Types of gears are diverse, but selection alone is only the first step. In high-speed transmission systems, abnormal wear, noise, or premature gear failure often leads to unplanned downtime and significant financial loss. These issues frequently stem from a disconnect between design and actual operating conditions. In the following sections, the LS Manufacturing expert team moves beyond basic theory to explore the underlying logic of gear selection, design, and manufacturing.

Learn how condition-based precision gear machining solutions can fundamentally enhance equipment reliability while drastically reducing total cost of ownership. Proper selection and manufacturing of the right gears for your application hold the secret to avoiding expensive losses due to downtime. To save you time, here’s a quick overview of the core conclusions.

Gear Type Quick Reference Table

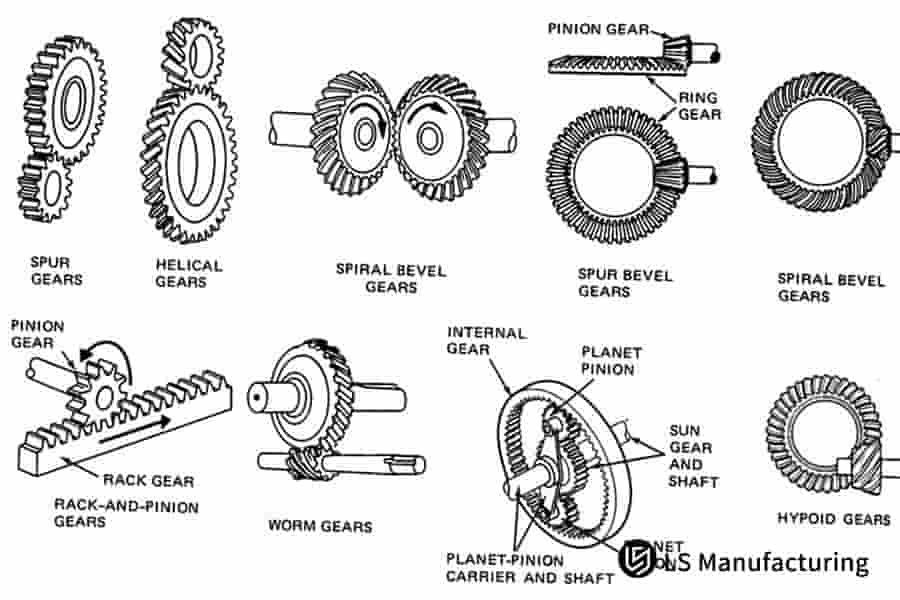

| Classification Method | Gear Type | Core Characteristics/Application Summary |

| Classification by tooth shape | Involute gears | Most in use, smooth transmission, mature manufacturing process. |

| Circular arc gear | It has high contact strength and is suitable for heavy machinery, but is sensitive to center distance. | |

| Cycloidal gear | It has good wear resistance and is often used in precision instruments such as flow meters and clocks. | |

| According to the relative positions of the two axes | Parallel shaft gears | It includes spur gears, helical gears, and herringbone gears, used for transmissions with parallel axis centers. |

| Intersecting shaft gears | Mainly bevel gears (straight teeth, helical teeth, arc teeth), used for transmission between intersecting shafts. | |

| Interlaced shaft gears | Examples include worm gears and hypoid gears, used for transmissions of spatially intersecting shafts. |

Involute gears have a balanced performance and therefore are the most versatile; helical gears are smoother and can support higher loads compared with spur gears in parallel shaft transmissions; spiral bevel gears are preferred for intersecting shaft transmissions in order to improve smoothness; for high-ratio crossed shaft transmissions, worm gears can be selected in order to achieve a compact layout.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

LS Manufacturing possesses cross-industry technical expertise in the field of precision gears. When developing high-reliability transmission systems, the team strictly adheres to relevant U.S. Department of Defense (DoD) standards for verification. Simultaneously, based on Additive Manufacturing (AM) standard processes, they develop lightweight gear modules and precisely master the matching logic for different gear types and operating conditions.

Based on our experience serving high-class industries like aerospace and medical equipment, we have established a gear knowledge base that involves the properties of materials and heat treatment processes. We use tooth profile modification technology to control the precision of robot joint gears within 1 arc minute and adopt carburizing and quenching processes to raise durability drastically in heavy-load conditions.

This guide is developed based on the measured data and in-depth fault analysis accumulated from tens of thousands of gearbox applications. It not only explains the theoretical characteristics of different types of gears but places particular emphasis on their real-world performance under actual operating conditions such as varying loads, temperature fluctuations, and long-term wear.

Why does incorrect gear selection lead to production line shutdowns?

