CNC turning is a manufacturing process that involves the use of computer-controlled machines to produce high-quality parts and components. These machines are programmed to accurately and precisely cut and shape various materials, including metals, plastics, and wood. In this article, we will discuss everything you need to know about CNC turning.

What is CNC Turning?

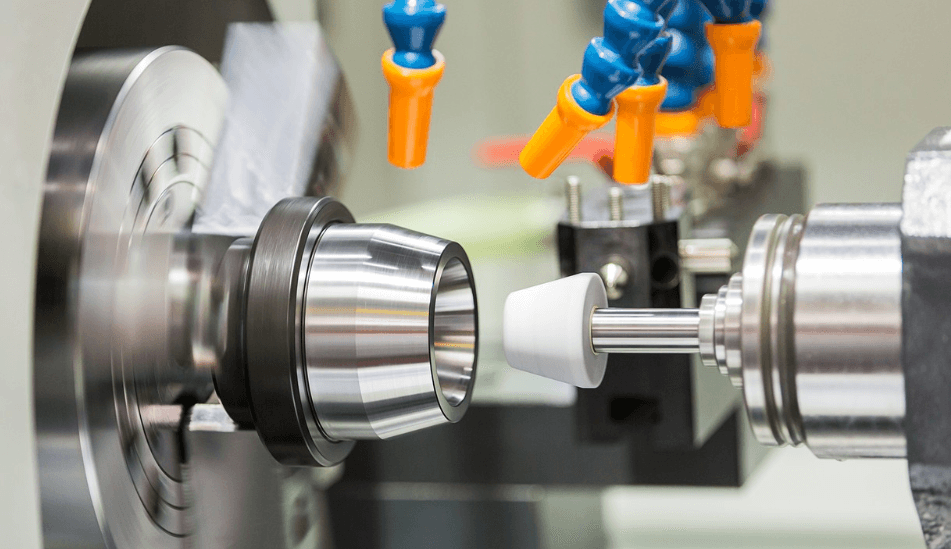

CNC turning is a machining process in which a cutting tool, typically a non-rotary tool bit, is fed into a rotating workpiece. The cutting tool is moved along the axis of the workpiece to produce cylindrical parts with precise dimensions. CNC turning is often used to create parts for the automotive, aerospace, and medical industries, among others. This process can be used with a variety of materials, including metals, plastics, and wood. The CNC turning process is performed by a computer-controlled machine tool called a lathe, which can be programmed to produce complex parts with high precision and accuracy. Overall, CNC turning is a versatile and efficient manufacturing process that is widely used in modern industry.

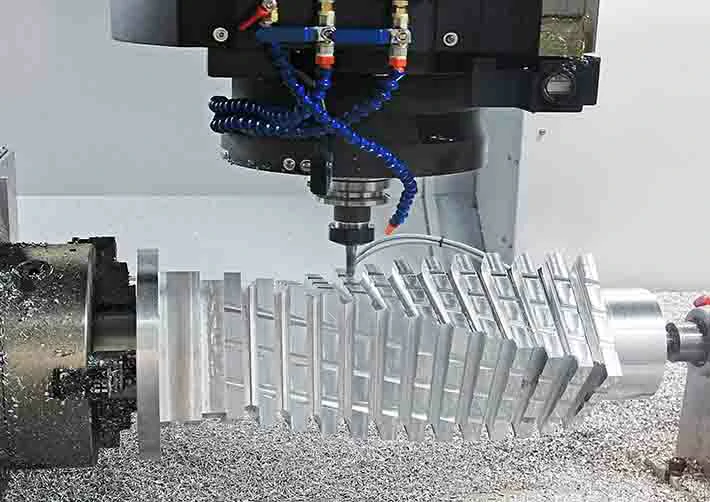

How Does CNC Turning Work?

CNC turning is a subtractive manufacturing process that uses a computer-controlled lathe to cut and shape materials into cylindrical parts. The process involves a cutting tool being fed into a rotating workpiece, which is then moved along the axis of the workpiece to produce parts with precise dimensions.

The CNC turning process begins with a design, which is created using computer-aided design (CAD) software. The design is then converted into a code that the CNC machine can understand, called G-code. This code is loaded into the CNC machine, which controls the movement of the cutting tool and the rotation of the workpiece.

