Aerospace CNC milling parts is the cornerstone of aircraft performance and safety. Processing problems of such materials as titanium alloys and high-temperature alloys result in fluctuating accuracy, delays in the delivery of projects, setting them at very great cost and compliance risks.

The inability of the traditional process to reach aerospace-grade standards, in addition to the lack of core capabilities such as the AS9100 system and 5-axis technology among suppliers, has resulted in inconsistent quality. The following paper will systematically describe how LS Manufacturing integrates systems, data, and advanced manufacturing in such a way as to provide highly reliable solutions.

The article will explain what is aerospace CNC milling. To save you time, here’s a quick overview of the core conclusions.

Modern Aerospace CNC Milling Quick Reference Guide

| Modules | Core Points | Key Content |

| Core Issues | Material Properties | Some critical difficulties in machining occur with difficult-to-machine materials like titanium alloys and high-temperature alloys. |

| Quality Requirements | The precision requirements in aerospace are much higher compared with the parts in ordinary industry. | |

| Compliance Requirements | Strict adherence to industry certifications such as AS9100. | |

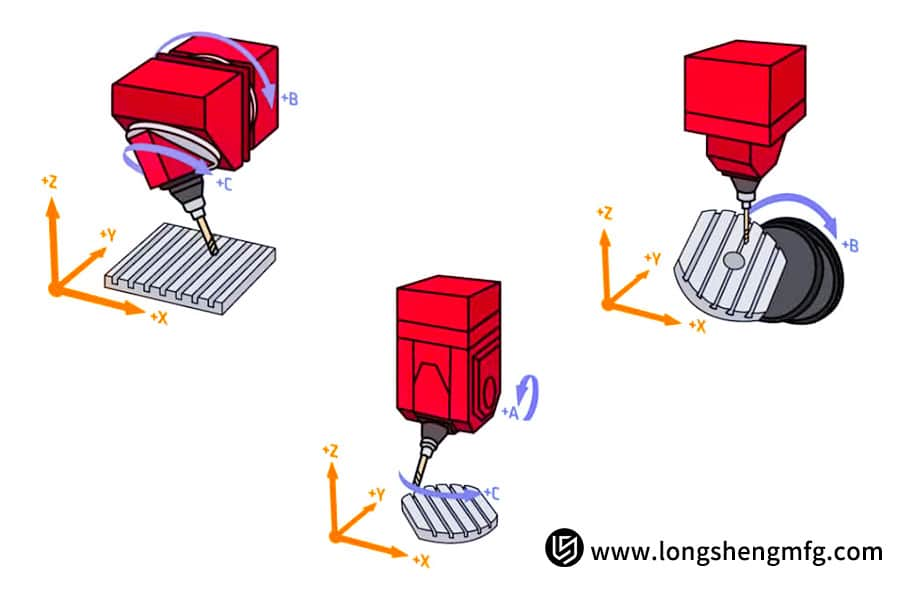

| Core Technologies | 5-Axis Machining | Completing complex surface precision machining in a single setup. |

| Process Database | Material Property-Based Customized Cutting Parameter System | |

| Process Monitoring | Real-time tool wear monitoring and quality control system. | |

| Solutions | Systematic Management | AS9100 quality system throughout the whole production process |

| Technology Integration | Deep integration of specialized processes and advanced equipment | |

| Service Guarantee | Full-lifecycle manufacturing services, from prototype to mass production. |

What worked for modern aerospace CNC milling was the synergy between technology, management, and systems. AS9100 quality standards, process solutions featuring special processes, and 5-axis machining technology are deeply integrated to ensure the parts will meet the high standards of aerospace in terms of precision, reliability, and consistency, thus forming a very solid basis on which this project will be a success.

Why Trust This Guide? Practical experience from LS manufacturing experts

We have manufactured more than 50,000 custom parts in the last decade alone, each one a teacher, instructing us in how to choose the best tap for alloys at elevated temperature, and how to get one-shot success in deep-hole threading on 5-axis machine tools.

For us, the reliability of the threaded connections on every structural component we machine for aerospace customers determines flight safety, while the biocompatibility of the threads on every implant we create for medical use affects patients’ health. It is part of the quest for ultimate reliability that is in our DNA, finding expression not only in the rigors of everyday operations but also in conformity to the International Aerospace Quality Group (IAQG) quality assurance system and to the IATF 16949 standard that guides us through complex supply chains.