Minor errors in gear selection can trigger an avalanche of failures in high-speed industrial systems. When gears lack the precision to match real operating conditions, or possess inadequate strength and lifespan, the result is unplanned production halts, plummeting yields, and even systemic equipment damage risks. In these critical scenarios, following a professional gear selection guide becomes indispensable for implementing a systematic approach to selection and obtaining reliable industrial gear solutions.

Precision mismatch and equipment vibration

If the precision grades of the selected gears are not high enough, they cannot meet the operating requirements of equipment at high speeds. Therefore, severe vibration and noise can occur in a transmission system. Under this constant and abnormal load condition, the abrasion of bearings, shafts, and other involved parts will increase, which will make the equipment lose accuracy permanently or cause it to suddenly fail.

Insufficient strength, possibly resulting in breakage of the tooth

Poor selection of the contact strength between tooth surfaces or tooth root bending strength under conditions of heavy load or impact load may easily lead to pitting, spalling, or even tooth breakage, resulting in fatal failures. Once a tooth breaks, fragments will lodge in the transmission chain; not only is the gearbox unusable, but it may also cause downstream equipment to suffer from cascading damage, with repair cycles lasting as long as several weeks, and huge losses result.

Lifespan Estimation Deviation and Unplanned Downtime

Without scientific lifespan estimation, selecting the gears relying only on experience would result in gears with a rated lifespan far below the overhaul cycle of the equipment. That is to say, the production line would be forced to stop in advance of planned maintenance, further interrupting the whole production schedule, leading to delayed orders and huge breach-of-contract penalties.

Professional gear machining selection is the primary safeguard for production continuity. This is the value of LS Manufacturing’s industrial gear solutions: we deliver precision gears compliant with leading standards (e.g., DIN/AGMA), while also providing comprehensive lifecycle guidance—from design support to material selection, heat treatment, and lubrication optimization.

Which kinds of gears determine the upper limit of equipment performance?

The design of a precision transmission system involves different types of gears that directly determine the upper limit of equipment performance. Gear properties explained: it not only governs transmission efficiency but also critically influences core performance indicators such as torque capacity, operational accuracy, service life, and noise control. The main types of gears and their respective characteristics determining the upper limit of the equipment performance are compared below.

| Gear Type | Core Performance Boundary | Decisive Impact on Equipment Performance |

| Involute Spur Gear | High load-bearing capacity, transmission efficiency up to 98% or more | Determines the reliability and power density upper limit of the basic transmission system. |

| Helical Gear | Smooth transmission Noise 3-5dB lower than spur gears | Influences directly the vibration and noise level as well as operational stability of high-speed devices. |

| Bevel Gear | Can transmit on crossing shaft. Wide range of speed ratio possible. | It determines the efficiency of spatial layout and torque transmission capacity of the steering transmission system. |

| Worm Gear | Offers high-speed ratio in single stage and excellent self-locking characteristics | Affects the balance of safety performance and transmission efficiency of heavy-duty lifting equipment. |

| Planetary Gear | Compact structure, power splitting increases load-bearing capacity by 3 times | Determines the torque output density and accuracy retention of equipment within a limited space |

The gear properties should be elaborated in detail, combined with specific application scenarios. Only by correctly understanding the performance boundary of each type of gear is it possible to accurately match equipment requirements at the design phase, avoiding overkill or underkill in performance, thereby deriving a transmission solution that strikes an optimal balance between reliability, efficiency, and cost.

How to balance strength and noise in gear design?

In designing precision transmission systems, gear design has always been subject to a core contradiction: the higher the strength pursued, the higher the operating noise; on the other hand, over-optimization for quietness may weaken load-bearing capability. The correct approach to designing gears is based on the systematic optimization of its parameters within given operating conditions.

Strategic Module Choice

The module directly affects both tooth root bending strength and transmission smoothness. A large module is required under heavy load conditions to improve the bending resistance. However, it will increase meshing impact. We upgrade precision in order to compensate for the noise impact brought by a large module while meeting its strength requirements: based on an ISO 5 level to ensure that the single-stage transmission efficiency is over 98%.

Dynamic Optimization of Pressure Angle

The standard 20° pressure angle is not the solution for all. In high speed situations (>3000rpm), 22-25° large pressure angle design is employed which reduces the tooth surface slip ratio effectively and lowers the noise by 4-6dB. Meanwhile, the edge contact is eliminated by profile modification techniques in order to avoid the stress concentration problem caused by the increased pressure angle.