Once the CNC machine is set up and the code is loaded, the cutting tool is brought into contact with the workpiece. The tool is then moved along the axis of the workpiece, removing material and creating the desired shape. The machine may also use coolant to help keep the cutting tool and workpiece cool during the cutting process.

The CNC machine can be programmed to make a variety of cuts, including facing, turning, drilling, and boring. This allows for the creation of complex shapes and designs with high precision and accuracy. The machine can also be programmed to make multiple cuts in a single operation, reducing the time and cost required to produce a part.

CNC turning is used in many industries to create parts out of various materials, including metals, plastics, and wood. The process is especially useful for creating parts with complex shapes or tight tolerances, as it allows for high precision and accuracy. Overall, CNC turning is an efficient and versatile manufacturing process that has become increasingly popular in modern industry.

What Materials Can Be Used in CNC Turning?

CNC turning is a versatile and efficient manufacturing process that can be used on a variety of materials. The process involves using a computer-controlled lathe to cut and shape materials into cylindrical parts with precise dimensions. The materials that can be used in CNC turning include:

Metals

Metals are one of the most common materials used in CNC turning. This includes a wide range of metals, such as aluminum, brass, copper, steel, and titanium. Each metal has its own unique properties, such as strength, durability, and conductivity, which make it suitable for different applications. For example, aluminum is often used in the aerospace industry due to its light weight and strength, while brass is often used in the manufacturing of musical instruments due to its acoustic properties.

Plastics

Plastics are another common material used in CNC turning. This includes materials such as acrylic, nylon, polycarbonate, and polypropylene. Plastics are often used in the manufacturing of consumer products, such as toys, electronics, and medical devices, due to their versatility and ease of manufacturing. They can also be used in the automotive industry to create lightweight parts that help to improve fuel efficiency.

Wood

Wood is a natural material that can be used in CNC turning. This includes a wide range of woods, such as oak, maple, and cherry. Wood is often used in the manufacturing of furniture, decorative items, and musical instruments due to its natural beauty and warmth. CNC turning can be used to create intricate designs and shapes in wood, allowing for the creation of unique and custom pieces.

Other Materials

CNC turning can also be used on a variety of other materials, including ceramics, composites, and glass. These materials are often used in specialized applications, such as the manufacturing of aerospace components or medical implants.

Overall, CNC turning is a versatile and efficient manufacturing process that can be used on a wide range of materials. By using a computer-controlled lathe, parts can be created with high precision and accuracy, making it an ideal process for creating complex shapes and designs.

What Are the Benefits of CNC Turning?

CNC turning is a versatile and efficient manufacturing process that offers a range of benefits over other machining methods. Here are some of the key benefits of CNC turning:

High Precision and Accuracy

One of the main benefits of CNC turning is its ability to produce parts with high precision and accuracy. By using a computer-controlled lathe, the cutting tool can be moved with a high degree of accuracy, allowing for tight tolerances and complex shapes to be created.

Consistency and Reproducibility

CNC turning also offers excellent consistency and reproducibility. Once the machine is set up and the code is loaded, the same part can be produced over and over again with the same level of precision and accuracy. This is particularly useful in industries where large quantities of parts need to be produced.

Increased Efficiency

CNC turning is a highly efficient manufacturing process that allows for the creation of parts quickly and easily. The machine can be programmed to make a variety of cuts in a single operation, reducing the time and cost required to produce a part. This makes CNC turning ideal for high-volume production runs.

Versatility

CNC turning is a versatile manufacturing process that can be used on a wide range of materials, including metals, plastics, and wood. This allows manufacturers to create parts for a variety of industries and applications, from aerospace components to medical implants.

CNC turning also allows for the creation of custom parts with unique shapes and designs. By using a computer-controlled lathe, parts can be created with high precision and accuracy, allowing for intricate designs and shapes to be produced.

Overall, CNC turning is a highly efficient and versatile manufacturing process that offers a range of benefits over other machining methods. By using a computer-controlled lathe, parts can be produced quickly, easily, and with a high degree of precision and accuracy. This makes CNC turning an ideal process for a wide range of industries and applications.

CNC Turning Machining Services

CNC turning machining services are used to create custom parts and components for a wide range of industries. This process involves using a computer-controlled lathe to cut and shape materials with precision and accuracy.