What you read here, therefore, is not some textbook theory but crystallized experience, put to the quality control test, with international standard management thinking woven inside. The shared experience aims to help you avoid the pitfalls we went through and reach directly to the core of efficient and reliable manufacturing.

Aerospace CNC Milling – The Cornerstone of High-Reliability Parts

Precision and reliability of its core components are at the heart of excellent performance in the modern aerospace industry. Among many manufacturing processes, aerospace CNC milling technology has been the irreplaceable cornerstone: not only a method by which digital models become tangible entities but also an enabling key technology for complex functions, challenging tolerances, and unleashing the performance of advanced materials. It provides a basis for high reliability in light of the following:

Capability of forming a complex geometry

5-axis simultaneous machining allows parts containing complicated free-form surfaces, like bladed disks and casings, to be manufactured in one setup. It avoids accumulated errors through multiple setups, providing a very high degree of consistency between geometric tolerances and design intent from the process source.

Precision control of extreme tolerances:

It integrates high-rigidity machine tools with precision process planning and intelligent compensation techniques, which can achieve micron-level dimensional accuracy and excellent surface integrity stably, satisfying extreme demands on both aerodynamic efficiency and structural fatigue life of aerospace parts in adverse operating conditions.

Maximizing Material Performance

For example, in the case of titanium alloys or other high-temperature alloys, which are difficult to machine, properly optimized parameters for cutting, tool path strategies, and cooling can control residual stresses and microstructure alteration during the machining process, hence maintaining or even improving the inherently high strength and fatigue resistance of such materials.

This powerful integration with automated production lines combined with real-time intelligent monitoring, could make a aerospace parts manufacturing system far superior to that based on traditional machining methods. This approach ensures that every part-from the first prototype to mass production-is dimensionally correct, performs well, and fundamentally assures high batch-to-batch consistency; it provides an unbreakable manufacturing foundation for flight safety.

Core Challenge Overcoming the Paradox of Machining Titanium and High-Temperature Alloys

Generally speaking, problems related to materials are usually the biggest challenge in making aerospace parts. The titanium CNC machining or high-temperature alloy machining forms a thorny paradox: it gives parts superior performance, while their uncontrollable characteristics directly pose the greatest threat to cost and delivery time.

| Challenges | Impacts |

| Material Properties | Titanium alloys work harden, and the very high strength at high temperatures makes machining difficult. |

| Tooling and Cost Pressures | The abnormally rapid wear of tools raises the tooling cost and results in inefficiencies through more frequent tool changes. |

| Quality and Delivery Risks | Unstable machining processes, which can easily create out-of-tolerance or scrapped parts, seriously delaying project progress. |

| Thermal management bottleneck | The inability to control the heat generated during cutting influences the surface integrity and increases tool wear. |

While piecemeal adjustments have been adopted across the industry, our team developed a systematic solution specifically engineered to overcome the persistent aerospace parts challenge and cost control, with full assurance of reliability for the finished, precision components.

Mastering Titanium Alloys: How Five-Axis Machining Releases the Material’s Real Potential

It is well known in the high-end manufacturing field that the titanium CNC machining is a challenge and that 5-axis machining technology will be the key to overcoming such a challenge. For LS manufacturing, this is not simply equipment upgrading but one of its core strategies: strongly unleashing, through process innovation, the potential of the material. Its advantages are reflected in three aspects:

Reduced clamping stress deformation

Traditional 3-axis machining requires a lot of clamping processes, which easily cause the accumulation of internal stresses and deformation in thin-walled and complex structures. 5-axis technology allows for multi-face machining in one clamping, hence eliminating repeated repositioning errors from its very root. It ensures dimensional stability and geometric accuracy of parts.

Optimal Tool Posture

The cutting edge, relative to the workpiece, is constantly adjusted to continue maintaining the optimum cutting position. This not only maintains stable cutting force but also effectively controls the accumulation of heat in cutting, avoiding work hardening resulting from localized high temperatures in the titanium alloy; hence, superior integrity is attained on the machined surface.

One-Stop Forming of Complex Curved Surfaces:

Compared with the 5-axis linkage, parts with complex aerodynamic shapes, such as impellers and casings, can be done with precision tool movement along the surface normal to ensure high-precision one-stop forming of the complex surface, which greatly shortens the process and avoids tool marks caused by staged machining.