Precise control of displacement coefficient

While positive displacement increases tooth thickness to improve bending strength, negative displacement avoids undercut. In one high-speed reducer project, the asymmetric displacement combination applied was +0.4/-0.2; with this optimization, torque capacity remained up to 180Nm, while noise was maintained below 62dB-a 15% optimization compared to the initial design.

Excellent gear design balances competing parameters systematically by applying gear design fundamentals and practices. Leveraging 2,000+ successful cases, LS Manufacturing creates multi-objective models optimizing strength, noise and lifespan for EV drivetrains and precision machinery. In a recent e-drive project, strategic optimization of module, helix angle and micro-geometry based on these fundamentals boosted fatigue life 30% while cutting transmission error 20%.

What requirements apply to gears depending on the related branch of industry?

Gear applications in industry span numerous fields, each with distinct performance demands. Understanding these differences is crucial for selecting appropriate industrial gear solutions, as they directly impact equipment reliability, efficiency, and lifespan. The table below compares core requirements across sectors:

| Industrial Sector | Core Performance Requirements | Common Gear Types and Manufacturing Characteristics |

| Industrial Robots/Precision Automation | High positioning accuracy, low backlash, high reliability | Mainly adopt high precision involute planetary gears and harmonic reducers with grinding processes and strictly controlled backlash. |

| Heavy Machinery/Mining Equipment | Extremely high load capacity, resistance to impact and wear | Uses large-module carburized and quenched gears often for a tooth surface of extremely high hardness and of a robust structure. |

| Automotive Transmissions | High transmission efficiency, low noise and vibration, lightweight | Widely uses precision-forged or shaving/honed helical gears, putting much emphasis on NVH performance and controlling weight. |

| Aerospace | Extremely high power density, reliability, resistance to extreme environments | Often uses high-quality alloy steel or special material gears. Shot peening and other strengthening processes are often applied in the pursuit of the highest possible power-to-weight ratios. |

Gear applications in industrial settings typically dictate the technological pathway for gear design and manufacturing. The best trade-off among performance, cost, and reliability will be the industrial gear solution. With unparalleled knowledge in materials, heat treatment, and precision manufacturing processes, we can offer customized high-performance gear products in several industries.

How does LS Manufacturing address industrial robot joint gear precision and lifespan challenges?

In the high-end equipment manufacturing field, the precision and service life of gears in an industrial robot joint determine directly the overall performance of the whole machine. This LS Manufacturing gear case will profoundly prove the key value of precision gear customization in solving core technology bottlenecks.

Customer Challenge

Precision degradation and pitting wear after long-term durability testing were serious problems occurring with the core joint gears of the new generation six-axis robots being developed by one leading industrial robot manufacturer. The result is that the repeatability error of the end effector of the robot is greater than the permissible range of ±0.1mm, seriously challenging the commercialization process of the product.

LS Manufacturing Solution

Instead of the above-mentioned drawing-based processing, we first used a dedicated team to perform tooth surface optimization calculations based on the robot’s kinematic model and actual load spectrum, with targeted modifications in tooth profile and direction. Further, with ultra-precision gear grinding, the accuracy of the tooth surface profile could be controlled, while deep carburizing and stabilizing heat treatment were developed to guarantee dimensional stability of the gears under long-term alternating loads.

Results and Value

The optimized gear pair had stable joint repeatability within ±0.05mm, and accelerated life testing showed that its service life reached three times that of the initial design. This not only helped solve the customer’s technical challenge but gave its products a significant market competitive advantage in positioning accuracy and reliability.

This LS Manufacturing gear case proves standard solutions often fail under extreme conditions, while precision gear customization—through systematic optimization of materials, design and process—achieves breakthrough performance in key components, creating a core advantage for high-end equipment manufacturing.

Precision in transmission begins with customization. Get the custom gear solution now!

What are the major competencies that a gear supplier needs to possess?

Selection of a gear manufacturing partner is a strategic decision, as this will directly impact the reliability of the performance of the transmission system. Capabilities here have a direct effect on product performance and lifecycle costs. A superior LS Manufacturing Level supplier has to surpass just processing drawings by having comprehensive collaborative innovation capabilities. Here are four key dimensions for evaluation of its core competencies:

- Design Collaboration and Optimization Capabilities: Such good suppliers should provide optimization suggestions at the early design stage, such as tooth profile change and proper material selection, to improve gear’s load-carrying capacity, noise performance, and service life from its source.

- Depth of Heat Treatment and Process Technology: The gear performance is guaranteed, especially for key working procedures such as heat treatment. In detail, carburizing, quenching, and nitriding should be considered while controlling the precision of tooth surface hardness, core toughness, and micro-deformation to provide the basis for durability.

