Custom gears that deliver optimal performance, longevity, and cost efficiency are essential yet challenging to achieve. Certain suppliers have suffered because they have some experiences about hard times because of difficulties caused by worn-out, irritating, and unmanageable cost factors with regard to designs and perhaps an ignorance about methodology on how they should be made. Hard designs and manufacturability because they cannot provide apt knowledge levels about nor stress ‘Design for Manufacturability’.

That would mean, as they said, “The task of this book will be to ‘be your ‘tech manual”’ as it relates to covering these gaps.” The ways and methods associated with balancing cost with scientific tooth profiles and Heat Treatment, continuing on, were discussed. Following that, it continued with regards to covering how the collaborative approach at LS Manufacturing relates with skills and knowledge associated with design and precision-maning. Continuing on, it related with regards to ‘how reliable and high-performance gear sets can be made’.

Custom Gears: Complete Quick-Reference Guide

| Section | Key Points |

| Introduction | The thing is, there is a requirement for personalized sets for efficient use, but there are some points about longevity and cost. |

| Core Issues | The misuse will be design-based, which is not optimally done. Thus, problems such as those dealing with wear, noise, and cost will arise. |

| Root Causes | Design-manufacturing gap, lack of expertise in DFM, and limited supplier technical capabilities. |

| Design Principles | Optimize tooth form for loading, noise, and manufacturability. |

| Material Selection | Material selection should be done on an application-by-application basis. |

| Heat Treatment | Heat treatment will be done on: Performing procedures of hardening and resilience. |

| Manufacturing Precision | Ensure tight tolerances and surface finishes with precision machining. |

| Testing and Validation | The implementation of rigorous testing for endurance, noise, and functionality. |

| LS Manufacturing Solution | All-inclusive collaborative process from design to production with extensive DFM analysis. |

| Value Proposition | High performance and wear-resistant gears with superior cost-effectiveness and competitive advantage. |

As there will be an optimization process at work among performance, which will be requiring some components, it will be imperative that there will be an implementation plan, which will have the role of filling a gap created as a result of designs. LS Manufacturing uses concepts among DFM and precision knowledge about cost effective gear manufacturing.

Why trust this guide? Practical experience from LS Manufacturing experts

Regarding custom gears, we have no knowledge but what we have gleaned from raw experience. It isn’t getting it done at LS Manufacturing. And every day on the shop floor, with just what we have on hand for gears, optimal meshing, no wear-out, and no noise. It isn’t some puzzle we solve with knowledge. We don’t solve it with knowledge but we solve it.

Our diligent process meets standards. It is our plan and intention to follow product and process specifications as determined and maintained by the National Association for Surface Finishing (NASF) and Metal Powder Industry Federation (MPIF). It is our hope that they will be satisfied in regards to our manufactured gears and that they will meet specifications as it relates to longevity, surface integrity, and accuracy. It is because of these reasons that we mention here, within the same section, about components associated with efficient power transmission, aerospace actuation components, and medical drives.

Based on over a decade of knowledge derived from implementing and using thousands of units, we have ascertained precisely the optimal heat treatment processes for core strength, the modifications required within the gear tooth to reduce noise exponentially, and the stage at which cost becomes an issue relative to better quality. All knowledge referenced here has been proven.

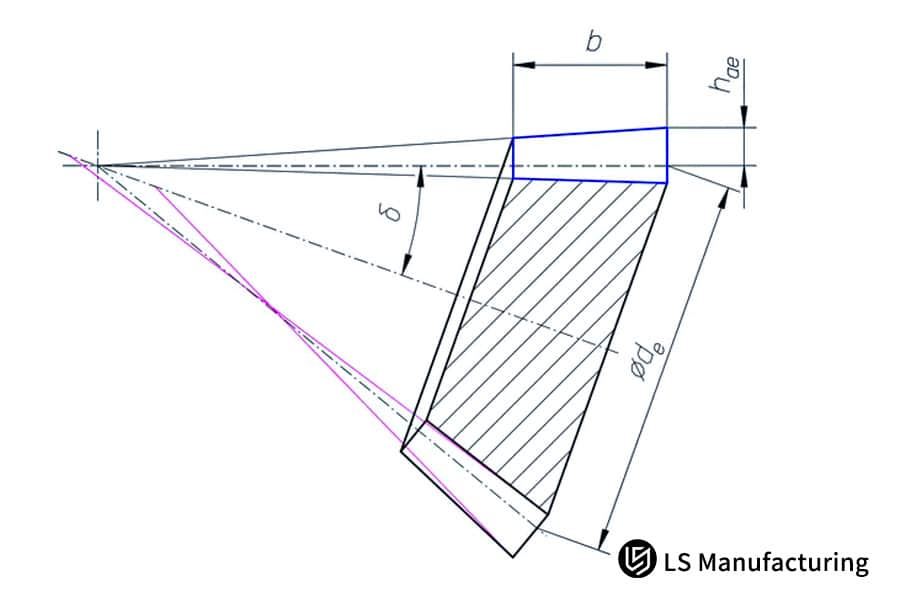

How to optimize gear design to improve performance through five key parameters?