One of the key benefits of CNC turning machining services is that they can be used to produce large quantities of parts with consistent quality. This is because the process is automated and can be programmed to create identical parts every time.

Another advantage of CNC machining is that they can be used to work with a wide range of materials, including metals, plastics, and composites. This makes it an ideal solution for a variety of industries, from aerospace and automotive to medical and consumer goods.

In addition, CNC turning machining services offer fast turnaround times and can help to reduce production costs. This is because the process is highly efficient and can be completed in a shorter amount of time compared to traditional machining methods.

Overall, CNC turning machining services are a reliable and cost-effective solution for creating high-quality parts and components for a variety of industries.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining service,CNC Milling Service,Custom Sheet Metal Fabrication Service,Extrusion Moulding services,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items

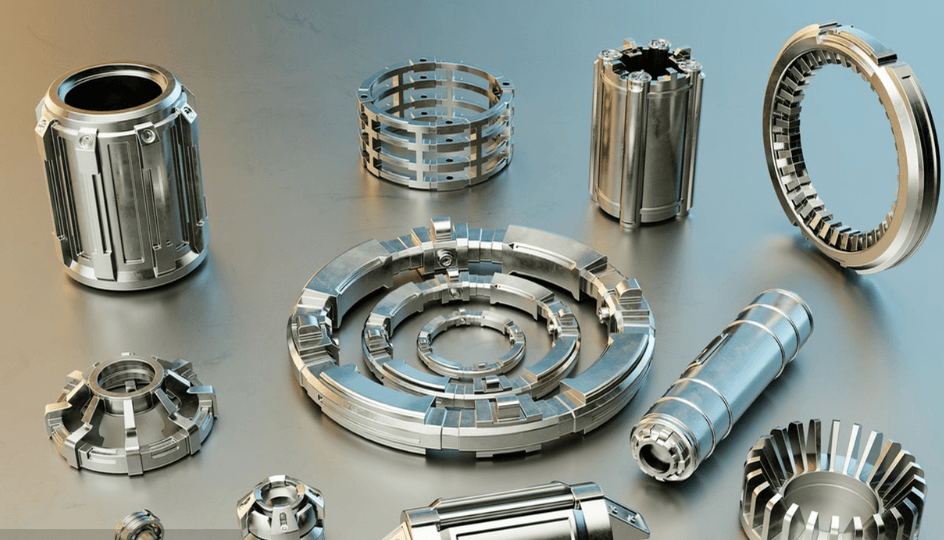

Applications of CNC Turning

CNC turning is a versatile and efficient manufacturing process that offers a range of benefits over other machining methods. Here are some of the key applications of CNC turning:

Automotive Industry

The automotive industry is one of the largest users of CNC turning. CNC turning is used to create a wide range of parts, including engine components, drive shafts, and suspension parts. The high precision and accuracy of CNC turning make it ideal for creating parts that need to withstand the high stresses and temperatures of the automotive environment.

Aerospace Industry

The aerospace industry is another major user of CNC turning. CNC turning is used to create a wide range of parts, including turbine blades, engine components, and structural components. The high precision and accuracy of CNC turning make it ideal for creating parts that need to withstand the high stresses and temperatures of the aerospace environment.

Medical Industry

The medical industry is another area where CNC turning is commonly used. CNC turning is used to create a wide range of parts, including surgical instruments, implants, and prosthetics. The high precision and accuracy of CNC turning make it ideal for creating parts that need to fit perfectly and function correctly in the human body.

Electronics Industry

The electronics industry is another area where CNC turning is commonly used. CNC turning is used to create a wide range of parts, including connectors, housings, and brackets. The high precision and accuracy of CNC turning make it ideal for creating parts that need to fit perfectly and function correctly in electronic devices.

Consumer Products Industry

The consumer products industry is another area where CNC turning is commonly used. CNC turning is used to create a wide range of parts, including toys, kitchen gadgets, and sporting goods. The high precision and accuracy of CNC turning make it ideal for creating parts that need to fit together perfectly and function correctly.

Overall, CNC turning is a highly versatile and efficient manufacturing process that finds applications in a wide range of industries. By using a computer-controlled lathe, parts can be produced quickly, easily, and with a high degree of precision and accuracy. This makes CNC turning an ideal process for creating complex shapes and designs in a variety of materials.