- Complete Quality Control System: A comprehensive quality management system such as ISO 9001, coupled with state-of-the-art test equipment like gear measuring centers and coordinate measuring machines, is indispensable to ensure the traceability and controllability of every stage, right from raw material to finished product, toward the attainment of high consistency during mass production.

- Relevant Project Experience: Successful cases in the past are the best proof. It is necessary to examine their successful experience under similar operating conditions, which can greatly reduce project risks and accelerate product maturity.

A gear manufacturing partner should be selected with much care on three broad dimensions: technical engineering, quality culture, and project experience. It positions LS Manufacturing as a strategic and trustworthy partner for its clients to solve high-end transmission challenges by offering deep expertise in the four dimensions.

FAQs

1. Can you accept small-batch customized orders? What is the MOQ?

We can provide customized small batch, multi-variety productions with a minimum order quantity as low as 1 piece, which fully meets your demands in product development, prototyping, and small-batch production.

2. How long does it take from design to receiving a sample?

The delivery time of the standard gear sample is 2 to 3 weeks. If there is any urgent need, then we can expedite it. The specific time will be confirmed according to the gear complexity and process requirements.

3. How do you ensure precision in the gears and consistency in quality?

The introduction of the ISO 9001 quality system with strict compliance, equipped with precision testing equipment such as gear measurement centers and CMMs, realizes full-process quality monitoring to ensure that each batch is in a state of stable precision with traceable data.

4. Do you have gears according to certain international standards such as AGMA and DIN?

Of course, we have long served the global market and are familiar with designing, manufacturing, and inspecting various gears in accordance with different international standards like AGMA, DIN, and JIS. Thus, our products can easily meet all your specifications.

5. Is free technical support provided at the gear design phase?

Yes, we do provide free DFM analysis, which is the gear design phase in product development to optimize your structure, materials, and processes in meeting the performance requirements while controlling costs.

6. How can material and processing techniques improve gear life?

According to operating conditions, we can recommend suitable high-quality alloy steels and suggest such strengthening processes as carburizing and quenching or even tooth surface grinding to raise wear resistance and contact fatigue strength in gears, thus increasing service life.

7. How are my drawings and intellectual property protected?

We will sign an NDA, a legally binding confidentiality agreement, before cooperation. Information security management measures will be adopted to keep all your design drawings and technical data strictly secret and ensure your intellectual property security.

8. What is the after-sales process in case of issues with product quality?

Our goal is to reply to all quality feedback within less than 24 hours once a problem has been identified as being our fault. We will initiate a resolution immediately, which includes rework and remanufacturing, to ensure that the problem has been correctly dealt with and the customer is satisfied.

How to Get a Quote for Custom Gears from Consultation?

The start of a precision gear customization project is done in a very smooth and transparent way. Getting in contact with LS Manufacturing will allow you to be supported in every process both on technical and commercial aspects. We have standardized ways in which to get a quotation to answer your requests quickly and professionally in order to drive your ideas to the final goal. Specifically, the process involves five important steps:

- Requirement Submission: You can send 3D drawings, 2D specifications, or detailed descriptions concerning working conditions by e-mail or via other online channels. This will be the foundation for moving ahead with the cooperation.

- Rapid Expert Appraisal: Upon receipt of your requirements, our engineers will perform an initial technical review within 24 hours and provide preliminary feedback on feasibility, estimated timeline, and cost range.

- In-depth Technical Communication: Your project engineer will contact you in detail, from the initial assessment up to discussing specifics such as heat treatment and precision levels, thus finalizing the best possible technical solution.

- Final Quote Confirmation: A formal quotation will be clearly and detailedly provided after confirmation, and all cost components will be listed with no hidden charges.

- Production Order Arrangement: After confirmation of the quotation and placing of the order, the project will be in the production scheduling phase, and you will have a project manager to follow up on the process.

For a quote, contact LS Manufacturing, specializing in precision gear customization. Our process is built on professional technical collaboration. When you consult with us, you receive not just a price, but a reliable solution grounded in extensive experience, enabling your project to start on the optimal track from the very beginning.

Conclusion

Selection of the right gears, while ensuring superior performance, is essentially a strategic decision related to equipment reliability, production efficiency, and the total cost of ownership. The subsequent in-depth analysis shall help one understand that partnership with experts like LS Manufacturing will provide deep technical expertise, combined with end-to-end quality control capabilities, thereby assuring the most appropriate way to avoid technical risks and deliver superior product performance.

Get in touch now and let expertise empower your equipment! Please upload your gear drawings or requirements descriptions now for a free technical evaluation and competitive quotation with the expert team from LS Manufacturing. Let us protect your business success with reliable drive solutions.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.