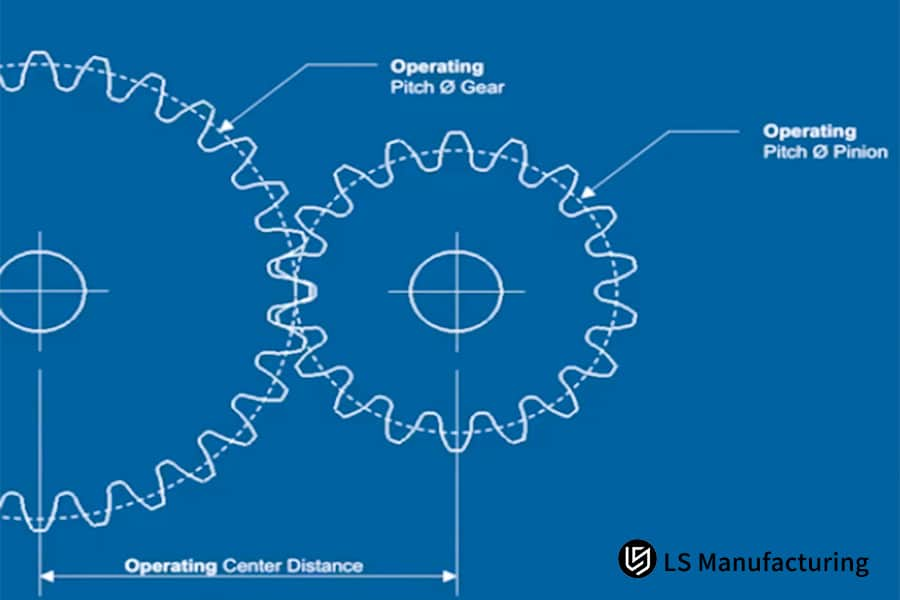

There exists an optimizing process as regards gear performance that at first begins with an understanding as regards controlling five basic parameters, which define the very essence of a gear. It all begins with an understanding that precision adjustment as regards five basic parameters will provide optimal performance as regards custom gears. The secret that hides within the gear design optimization and making them high-performance gears begins with an understanding and applying as regards five fundamental parameters

- Module: It describes size and strength. As for the value given on module, as it increases, it would be heavier, larger, but with more weight capacity.

- Pressure Angle: It impacts bending strength and functionality. The standard pressure angle makes use of optimum values. A larger pressure angle would result in higher strength but heavy loading on bearings and acoustic effects.

- Helix Angle: It has an imperative role as for optimizing a progressive meshing action among these teeth. Its importance would be highly conspicuous as for preventing noise and vibrations among high-performance gear drive systems. It would increase contact among some of these teeth.

- Addendum Coefficient: It defines the weightage of the value of height among these. It will play an extremely critical role within the contact ratio and thus smooth meshing and no undercutting, on the basis of improvement and modification of the value.

- Profile Shift Coefficient: A key tool in gear design optimization for adjusting the center distance without changing the gear ratio. It is essential for preventing undercut in pinions, improving wear resistance, and fine-tuning the gear pair‘s performance in compact assemblies.

There will be some progress as regards custom gears with a process that will demand a synergy among parameters. There will be no optimum level as regards any specific parameter. It will be totally dependent on what will be desirable as regards the performance feature, such as maximum strength, no noise, and smallest size. To optimize, these five parameters will have to be married.

How should performance and cost be balanced when selecting gear materials and heat treatment processes?

It plays an extremely vital role in performance and cost optimization. It would be aptly explained within a gear design guide, that optimization or making an optimal selection would achieve ‘durability without unwarranted expenditure’. The result and consequence of making an optimal selection have a very vital role as factors for success achieved within high-value gear manufacturing.

| Material & Process | Core Characteristics |

| 20CrMnTi (Carburizing) | It can be effectively used for making high surface hardness and wear-resistant components and working under heavy loads. |

| 42CrMo (Quenching and Tempering) | It contains a tough core and moderate strength at relatively low cost. |

| Stainless Steel (Nitriding) | Bevalved and corrosion-resistant with moderate hardness. |

| Alloy Steel (Nitriding) | Higher surface hardness with no distortion factor, and more suited for precision work. |

The most optimal and cost-effective gear will, thus, be one that perfectly meets a specific functionality requirement. A detailed and strict gear design guide will, thus, constitute an objective standard for ascertaining a specific application requirement based on specific needs so that either high-value gear manufacturing or successful completion can be ensured. The greatest success factors for precision gear manufacturing will, thus, be an intelligent basis for making decisions on needs.

