

Upload CAD files (STEP, IGES, SLDPRT, etc.) via our quoting system, or provide 2D drawings (with specs) or physical samples.

Can you provide gear prototypes for testing?

Yes—single prototypes are delivered in 1-3 days (complexity-dependent), using production processes to reflect final part performance. Iterative design optimization is supported.

How do you package gears for shipment?

Yes—our engineering team offers material selection, DFM recommendations, load calculations, tolerance optimization, and cost-reduction guidance to refine your gear design.

Can you provide design assistance for gear manufacturing?

Custom gear manufacturing is our specialty. Our engineering team works with your specs (or provides design support), including DFM recommendations and 3D modeling/prototype validation.

Have other questions or need more details? Contact us—our team supports all your gear machining needs.

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

Gear Machining & Manufacturing Latest News & Blog

Deep understanding of industry knowledge and real-time updates at any time.