The effective integration of 5-axis machining with the properties of titanium alloys by means of precise thermal management, force control, and geometric realization in the LS Manufacturing system solves not only the inherent problems in titanium alloy machining but also fully develops its strength and lightweight potential as a high-performance material.

Extreme Heat Resistance; Machining of High-Temperature Alloys and Reliability of Engines

Reliability in the core hot-end components directly influences both performance and safety, as modern engine parts manufacturing continuously pushes operational boundaries. Technology for high-temperature alloys machining is the core foundation supporting the manufacture of engine parts to reach extreme heat-resistant requirements, and its precision control level is related to the final durability of the parts.

| Key Aspects | Their Specific Impact on Reliability |

| Material Property Understanding | Mastery in strengthening mechanisms and high-temperature mechanical behavior of high-temperature alloys provides a basis for formulating correct machining strategies. |

| Thermal control | This is aimed at controlling the temperature at which the material is being cut and avoiding overheating that results in microstructural alteration and generation of hot cracks. |

| Deformation control technology | The toolpaths and cutting parameters are optimized to release and balance machining stress for ensuring surface accuracy in such thin-walled parts as blades. |

| Surface integrity assurance | Get a surface with high quality, low residual stress, and without a recast layer, which will directly improve the high-temperature fatigue life of parts. |

| Geometric accuracy | Realized for the main components, including the aerodynamic surface and tenons, based on dimensional and contour accuracies that allow for assembly accuracy and aerodynamic efficiency. |

From single crystal blade directional crystallization control to turbine disk tenon precision machining at the micron level, every precision milling injects genes that are reliable into parts. It is only through controlling these parameters of heat, force, and deformation at their most extreme in manufacture that core components can be forged to improve life and raise the level of safety under the extreme conditions of operation. That is where the core value of engine parts manufacturing lies.

AS9100 Certification – Source a Zero-Risk Supply Chain for Aerospace

In the aerospace industry, quality is built into an item as an integral part of a well-planned, systematic process rather than relying on the basis of final inspection. The value of the AS9100 CNC machining system lies in the fact that it provides not just an entry threshold but a core frame guiding us toward the attainment of risk-free supply chain management. Such quality systems assure customers of quality in addition to industry standards using the following practices:

- End-to-end traceability: The digital files will be established from warehousing raw materials to production batches, including processing parameters for every piece of equipment. It ensures traceability end to end to promptly locate, isolate, and handle any anomaly that may arise and hence minimize risks.

- Data-Driven Continuous Improvement: That does mean the system requires monitoring and analysis of each key process. That’s driving us to solve the problem not passively but actively: identify the trend, predict the risk, and continuously optimize the process to make a fundamental improvement in process stability and capability.

- Failure Prevention Models: With the mandatory use of risk identification tools, such as FMEA, backed by rigorous change management, quality control is about “pre-inspection,” not “post-inspection,” which systematically prevents the flow of known and potential failure modes downstream.

AS9100 certification creates a transparent, reliable, self-evolving manufacturing ecosystem that not only makes sure every delivered part is to specification but also one with verifiable and consistent extremely high reliability, hence fundamentally reducing project risks for customers.

Precision Milling: Why Minor Differences Determine Project Success or Failure?

Precision vs Conventional Milling in high-end manufacturing represents the fundamental difference in mastering “minor differences.” The controllability of “minor differences” directly defines the upper limit of aircraft parts machining, and becomes the key to success or failure. In particular, its influence is reflected in three core aspects:

Determination of Aerodynamic Performance and Fuel Efficiency

The deviations in surface profiles at the level of microns can seriously affect changes in airflow by turning turbulent or causing increased drag, which directly translates to thrust loss and decreased fuel economy, making even advanced designs ineffective. For instance, in engine blades or wing structures,

Affecting Structural Fatigue Life and Reliability

Besides, in the case of parts, microscopic defects, sharp edges, or residual stress concentration points on the surface serve as a source of fatigue cracks under such long-time alternating load actions. Especially, the good surface integrity obtained by precision milling may delay crack initiation and is fundamental for ensuring long service life and flight safety.

Minimizing Inefficiency at Assembly and System Stability

A modern aircraft is composed of tens of thousands of parts. Any dimension deviation at any connection will lead to a potential stress concentration or interference during final assembly, and this causes rework delays or even system failure.