What key processes and technologies are needed to achieve high-performance gear manufacturing?

Due to the very controlled production process, it becomes feasible and possible only for high-performance gears with excellent performance qualities. From materials and components, and then down to a process that culminates with incorporating various technologies and knowledge/skills – that should be and can be achieved. Below, there will be an encapsulation of some steps necessary for capabilities that will make sure that every reliable LS Manufacturing custom gear to our esteemed partners:

| Critical Manufacturing Process | Control Points and Our Capability at a Glance |

| Material Preparation & Forming | Controlled cutting, forging, or rolling to optimize the grain flow and structural integrity of the base material. |

| Rough Machining | Precision pre-machining to establish correct geometry, leaving appropriate stock for subsequent finishing processes. |

| Heat Treatment | Advanced process control (e.g., controlled atmosphere/carburizing) to achieve target hardness while minimizing part distortion. |

| Precision Finishing (Grinding/Honing) | precision grinding or hone with extremely fine tooth geometry with precision of LS Manufacturing with an AGMA quality level up to 12. |

| Surface Improvement | It also encompasses developments such as gear rolling, which assist in enhancing contact pattern and consequently surface finish. |

Finally, it can be culminated that for high-performance gears, there should be an incessantly developing platform. It can be done exclusively with convergence and control regarding precision grinding with specifications. It is extremely essential, as it determines on procedures and methods for precision gear manufacturing. It encompasses exactly what customized services at LS Manufacturing custom gear.

How to systematically control the total cost of ownership for custom gears?

To understand the high-value gear manufacturing process, I would like to learn more about cost factors beyond buying and focus on costs relating to ownership.The most effective strategy involves strategic gear design optimization from the very beginning, focusing on longevity and reliability to minimize long-term expenses associated with replacement parts and machine downtime. Managing custom gear cost is about balancing initial investment with long-term operational efficiency.Controlling custom gear cost relies on a systematic analysis of four key factors:

- Design Complexity: Geometric reduction based on consideration of Design for Manufacturability will result in reducing machining cost and times. It clearly and articulately set an imperative principle with regards to best smart gear design optimization.

- Material/Process Selection: Material-process selection based on consideration of capabilities either match but do not exceed specifications will be enunciated as principle for high-value gear manufacturing.

- Accuracy Grade: Accuracy grades on ‘fit-for-purpose’ accuracy eliminate unnecessary expensive costs on extremely tight accuracy.

- Batch Size: Based on economies of scales or pre-forms for optimal production batches, costs per unit have been maintained on optimizing production size.

The method of optimum control analysis and optimum tradeoffs is very much required. Proactive gear design optimization and judicious process selection are crucial. Economically optimum solution with due consideration given to costly high-value gear manufacturing takes into consideration life and optimum reliability. It precisely calculates cost with regard to replacement and downtime and maximum value as an advantage attribute with regard to control custom gear cost.

Case Study of Customized High-Precision Reducer Gears for Industrial Robots: How LS Manufacturing Solves the Challenges of Lifespan and Noise

It shows that knowledge and expertise on engineering will provide solution for specific problem. A company that worked with industrial robot manufacturers had an extremely large problem. The precision gears assembled on core reducers could not satisfy preferred ones. It implies that they needed an engineering solution that will solve longevity and accuracy within a system solution based on robot functionality.

Client Challenge

Problems regarding high-cycle fatigue were introduced by custom gears from a leading robot manufacturer and were substantiated as precision reducers. Unsatisfactory solutions would not be able to reach life criteria at 10,000 hours.

LS Manufacturing Solution

We engaged in solution redesign for our customer on high-performance gear solution. We supplied varied shapes on the tooth surface for maximum loading capabilities, supplied high-grade carburized steel with strict control on case depth and hardness, and supplied ultra-precision grinding services with maximum precision on tooth form and location.

Results & Value

LS Manufacturing custom gear met 5 dB sound reduction and offered more than 15,000 hours on fatigue life substantiation. It directly and positively influenced and reinforced our customer because it made them better and more valuable.

In summary, this project exemplifies how a collaborative, technically-driven approach can transform a component’s performance. By addressing root causes in design, material, and process, we delivered a high-performance gear solution that exceeded initial targets. This outcome underscores the tangible benefits of partnering with a dedicated specialist for critical custom gear applications.