Advancements in CNC Turning

CNC turning is a subtractive manufacturing process that has been widely used in modern industry for several decades. Over the years, advancements in technology have led to improvements in the efficiency, precision, and versatility of CNC turning. Here are some of the key advancements in CNC turning:

Automation and Robotics

One of the major advancements in CNC turning has been the integration of automation and robotics into the process. This has allowed for the creation of unmanned machining cells, in which the CNC lathe can operate without human intervention. Robotic arms can be used to load and unload parts, while sensors can be used to detect and correct errors in the process. This has led to improvements in efficiency, as well as a reduction in errors and accidents.

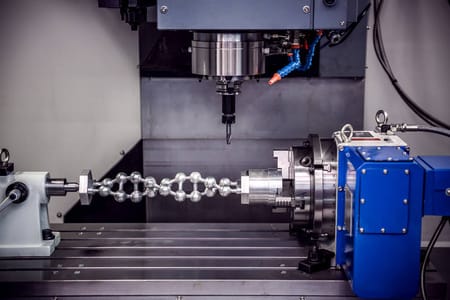

Multi-Axis Machining

Another key advancement in CNC turning has been the development of multi-axis machining. This involves using a CNC lathe with more than two axes of motion, which allows for the creation of complex geometries and shapes. Multi-axis machining can be used to create parts with features such as undercuts, tapers, and compound angles, which would be difficult or impossible to produce with traditional two-axis machining.

High-Speed Machining

High-speed machining is another advancement in CNC turning that has led to improvements in efficiency and productivity. This involves using specialized cutting tools and techniques to increase the speed of the machining process, while maintaining high accuracy and precision. High-speed machining can be used to reduce cycle times, increase throughput, and reduce tool wear.

Computer-Aided Design and Manufacturing (CAD/CAM)

The development of computer-aided design and manufacturing (CAD/CAM) software has been another major advancement in CNC turning. CAD/CAM software allows designers and engineers to create 3D models of parts, which can then be converted into G-code that can be understood by the CNC lathe. This has led to improvements in accuracy, as well as a reduction in the time and cost required to design and manufacture parts.

Additive Manufacturing

While not strictly an advancement in CNC turning, the development of additive manufacturing has had a significant impact on the manufacturing industry as a whole. Additive manufacturing involves using 3D printing technology to create parts layer by layer, using materials such as plastics, metals, and ceramics. While CNC turning is a subtractive process that involves removing material from a block, additive manufacturing is an additive process that involves adding material layer by layer. Additive manufacturing can be used to create complex geometries and shapes that would be difficult or impossible to produce with traditional machining methods.

Limitations of CNC Turning

While CNC turning is a versatile and efficient manufacturing process, it does have some limitations that should be taken into account when designing parts. Here are some of the key limitations of CNC turning:

Size and Shape

One of the main limitations of CNC turning is the size and shape of parts that can be produced. CNC turning is best suited to creating cylindrical parts with relatively simple geometries. Parts that are too large or have complex shapes may be difficult or impossible to produce with a CNC lathe.

Material Selection

While CNC turning can be used on a wide range of materials, there are some materials that are more difficult to machine than others. For example, materials that are prone to chipping or cracking, such as ceramics or glass, may be difficult to machine without causing damage to the part or the machine.

Cost

CNC turning can be an expensive manufacturing process, particularly for small production runs. The cost of the machine, tooling, and programming can be significant, and may not be justifiable for small-scale production.

Tool Wear

CNC turning involves the use of cutting tools, which can wear down over time. Tool wear can lead to a decrease in precision and accuracy, as well as an increase in the time and cost required to produce parts.

Surface Finish

CNC turning can produce parts with a high degree of precision and accuracy, but the surface finish may not be as smooth as other machining methods. Parts may require additional finishing processes, such as sanding or polishing, to achieve the desired surface finish.

Complexity

While CNC turning can be used to create parts with complex geometries, there are limits to the complexity that can be achieved. Parts with very intricate or complex shapes may require additional machining processes or may be difficult or impossible to produce with a CNC lathe.

Conclusion

CNC turning is a powerful and versatile manufacturing process that can be used to create high-quality parts and components from a wide variety of materials. While there are limitations to the process, the benefits of CNC turning make it a valuable tool in many industries. As CNC turning technology continues to advance, it is likely that we will see even more applications of this powerful manufacturing process in the future.