Precision of aerospace parts achieves micron-level precision, establishing a chain of causation from part performance to system reliability. Only in the very low-tolerance field of aerospace does such control over every minute feature form the cornerstone of high-end equipment quality.

Commitment to Quality-Mass Production with Uniformity of a Few Microns

What keeps LS Manufacturing aerospace ahead in the field of advanced manufacturing is its relentless commitment to quality control. We fully understand that true quality is not detected; it’s built through a comprehensive system. Three core pillars to ensure consistency include the following:

- Process Reliability Assurance: Here, high-precision 5-axis machining centers are used whose thermal stability and dynamic accuracy form the hardware basis for constant production of high-quality results. We maintain this equipment in optimum condition-be it through preventive maintenance or periodic calibration.

- Real-time Process Monitoring: Integrated in-machine measurement capabilities identify feature dimensions in real time after critical processing. This “manufacturing as inspection” model quickly detects deviation trends and can automatically compensate in subsequent processing, thereby effectively avoiding the generation of nonconforming products.

- End-to-End Traceability: From raw materials to finished products, all processing parameters, inspection reports, and equipment logs establish a complete chain of data. It satisfies not only the quality control requirements in the aerospace field but also the requirement for complete traceable evidence in quality analysis.

A core concept of LS Manufacturing aerospace quality system is the creative application of advanced quality management methods, originally developed for mass production, to meet the exacting demands of small-batch aerospace orders. This approach enables a robust consistency guarantee by integrating quality assurance throughout every stage of the manufacturing process.

From 30 days to 10 days, resolve the delivery crisis of Titanium alloy structural components

Each success story in the aerospace field is related to overcoming challenges at the limits of technology and living up to customer promises. This urgent project to fabricate a drone’s main frame with a titanium alloy reflects well on LS Manufacturing aerospace capability within the sector:

Client Challenge

The problem was how to develop a new drone from an aerospace equipment manufacturer, whose main frame was made of titanium alloy, structurally complicated with many thin walls. For a long time, traditional suppliers had never been able to control serious deformation caused by machining stresses in the titanium CNC machining, and the product yield was always extremely low. This has delayed the project by almost a month and would probably affect the entire development schedule.

LS Manufacturing Solution

Thus, when the task came, our process team responded very quickly by leaving the traditional conservative machining strategy. With profound analysis of the mechanism of deformation, the team ingeniously put forward a systematic solution: design a multi-point flexible vacuum fixture customized for the part to realize precise clamping with minimum stress, then use 5-axis CNC technology with dynamic milling strategy characterized by small depth of cut, fast feed, and high-pressure cutting fluid to precisely control the heat input in the cutting area so that the complicated structure could be completed in one clamping.

Results and Value

The above precise process design solved not only the deformation problem but also shortened the total delivery cycle from the customer’s expectation of 30 days down to an amazing 10 days. The critical flatness accuracy of the final part was kept within 0.02mm, far beyond the customer requirement, helping the customer pass the most critical design review. Based on this excellent collaborative experience, a long-term strategic cooperation agreement was signed with LS.

This successful case best demonstrates that, facing sharp challenges in the titanium CNC machining, LS Manufacturing aerospace is confident in transforming this crisis into opportunity with deep process knowledge and technological innovation capability, and creating value to be the customer’s most trustworthy R&D and manufacturing partner.

Supplier Selection Guide: 5 Key Questions to Find the Right Partner

Sourcing the right aerospace CNC milling supplier forms the very bedrock upon which an entire, successful project in aerospace manufacturing depends. It is not just about the products you purchase but about selecting a long-term partner who will share risks and create value with you. We recommend that decisions be made upon informed choices, and for that, an in-depth evaluation of probable suppliers has to be done based on the following checklist:

| Evaluation Dimensions | Core Issues |

| Quality System Depth | How would your company be able to prove that your understanding of aerospace quality systems such as AS9100 are integrated into daily practices and not just a certificate? |

| Material & Process Experience | Do you have any successful case and solutions to share dealing with the machining of materials similar to the ones I will be using in my project, like titanium alloys? |

| Technical Strategy Assurance | What are your five-axis machining strategies and specific deformation control solutions for the key characteristics of my parts? |

| Process Control Capability | If there were to be a smaller batch of products, how would consistency be maintained using the data and processes in place? Describe your monitoring and traceability. |

| Mechanism of Collaborative Response | How would you communicate and solve a problem in case of a technical difficulty or design change? |

Successful partner selection should be more than comparing price and delivery time. The value proposition of a top-rated aerospace CNC milling supplier includes robust quality systems, technical know-how, and proactive collaboration to deliver predictable, low-risk manufacturing assurance to you and earn its rightful place as a solid and reliable link in your supply chain.