Ready for an upgrade in optimizing your gear life and performance? Contact us today and get free advice on optimizing your designs.

What core competencies should be examined when evaluating a custom gear manufacturer?

Looking out for optimal partners will be a giant leap towards making your project successful. A good custom gear manufacturer will be very interested in your project as compared to machining. Once you read more about this analysis, you will be made capable of learning more about how to select a gear supplier who could have met your needs with performance, reliability, and quality. We will discuss some factors that you would be interested in your project. As a formality, some factors would be considered at the time of finding a manufacturer like LS Manufacturing:

Design and Engineering Support:

It should be very specific about your skills and aptitude as regards your skills and aptitude pertaining to Design for Manufacturability (DFM), and at the same time, discuss your tools and techniques as regards your stress analysis simulation using finite element analysis. It should be specific about your skills and relevance as regards optimal custom gears.

Capability for Manufacturing and Inspection

Talking about capabilities with regards to equipment they own, it would be possible to discuss, for instance, CNC gear hobbing and grinding machines, and gear measurement centers. Their capability with regards to these equipment would be apt and appropriate, with regards to improving accuracy with low noise levels with regards to prototyping as well as production. Their advanced CNC gear hobbing capabilities would help them with optimal production with tooth geometry, and grinding capabilities would help them with acquiring excellent surface finishes. Furthermore, with an ever-increasing number of gear measurement centers, it would be possible to achieve a verification loop wherein specifications and goals for all components would be appraised and measured at a preliminary stage.

Control Process and Quality Systems

Their traceable internal control process with regards to materials processed with traceable certification with regards to heat treatment processes would be implemented with regards to control processes and quality systems as ISO 9001 and IATF 16949. It is because they allow the root cause analysis facilitated at a detail level. But these certificates would not be satisfactory and acceptable if they have to improve more on customization services as producers of better customized gears. A degree of customization will include that they should have process knowledge on the part of engineering personnel who have to apply it while conquering new challenges.

As a result, your excellent discerning judgment will be at a crossroads of technique knowledge and process knowledge. A excellent custom gear manufacturer company would be recognized as having a degree of cooperation and business culture that emphasizes quality. Your knowledge about what works well within a criteria set for successful source selection for your own gear will enable you to identify a person, as with LS Manufacturing, who will bring you not only product but performance.

What are the typical stages in the process of customizing gears in collaboration with LS Manufacturing?

A good understanding of the work process will be necessary for a smooth and successful project. A properly set up and professional custom gear collaboration process will achieve that, and it will bring a custom gear with all criteria. A structured process at LS Manufacturing will make sure that there will be transparency and trust from start to end. A structured process will define clearly what it will be like working with a custom gear manufacturer, as it is at LS Manufacturing. A structured collaboration process for LS Manufacturing custom gears will include:

- Requirements & Technical Alignment: It covers requirements and alignment because it takes into consideration that all requirements and working constraints with regard to performance have already been analyzed and would therefore form a basis for projects.

- Co-design & DFM Analysis: Our engineering experts would co-operate with your experts on designs and analyses related to your product so as to get it optimized for performance and manufacturability.

- Solution Finalization & Quotation:The proposal with a quote will be finalized based on finalized specifications and schedule.

- Material Procurement & Full-process Manufacturing: As soon as there is an entry of an order into the processing stage, then there begins the procurement of materials with regard to product manufacuting. Machined, Heat Treated, and so on.

- Comprehensive Inspection & Testing: The batches will have to undergo testing with regards to size, materials, as well as functionality, before they qualify based on the recommended guidelines.

- Delivery & After-sales Support: The finished LS Manufacturing custom gears are delivered on schedule, supported by documentation and ongoing technical support as needed.

Therefore, it can be concluded from the discussion above that it would be possible to have optimal cooperation with custom gear collaboration process if it took communications and commitment with visible steps and buying as an added value. It would be possible to achieve cooperation with an optimal form of partnership based on an experienced custom gear manufacturer, and as a result, you will get not only an article but an optimal solution as well.

How long is the typical cycle from inquiry to delivery for custom gears?

The calculation for actual custom gear lead time index will not be an easy task as it will be measured based on the project variables and not the project schedule. It will be measured based on the gear manufacturing cycle as it will allow you not only to learn about your project goals, but it will allow you to manage your project. It depends on the overall project analysis, and the project schedule will be provided within your transparent business organization. It will be an attribute qualified for high-value gear manufacturing because speed, quality, and cost will be achieved. Several factors will impact your gear manufacturing cycle, as will be shown below:

Complexity and Specification

The basic standards, specifications related to precision, and specifications related to American Gear Manufacturing Association specifications. These specifications will help in ensuring that the gears will be fit not only within the standards set forth in dimensional and geometric tolerance related to precision but will also be within specifications related to strength as set forth by industry standards. These specifications have to be apt with regard to standards related to precision and specifications related to AGMA.