Leading the Future: Innovative Technologies Drive Long-Term Competitiveness

In the fast-changing world today, the competitiveness of aerospace manufacturing future no longer depends on the production capacity in the present but increasingly relies on the forward-looking layout and integration capability in innovative processing technology. We are sincerely integrating forward-looking technology into the manufacturing closed loop and striving to be a reliable technology partner that meets customers’ needs in the future.

Intelligent Machining and Digital Twins

Data collection, including but not limited to cutting forces and vibrations, is performed with the real-time sensing system deployed in our production lines, comparing that with digital twin models of parts. In this way, the machining process transitions from “experience-driven” to “data-driven,” enabling the prediction and automatic compensation of tool life in the micro-wear stage, offering near-zero defect preventative production.

Sustainable manufacturing and new material applications

We will promote research on online recycling and reusing technologies for titanium alloy scraps, and develop special processes for processing new lightweight materials such as composites and intermetallic compounds. This will not only help meet the requirements of environmental protection but also establish a technological basis in the materials’ application for the next generation aircraft.

Human-Machine Collaboration and Knowledge Accumulation

We developed an expert process system that turns the experiences of senior engineers into executable algorithmic rules, helping new employees to rapidly develop high-quality process solutions. This effectively solves the challenge of talent experience transmission and liberates more manpower to focus on creative process optimization and innovation.

In short, our investment in innovative processing technology is in support of the vision of a smarter, greener, and more resilient manufacturing system. By working with us, customers get not only current parts solutions but also a strategic partnership for jointly facing future technological challenges and mitigating long-term R&D risks.

FAQs

1. Is 5-axis machining economical on small-batch, highly complex aerospace parts?

Very affordable: in the case of complicated parts, 5-axis machining is usually much more economical than conventional multi-stage machining by saving clamping, tooling, and secondary operations. We provide efficient small-batch solutions for aerospace.

2. What is the biggest technical problem in machining titanium alloy? How to solve it?

The core manages the cutting heat and avoids work hardening of a machined component. We manage heat effectively owing to our specialized tool geometry, high-pressure cooling technology, and optimized cutting parameter database that ensure machining stability and surface integrity.

3. What, precisely, is the added value of an AS9100 certification to customers?

It gives you “certainty.” From raw material to finished product, everything is traceable and verifiable. This means that your quality risks and supply chain uncertainties are at a minimum.

4. Does your quote include all quality inspection fees?

Yes, our quote is transparent. The standard quality inspection processes according to AS9100 requirements include first-article inspection and critical dimension process monitoring. There are no hidden costs.

5. Can you handle large or structurally complicated aerospace parts?

We have 5-axis machines with large strokes and our programming team has particular strengths in establishing a machining strategy in creating complicated parts, including manufacturability and precision.

6. How long does it take from inquiry to receiving a quote?

Besides, for regular needs, we promise to offer detailed quotations and preliminary process plans in 24 hours. Urgent projects will be handled via the fast response channel.

7. My design drawings require optimization. Can you, please help?

Of course, our engineers will provide free DFM analysis, including professional advice related to manufacturability and cost optimization; it is our standard service procedure.

8. How does one start working together to have this process unfold hassle-free?

You will be providing only your 3D model/drawings. Then, you will have one project manager in charge of technical communication, updating of schedule, and coordination for delivery to keep the process clear and smooth.

Conclusion

Choosing the right manufacturer in such an important industry as aerospace manufacturing means much more than just the purchase of a service; it is about injecting certainty into your project. Equipped with technical depth, systematic quality management, and customer-centric service, LS Manufacturing aspires to be the most reliable extended manufacturing team for customers.

Take action now to fill your project with confidence! Contact us snd upload your part drawings now for a free Manufacturability Analysis Report by the experienced team at our working in the aerospace industry. It will include process feasibility assessments, warnings about potential risk points, and suggestions for optimization that will drive insightful decisions and take the first step toward successful collaboration.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.