Production Volume and Stage

Production unit/samples would also include the fact that lead-time required for custom production would be shorter because it would be shorter by 2-4 weeks compared to 4-8 weeks. It would be acceptable and correct at the same time, though, to state that the shorter cycle duration would be limited within and would solely pertain at that stage wherein sample verification would be made—and would not yet have begun extending it within an accelerated ratio as it would be needed for full production.

Material and Process Requirements

There would be some procurement specifications, for example, deep case carburizing and surface finishes, which would have an unaccountably large effect on project scheduling. It should be kept in mind here that some operations, for example, deep case carburizing and controlled quenching operations, would include some thermal cycles. It is absolutely very clear here that these operations would be highly labor- and time-consuming. It should be kept in mind here that some special surface finishes with some special importance regarding surface roughness and superfinish would include some machining operations.

As it would be anything but a couple of weeks for prototyping and several weeks for production for an average period pertaining to a gear manufacturing cycle, it would be better obtained after an elaborate project analysis. However, at LS Manufacturing, with our dynamic supply chain and production focus on a lean process, short for custom production. It literally captures our commitment for high-value gear manufacturing, and would have you receive your precision gears within a short and efficient period.

FAQs

1. What is the minimum order quantity (MOQ) for custom gears?

We have skills and abilities that make us qualified to fulfill orders involving single sample testing orders from prototyping to large scale productions. MOQs will therefore vary based on your orders involving various levels of R&YD verification and large scale productions. We are aware of cost savings and single batch productions involving various levels R&YD. It is on these that we have no high MOQs. You will therefore have an opportunity to design your orders as you want and we will be able to fulfill your single sample testing as well as large scale productions.

2. What is the highest precision level you can achieve?

We also have available to us the fact that optimal accuracy has been attained with either the AGMA 12 or the ISO 3. Whichever it might be, it will be resolved within your specifications and cost-effectiveness eventually. We have been very successful at optimizing cost and delivering cycle time for precision gear grinding tools and methods.

3. How long does it take from receiving an inquiry to providing a quote?

First and foremost, we will address your queries regarding the full designs. It will take 1-2 business days for us to be capable of giving a detailed quotation and solution for your query. However, as regards your queries about more discussions and solution optimization, our technical engineers will be more proactive with you; thus, there will be no delay because we do not have any information.

4. Do you provide material certification and complete testing reports?

We would be glad to provide you with detailed reports on certification and testing of materials, like tooth profile and direction reports, thickness of hardness layer reports, and so on. We would be glad to provide you with testing reports from some objective and authorized third-party sources for every lot of our product so that you have a comprehensive confirmation on your product quality from raw materials stage to product stage.

5. If my old gear fails, can you analyze, replicate, or improve it?

Yes, we do have expertise in failure analysis and could assist with optimizing your designs. We would learn some insights from your product failure analysis, metallography, and hardness testing, and a number of sources.

6. In which industries do you have extensive experience in custom gear manufacturing?

We have very successful projects based on different sectors, for example, industrial automation, new energy vehicles, and medical. We can also very soon identify your needs. We are aware of different industries and can also adapt and effectively respond to different challenges and value addition opportunities within your business.

7. How do you ensure consistency in large-volume gear production?

Furthermore, we also have consistency within qualified batches. It will be because a consistent product will be made with tight control facilities on process and testing facilities. We have testing facilities and tracking facility online that will improve us, no matter how small, so there are no gaps.

8. How can new customers begin their first custom gear project?

You will just have to contact us with your designs and sample details. We will be there with you. We will be there with you personally from analysis and on through your receiving your product. We will make your first experience with us easy.

Conclusion

To make your project on custom gears successful, there should be an optimal association and expertise on optimal designs, optimal production, and cost-effectiveness. When you get associated with us at LS Manufacturing, you will be able to attain an optimal association with your product and expertise on optimal designs. Our approach follows proven gear design guidelines, ensuring each solution balances performance, durability, and efficiency.

You can launch your upgrade and start optimizing your gear performance today itself without waiting for a better opportunity. You have to click on ‘Get Free Gear Design Optimization and Quotation Consultation‘ and let us know your requirements. We at LS Manufacturing will be pleased to provide an optimal complete high-performance gear solution for your thriving business.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.